Drill bit impregnated with diamond film and manufacturing method thereof

A technology of impregnated diamond and diamond film, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problem of uneven distribution and force, affecting the wear resistance, drilling efficiency and service life of diamond bits problems such as falling off, to achieve the effect of easy promotion, improve drilling efficiency, and reduce cutting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

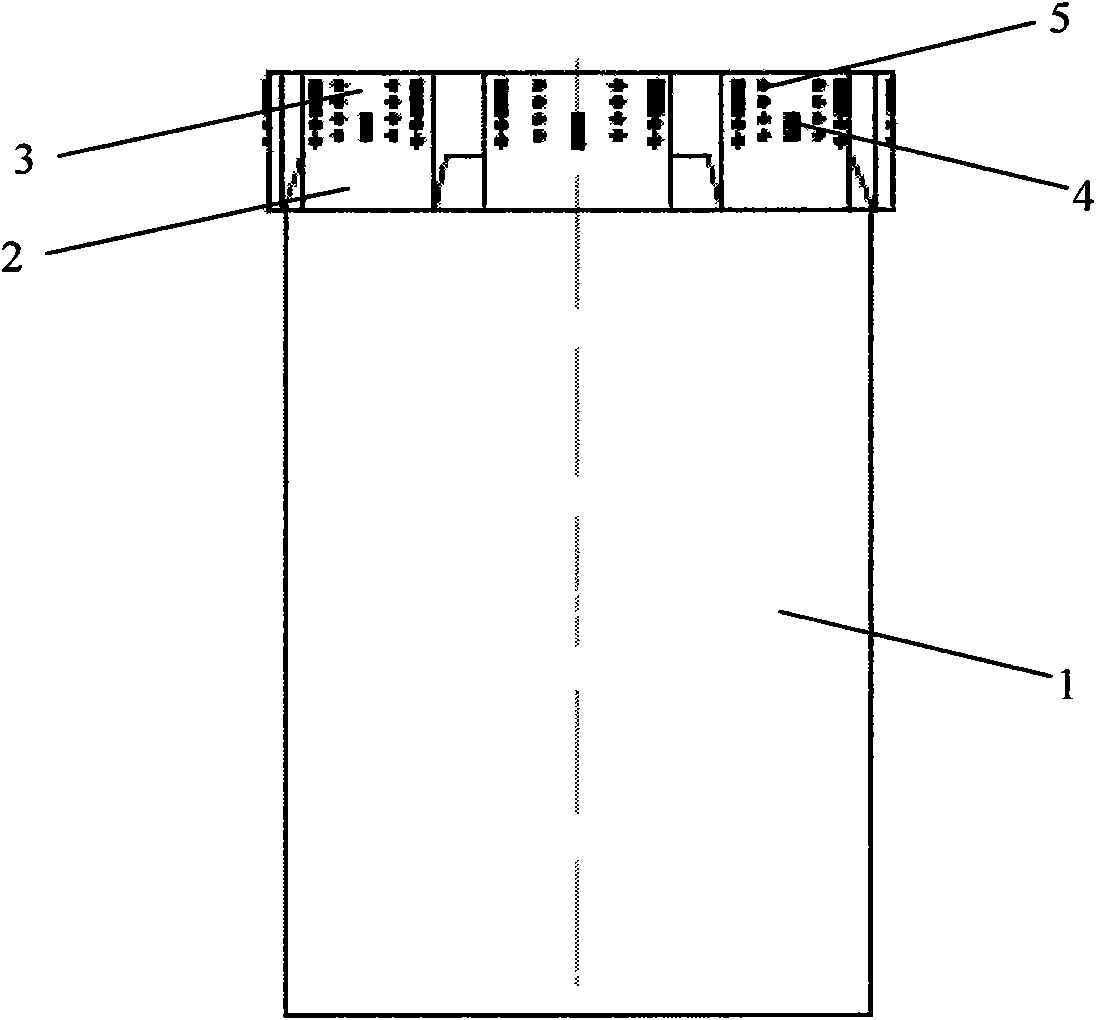

[0036] Example 1 The overall structure of the drill bit with impregnated diamond film of the present invention will be described with reference to the drawings

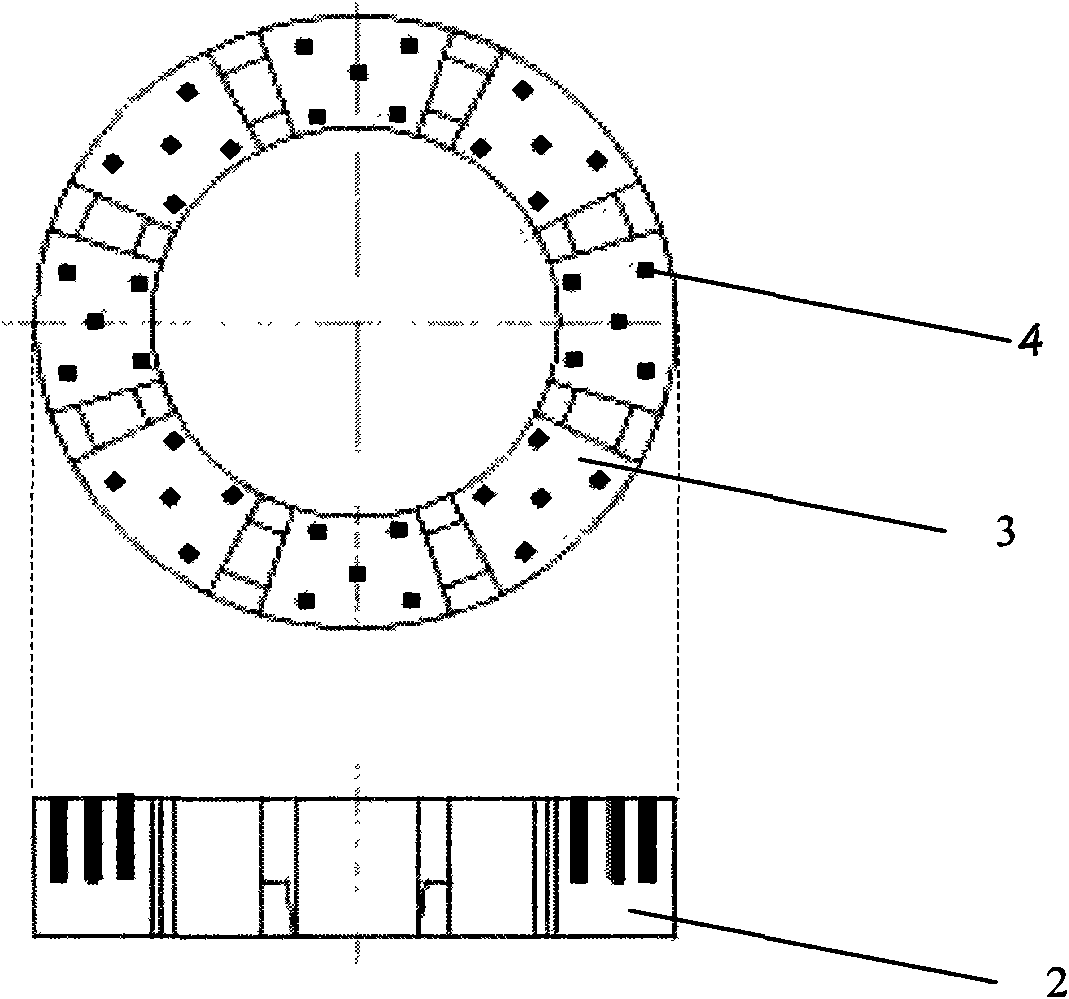

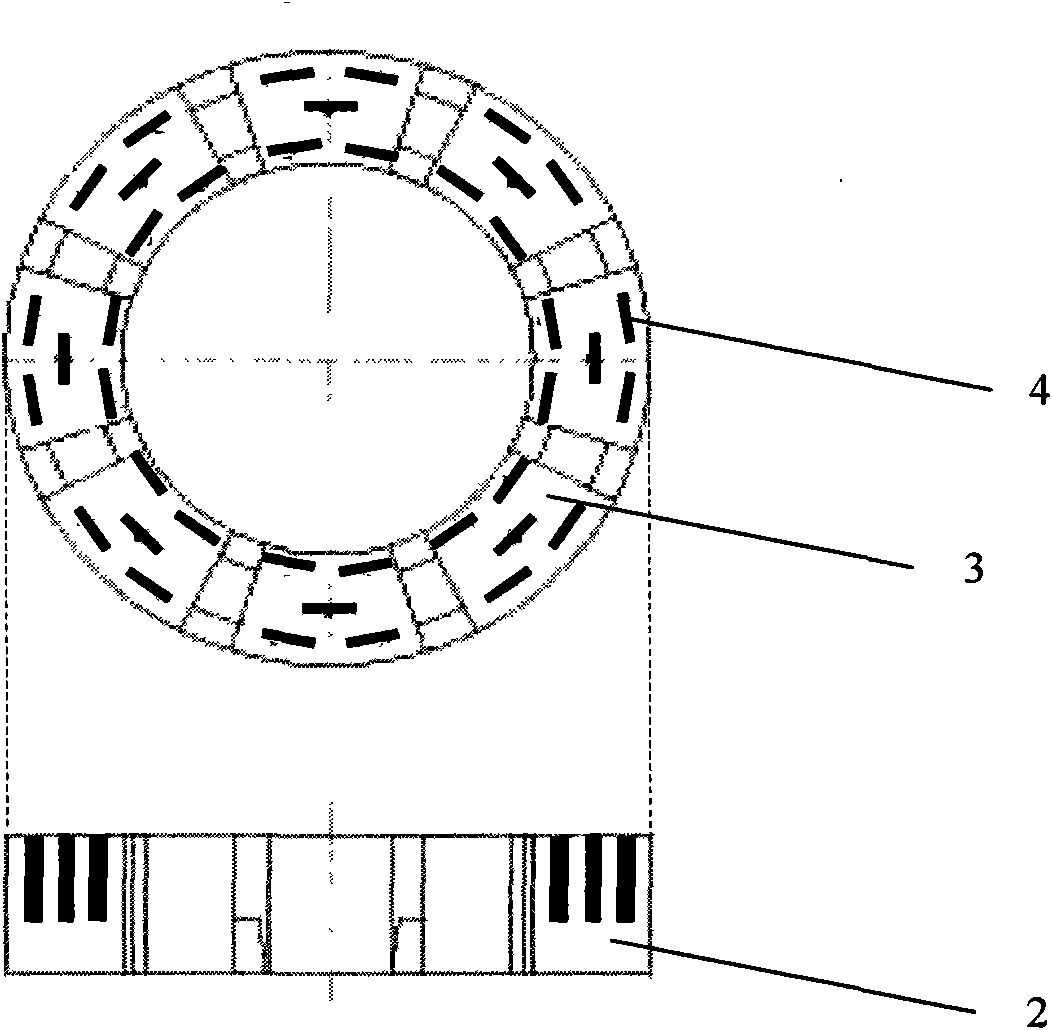

[0037] in Figure 1~4 Among them, 1 is a steel body, 2 is a working layer, 3 is a matrix material, 4 is a diamond film, and 5 is a diamond grain. Among them, the impregnated diamond film 4 in the carcass material 3 constitutes the working layer 2.

[0038] Same as the existing drill bit, the drill bit impregnated with diamond film is also composed of a steel body 1 and a working layer 2 fixed together coaxially in sequence. However, the working layer 2 of the present invention is composed of a diamond film 4 inlaid and arranged in the carcass. Composition in material 3, see figure 1 . The diamond film 4 may be sheet-shaped, such as image 3 ; It can be columnar, such as figure 2 ; It can be arranged alternately in flakes and bars, such as Figure 4 .

[0039] The length of the diamond film 4 is less than or equal to the ...

Embodiment 2

[0041] Example 2 The structure of a drill with diamond grains 5 embedded between diamond films 4

[0042] Figure 5 The lip surface and the cross-sectional schematic diagram of the working layer of the drill bit with diamond grains embedded between the diamond films of the present invention are given. Among them, 5 are diamond grains. The diamond grains 5 can be mixed and impregnated in the matrix material 3; or the diamond grains 5 can be uniformly adhered to the columnar or sheet-shaped diamond film 4, and then embedded in the matrix material 3. Figure 5 Shown is the structure of the latter case.

Embodiment 3

[0043] Example 3 The structure of the drill with the diamond film 4 as a gauge

[0044] Figure 6 A schematic diagram of the lip surface and the cross-section of the drill bit working layer with the diamond film of the present invention functioning as a gauge is given. Wherein, the surface of the diamond film 4 is exposed on the inner or / and outer side of the working layer 2, and plays a role of gauge during use. The side surface of the bar-shaped diamond film 4 can also be exposed on the inner or / and outer side of the working layer 2, which also functions as a gauge during use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com