Polyvinyl chloride insulating layer for automotive electric wire

A polyvinyl chloride and polyvinyl chloride resin technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of raw material selection and quality consistency, and achieve low odor or odor and optimize wear resistance , enhance the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

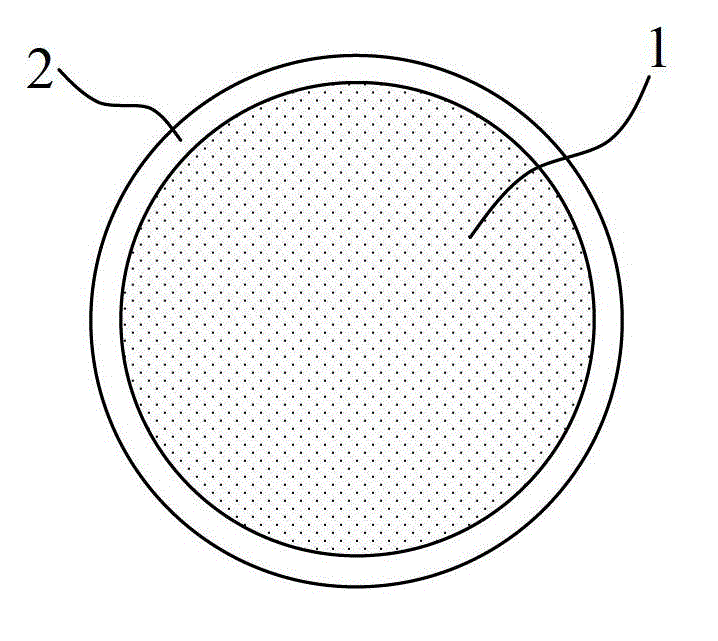

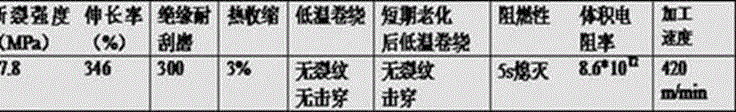

[0030] Embodiment 1: A polyvinyl chloride insulating layer applied to automobile wires, the polyvinyl chloride insulating layer 2 is coated on the outer surface of the cable core 1, and the polyvinyl chloride insulating layer 2 is obtained by processing the following components by weight :

[0031] 100 parts of polyvinyl chloride resin,

[0032] 25 parts of trioctyl trimellitate,

[0033] Purified dioctyl terephthalate 11 parts,

[0034] 5 parts epoxy soybean oil,

[0035] Calcium carbonate 19 parts,

[0036] Calcium-zinc composite stabilizer (105°C) 7 parts,

[0037] 1 part of high melting point polyethylene wax,

[0038] Phenolic antioxidant 1010 0.16 parts,

[0039] Acrylic resin 2 parts,

[0040] 3 parts barium sulfate,

[0041] Silicone powder 1.6 parts;

[0042] 1.5 parts of di-isooctyl terephthalate.

[0043] The degree of polymerization of the polyvinyl chloride resin is 1300.

[0044] Above-mentioned calcium carbonate is nano calcium carbonate.

[0045] Th...

Embodiment 2

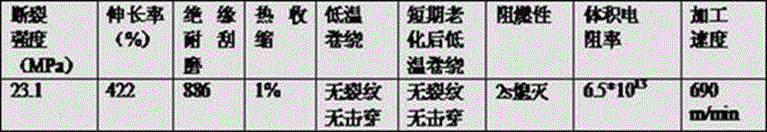

[0052] Embodiment 2: A polyvinyl chloride insulating layer applied to automobile wires, the polyvinyl chloride insulating layer 2 is coated on the outer surface of the cable core 1, and the polyvinyl chloride insulating layer 2 is obtained by processing the following components by weight :

[0053] 100 parts of polyvinyl chloride resin,

[0054] 26 parts of trioctyl trimellitate,

[0055] 10.5 parts of purified dioctyl terephthalate,

[0056] 4.8 parts of epoxidized soybean oil,

[0057] Calcium carbonate 20 parts,

[0058] Calcium-zinc composite stabilizer (105°C) 7.5 parts,

[0059] Polyethylene wax (high melting point polyethylene wax) 1.2 parts,

[0060] Phenolic antioxidant 1010 0.15 parts,

[0061] Acrylic resin 1 part,

[0062] 3.2 parts of barium sulfate,

[0063] Silicone powder 1.5 parts.

[0064] The degree of polymerization of the polyvinyl chloride resin is 1300.

[0065] The above-mentioned calcium carbonate is composite calcium carbonate formed by acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com