Patents

Literature

63results about How to "Soft appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

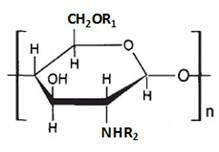

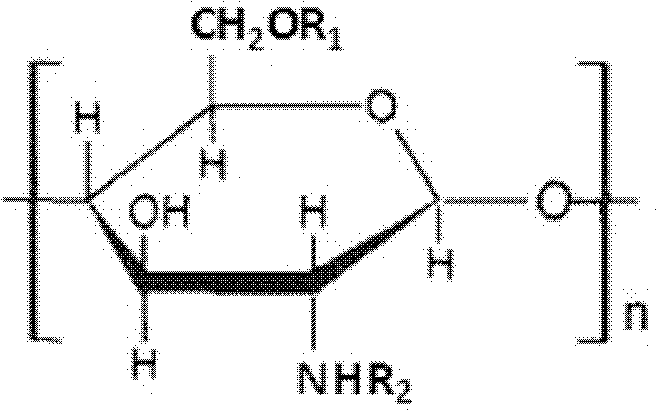

Chitosan-based styptic sponge and preparation method thereof

InactiveCN102526795AImprove stabilityMaintain coagulation activityAbsorbent padsBandagesWound healingThrombin activity

The invention relates to chitosan-based styptic sponge with a thrombin immobilization effect, and the chitosan-based styptic sponge is a porous sponge made from chitosan with the thrombin immobilization effect and hemostatic. The preparation method of the chitosan-based styptic sponge provided by the invention comprises the following steps: immobilizing thrombin with chitosan or carboxymethyl chitosan, and adding other styptics, cryoprotectants and crosslinking agents to prepare the porous styptic sponge, wherein the weight ratio of the chitosan or carboxymethyl chitosan to the thrombin is 100:(0.1-20); pre-freezing, lyophilizing in vacuum, casting, cutting, encapsulating and sterilizing to prepare the chitosan-based styptic sponge. According to the chitosan-based styptic sponge, the thrombin is immobilized through the chitosan or carboxymethyl chitosan, so that the stability and procoagulant activity of the thrombin can be improved, and the property of the prepared chitosan-based styptic sponge is more stable, the procoagulant and wound healing effects are remarkably improved, and the chitosan-based styptic sponge can be widely applied to wound or surgery hemostasis.

Owner:WUHAN GENERAL HOSPITAL OF GUANGZHOU MILITARY

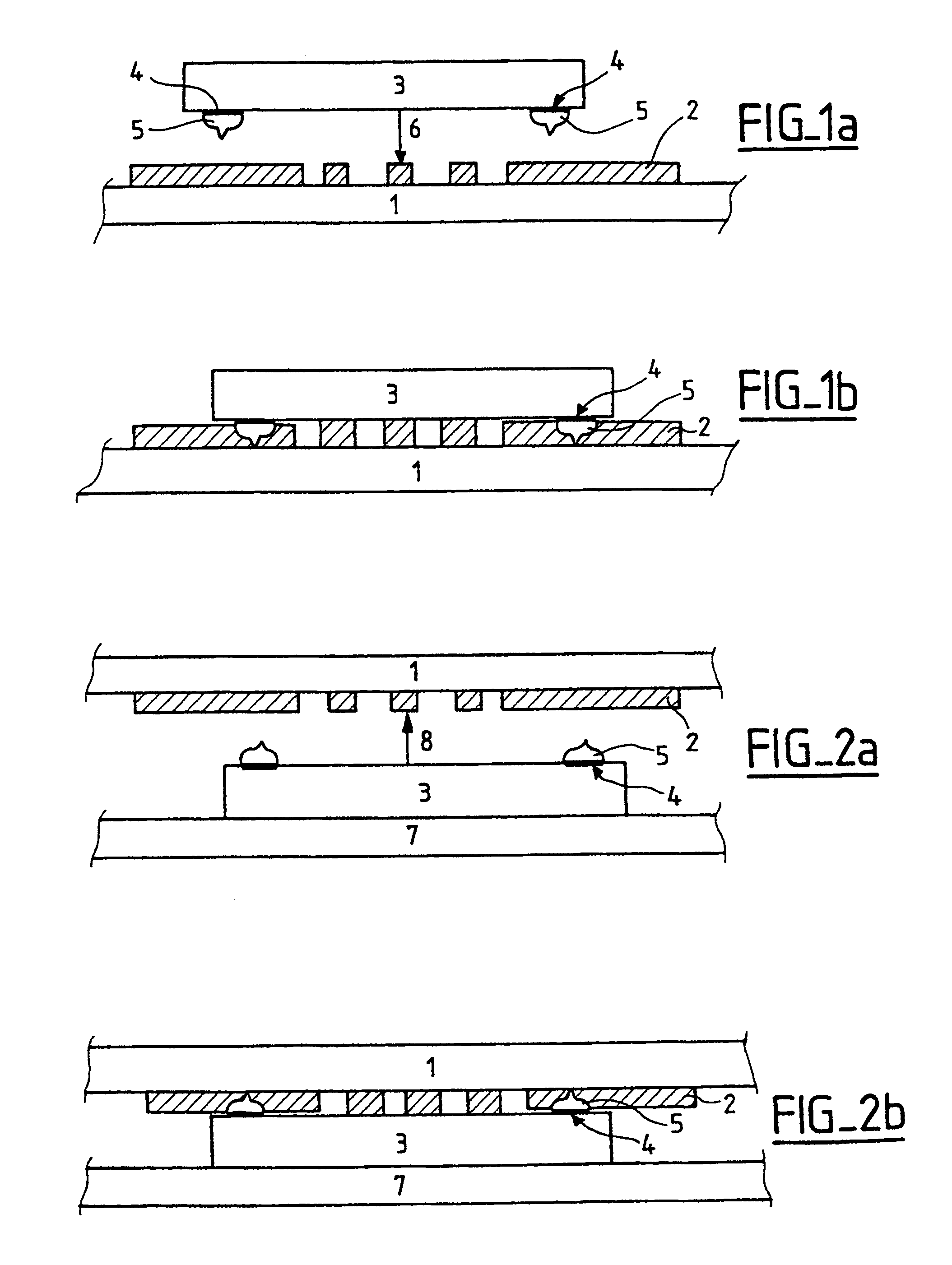

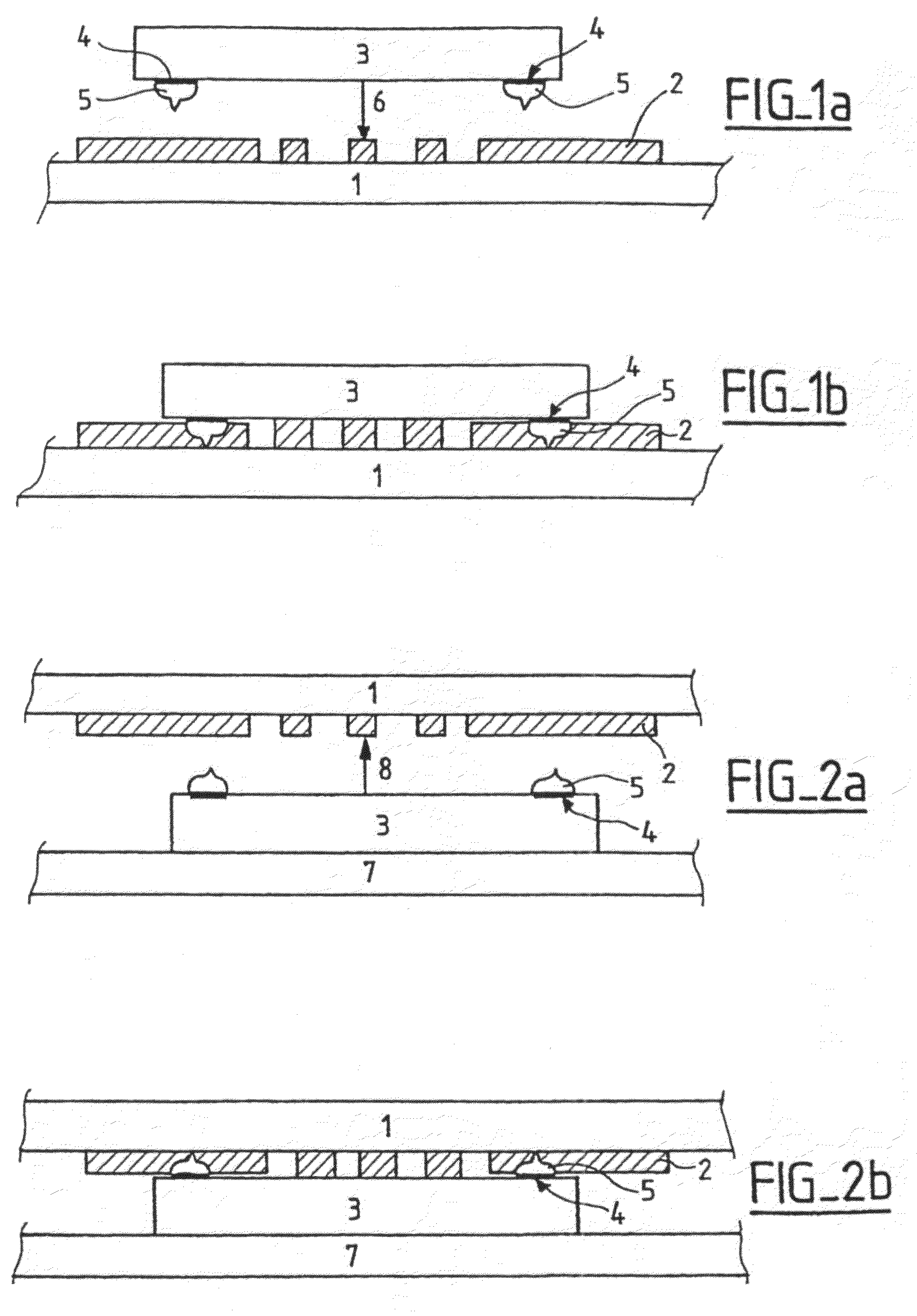

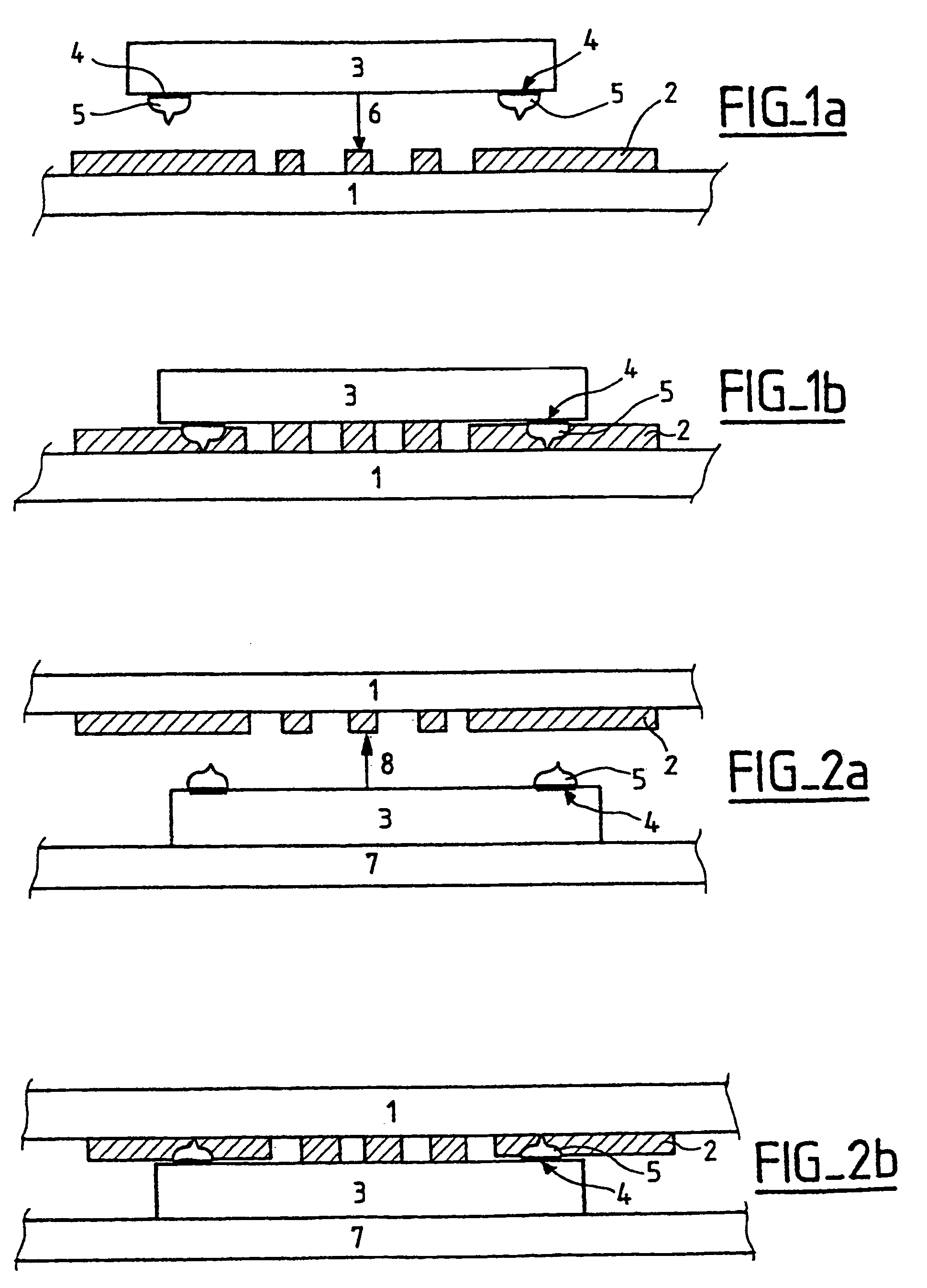

Method for making contactless cards

InactiveUS6957481B1Improve permeabilityQuality improvementPrinted circuit assemblingElectrically conductive connectionsContact freeElectrical and Electronics engineering

Owner:GEMPLU

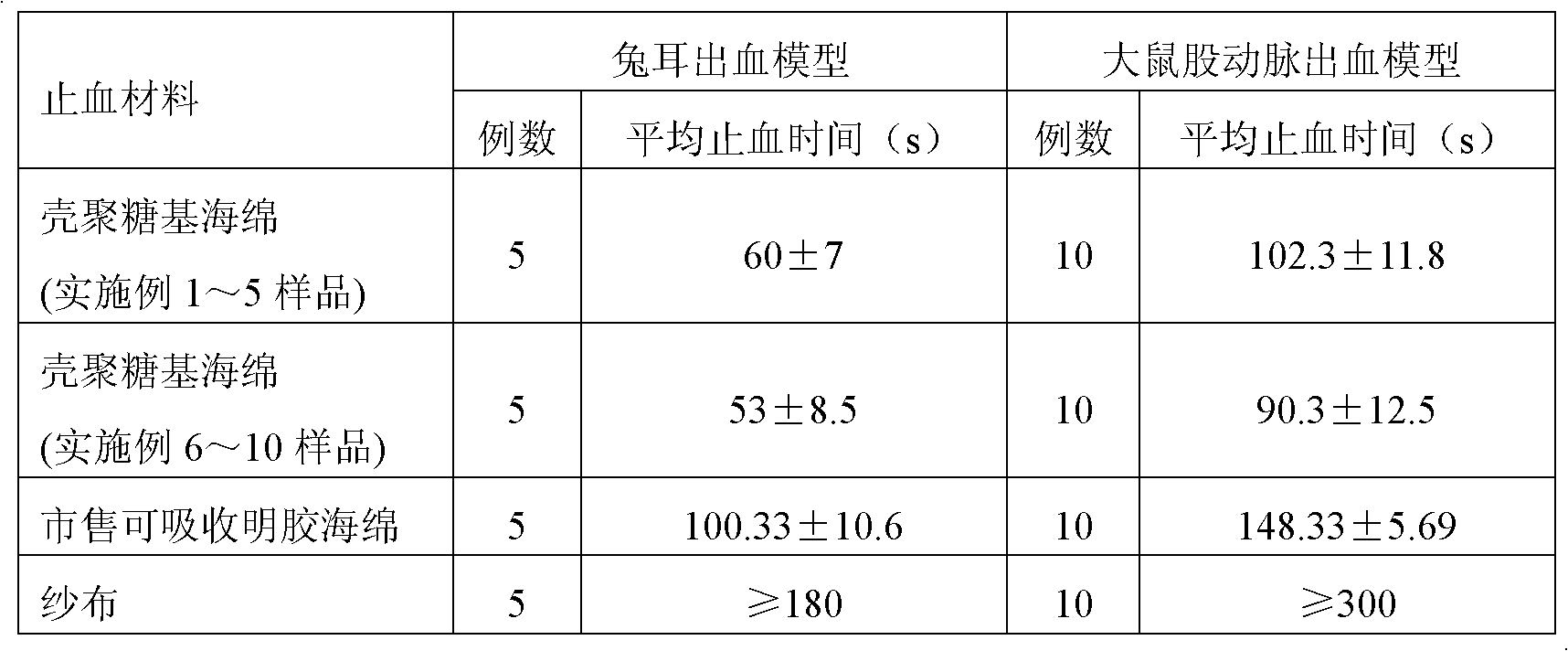

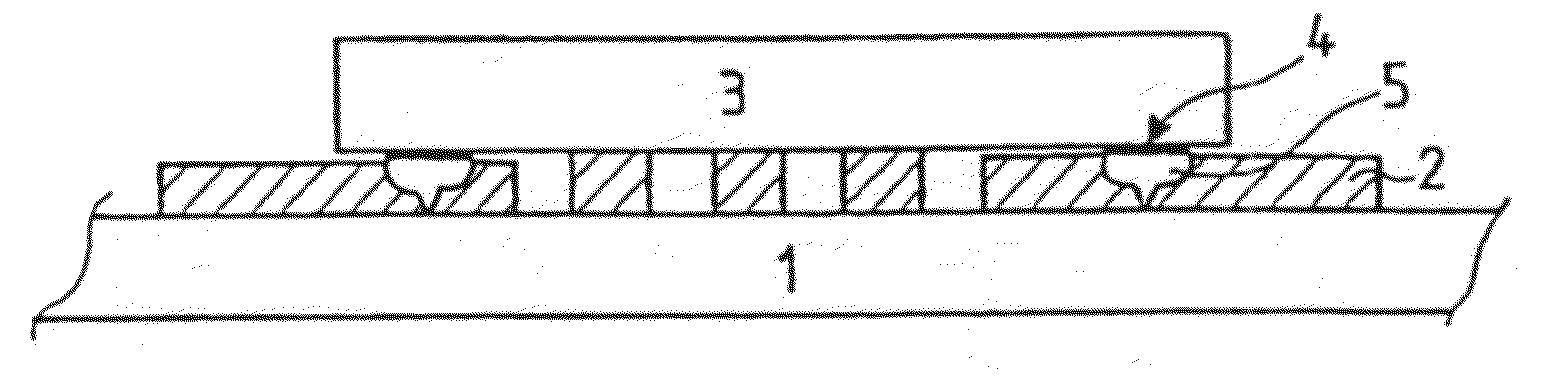

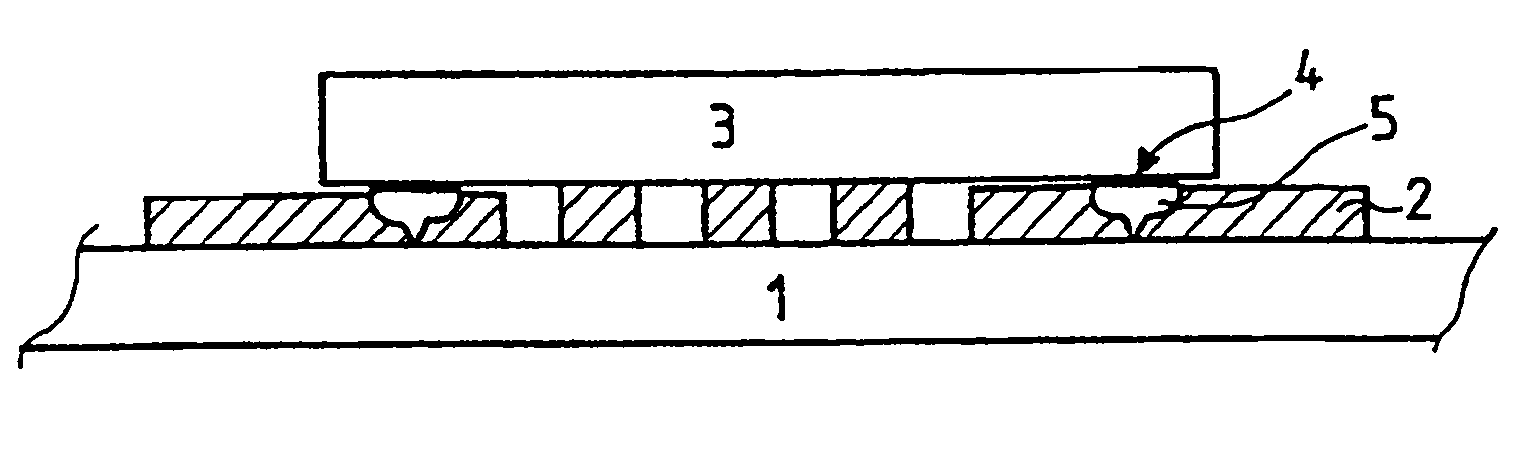

Contactless transponder

InactiveUS7494068B2Quality improvementExtended service lifeOther printing matterSolid-state devicesConductive materialsElectrical contacts

A contactless transponder includes an antenna made from a conductive material that is disposed on a surface of a substrate. An integrated circuit chip having electrical contacts is mounted on a surface of the antenna that is remote from the substrate. The contacts of the chip are embedded in the material of the antenna, and at least a portion of the chip protrudes above the surface of the plane defined by the remote surface of the antenna.

Owner:GEMPLU

Method for making contactless cards

InactiveUS7204427B2Quality improvementExtended service lifeOther printing matterSolid-state devicesContact freeEngineering

Owner:GEMPLU

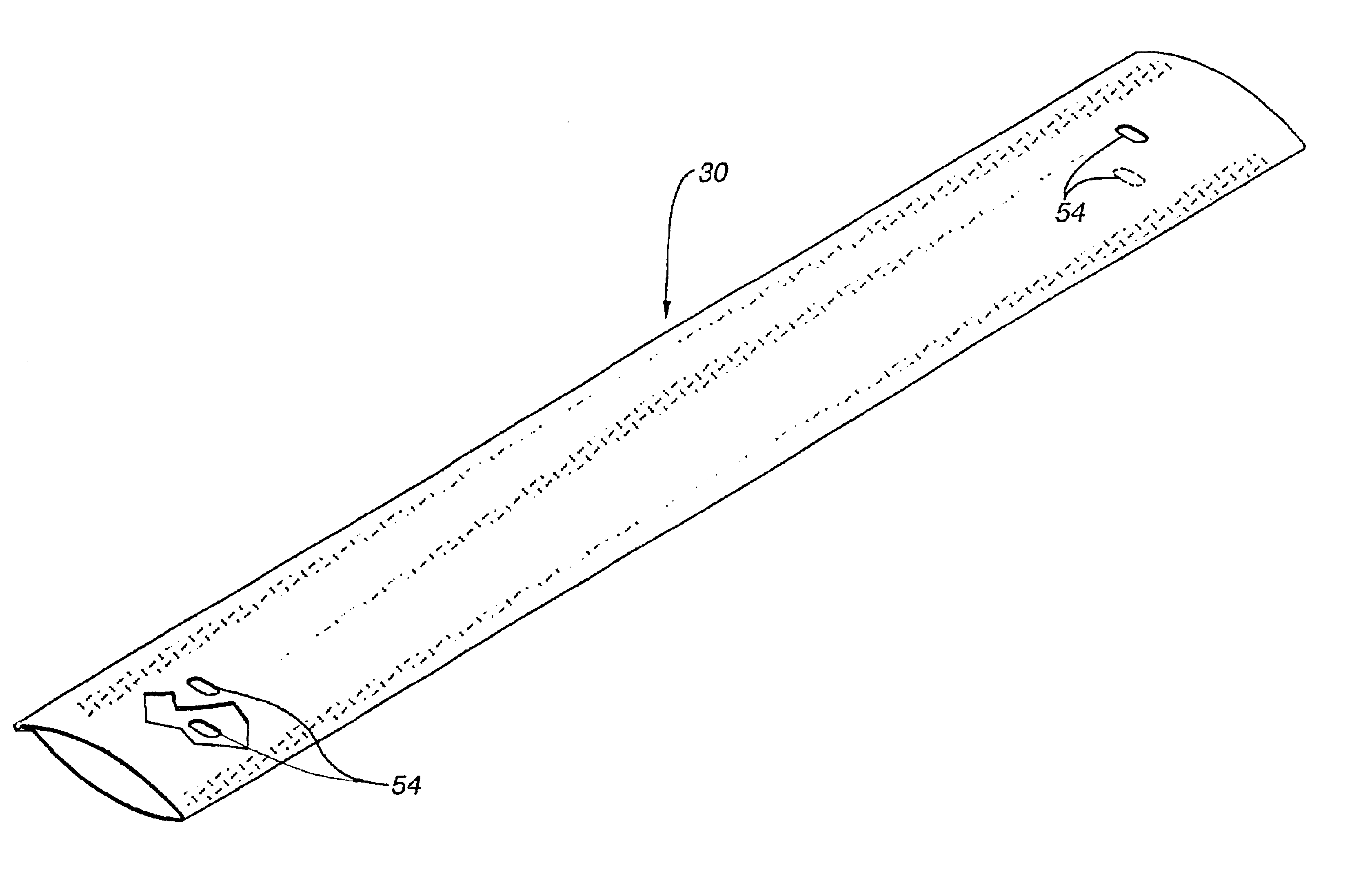

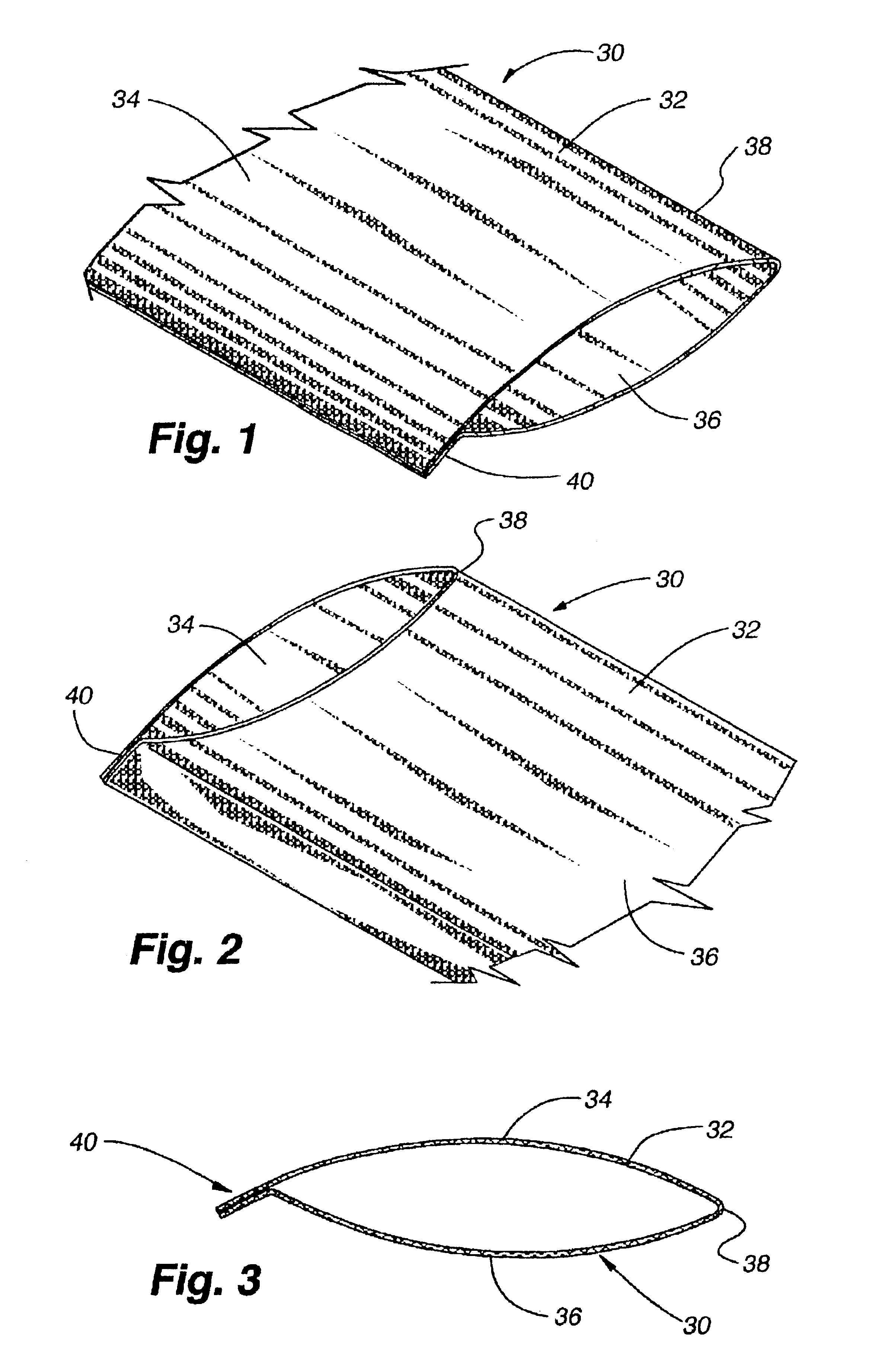

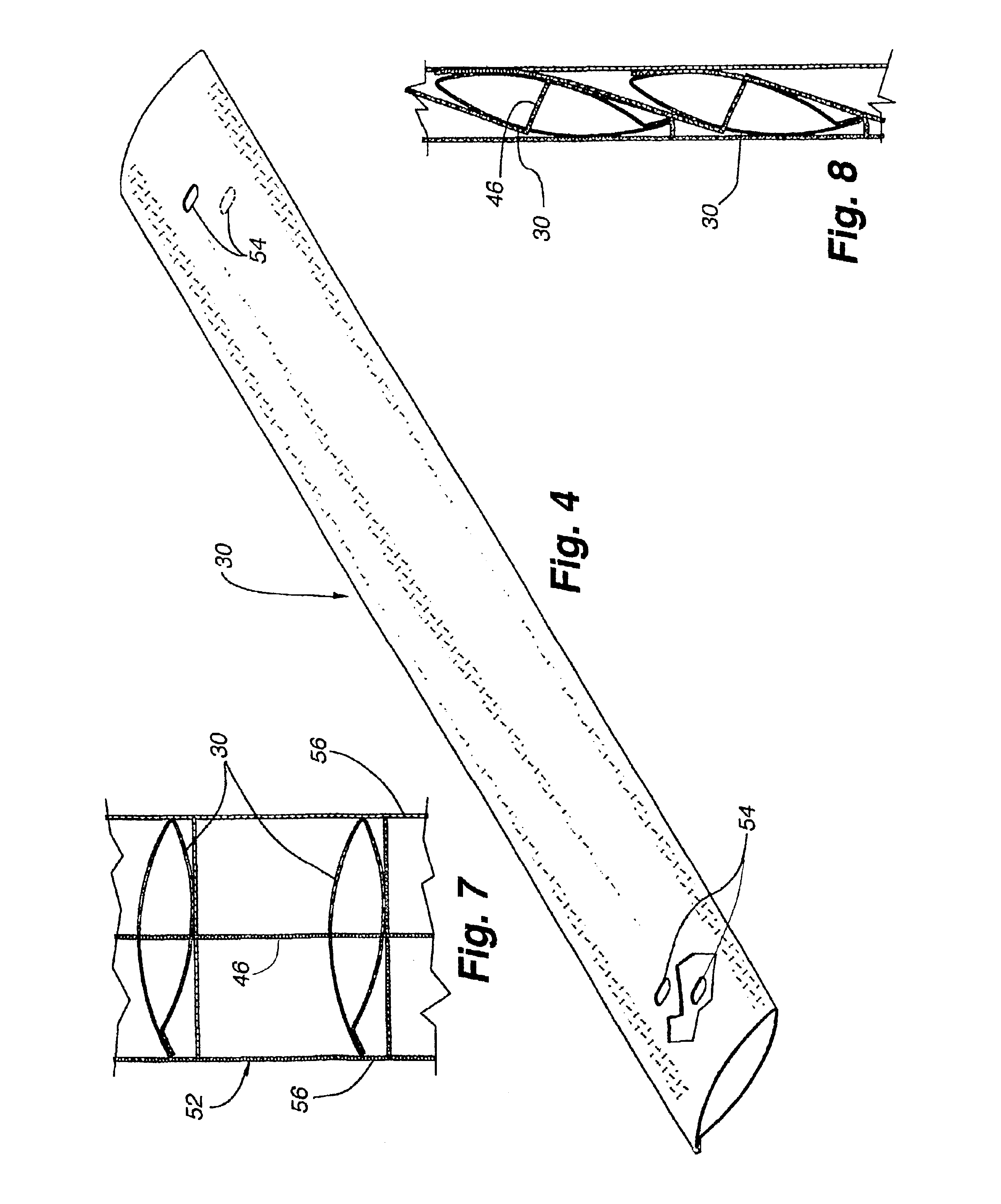

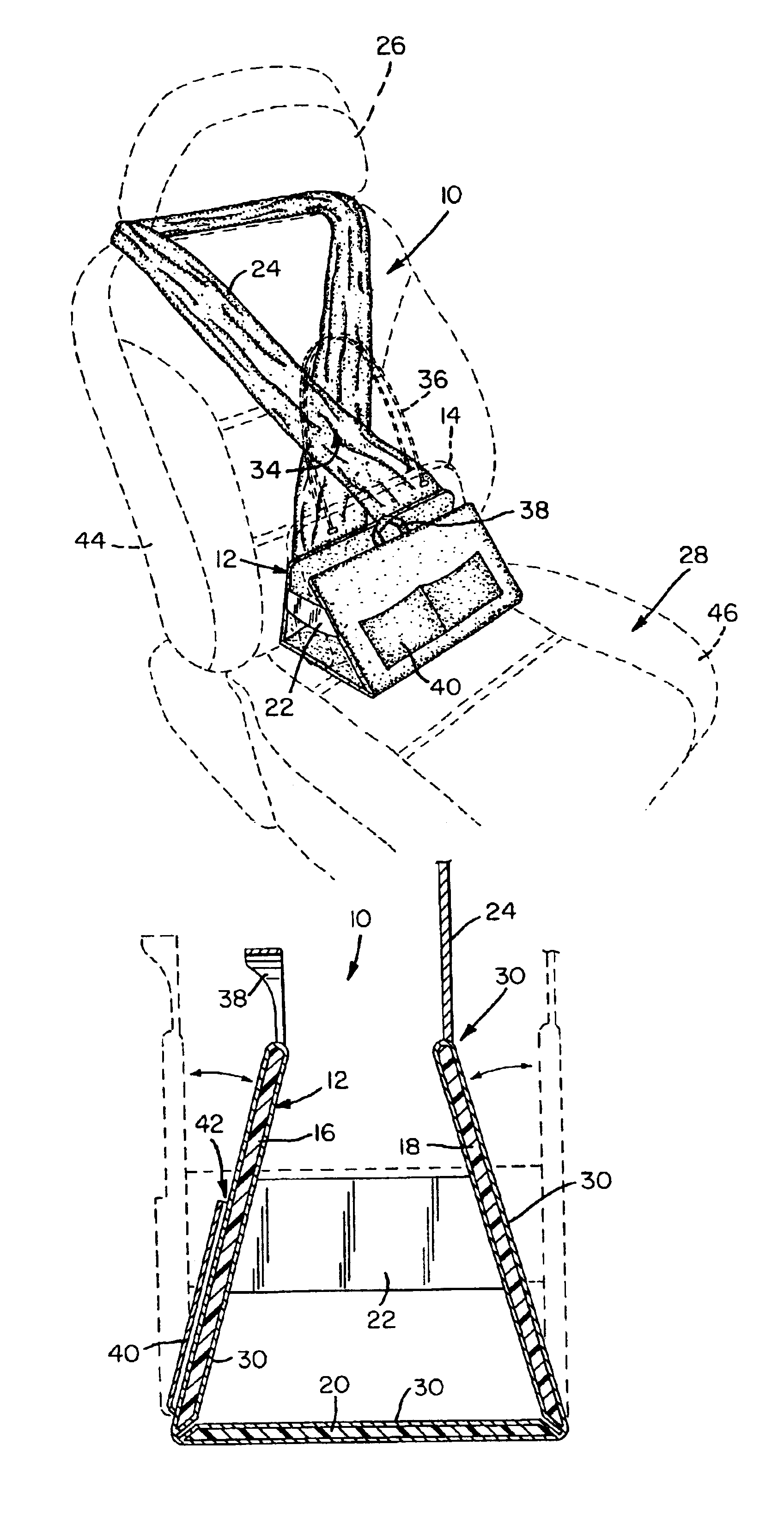

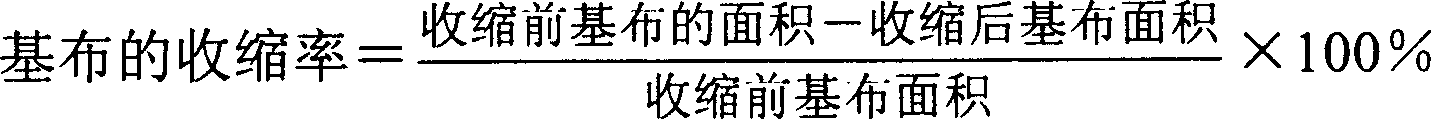

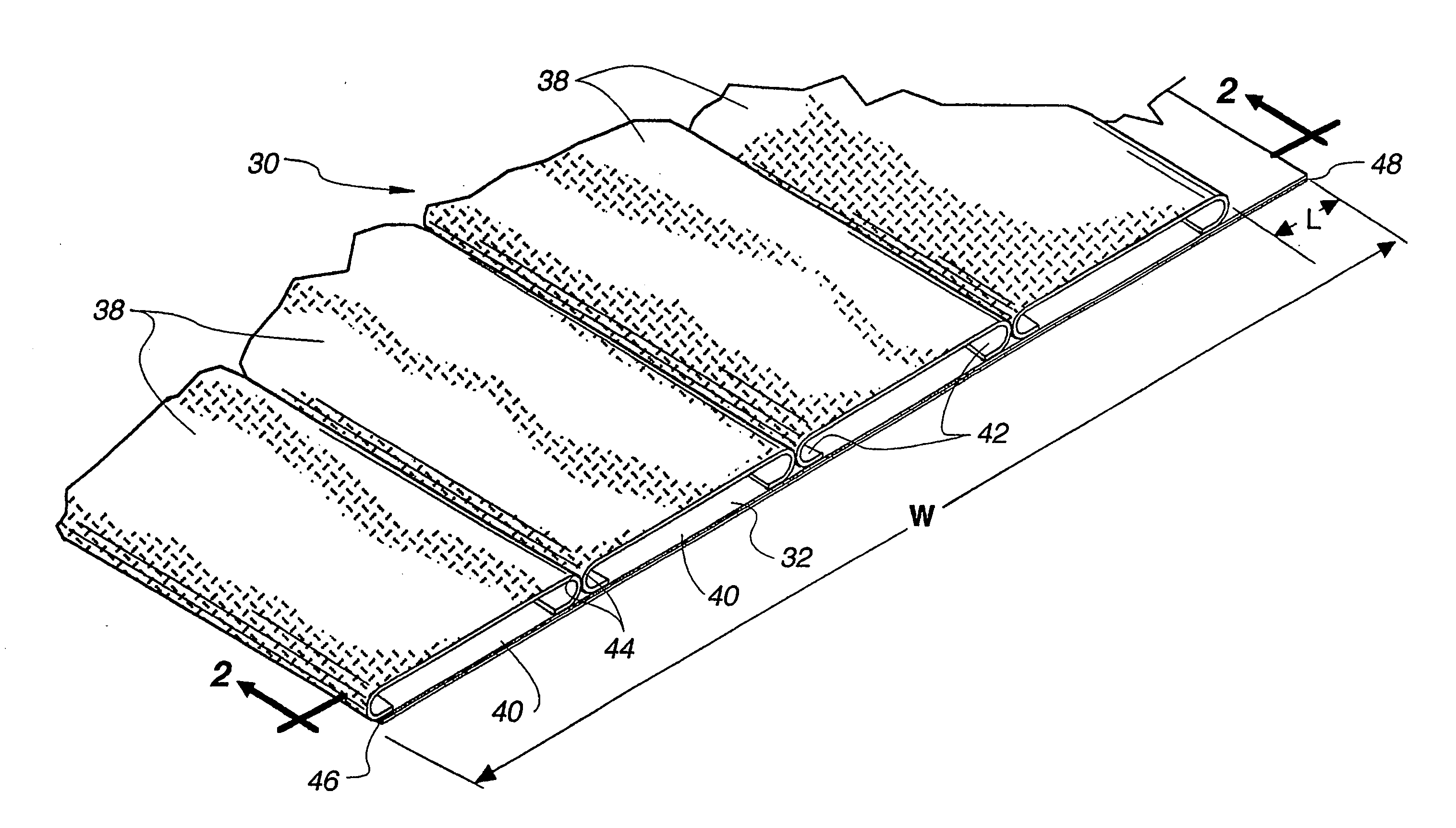

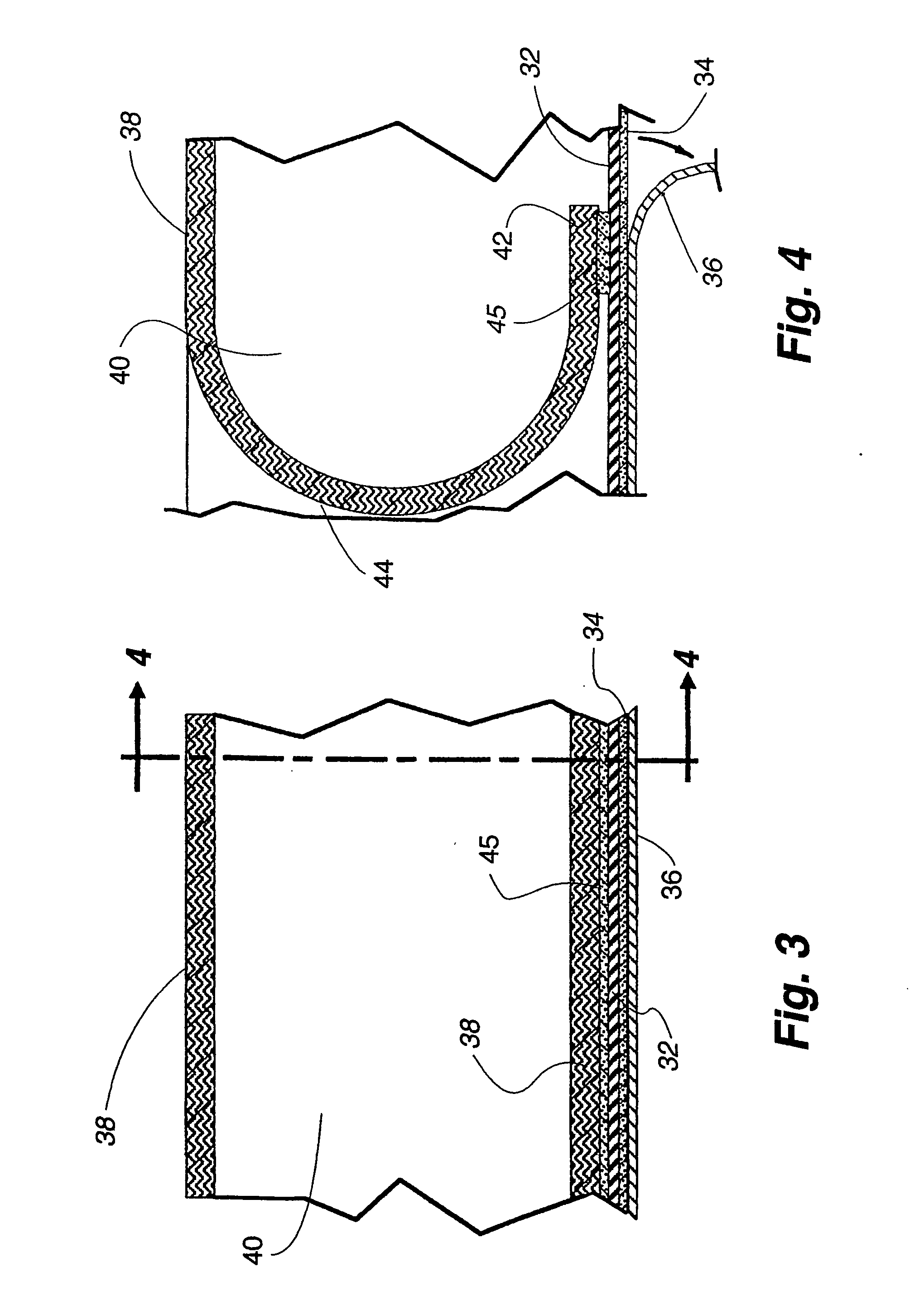

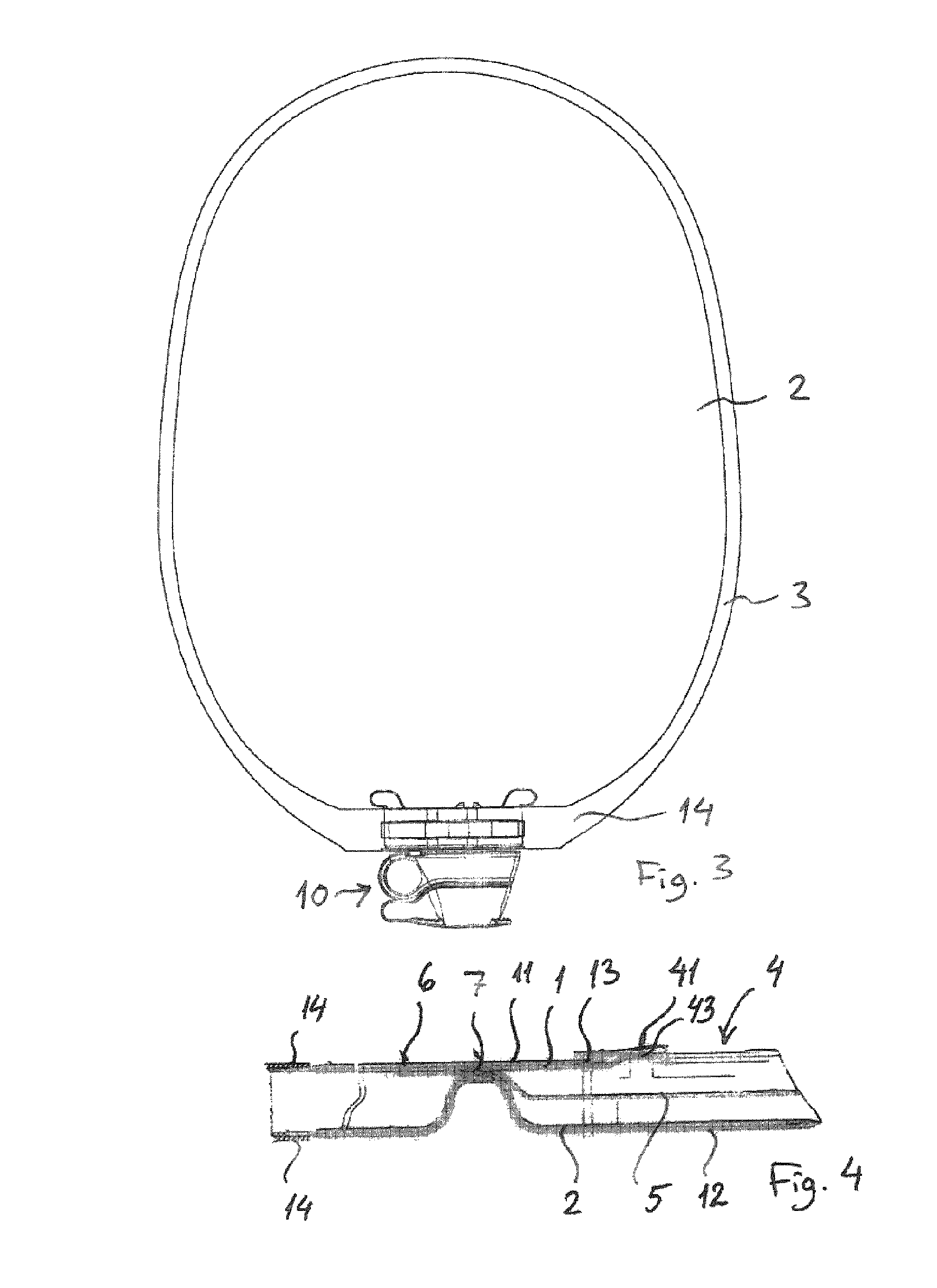

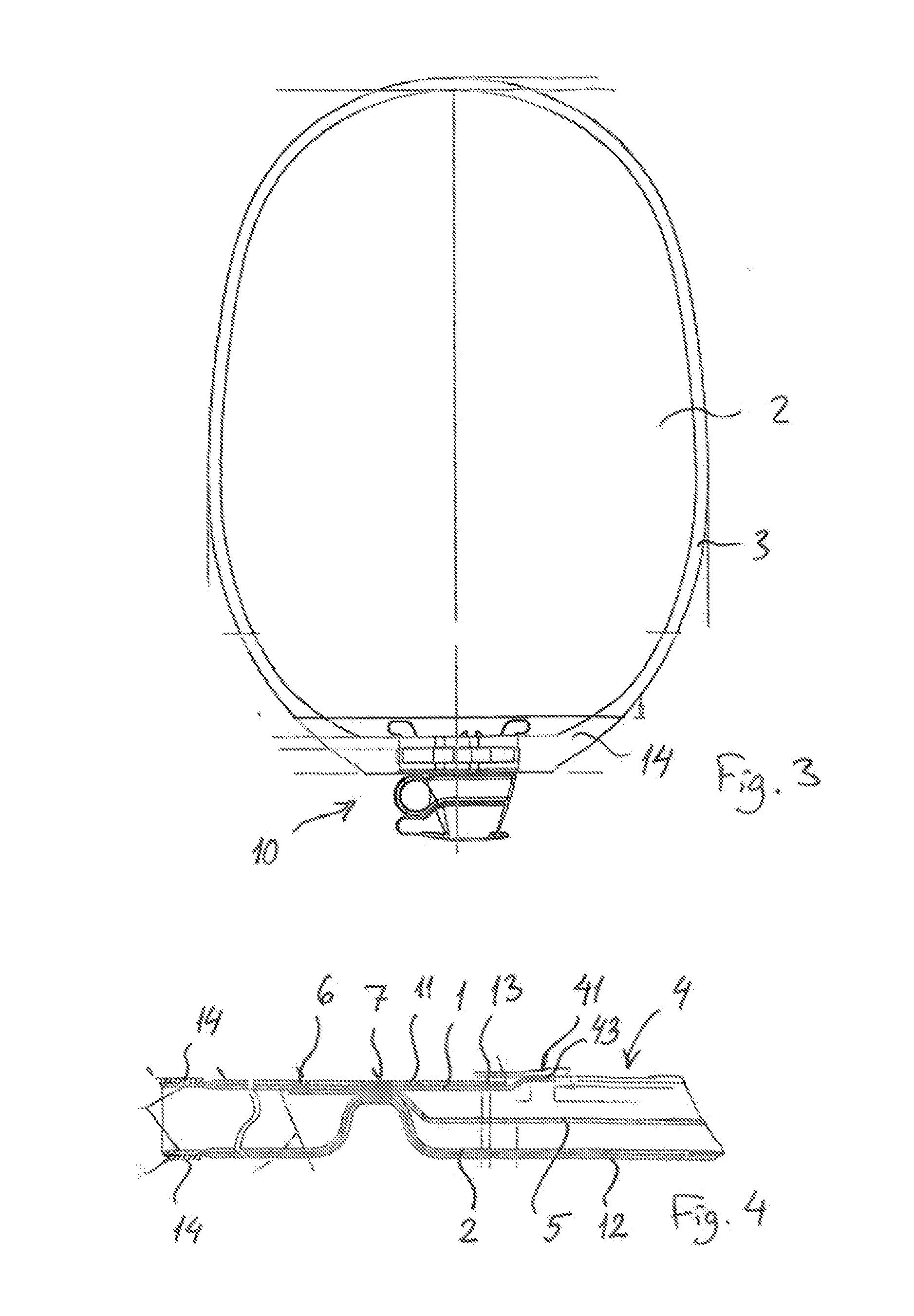

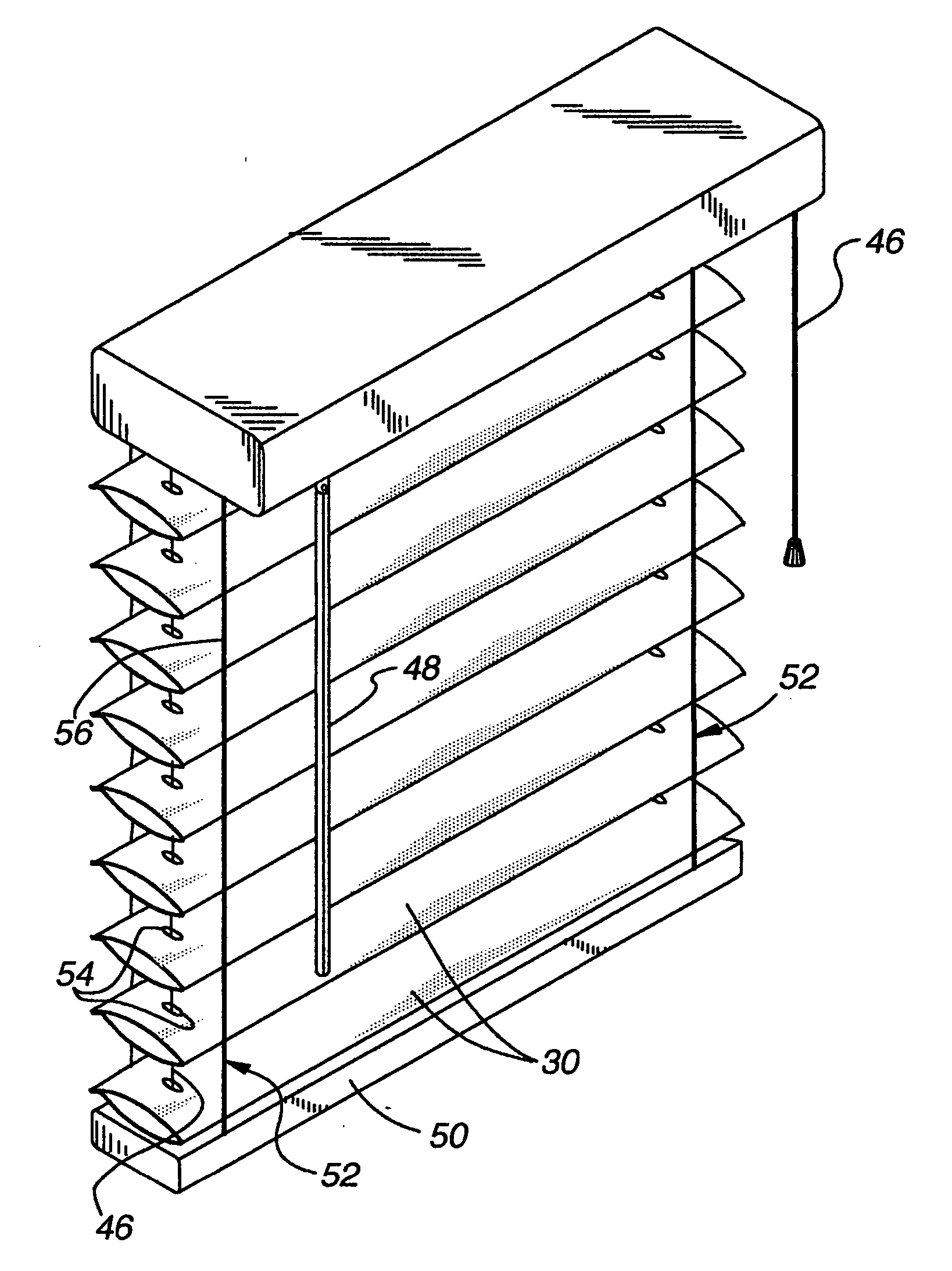

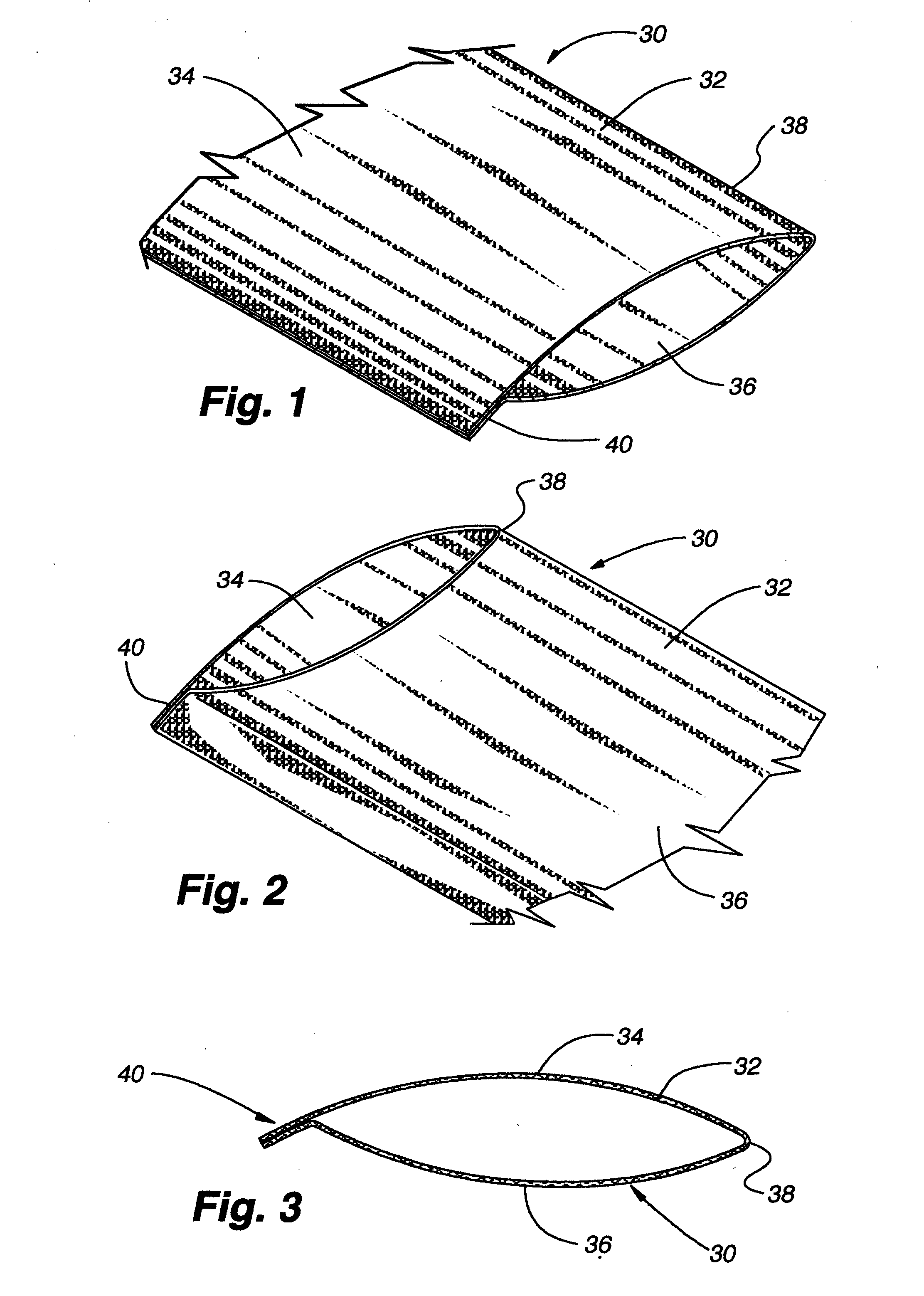

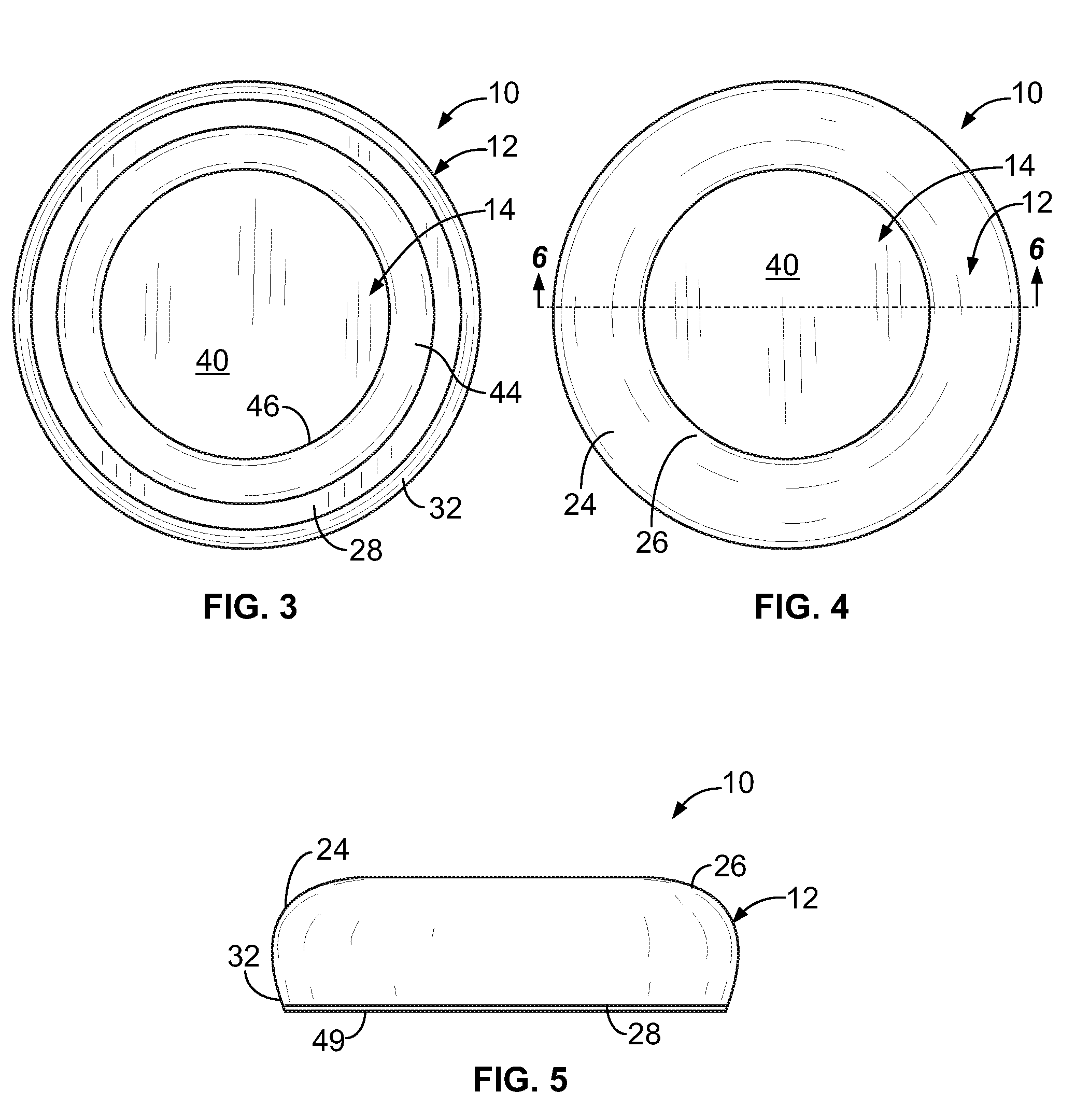

Tubular slat for covering for architectural openings

InactiveUS7100666B2Soft appearanceRetaining structural rigidityLamination ancillary operationsClosuresGlass fiberEngineering

A slat or vane (30) for use in a covering for an architectural opening is suitable for use in either a horizontal or vertical orientation and in a horizontal orientation will not sag or droop, and in a vertical orientation will rotate uniformly along its length when rotated from end thereof. The slat (30) is formed in a tubular configuration and has a base material of glass fibers bonded together in a thermoformable resin so as to maintain the arcuate curvature desired for the tubular slat or vane (30). The slat (30) can be repeatedly deformed and will always return to its original configuration.

Owner:HUNTER DOUGLAS INC

Environment-friendly collagen fiber leather substrate and production method thereof

ActiveCN102115955AIncrease profitNo pollution in the processFilament/thread formingNon-woven fabricsFiberPolymer science

At present, researchers do the research of reasonable utilization of chrome-containing leather shavings all the time; however, the leather shavings of leather making enterprises are difficult to treat in batch. The invention provides an environment-friendly collagen fiber leather substrate which is characterized by comprising an intermediate-layer fiber web, a surface-layer fiber web tightly connected on the upper surface of the intermediate-layer fiber web, and a bottom-layer fiber web tightly connected on the lower surface of the intermediate-layer fiber web, wherein the surface-layer fiber web and the bottom-layer fiber web respectively comprise the components by mass percentage of: 90 to 97 percent of collagen fibers, 3 to 10 percent of polylactic acid bi-component fibers; the intermediate-layer fiber web is made of polylactic acid bi-component fibers; the weight of the surface-layer fiber web and the weight of the bottom-layer fiber web are both 30 to 150 grams per square meter; and the weight of the intermediate-layer fiber web is 10 to 30 grams per square meter. The non-woven synthetic leather substrate prepared by using collagen fiber extracted from leather leftovers has good simulation performance, avoids secondary pollution to the environment, and is beneficial to the follow-up coating of PU (polyurethane).

Owner:GUANGZHOU CANUDILO FASHION & ACCESSORIES CO LTD

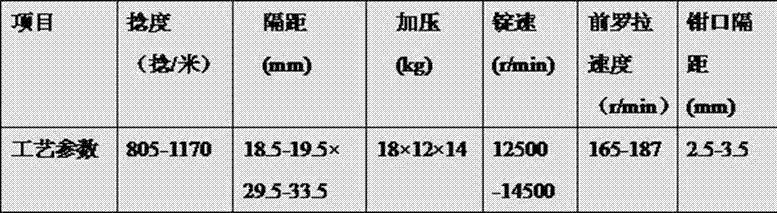

Fine cashmere single-yarn textile and its production process

The invention relates to a high counts pure cashmere single yarn fabric and the manufacture method. It is spinning from pure cashmere high counts single yarn fabric and aqueous fusion. The mightiness could reach 200CN, weaving density 160 / 10cm-200 / 10cm. Using dying machine taking the place of washing dolly while washing, the rolling speed is 30-35round / minutes, fabric softening agent 0.1-0.5G / L, washing for 20-30 minutes in 50-80 degree centigrade water to form high counts pure cashmere single yarn fabric. The invention exerts the advantages of the fiber to extreme.

Owner:INNER MONGOLIA KINGDEER CASHMERE

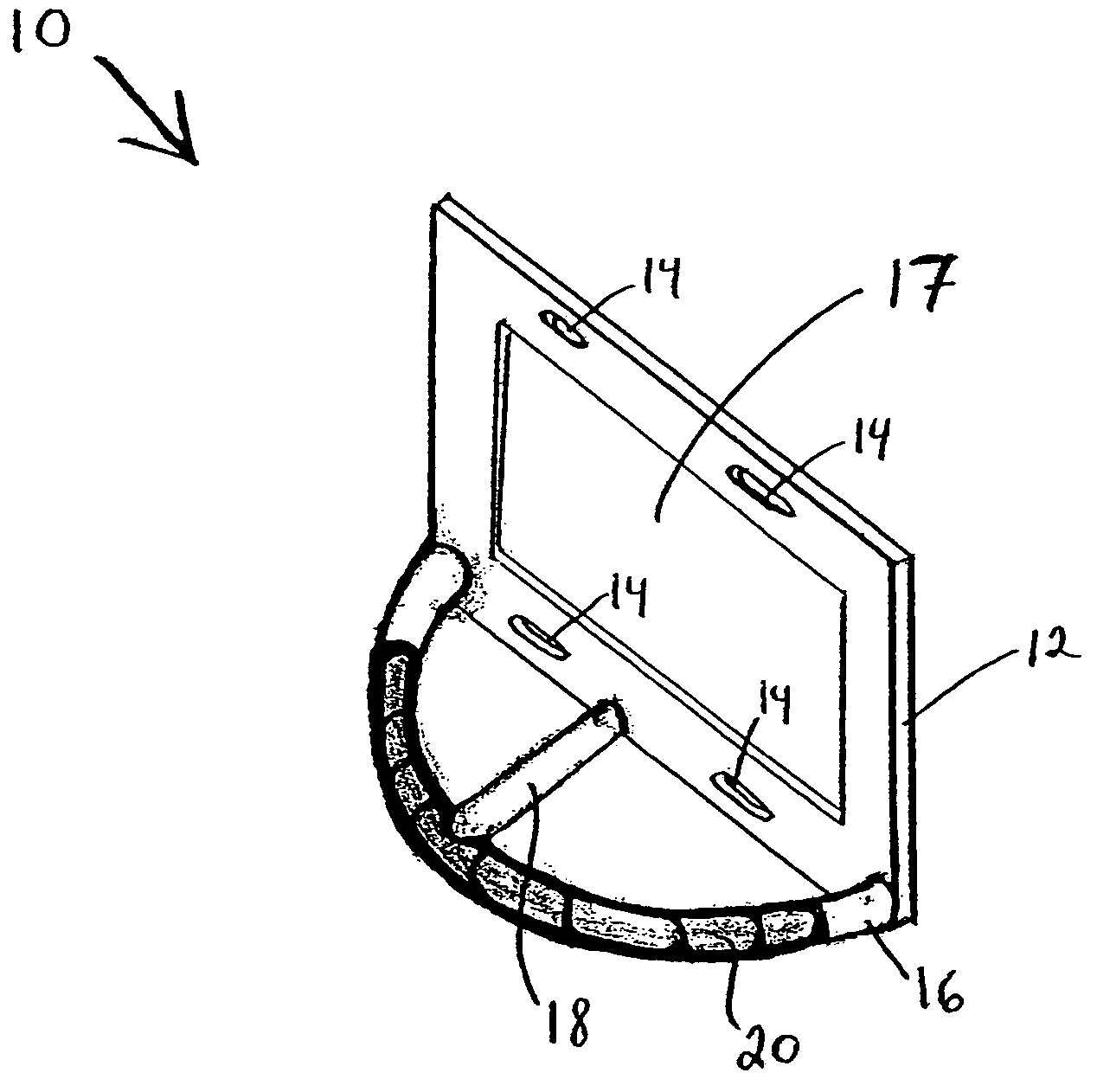

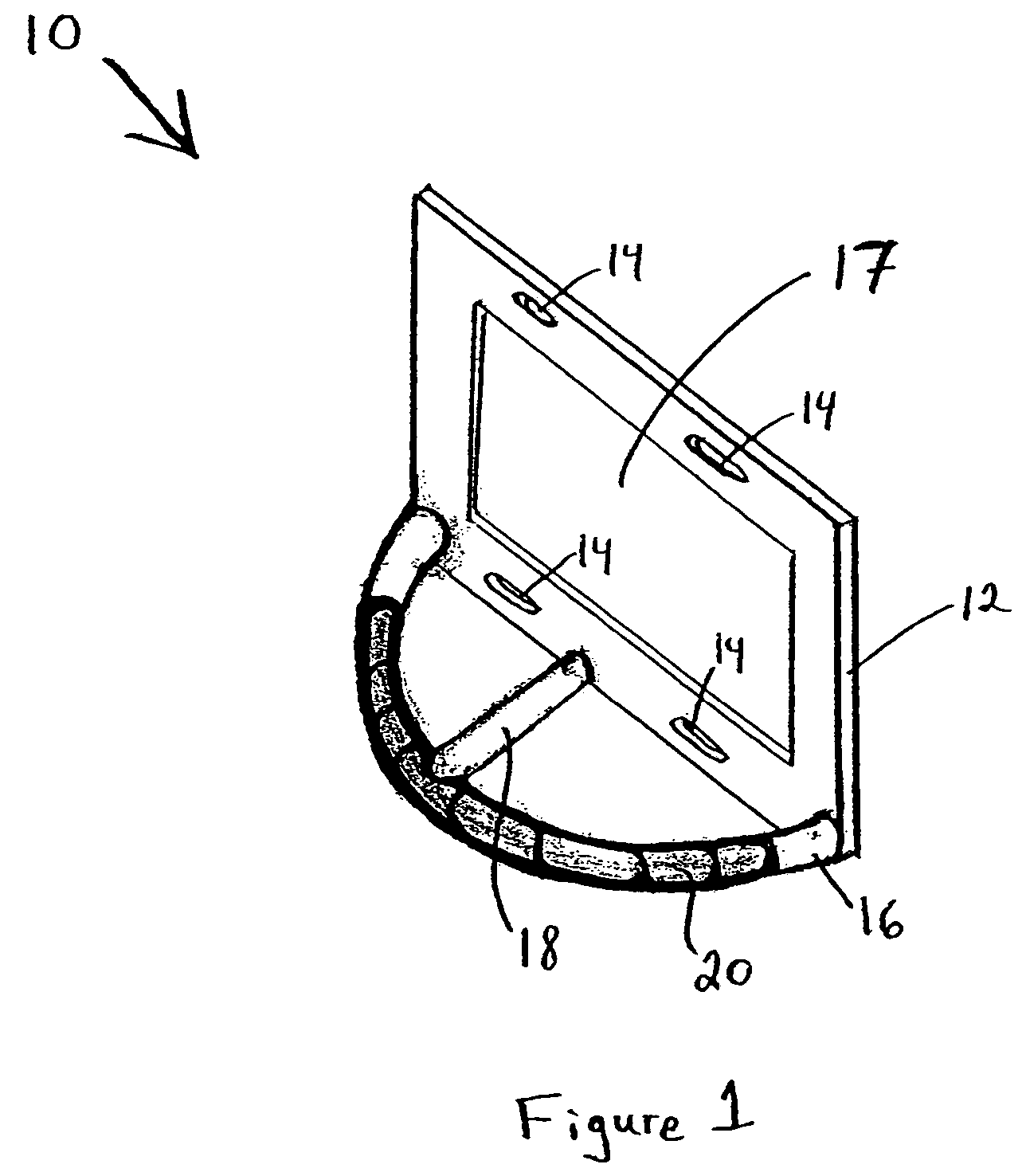

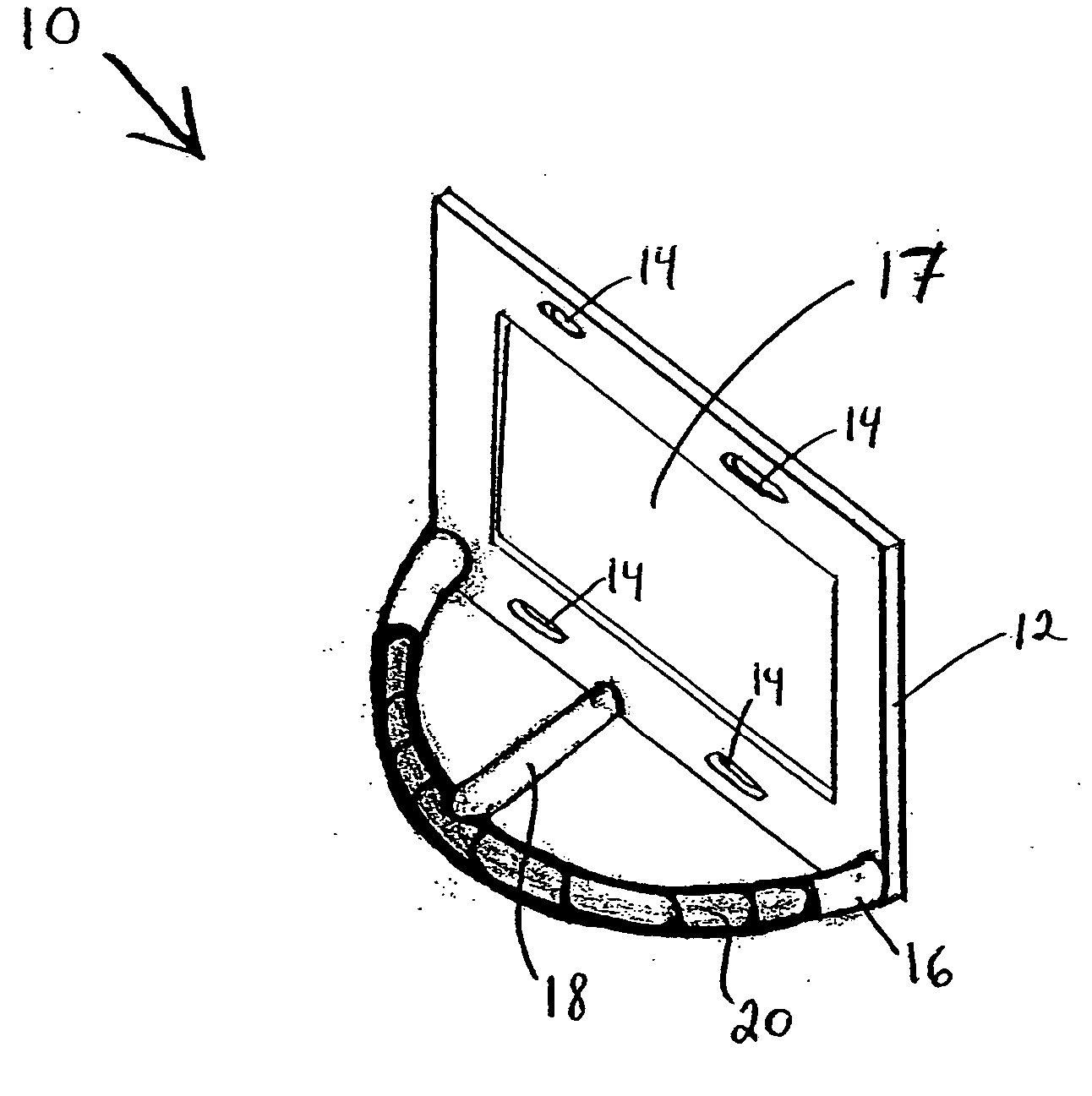

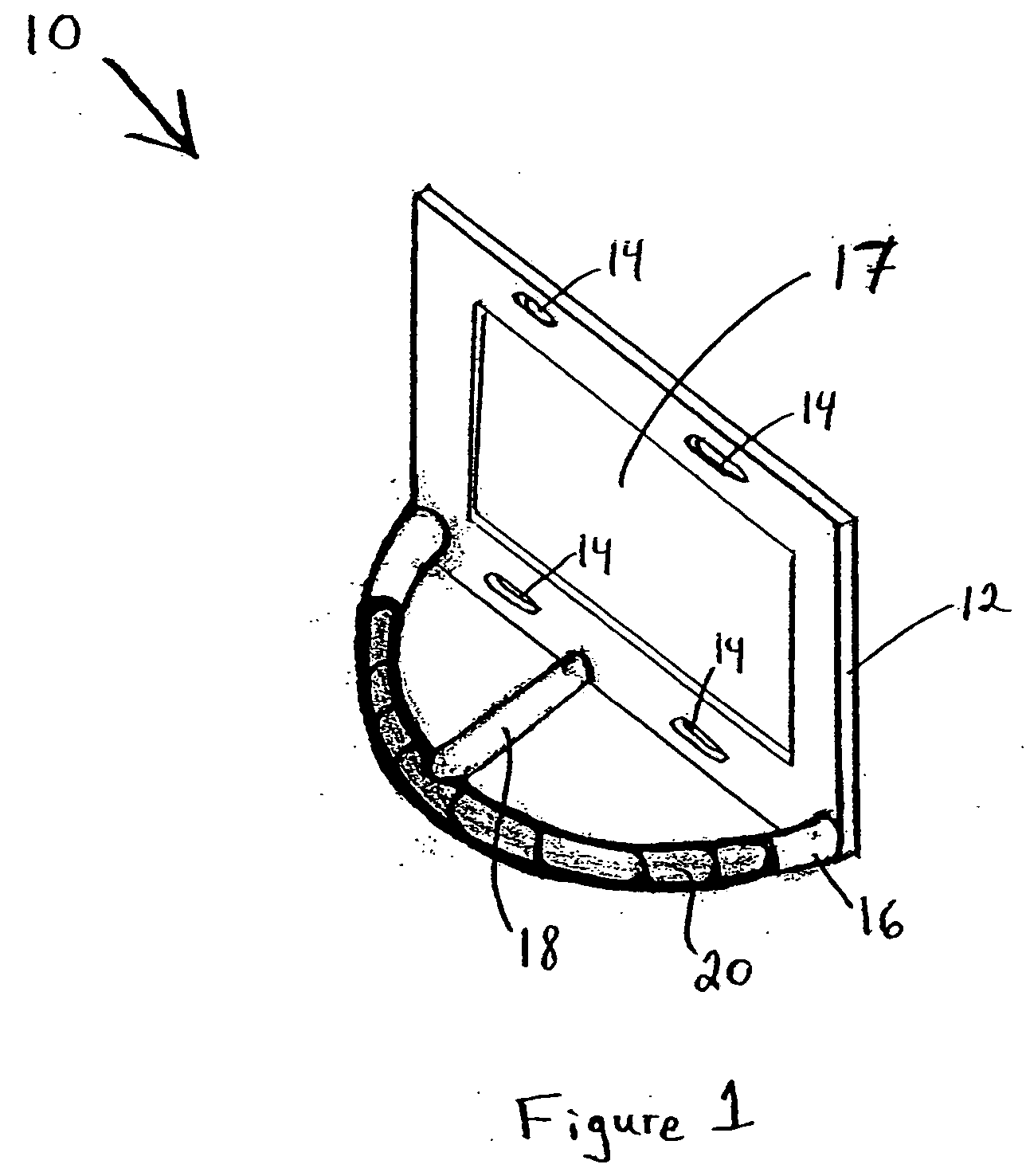

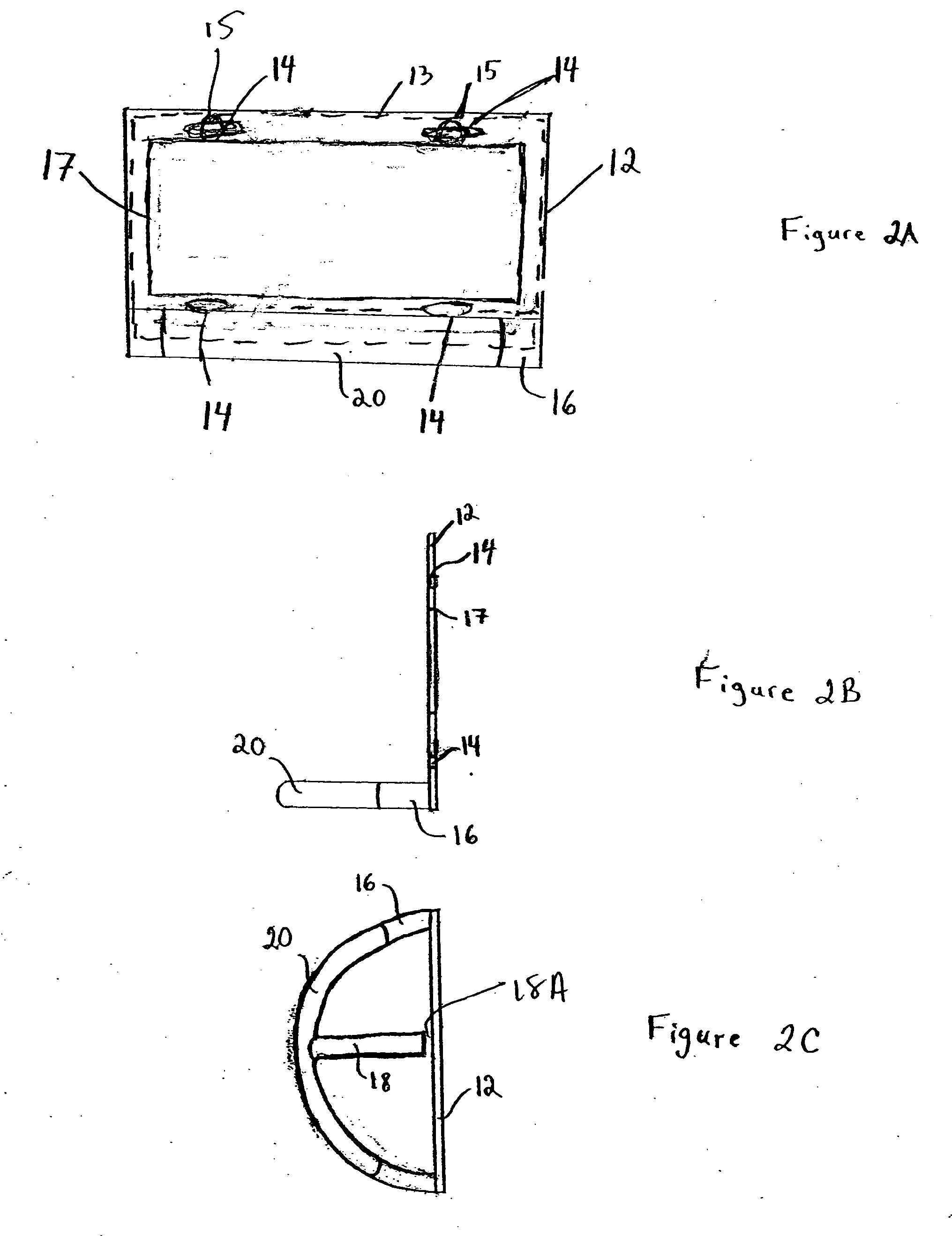

License-plate frame bumper guard

A bumper guard mountable to a vehicle license-plate mounting fixture, the mounting fixture being adapted to receive a license-plate having at least one mounting recess. The bumper guard comprises a first member having a front and rear surface. The rear surface is configured to be disposed adjacent to the mounting fixture. The license plate can be disposed on the front surface of the first member or on the rear surface between the rear surface of the first member and the mounting fixture. At least one recess in the first member is arranged to align with a fastening member of the vehicle license plate mounting fixture. At least one guard arm extends a predetermined distance from the front surface of the first member. The first member is mountable to the vehicle license plate fixture fastening member by at least one fastening device.

Owner:LEVINE JEFFREY K

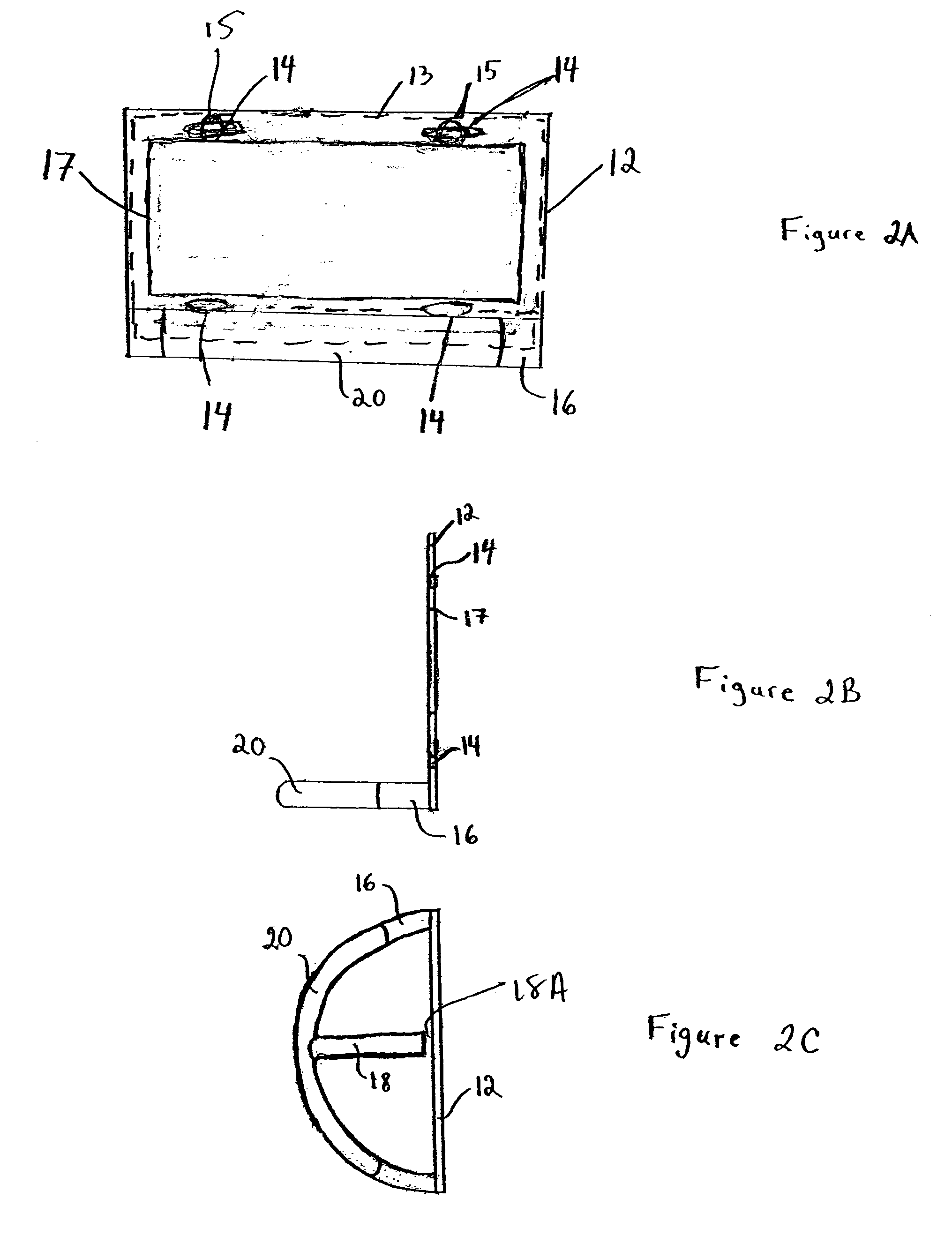

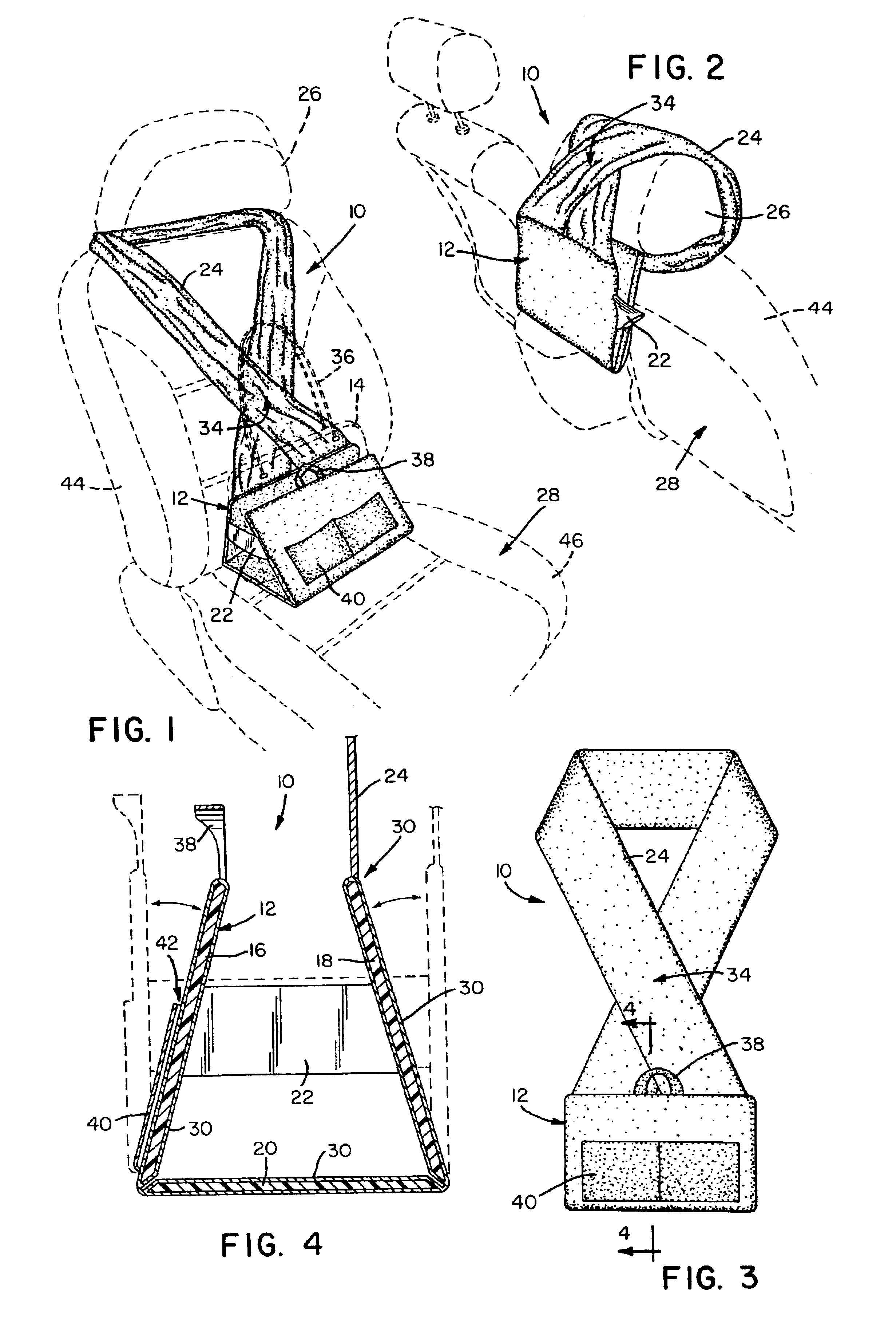

Purse caddy

InactiveUS6896164B2Not impair the ability of a driver to control her vehicleSoft appearanceTravelling sacksTravelling carriersFront panelEngineering

A purse caddy for supporting a purse in an upright condition upon a vehicle seat. The purse caddy includes an open-topped box dimensioned to receive a purse and a strap for supporting the open-topped box. The open-topped box has: a bottom panel, a front panel hingedly secured to the bottom panel and extending upwardly from the bottom panel, a back panel hingedly secured to the bottom panel at a location remote from the front panel and extending upwardly from the bottom panel, and at least one elastic strip connecting the front panel and the back panel together at a height above the bottom panel. The opposed ends of the strap are connected to the back panel so as to form a loop for encircling a support like the headrest of a vehicle seat.

Owner:FIALLA DORI EVA H

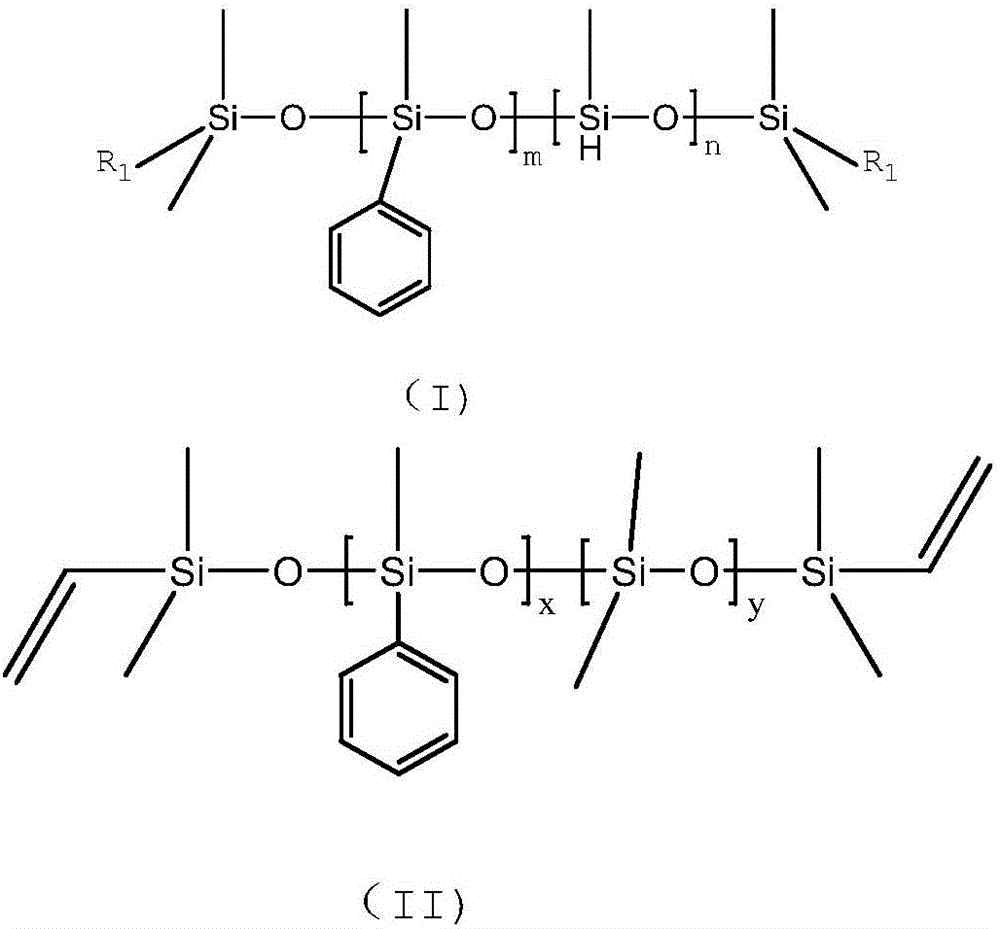

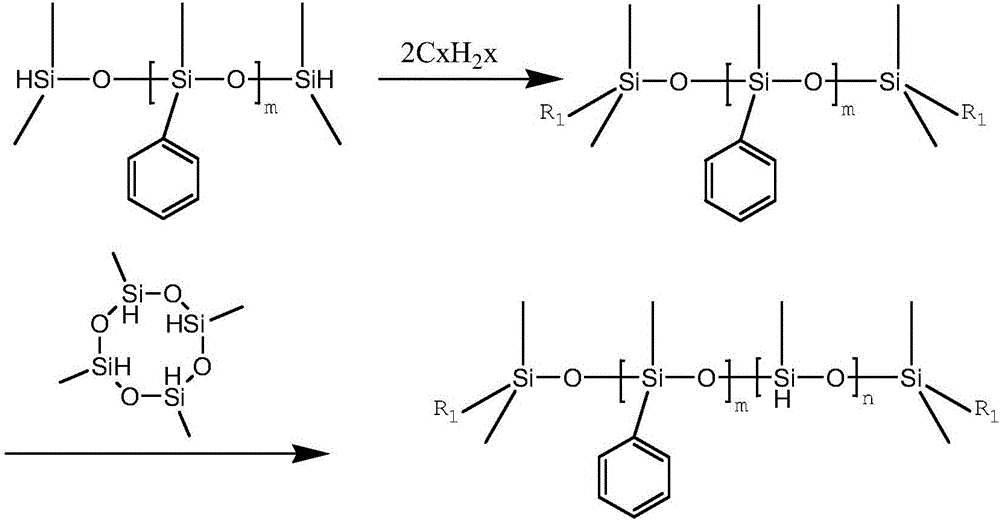

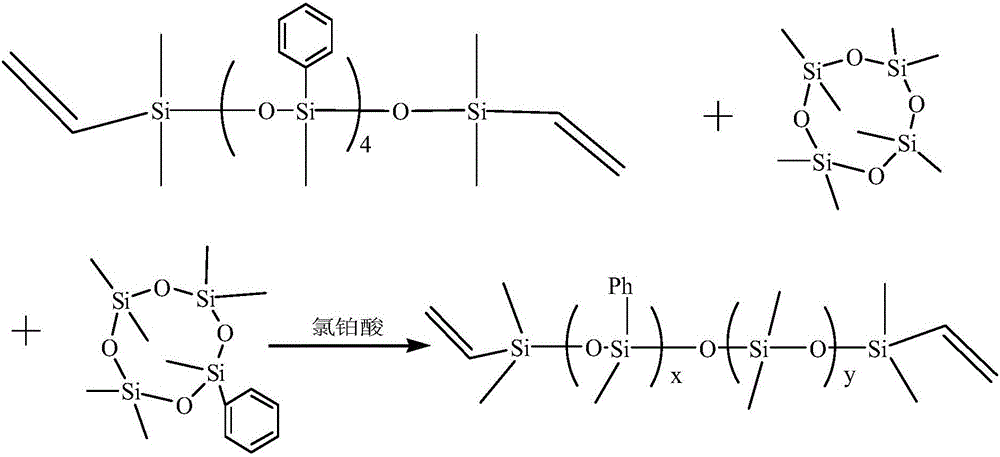

Organic silicone elastomer gel and preparation method thereof

ActiveCN106633076AImprove stabilityGood compatibilityCosmetic preparationsMake-upPolymer scienceWhitening Agents

The invention relates to the field of high polymer materials, in particular to organic silicone elastomer gel and a preparation method thereof. The organic silicone elastomer gel is prepared from a copolymer of a first polymer and a second polymer as well as a carrier fluid, wherein the structural formula of the first polymer is (I), the structural formula of the second polymer is (II), R1=CzH2z+1, z=8-18, m, n=8-15, x=10-20 and y=15-25. The organic silicone elastomer gel is well compatible with most oil and active ingredients (such as essence, sun-screening agents, skin whitening agents, vitamin and vitamin derivatives), is easy to add and is used as a thickener for water-in-oil and anhydrous formulas. The invention further provides the preparation method of the organic silicone elastomer gel to facilitate industrial production.

Owner:湖南斯洛柯有机硅有限公司

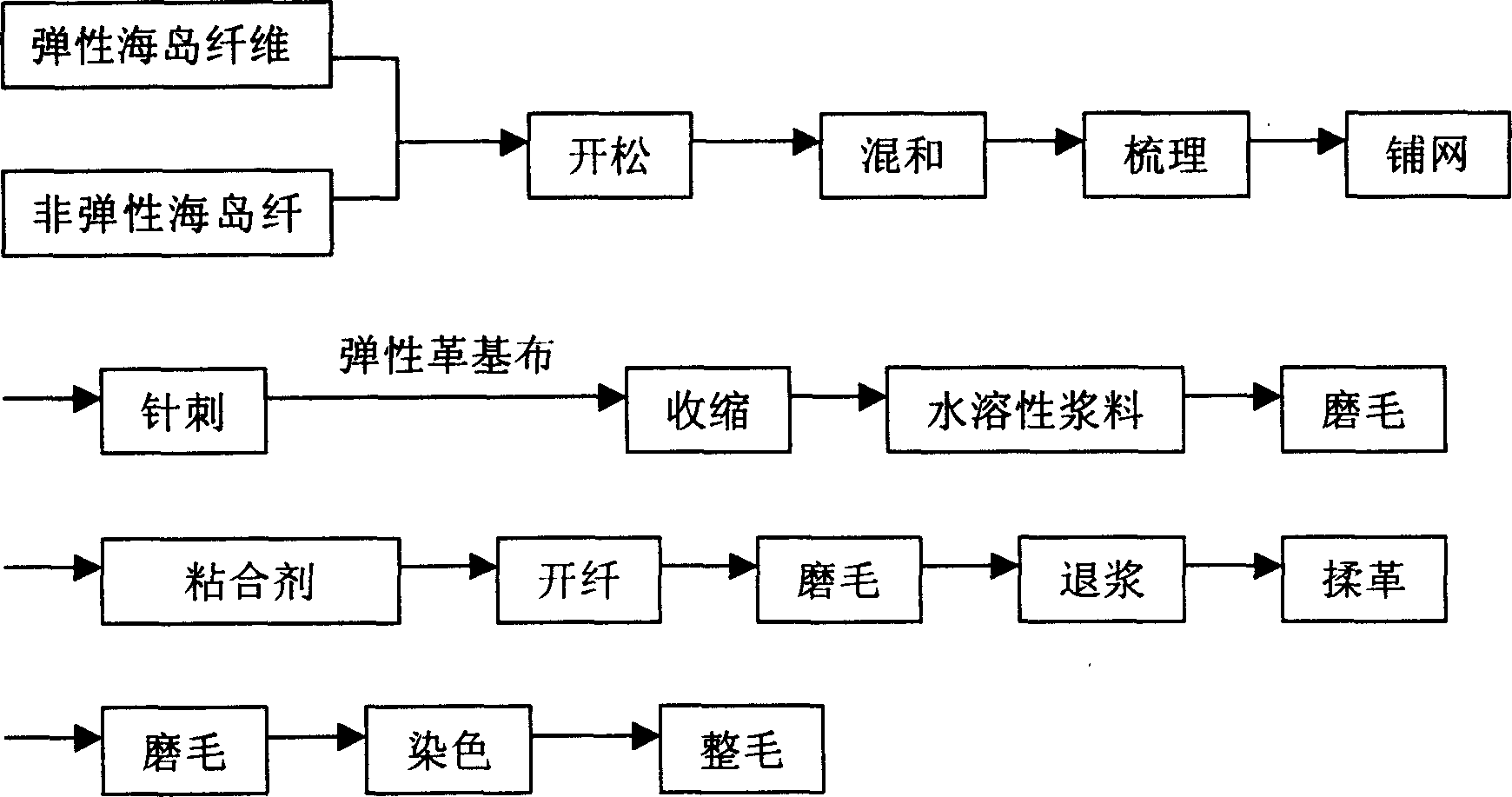

Raising method for elastic non-woven base fabric

The present invention adopts elastic sea-island fibre and inelastic sea-island fibre according to weight ratio of (20:80)-(80:20), and adopts the following steps: mixing, opening, carding, web-laying and needling to obtain elastic leather base fabric, then making shrinkage, applying water soluble slurry, sanding, applying adhesive, opening fibre, sanding, desizing, mellowing leather, sanding, dyeing and finishing so as to obtain the invented elastic non-woven base fabric.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL +1

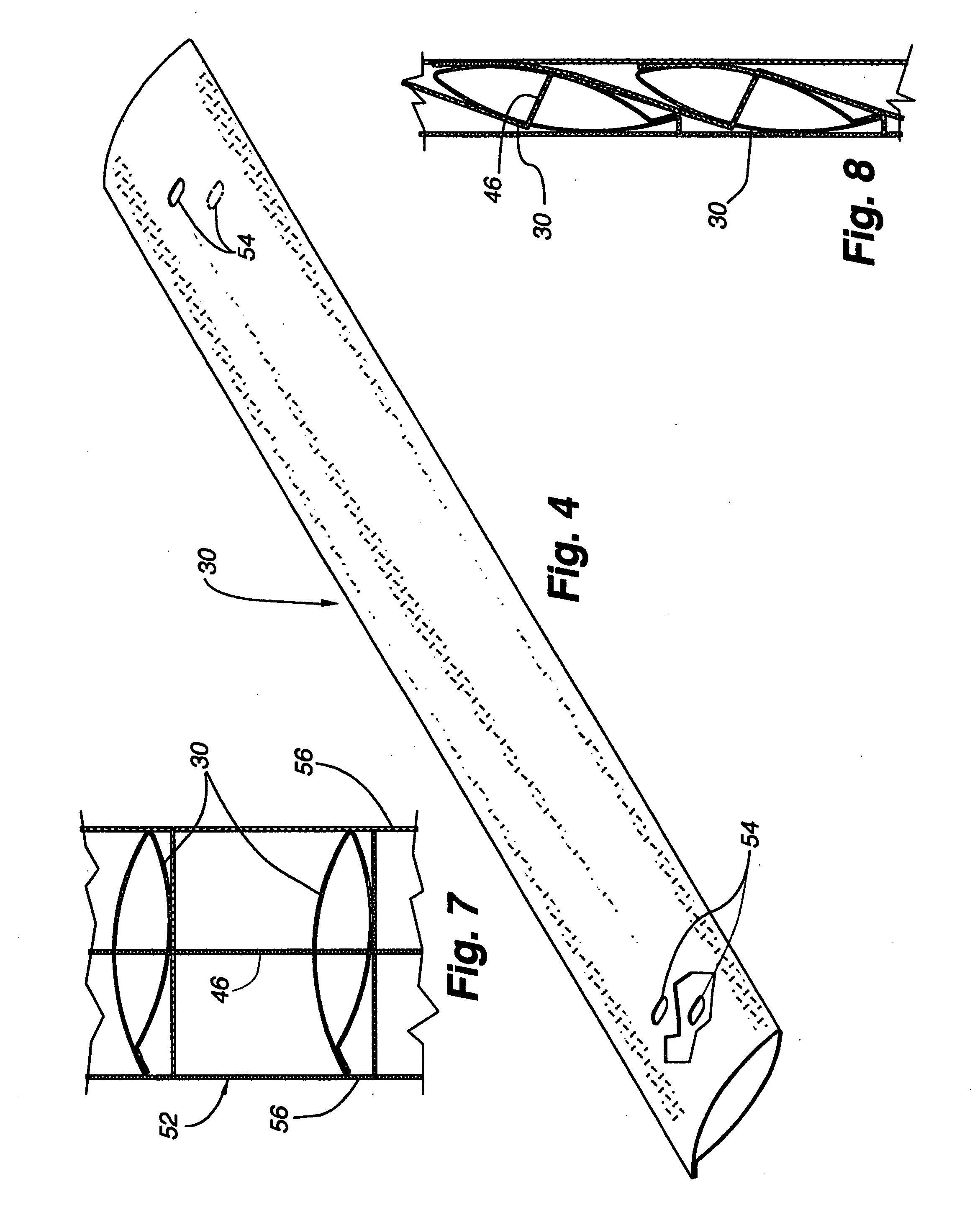

Covering for architectural surfaces and method of forming and applying same

InactiveUS20060048659A1Dampening acousticSoft and warm appearanceCylinder pressesCovering/liningsDividing attentionBiomedical engineering

Owner:HUNTER DOUGLAS INC

Environment-friendly collagen fiber leather substrate and production method thereof

ActiveCN102115955BIncrease profitNo pollution in the processDryer sectionFilament/thread formingFiberSurface layer

At present, researchers do the research of reasonable utilization of chrome-containing leather shavings all the time; however, the leather shavings of leather making enterprises are difficult to treat in batch. The invention provides an environment-friendly collagen fiber leather substrate which is characterized by comprising an intermediate-layer fiber web, a surface-layer fiber web tightly connected on the upper surface of the intermediate-layer fiber web, and a bottom-layer fiber web tightly connected on the lower surface of the intermediate-layer fiber web, wherein the surface-layer fiberweb and the bottom-layer fiber web respectively comprise the components by mass percentage of: 90 to 97 percent of collagen fibers, 3 to 10 percent of polylactic acid bi-component fibers; the intermediate-layer fiber web is made of polylactic acid bi-component fibers; the weight of the surface-layer fiber web and the weight of the bottom-layer fiber web are both 30 to 150 grams per square meter; and the weight of the intermediate-layer fiber web is 10 to 30 grams per square meter. The non-woven synthetic leather substrate prepared by using collagen fiber extracted from leather leftovers has good simulation performance, avoids secondary pollution to the environment, and is beneficial to the follow-up coating of PU (polyurethane).

Owner:GUANGZHOU CANUDILO FASHION & ACCESSORIES CO LTD

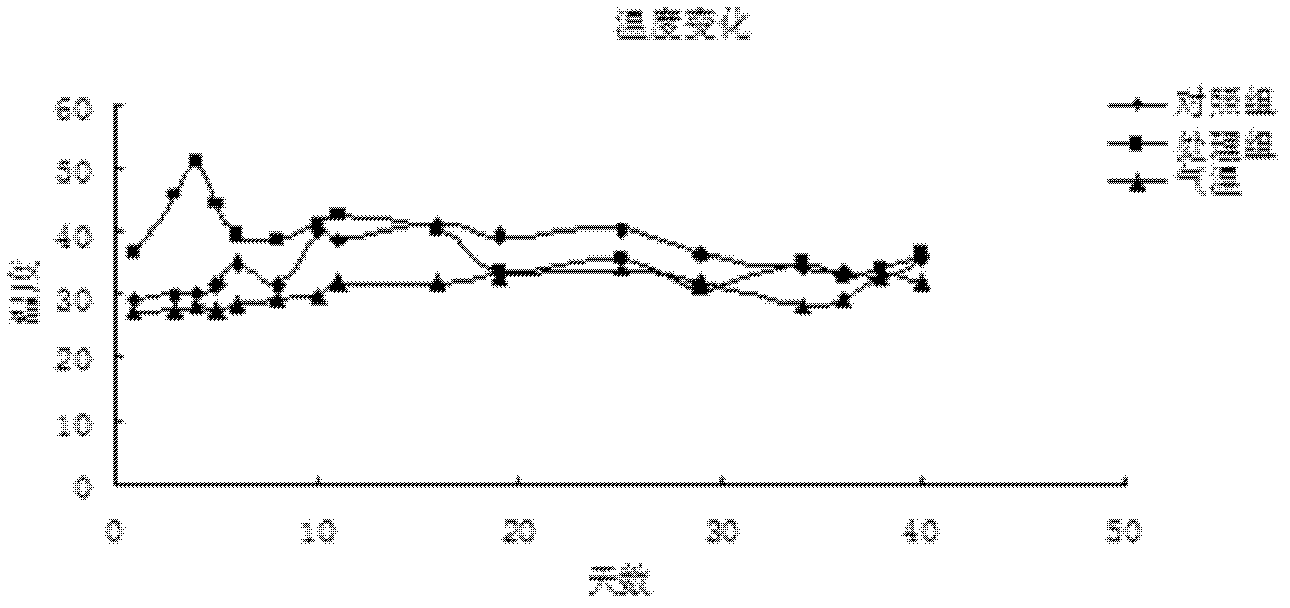

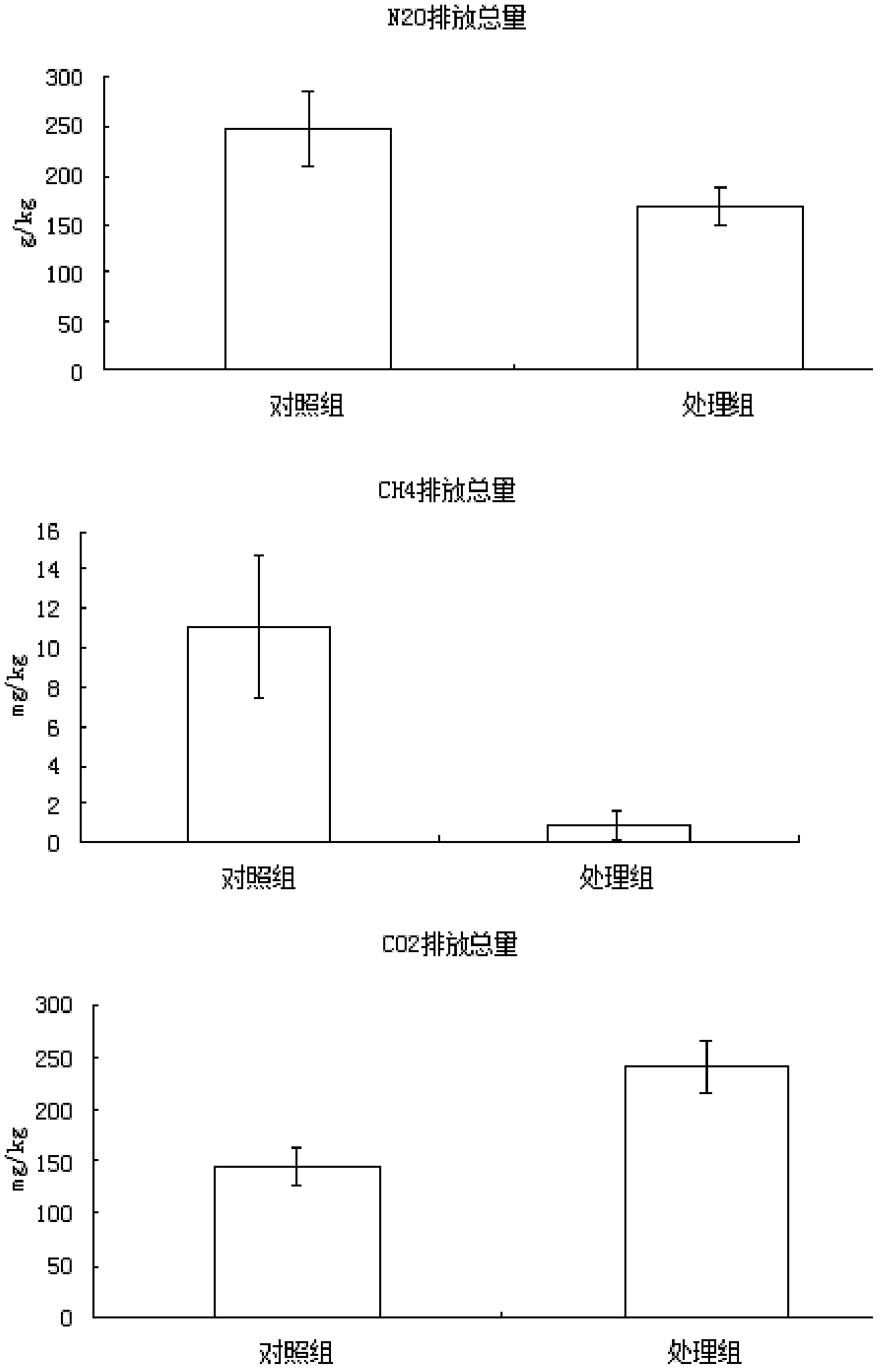

Multifunctional soil maturing agent and preparation method thereof

InactiveCN102674917AAppearance darkSoft appearanceBio-organic fraction processingOrganic fertiliser preparationEvery Three DaysSoil conditioner

Disclosed are multifunctional soil maturing agent and a preparation method thereof. The soil maturing agent comprises biochar and poultry excrement in a weight ratio of 10:3-10:5. The preparation method includes: mixing the biochar and the poultry excrement proportionally, well mixing, and adjusting water content to about 60%; and covering the mixture with a thin layer of biochar, turning compost each day 20 days before composting, keeping the water content of 60% unchanged, turning the compost once every three days from the twentieth day to the thirtieth day, turning the compost once a week, and avoiding sunlight and rain. The compost is made of mixture of biochar and farm poultry excrements such as pig excrement. The problems of odor, long formation time and low fertilizer efficiency of traditional compost are solved. The poultry excrements can be also be used fully, and waste is turned into wealth. Composted products can be used as oil conditioner / maturing agent and gardening medium. The multifunctional soil maturing agent has promising market prospect.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

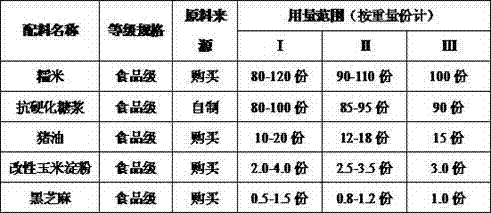

Anti-hardening white square rice cake and production method thereof

InactiveCN102771714AExtended soft periodSolve short-term hardening quality problemsFood preparationBiotechnologyMaize starch

The invention relates to the technical field of food processing methods, in particular to an anti-hardening white square rice cake and a production method for the anti-hardening white square rice cake. The anti-hardening white square rice cake is produced by taking glutinous rice flour, anti-hardening syrup, lard oil, modified maize starch and black sesame and the like as raw materials, and according to a certain formula, performing the following steps of: (1) checking materials; (2) making the glutinous rice flour; (3) frying the black sesame; (4) mixing; (5) beating; (6) stewing; (7) re-steaming; (8) cooling, re-moisturizing and slicing; and (9) packaging and the like. The anti-hardening white square rice cake not only keeps the characteristics that the conventional white square rice cake is moist, soft, frozen grease-like, sweet and delicious and the like; and compared with the conventional white square rice cake, the a quality problem of short-term hardening is avoided and a softness guarantee period is prolonged by 40-45 days.

Owner:东莞市圣心食品有限公司

License-plate frame bumper guard

ActiveUS20060191173A1Easy to installEasy to disassembleBumpersSignsEngineeringMechanical engineering

A bumper guard mountable to a vehicle license-plate mounting fixture, the mounting fixture being adapted to receive a license-plate having at least one mounting recess. The bumper guard comprises a first member having a front and rear surface. The rear surface is configured to be disposed adjacent to the mounting fixture. The license plate can be disposed on the front surface of the first member or on the rear surface between the rear surface of the first member and the mounting fixture. At least one recess in the first member is arranged to align with a fastening member of the vehicle license plate mounting fixture. At least one guard arm extends a predetermined distance from the front surface of the first member. The first member is mountable to the vehicle license plate fixture fastening member by at least one fastening device.

Owner:LEVINE JEFFREY K

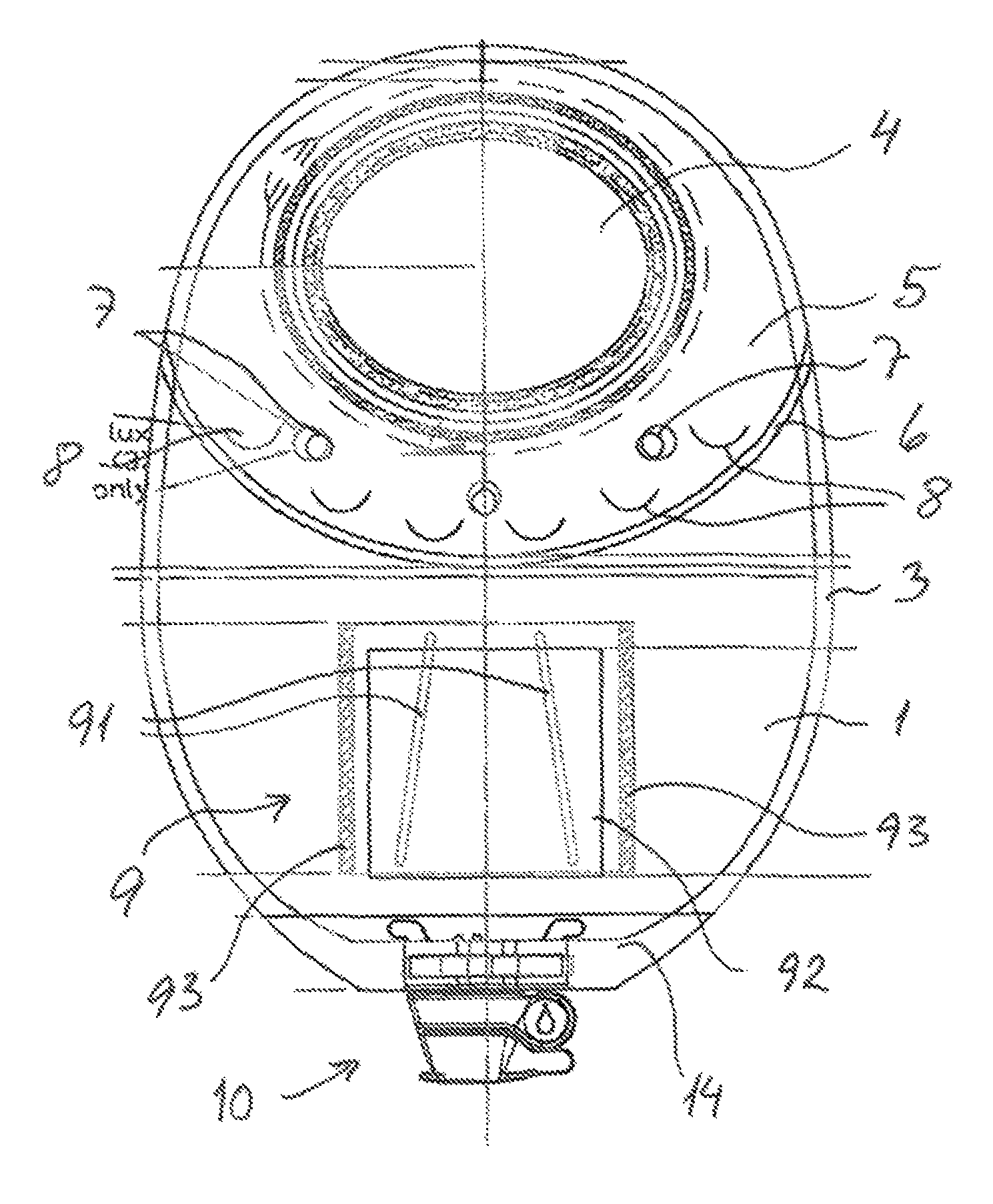

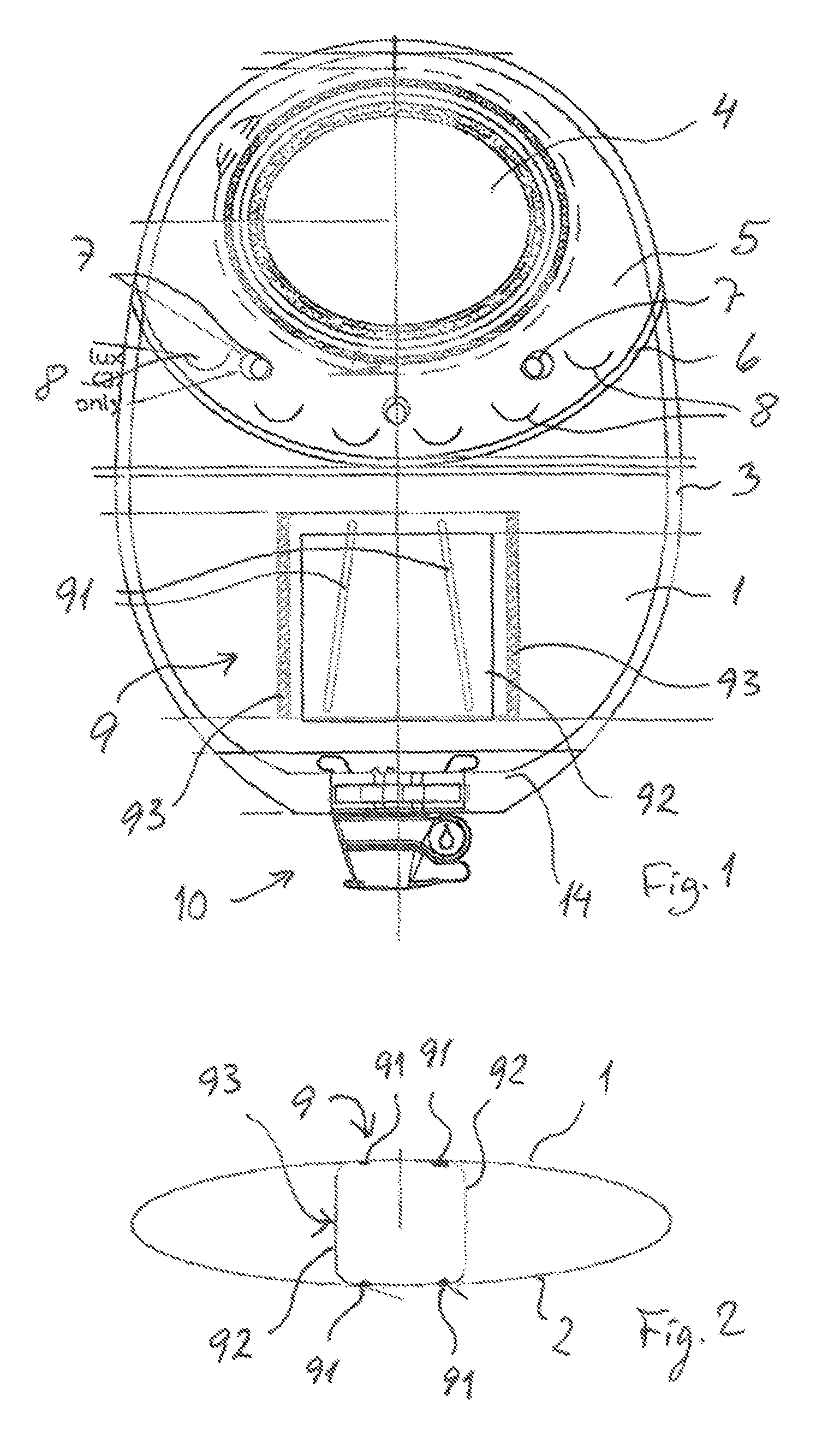

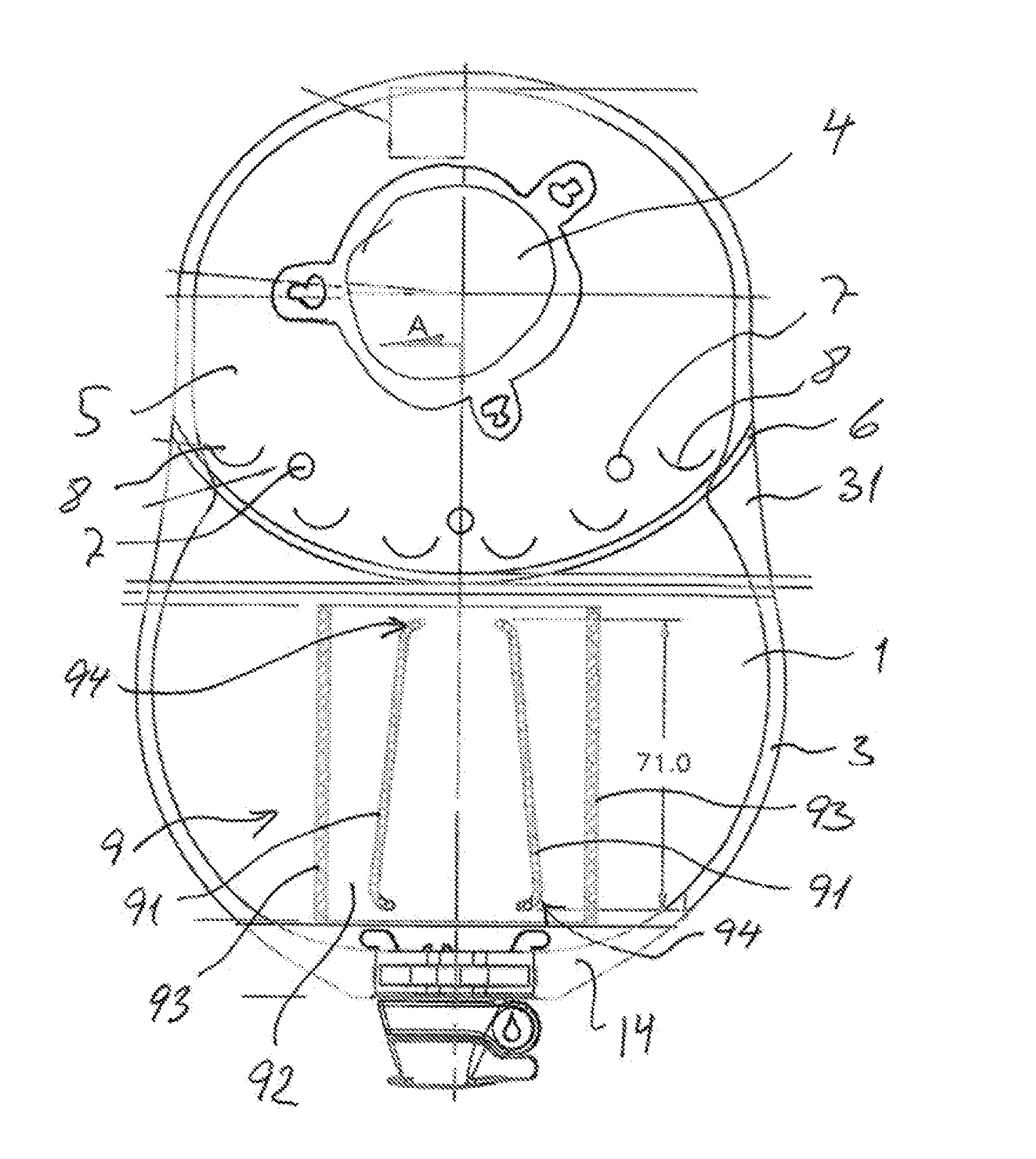

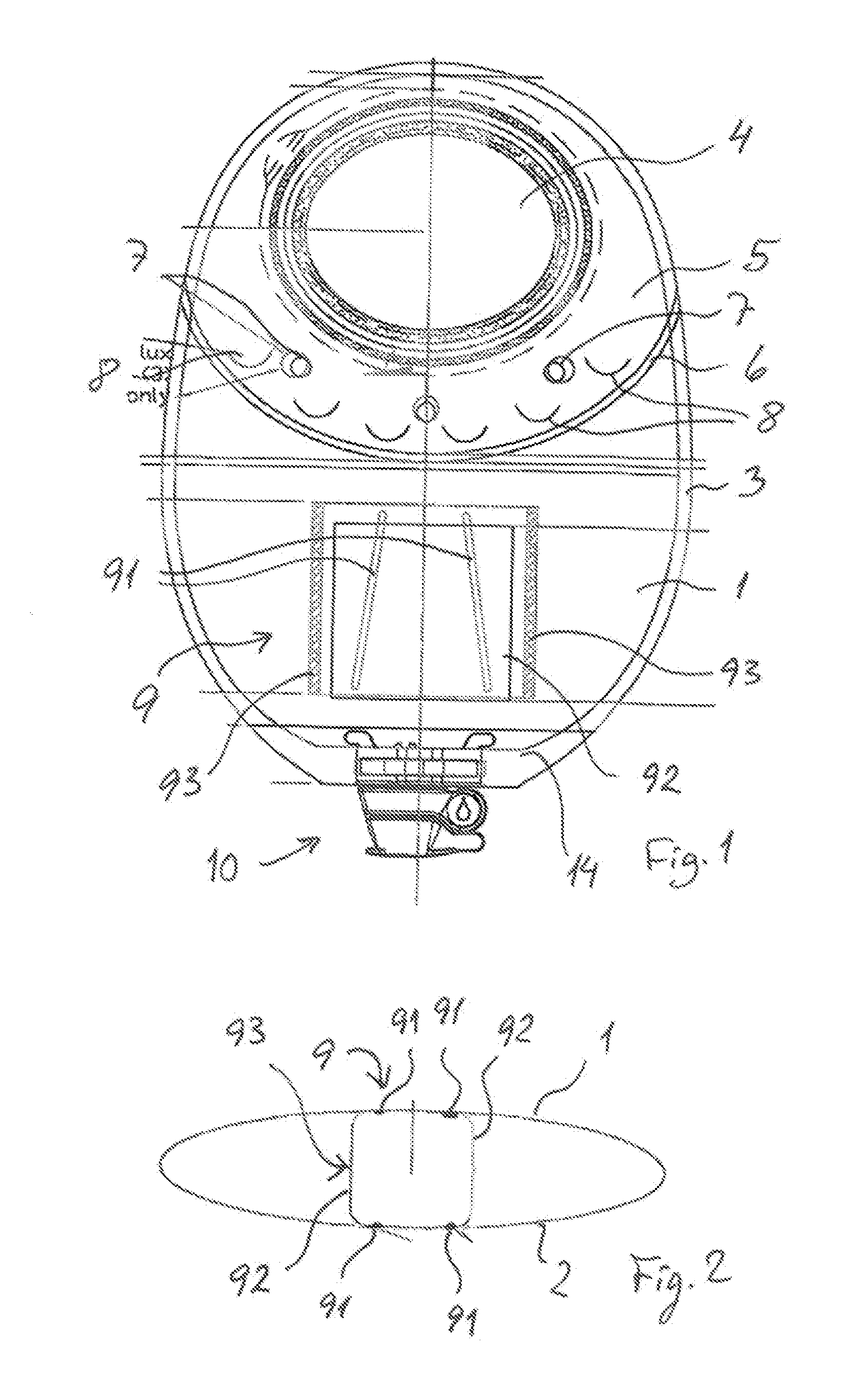

Pouch for collecting liquid excretions

The present invention concerns a pouch for collecting liquid excretions for collecting liquid human waste, said pouch comprising a first and second wall sealed together along their periphery defining an inlet top portion and a bottom portion defining a collection chamber, an inlet opening provided in the top portion of the first wall, and an anti-reflux film provided in the top portion between said first and second walls, wherein the anti-reflux film is sealed along its lower periphery to the first wall by an anti-reflux seal across the first wall, and wherein a plurality of spot welds are provided above the anti-reflux seal and wherein a plurality of slits are provided in the anti-reflux film between the anti-reflux seal and the spot welds.

Owner:HOLLISTER INCORPORAED

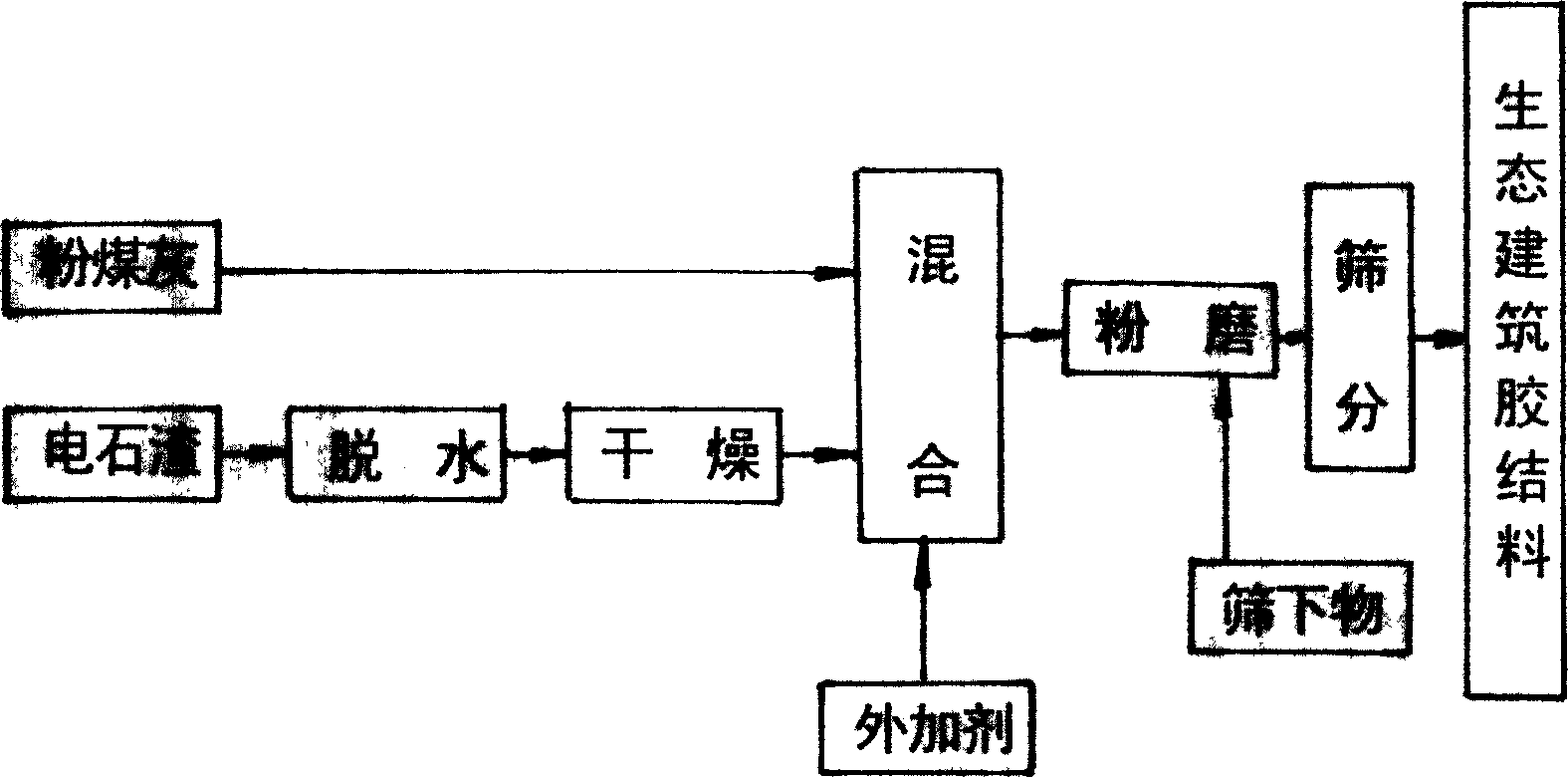

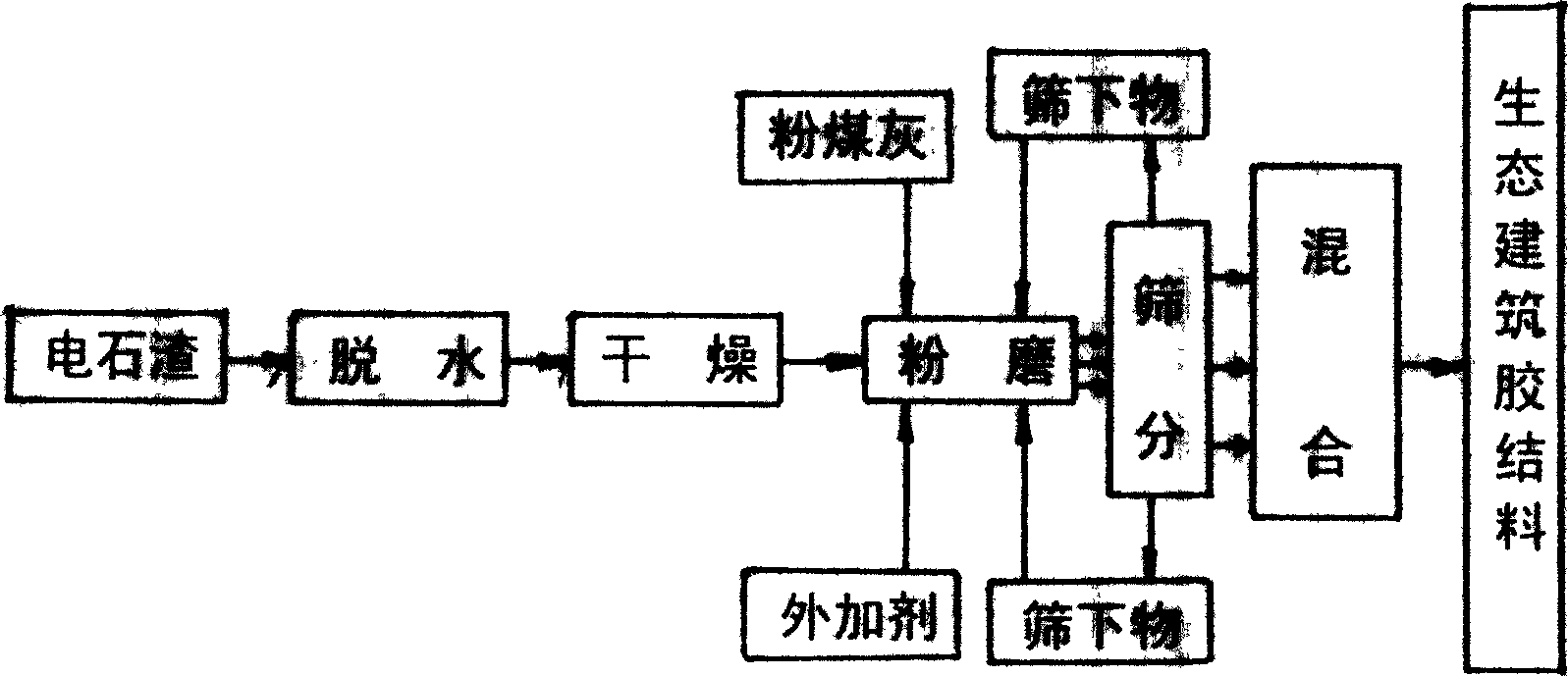

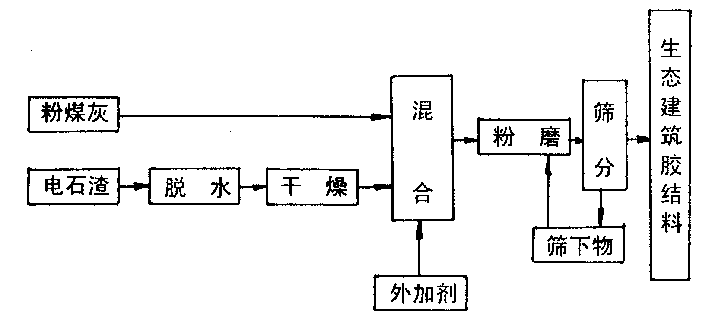

Mfg. of ecological building agglutinating material by using carbide slag

The present invention relates to a cement, in the concrete it is an environment-protecting cement which utilizes the carbide slag to make ecological building cementing material. Its production process includes the following steps: using carbide slag slurry whose water content is 90%, sedimentation to make dehydration, mechanical dehydration, drying, mixing with flyash and additive, grinding, sieving, grinding material under the sieve and sieving so as to obtain the invented ecological building cementing material. Its formula includes (by wt%) CaO 40-72, SiO2 20-51, additive 1-8 and other component 1-37.

Owner:章亮庄

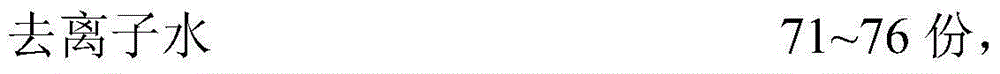

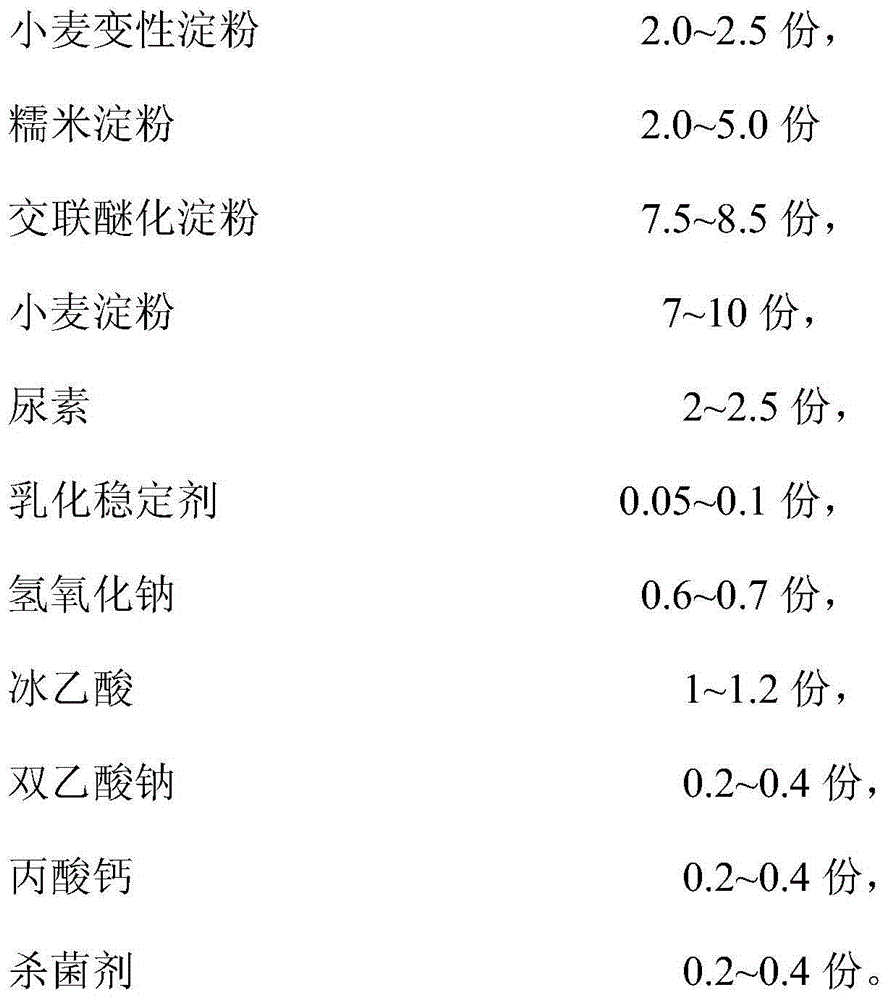

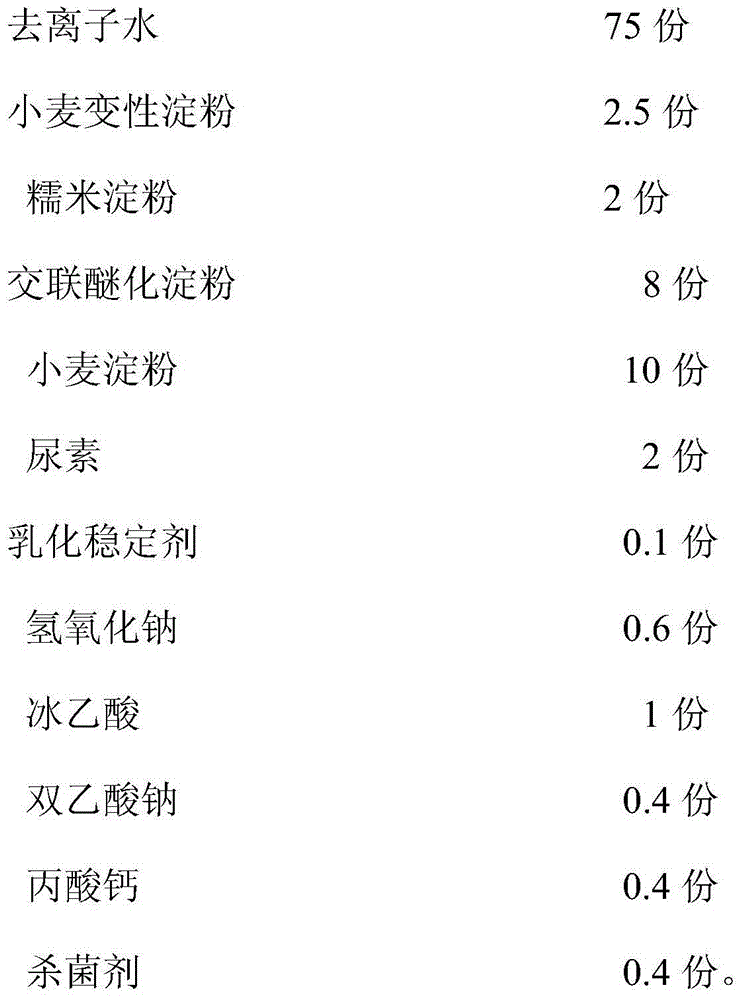

Sticky rice wet glue added with emulsion stabilizer and preparation method thereof

InactiveCN104559829ACompatibility is reasonableHigh viscosityNon-macromolecular adhesive additivesStarch adhesivesEmulsionAdhesive

The invention relates to an adhesive for wallpaper industry and particularly relates to sticky rice wet glue added with an emulsion stabilizer and a preparation method thereof. According to the invention, the emulsion stabilizer is added in a production process of the sticky rice glue to produce a sticky rice wet glue product. The sticky rice wet glue product has strong binding power and can be mixed with water 100%, the wallpaper adhesion area is increased, the decoration cost of users is reduced, the preparation process is simple, the production cost is low, and the product is stable to store and is convenient to use.

Owner:GAREFU TECH CO LTD

Pouch for collecting liquid excretions

ActiveUS20140163497A1Easy to manufactureHigh activityLaminationLamination apparatusRefluxHuman waste

The present invention concerns a pouch for collecting liquid excretions for collecting human waste, said pouch comprising a first and second wall sealed together along their periphery defining an inlet top portion and a bottom portion defining a collection chamber, an inlet opening provided in the top portion of the first wall, and an anti-reflux film provided in the top portion between said first and second walls, wherein the anti-reflux film is sealed along its lower periphery to the first wall by an anti-reflux seal across the first wall, and wherein a plurality of spot welds are provided above the anti-reflux seal and wherein a plurality of slits are provided in the anti-reflux film between the anti-reflux seal and the spot welds.

Owner:HOLLISTER INCORPORAED

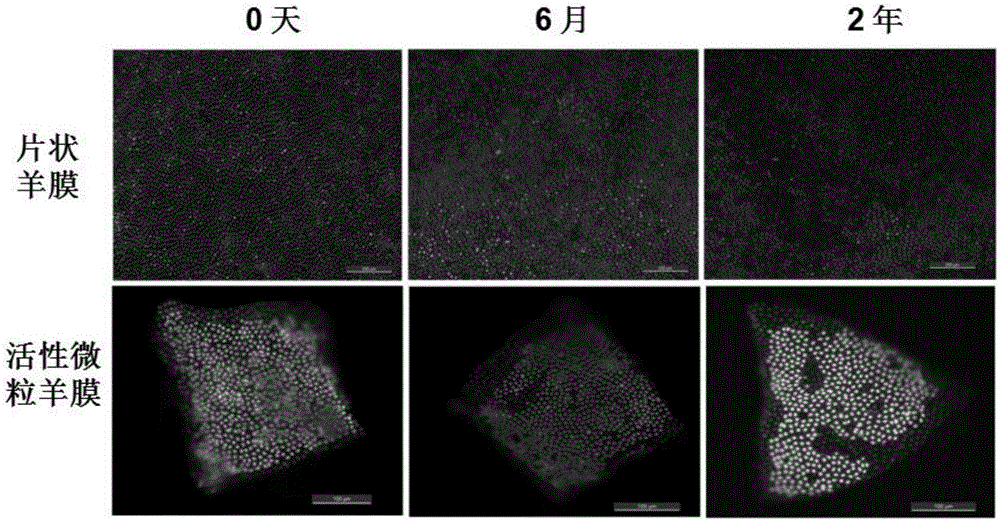

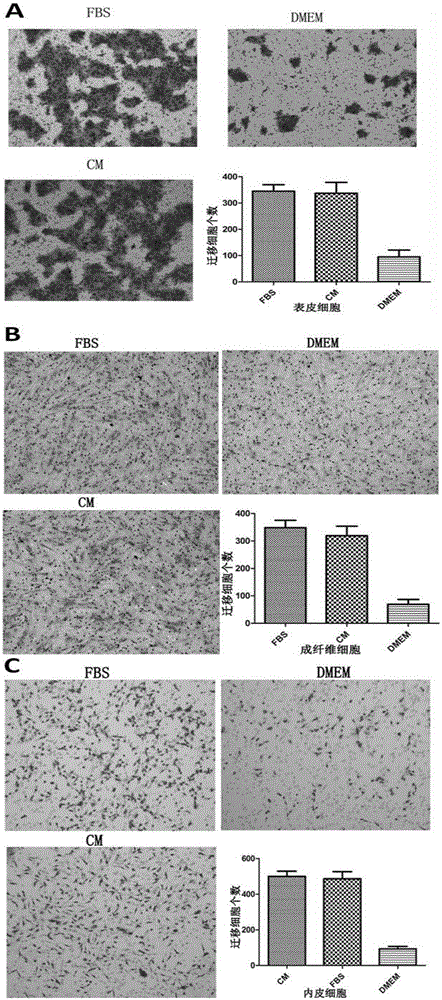

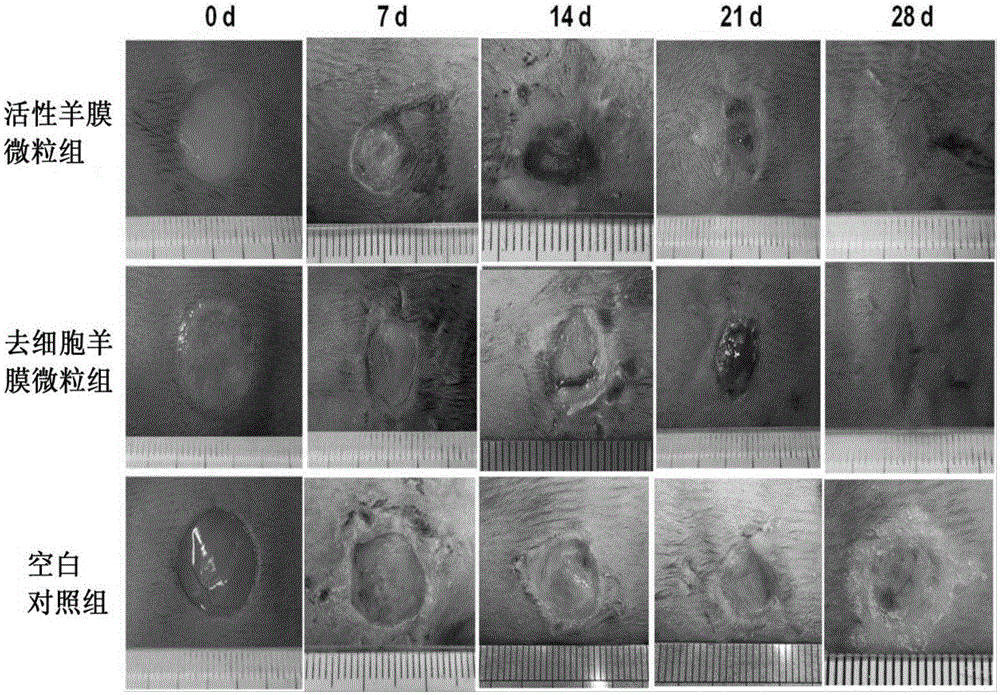

Amnion innate stem cell carried frozen active amnion particle and conditioned medium and application thereof

ActiveCN105018417AAvoid spreadingRetain activityDead animal preservationEmbryonic cellsDiseaseCuticle

The invention relates to the technical field of tissue engineering and medical wound repairing, in particular to an amnion innate stem cell carried frozen active amnion particle and a conditioned medium and application thereof. Discarded fresh amnions are prepared into particles and then frozen into liquid nitrogen by means of serum-free stem cell freezing liquid; thus, complete matrix components of amnion are maintained while amnion epithelial cell activity is maintained for a long time, and further, disease transmission is avoided effectively. The conditioned medium which is prepared and collected by means of the frozen active amnion particles can promote chemotaxis and migration of human epidermal cells, fibroblast and endothelial cells effectively. In terms of zoografting, wound healing can be improved by multiple ways of regulating inflammatory reaction, promoting vascularization, quickening epithelization and the like through the active amnion particles; further, the amnion matrix can be directly used as a dermis equivalent to induce dermal regeneration so as to improve wound healing quality remarkably. The amnion innate stem cell carried frozen active amnion particle and the conditioned medium thereof can provide simple but effective ways for wound repairing.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

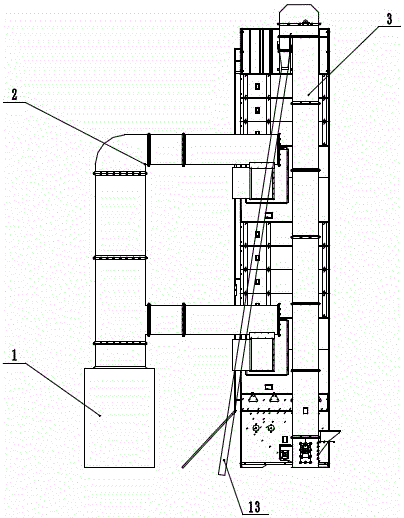

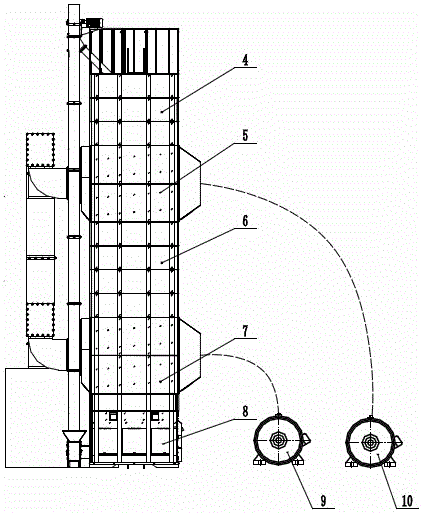

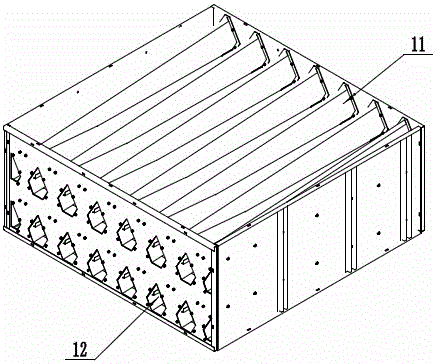

Batched circulating dryer used for wheat and drying method

InactiveCN106052356AReduce the number of cyclesReduce breakage rateDrying gas arrangementsDrying solid materialsEngineeringTower

The invention provides a batched circulating dryer used for wheat and a drying method. The dryer comprises a hot blast heater, an elevator, a first draught fan, a second draught fan and a drying tower. The drying tower comprises a second tempering section, a first drying section, a first tempering section, a second drying section and a grain unloading section. Corner boxes are installed in the first drying section and the second drying section. The wheat drying method includes the following steps that the hot blast heater is ignited, and to-be-dried wheat enters the drying tower; the first draught fan and the second draught fan are started, a motor of the grain unloading section is started to unload grain, and a system enters the circulating drying process; during primary circulation, the wheat moves downwards from the top of the drying tower and passes through the second tempering section, the first drying section, the first tempering section and the second drying section to be subjected to heat exchange, and the wheat enters the grain unloading section after being dried twice; the wheat enters the elevator through the grain unloading section and is elevated again into the drying tower, and the next time of circulation is conducted; and after the wheat participates in multiple times of circulation, drying of the batched wheat is completed.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

Use of a lotion composition on an absorbent article for reducing adherence of feces or menses to the skin

InactiveCN101678142AReduce odorGuaranteed appearanceCosmetic preparationsToilet preparationsFecesHuman skin

The present invention relates to lotion compositions comprised on a body facing surface of an absorbent article such as a diaper, training pants or adult incontinence product. The lotion composition reduces the adherence of feces or menses to the human skin. The lotion composition comprises at least two compounds wherein one first compound is liquid at 25 DEG C and at least one second component which is solid at 25 DEG C. An effective amount of the lotion composition is comprised on a body facing surface of an absorbent article which is intended to be worn by a wearer.

Owner:PROCTER & GAMBLE CO

Semi-worsted porous segment color slub yarn and preparation method thereof

The invention relates to a semi-worsted porous segment color slub yarn. The semi-worsted porous segment color slub yarn is prepared from base yarn and decorative yarn, wherein the base yarn is prepared from prolivon fibers, spun silk fibers and wool fibers, and the decorative yarn is prepared from aloe viscose fibers and antibacterial hollow polyester fibers. The slub yarn prepared through the method is colorful, rich in color, changeable in pattern, unique in style, rich in layer change and special in shape, and can generate a flash effect after the fibers in different colors are combined into threads; due to the fact that the yarn is rich in color and diversified in shape change, a fabric manufactured through processing is antibacterial, capable of diminishing inflammation, protecting skin and beautifying the face, good in moisture absorption and good in dyeing property and elasticity, does not generate adverse reactions when making contact with the human body, and is not easy to damage by worms or rot, unique in appearance, good in drapability, good in comfort degree, good in abrasion resistance, natural in color and wide in application range; the processed fabric is strange in style and has the health-care functions of resisting bacteria, protecting the skin, strengthening the body, beautifying the face, moisturizing the skin, being good in comfort degree and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Tubular slat for coverings for architectural openings

ActiveUS20060027340A1Soft fabric appearanceSmooth rotationMechanical working/deformationLamination ancillary operationsGlass fiberEngineering

A slat or vane for use in a covering for an architectural opening is suitable for use in either a horizontal or vertical orientation and in a horizontal orientation will not sag or droop, and in a vertical orientation will rotate uniformly along its length when rotated from end thereof. The slat is formed in a tubular configuration and has a base material of glass fibers bonded together in a thermoformable resin so as to maintain the arcuate curvature desired for the tubular slat or vane. The slat can be repeatedly deformed and will always return to its original configuration.

Owner:HUNTER DOUGLAS INC

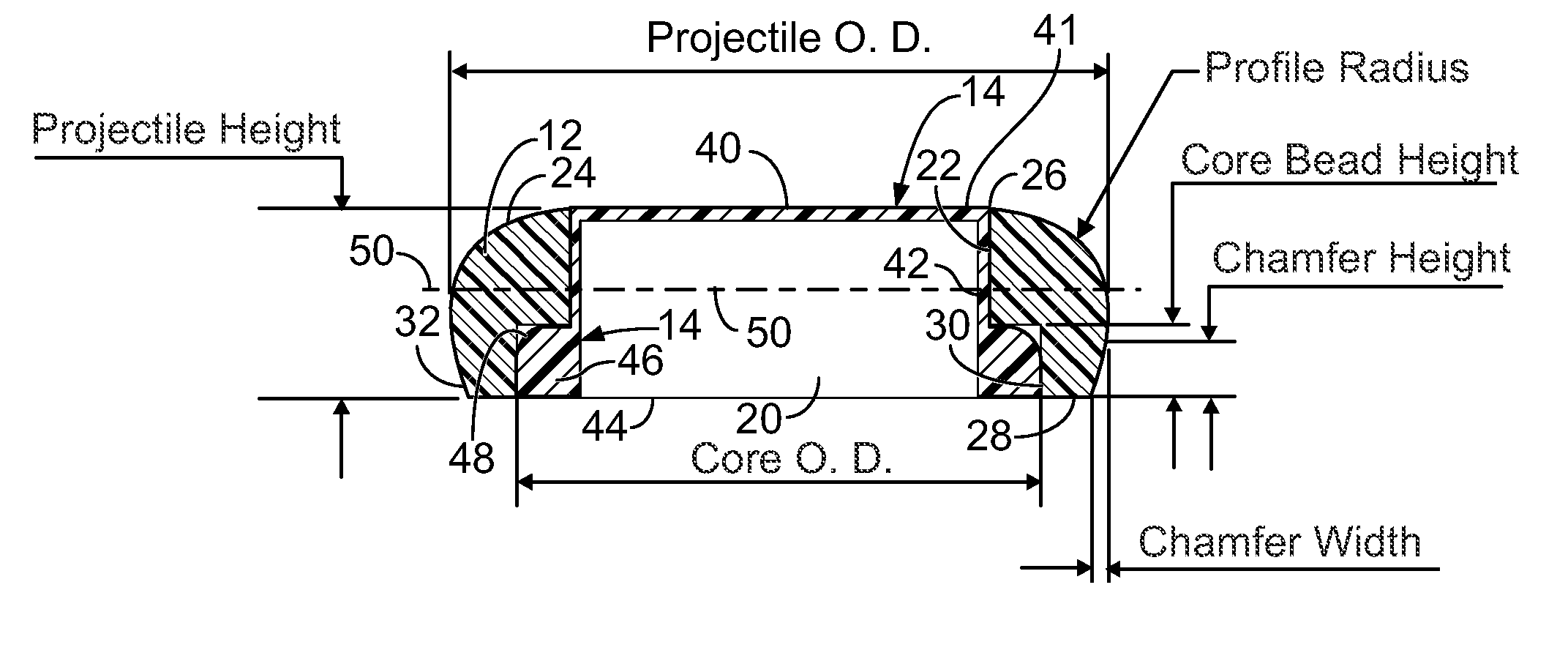

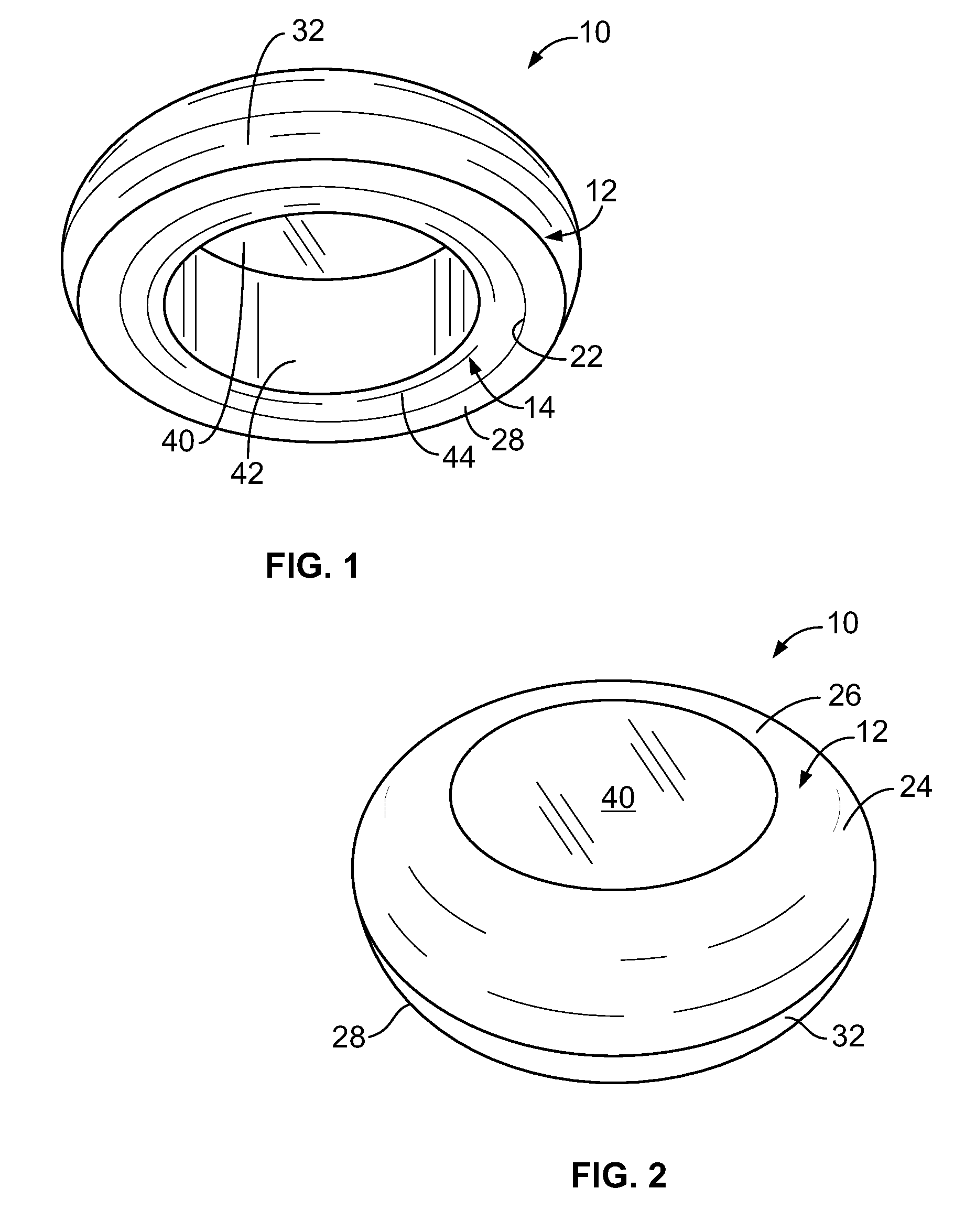

Aerodynamic flying disc

ActiveUS8784152B2Soft appearanceRobust interiorCeramic shaping apparatusToy aircraftsEngineeringMechanical engineering

Owner:HASBRO INC

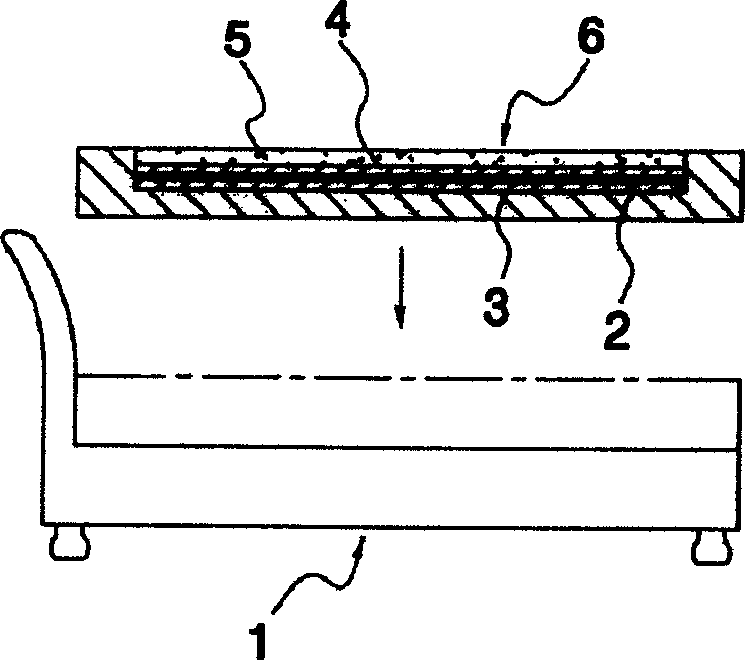

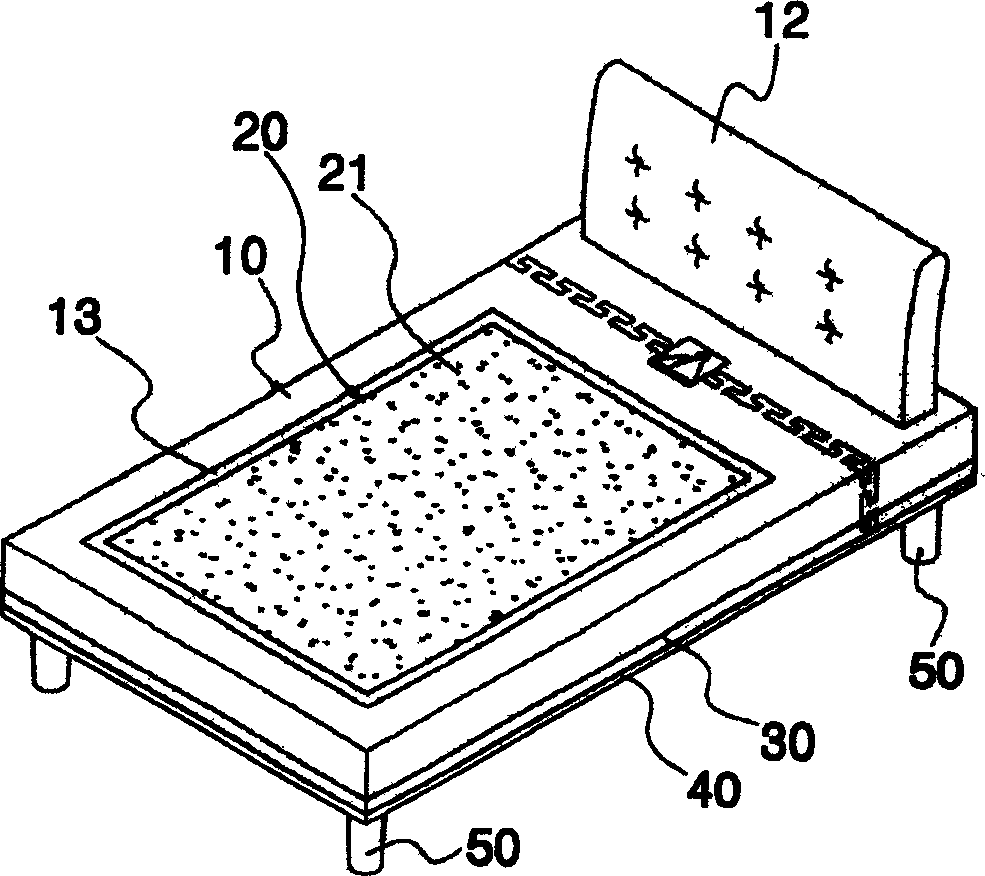

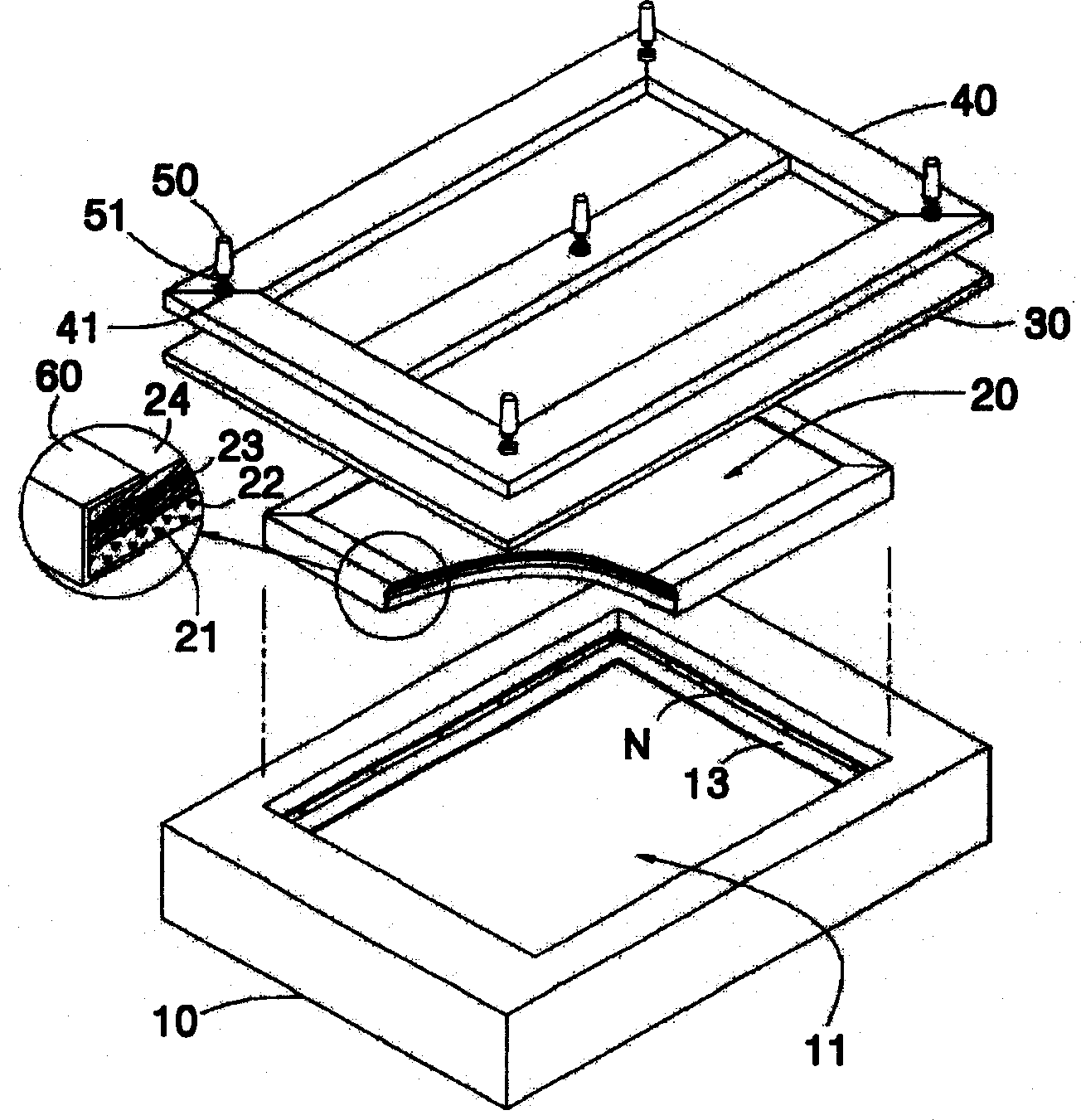

Mattress integrated stone bed

A connector for a synthetic resin pipe is provided to easily and stably connect the synthetic resin pipes by heating fused members with a high-frequency molding machine. Grooves(3,3') and protrusions(4,4') are formed at the outside of connecting bodies(2,2'). Coupling holes(6,6') are formed at both sides of the connecting bodies. Fused members(9,9') are disposed at the inner faces of the connecting bodies. A high-frequency molding machine is connected to a connecting ring(21) and a press plate(22) enclosing the connecting bodies, and heats the fused members.

Owner:曹茂铉

Method for producing cold-food products containing pullulan

The invention relates to a method for producing cold-food products containing pullulan. The implementation steps are as follows: (1) fully dissolving the pullulan with purified water for reserve, wherein weight ratio of the pullulan raw material is 0.01-0.1%; (2) preparing other raw materials by weight percent: 60-70% of fresh milk, 15-22% of butter, and 10-18% of white granulated sugar, mixing the raw materials to mix with water well, wherein the weight ratio of raw materials to water is 3:1, pouring into a cooking tank for stewing for 20-30 min, and performing pasteurization; (3) mixing and homogenizing the aqueous solution of the pullulan with the stewed raw material liquid, and then aging for 30-60 min; (4) precooling until the temperature is 0-10 DEG C, and swelling to produce frost by an ice cream machine, or performing cast pouring, plugging a stick for freezing under the temperature of minus 22-minus 25 DEG C, and finally dissolving the frost and withdrawing the pattern for shaping; and (5) packaging to obtain a novel ice cream or popsicle, and storing under the temperature of minus 18 DEG C. The manufactured ice cream and popsicle have smooth and transparent appearance and excellent anti-melting capacity, wherein the ice cream has refreshing, gentle and soft taste, the popsicle has refreshing, crisp and arenaceous taste. The invention has the advantages of reasonable recipe, simple process and excellent effect.

Owner:天津实发中科百奥工业生物技术有限公司

Glutinous rice wet glue with high bonding strength

InactiveCN107629725ARich sourcesHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesHydrogen peroxideSodium polyacrylate

The invention discloses a glutinous rice wet glue with high bonding strength, wherein the glutinous rice wet glue comprises the raw materials in parts by weight: 115-125 parts of a main material, 2-8parts of urea, 1-2 parts of hydrogen peroxide, 1-2 parts of sodium benzoate, 1-2 parts of a bactericide, 2-5 parts of an epoxidized soybean oil compound, 2-4 parts of sodium polyacrylate, 10-16 partsof alum, and 200-300 parts of deionized water. The main material comprises the raw materials in parts by weight: 60-80 parts of glutinous rice flour, 15-35 parts of japonica rice flour, 15-25 parts ofbaked dextrin, and 4-10 parts of carboxymethylated starch. The glutinous rice wet glue with high bonding strength is relatively low in cost, rich in raw material sources, high in bonding strength, safe, environmentally friendly, degradable and not easy to harden after being stored for a long time, and has the viscosity and stability improved.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

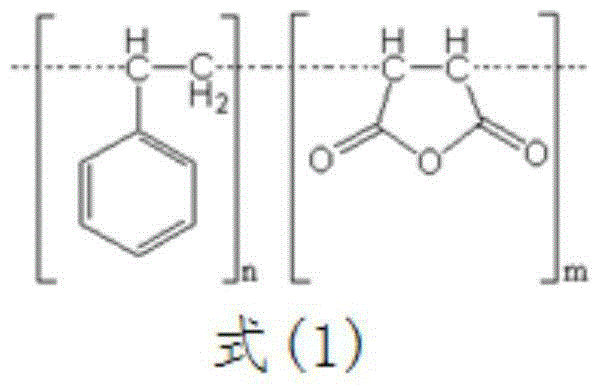

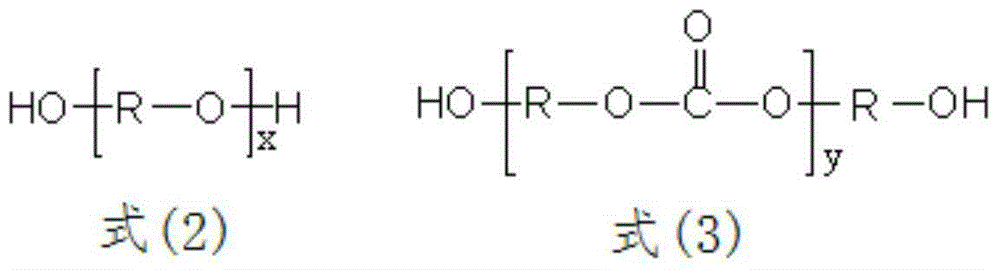

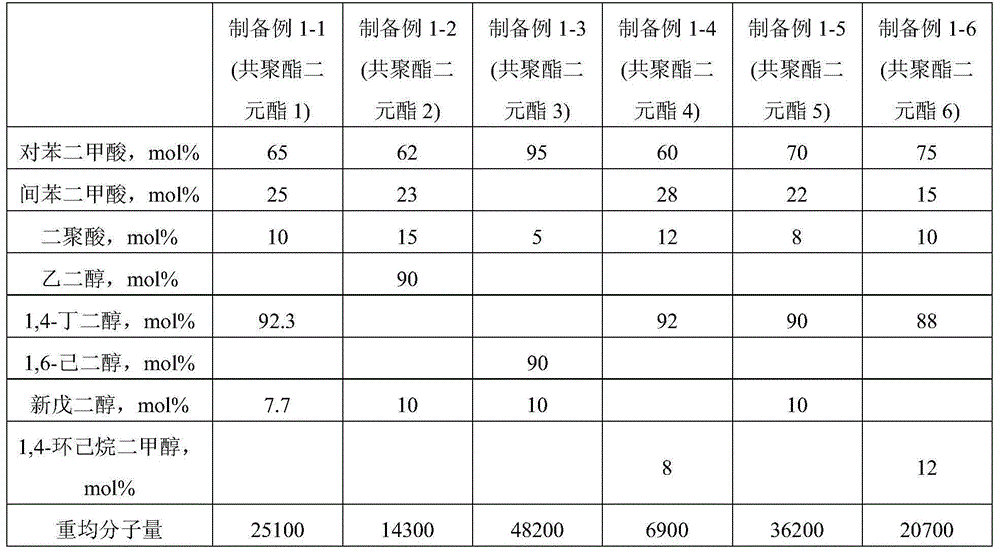

Transparent polyester type polyurethane hot-melt adhesive composition

ActiveCN106566457ATransparent appearanceSoft appearancePolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterPolyol

The invention provides a transparent polyester type polyurethane hot-melt adhesive composition. The composition comprises a) 90 to 99 wt% of polyester type polyurethane with a weight average molecular weight of 10, 000 to 200, 000 and b) 1 to 10 wt% of a polyol-grafted styrene-maleic anhydride copolymer, wherein the total weight of the polyester type polyurethane and the polyol-grafted styrene-maleic anhydride copolymer is taken as reference. The polyester type polyurethane hot-melt adhesive composition is to mold, and an adhesive film prepared from the composition is transparent, soft and water-resistant, has good whitening performance and is applicable to slide fasteners, clothes and textiles.

Owner:上海理日化工新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com