Textile bleaching and dyeing sewage treatment device

A sewage treatment device and textile technology, which is applied in the fields of sewage treatment and environmental protection, can solve the problems of refractory degradation, large amount of chemical agents used, and high treatment costs, and achieve the effects of reducing harmful substances, reducing bacterial growth, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

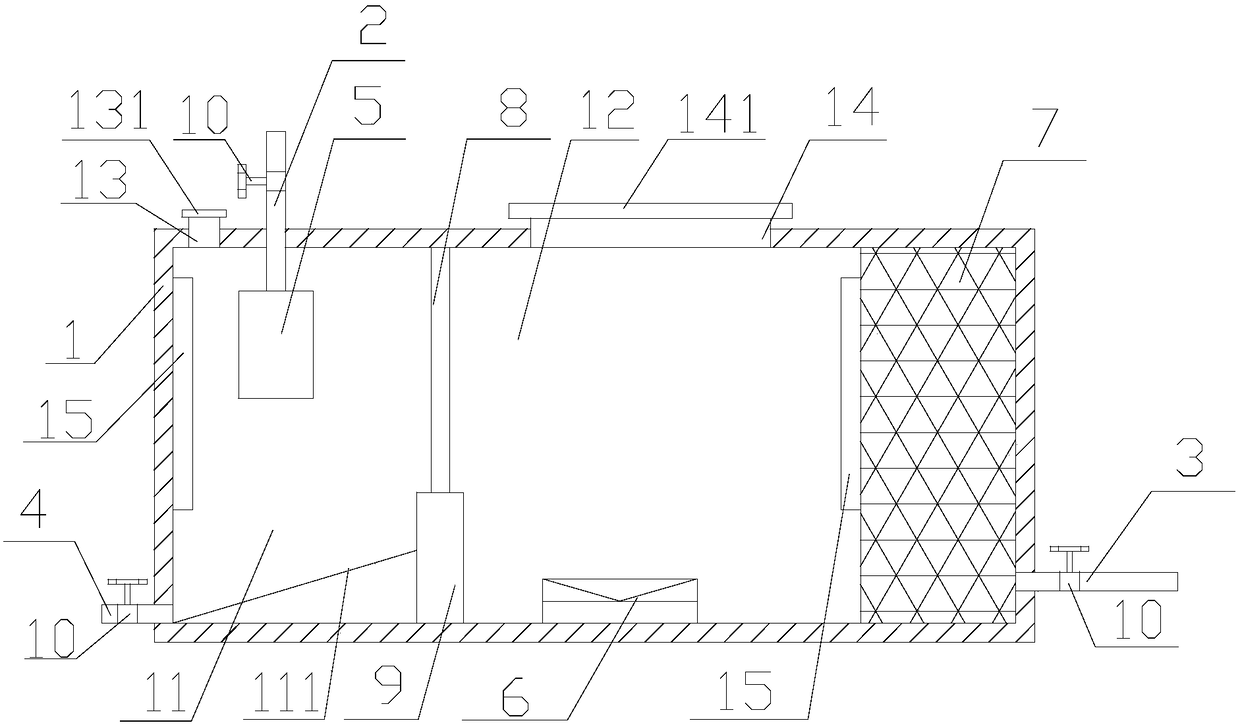

[0014] refer to figure 1 , a textile bleaching and dyeing sewage treatment device of the present invention, comprising a main box body 1, a sewage inlet pipe 2, a drain pipe 3, a sewage pipe 4, a filter element 5, an ultraviolet germicidal lamp 6, an activated carbon bag 7, a filter screen plate 8, and a vertical plate baffle Plate 9, the lower end of the main box body 1 is provided with a vertical plate baffle 9, and the upper end of the vertical plate baffle 9 is provided with a filter screen 8, and the vertical plate baffle 9 and the filter screen 8 will be The inside of the main box 1 is divided into two cavities, the two cavities are respectively the first filter cavity 11 and the second filter cavity 12, the main box 1 is provided with a sewage inlet pipe 2, the The sewage inlet pipe 2 runs through the main box body 1 and extends to the inside of the first filter chamber 11. The sewage inlet pipe 2 is provided with a filter element 5, and the filter element 5 is detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com