Textile bleaching device

A textile and box technology, applied in the field of textile bleaching devices, can solve the problems of insufficient bleaching agent dissolution, affect the bleaching effect, and low bleaching rate, and achieve the goal of avoiding excessively high water temperature, increasing the bleaching effect, and increasing the bleaching efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

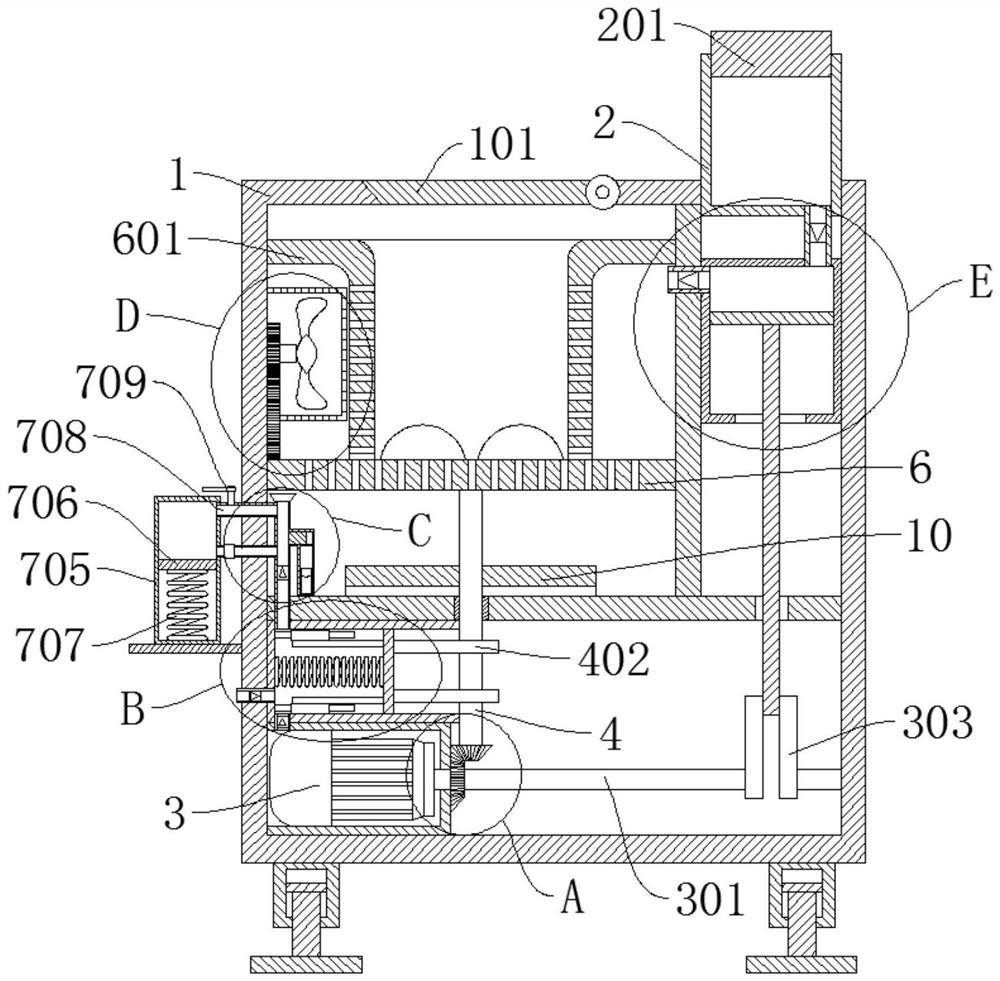

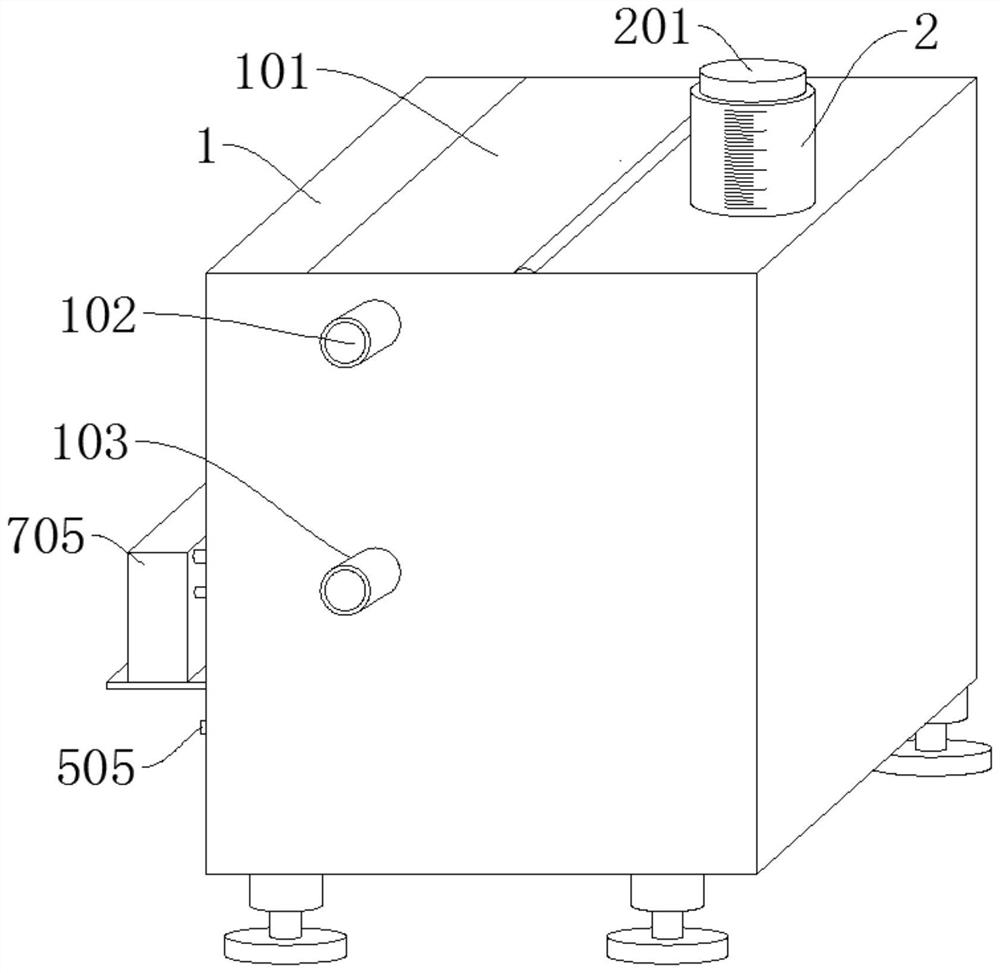

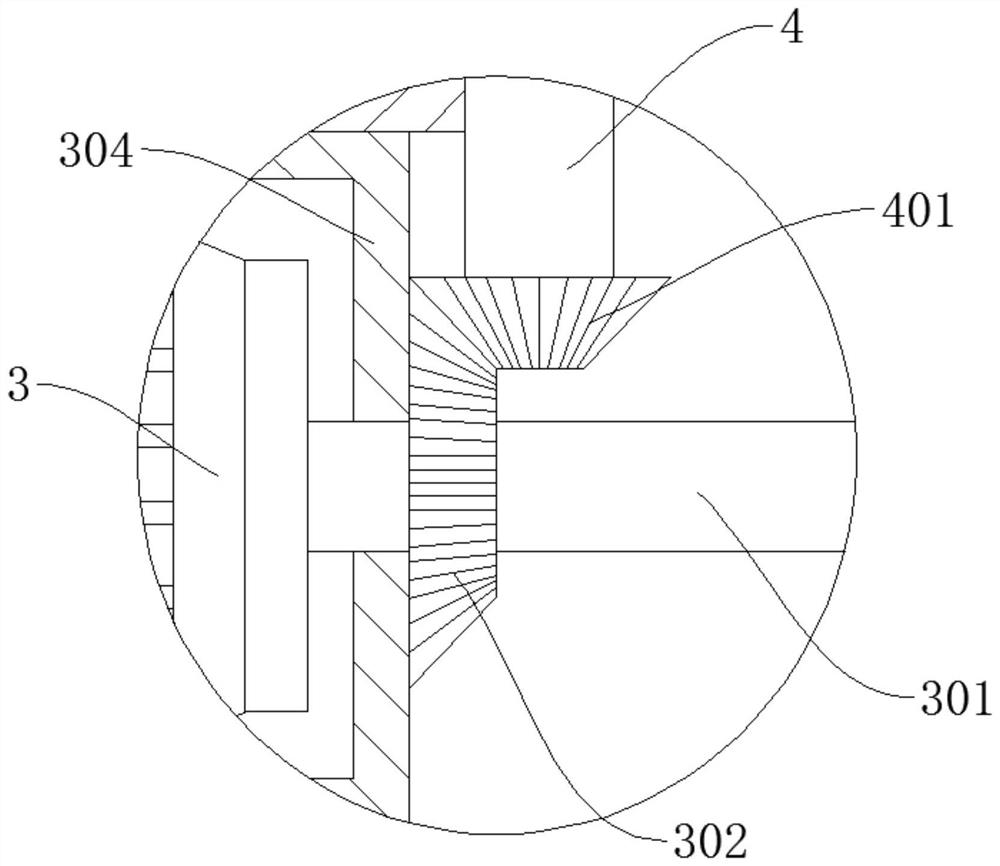

[0038] refer to Figure 1-7, a textile bleaching device, comprising a box body 1, a feeding pipe 2, a box door 101, the box door 101 is rotatably connected to the box body 1, the feeding tube 2 is fixedly connected to the box body 1, and the box body 1 is provided with There is a partition 11, a driving motor 3 is arranged in the box body 1, and the driving motor 3 is located under the partition 11. The output end of the driving motor 3 is fixedly connected to a rotating shaft 301, and a bevel gear 302 is arranged on the rotating shaft 301, and the rotating shaft 302 rotates in the box body 1. Connected with a rotating shaft 4, the lower end of the rotating shaft 4 is provided with a driven gear 401, the driven gear 401 meshes with the bevel gear 302, and the rotating disk 6 is connected to the inside of the box body 1, the rotating disk 6 is located above the partition 11, and the rotating disk 6 is fixed Connected to the end of the rotating shaft 4 away from the driven gear ...

Embodiment 2

[0041] refer to Figure 1-7 , a textile bleaching device, which is basically the same as in Example 1, furthermore, the side wall of the box body 1 is provided with an incubator 705, and a sealing plate 706 is slidably connected in the incubating box 705, between the sealing plate 706 and the incubating box 705 A second spring 707 is connected between them, an air guide pipe 703 is connected between the incubator 705 and the exhaust pipe 506, a pressure valve 704 is provided on the air guide pipe 703, an air jet pipe 708 is connected between the incubator 705 and the exhaust pipe 506, The jet pipe 708 is provided with a control valve 709. When the sealing block 702 seals the exhaust pipe 506, the air pressure in the exhaust pipe 506 increases, the pressure valve 704 opens, and the hot gas produced by the gas cylinder 5 flows along the exhaust pipe 506, the air guide pipe 703 enters the incubator 705. As the gas in the incubator 705 increases, the sealing plate 706 is pressed a...

Embodiment 3

[0043] refer to Figure 1-7 , a textile bleaching device, which is basically the same as that of Embodiment 1, furthermore, a dehydration bucket 601 is fixedly connected to the turntable 6, and the dehydration bucket 601 is rotatably connected in the box body 1, and the dehydration bucket 601 is densely covered with through holes to connect After the water in the tank 1 is discharged, the dehydration bucket 601 rotates with the turntable 6, and the water attached to the textile in the bucket is separated from the textile under the action of centrifugal force, and the separated water is discharged along the through hole, and is discharged out of the tank through the drain pipe 103. Body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com