Steel wire hoisting gear in steel wire copper-plating production line

A lifting and landing device, production line technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems affecting product quality and other issues, and achieve the effect of avoiding quality decline and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

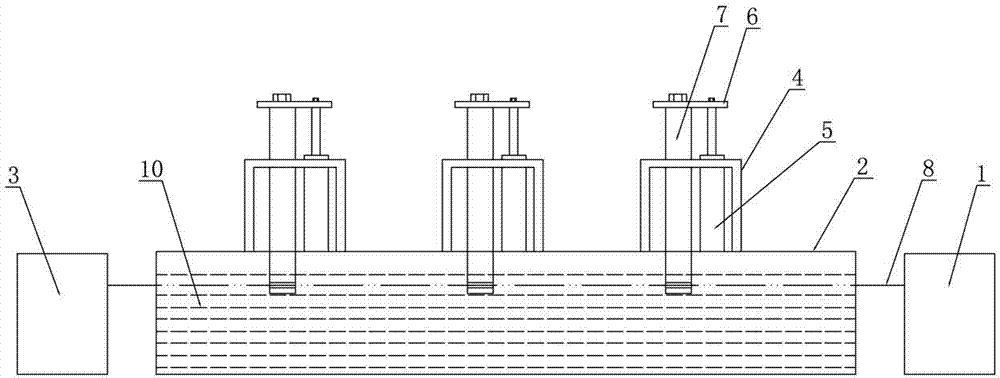

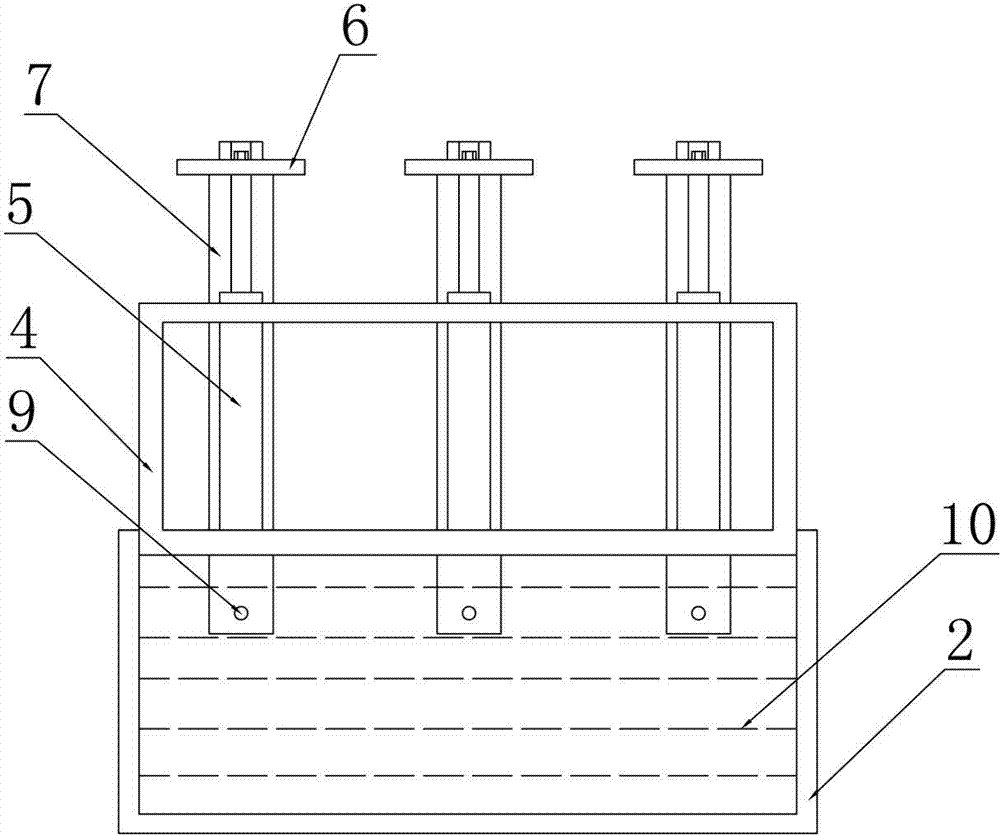

[0010] Such as figure 1 , figure 2 As shown, the steel wire lifting device in the described steel wire copper plating production line includes a steel wire pay-off device 1 distributed sequentially along the steel wire running direction, a copper plating tank 2 with a reaction solution 10, and a steel wire take-up device 3, along the steel wire In the running direction, at least one steel wire lifting and falling line that can make the steel wire rise and fall is provided above the copper plating tank 2. In this embodiment, three steel wire lifting and falling lines are arranged above the copper plating tank 2 along the running direction of the steel wire. In actual production The number of steel wire lifting lines can be adjusted according to actual production needs; each steel wire lifting line includes at least two spaced apart steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com