Large-sized optical fiber preform stretching furnace and use method thereof

A technology of optical fiber preform and large size, which is applied in manufacturing tools, glass manufacturing equipment, etc. It can solve the problems of short service life, difficult maintenance, and easy damage of graphite parts, and achieve the effects of good surface, clean environment, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

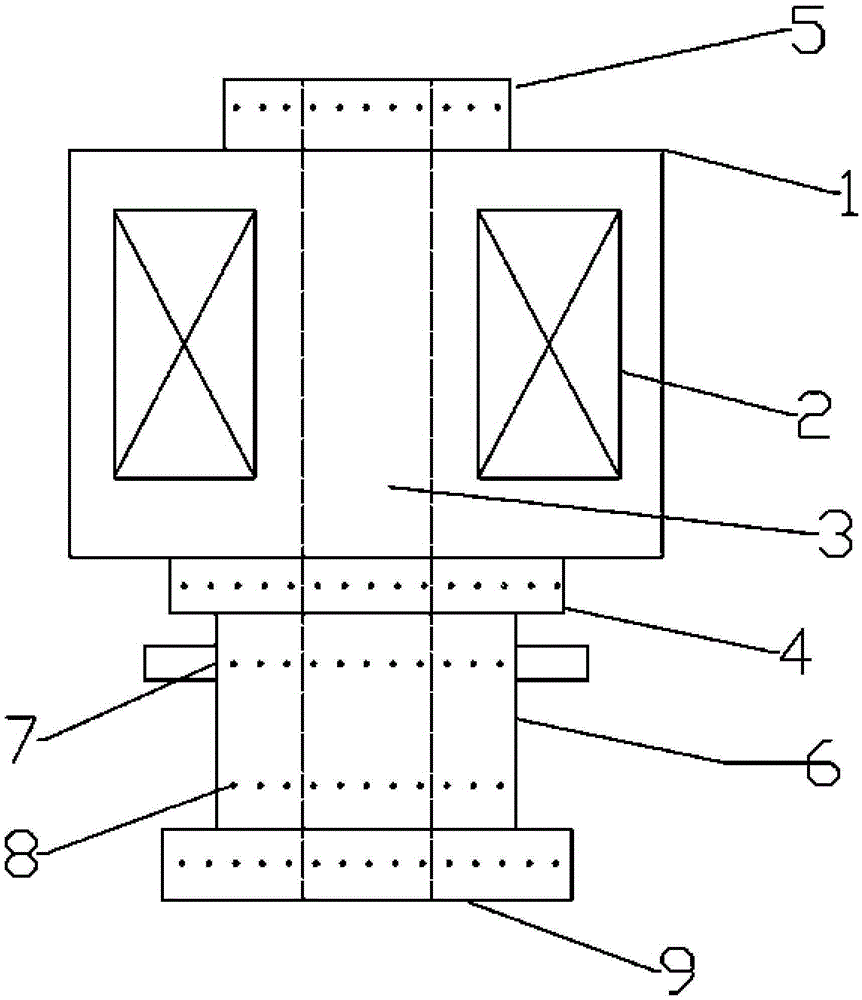

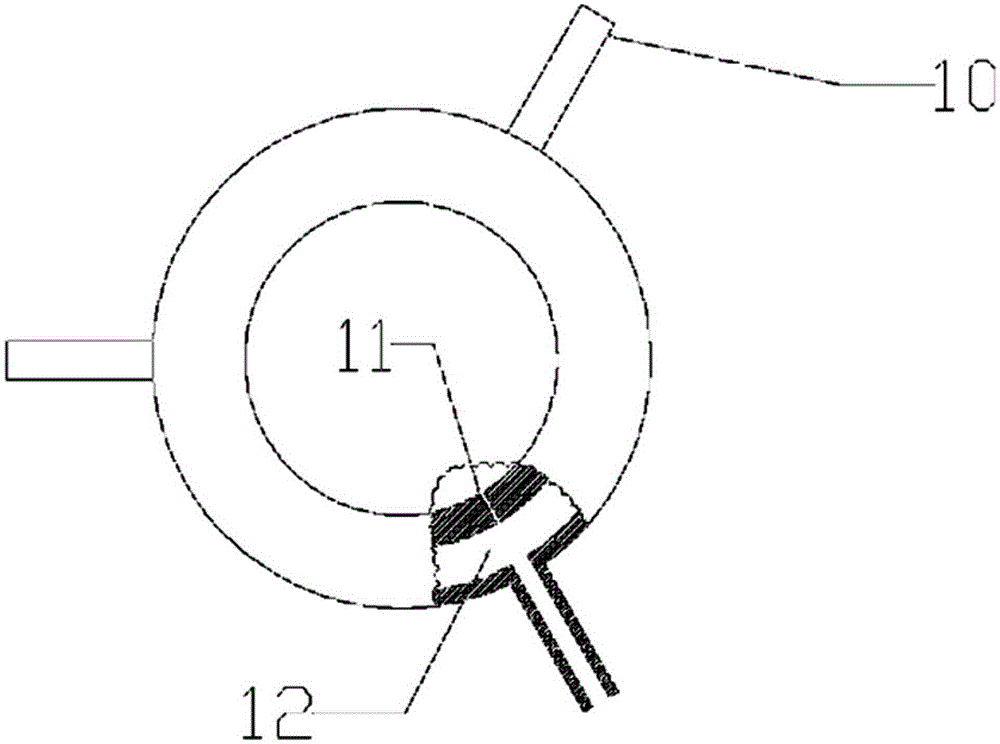

[0033] Such as Figure 1 to Figure 2 As shown, it is a large-scale optical fiber preform drawing furnace according to this embodiment, including: a furnace body 1, a lower sealing device 4 arranged below the furnace body 1, an air purification system 6 in the furnace, and a bottom sealing device. Apparatus 9, wherein an equipment cavity 3 for accommodating the quartz sleeve is formed inside the furnace body 1, and one or more heaters for continuously heating the quartz sleeve are arranged inside the equipment cavity 3 Mechanism 2; the air purification system 6 in the furnace includes a housing, an air extraction system 7 for exhausting exhaust gas, and an air supply system 8 for supplementing sealing gas, and the air extraction system 7 and the air supply system 8 are set On the housing; the equipment cavity 3 communicates with the lower sealing device 4, the furnace air cleaning system 6 and the hollow part of the bottom sealing device 9, and the lower sealing device 4 and / ...

Embodiment 2

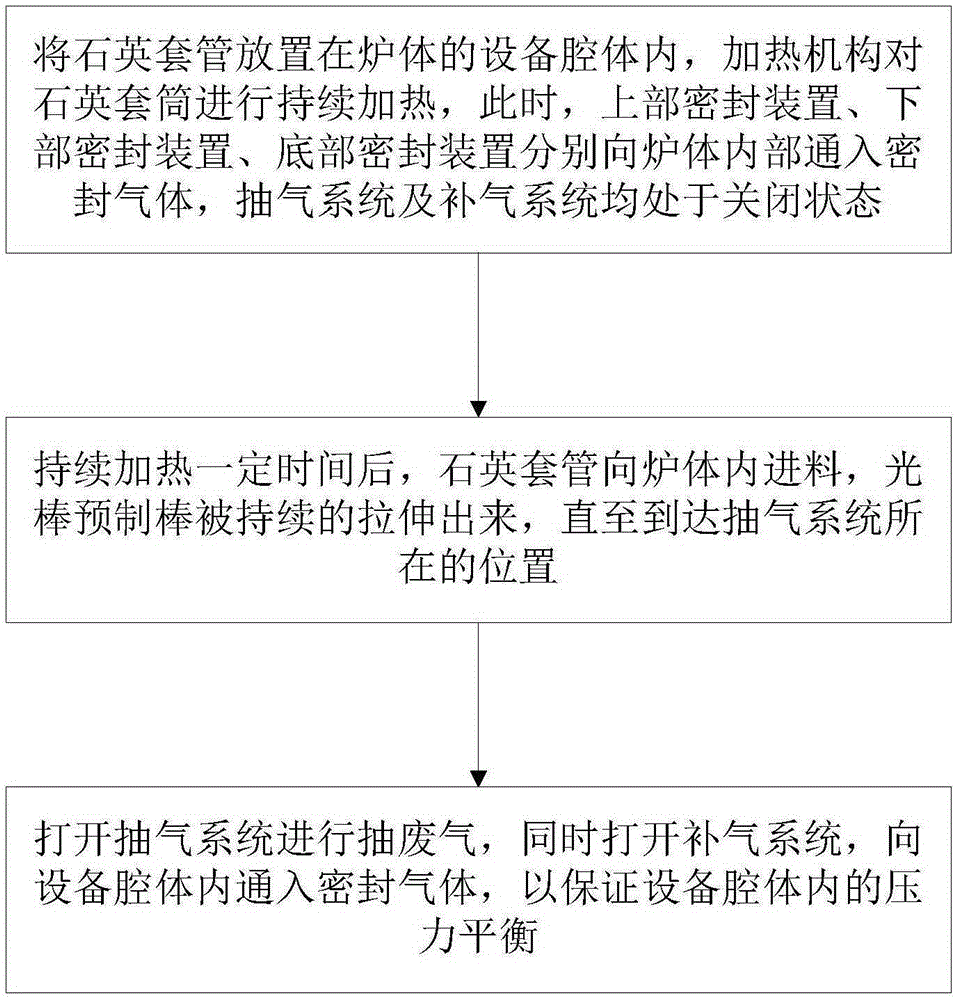

[0041] Such as image 3 As shown, a method for using a large-size optical fiber preform drawing furnace according to this embodiment includes the following steps:

[0042] S1: Place the quartz sleeve in the equipment cavity of the furnace body, and the heating mechanism will continue to heat the quartz sleeve. Both the air system and the air supply system are closed.

[0043] S2: After continuing to heat for a certain period of time, the quartz sleeve is fed into the furnace body, and the light rod preform is continuously stretched out until it reaches the position of the exhaust system.

[0044] S3: Turn on the exhaust system to pump out exhaust gas, and at the same time turn on the air supply system to feed the sealed gas into the equipment cavity to ensure the pressure balance in the equipment cavity.

[0045] Preferably, the step S3 specifically includes:

[0046] Turn on the exhaust system to extract the exhaust gas, the exhaust gas flows into the cavity through the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com