Method for curing pit mud

A technology for pit skin mud and seeds, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of lack of maintenance of pit skin mud, insufficient number of functional bacteria caproic acid bacteria, and failure to consider the nutrition and metabolism of functional microorganisms, so as to avoid quality degradation, The effect of improving the quality and moisturizing of pit skin mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

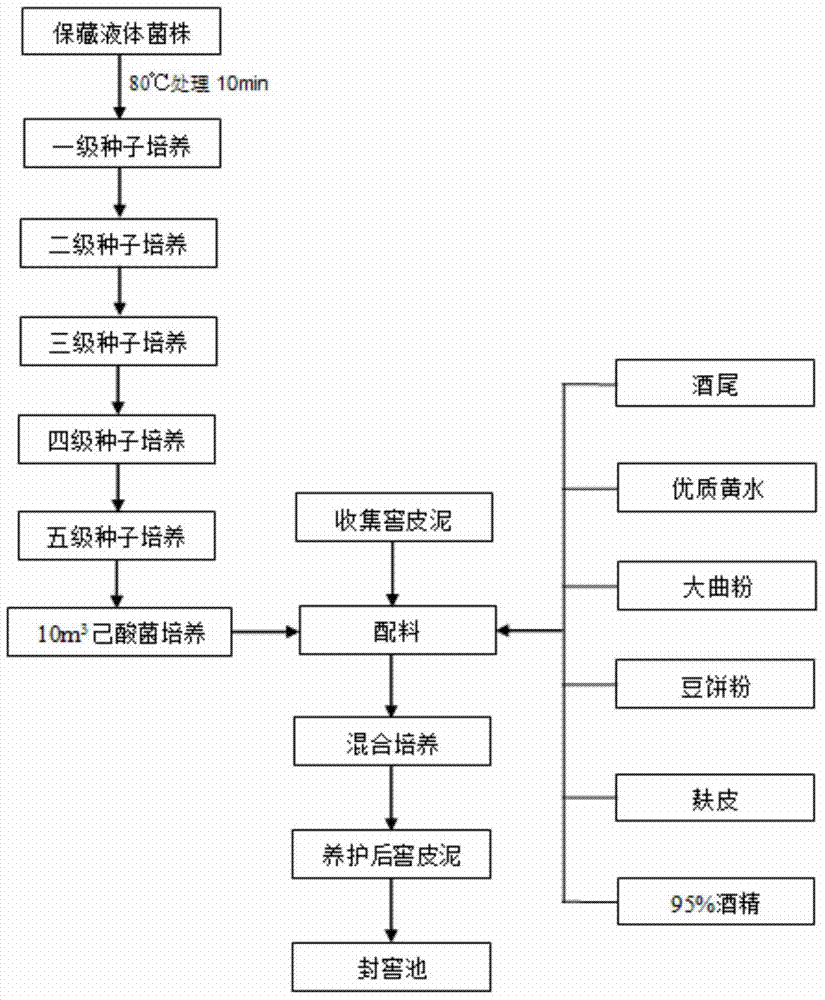

[0031] (1) Expanded cultivation of caproic acid bacteria seeds: ① first-level seed cultivation: After the liquid bacterial strains stored in the refrigerator were treated at 80°C for 10 minutes, they were inserted into a 100mL triangular flask with a liquid volume of 100mL according to 10% of the inoculum, and placed at 35 Cultivate at ℃ for 7 days to obtain first-grade seeds for use; ②Second-level seed cultivation: transfer the first-grade seed liquid into a 1L Erlenmeyer flask with a liquid volume of 1L according to the inoculation amount of 10%, and cultivate at 35°C for 7 days to obtain second-grade seeds for use; ③Tertiary seed cultivation: Put the secondary seed liquid into a fermenter with a liquid volume of 10L according to the inoculation amount of 10%, and cultivate it at 35°C for 7 days to obtain the third-grade seeds for use; ④Fourth-grade seed cultivation: Put the third-grade seeds According to the inoculation amount of 10%, it was put into a fermenter with a liqui...

Embodiment 2

[0046] The process flow chart of this embodiment is as figure 1 shown

[0047] A maintenance method for pit-sealed skin mud, comprising the following steps:

[0048] (1) After the five-stage expanded cultivation of caproic acid bacteria strains, the five-stage seed liquid of caproic acid bacteria is obtained;

[0049] The cultivation method of described caproic acid bacteria five-grade seed liquid is as follows:

[0050] ① After the refrigerator-preserved liquid bacteria were treated at 85°C for 10 minutes, 10% of the inoculation amount was transferred into a 100mL Erlenmeyer flask with a liquid volume of 100mL, and cultured at 37°C for 7 days to obtain a first-grade seed liquid for use;

[0051] ② Put the primary seed liquid into a 1L Erlenmeyer flask with a liquid volume of 1L according to the inoculum amount of 10%, and cultivate it at 30°C for 7 days to obtain the secondary seed liquid for use;

[0052] ③Put the secondary seed liquid into a fermenter with a liquid volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com