Colorful pencil lead writing smoothly and preparation method of colorful pencil lead

A color and lead technology, which is applied in pencil lead, household utensils, applications, etc., can solve the problems of poor covering ability, effort, and high hardness of colored lead, so as to improve covering power and smoothness without roughness and smoothness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

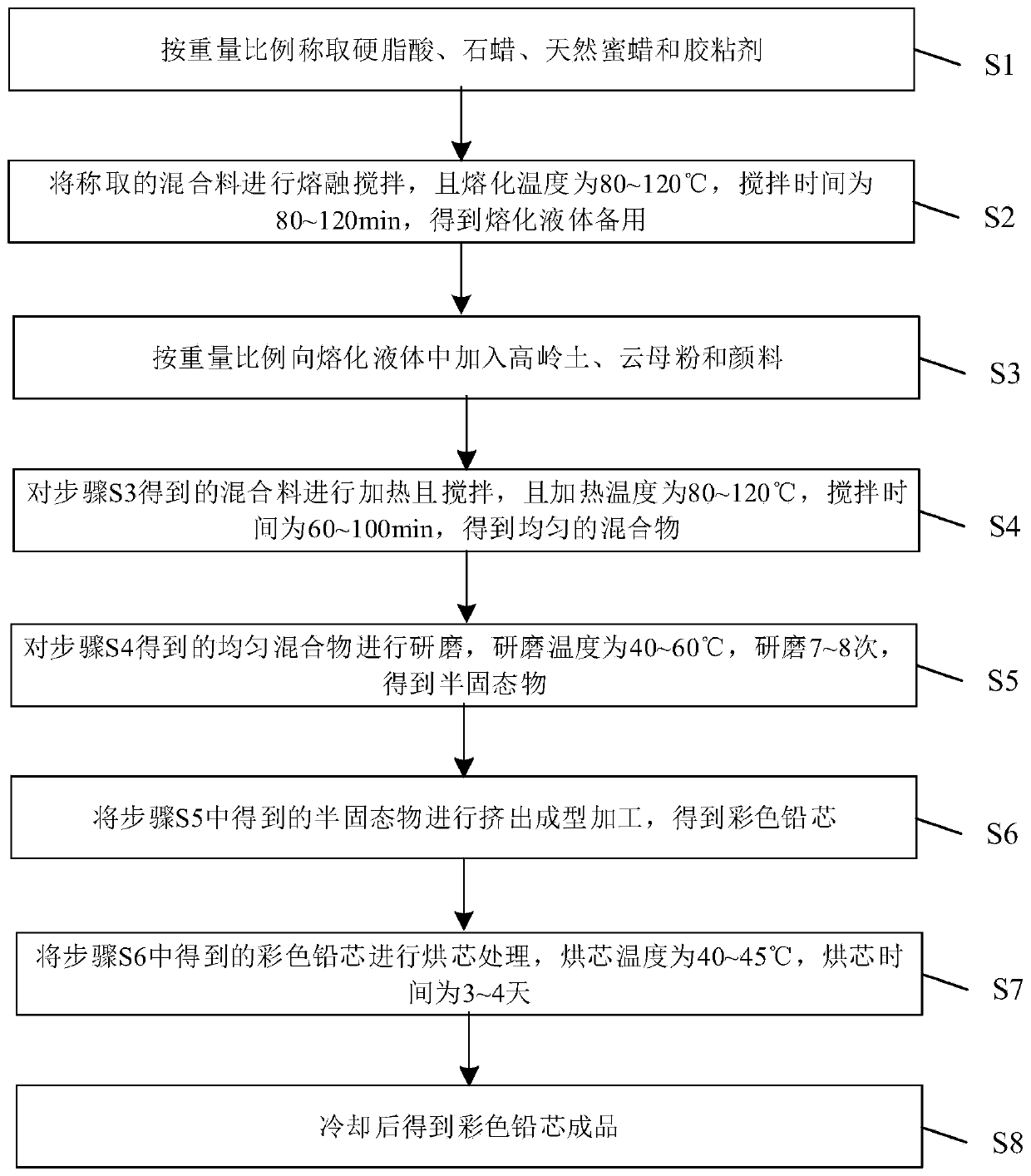

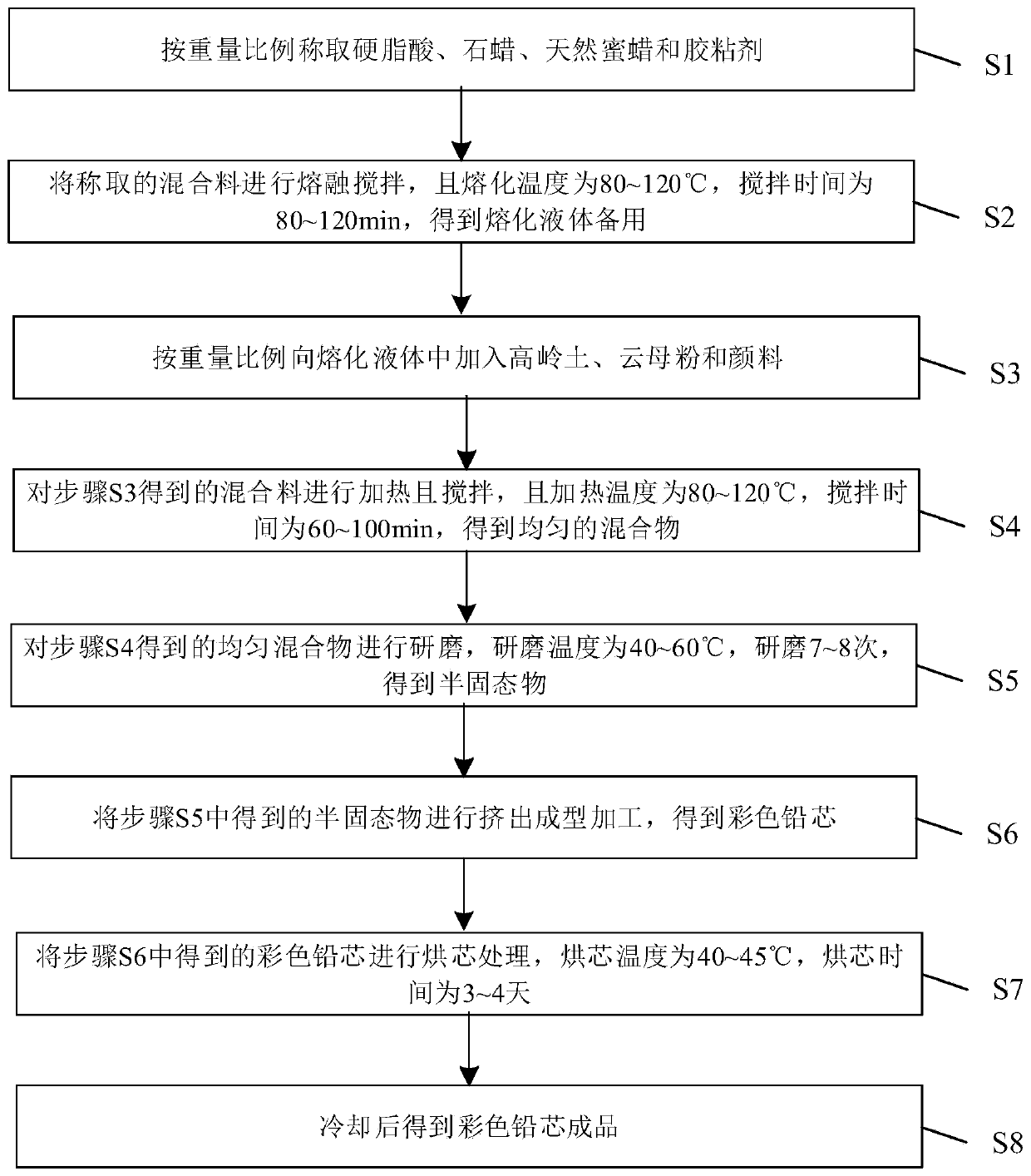

Method used

Image

Examples

Embodiment 1

[0053] A kind of smooth writing color lead core, the batching of color lead core comprises the following components by weight: 38 parts of kaolin, 10 parts of mica powder, 25 parts of stearic acid, 8 parts of paraffin wax, 5 parts of natural beeswax, red 12 parts of pigment and 2 parts of adhesive.

Embodiment 2

[0055] A kind of smooth writing color lead core, the batching of color lead core comprises the following components by weight: 40 parts of kaolin, 8 parts of mica powder, 25 parts of stearic acid, 8 parts of paraffin wax, 5 parts of natural beeswax, red 12 parts of pigment and 2 parts of adhesive.

[0056] As can be seen through experimental testing, the color lead softness test average value in embodiment 1 is 3.65, and the smoothness test average value is 4.13, and the colored lead core softness test average value in embodiment 2 is 4.10, and the smoothness test average value is 4.10. It is 5.02, where the larger the value of softness is, the softer it is, and the larger the value of smoothness is, the smoother it is. After multiple experimental designs by the applicant, and optimization of the ratio of different components of kaolin and mica powder, experiments have proved that when the ratio of kaolin and mica powder is 5:1, the softness and smoothness of the colored lead ...

Embodiment 3

[0058] A kind of smooth writing color lead core, the batching of color lead core comprises the following components by weight: 40 parts of kaolin, 8 parts of mica powder, 25 parts of stearic acid, 5 parts of No. 56 paraffin wax, 3 parts of No. 60 paraffin wax , 5 parts of natural beeswax, 12 parts of red pigment and 2 parts of adhesive.

[0059] Compared with Example 2, the color lead softness test average value in Example 3 is 4.37, and the smoothness test average value is 5.43. According to the experimental results, it can be known that natural beeswax is compounded with two kinds of paraffin waxes with different melting points. Colored leads are softer and smoother for smoother writing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com