High-protein bean curd with smooth, tender and crisp taste and preparation method of bean curd

A high-protein, high-taste technology, applied in the field of food processing, can solve the problems of soybean dietary fiber particle size constraints, affecting the taste and texture of tofu, soybean dietary fiber processing, etc. The effect of degree increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

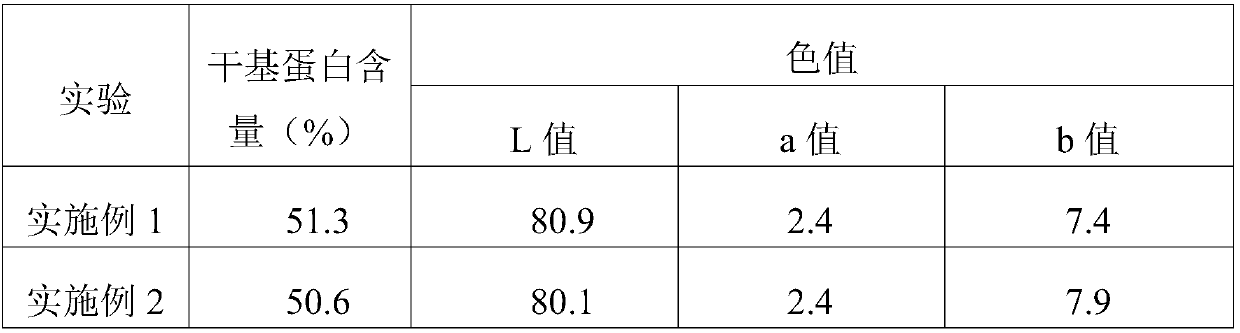

Embodiment 1

[0039] A method for preparing high-protein, smooth and tender tofu, comprising the steps of:

[0040] (1) Selection of raw materials: select gel-type soybean protein and low-temperature edible soybean meal with a protein content of 55.2% on a dry basis, and the ratio of the two is 1.67:1;

[0041] (2) Superfine pulverization: the low-temperature edible soybean meal is pulverized with an airflow superfine pulverizer, and the pulverization particle size is 100-110 mesh;

[0042] (3) Ultra-high pressure treatment: mix low-temperature edible soybean meal powder with water at a ratio of 1:2, and process it for 15 minutes under a pressure of 500Mpa, and the treated slurry is ready for use;

[0043] (4) Grinding 1: Add soybean protein isolate and water into the colloid mill at a ratio of 1:5.5, grind at a grinding speed of 3000r / min for 5min, add soybean oil, the amount of soybean oil added is 0.8 times that of soybean protein isolate, and grind at a speed of 4500r / min , grinding ti...

Embodiment 2

[0047] A method for preparing high-protein, smooth and tender tofu, comprising the steps of:

[0048] (1) Raw material selection: select gel-type soybean protein isolate and low-temperature edible soybean meal with a protein content of 54.9% on a dry basis, and the ratio of the two is 5:1;

[0049] (2) Superfine pulverization: the low-temperature edible soybean meal is pulverized with an airflow superfine pulverizer, and the pulverization particle size is 130-140 mesh;

[0050] (3) Ultra-high pressure treatment: mix the low-temperature edible soybean meal and water at a ratio of 1:3, the pressure is 600Mpa, the treatment time is 20min, and the treated slurry is set aside;

[0051] (4) Grinding 1: Add soybean protein isolate and water into the colloid mill at a ratio of 1:5.5, grind at a grinding speed of 3000r / min for 10min, add soybean oil, the amount of soybean oil added is 1 times that of soybean protein isolate, and grind at a speed of 4000r / min , grinding time 1min;

[...

Embodiment 3

[0055] A method for preparing high-protein, smooth and tender tofu, comprising the steps of:

[0056] (1) Selection of raw materials: select gel-type soybean protein isolate and low-temperature edible soybean meal with a protein content of 55.6% on a dry basis, and the ratio of the two is 1.25:1;

[0057] (2) Superfine pulverization: the low-temperature edible soybean meal is pulverized with an airflow superfine pulverizer, and the pulverization particle size is 60-70 mesh;

[0058] (3) Ultra-high pressure treatment: mix low-temperature edible soybean meal and water at a ratio of 1:1.5, the pressure is 200Mpa, the treatment time is 10min, and the treated slurry is ready for use;

[0059] (4) Grinding 1: Add soybean protein isolate and water into the colloid mill at a ratio of 1:4.5, grind at a grinding speed of 3000r / min for 3min, add soybean oil, the amount of soybean oil added is 0.1 times that of soybean protein isolate, and grind at a speed of 5000r / min , grinding time 5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com