Organic silicone elastomer gel and preparation method thereof

A body gel and silicone technology, applied in the field of silicone elastomer gel and its preparation, can solve the problem of clogged pipes and nozzles of spray curing equipment, poor recovery of silicone elastomer powder particles and materials and/or working hours, Loss and other problems, to achieve long-lasting skin texture, high stability, and reduce the effect of stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

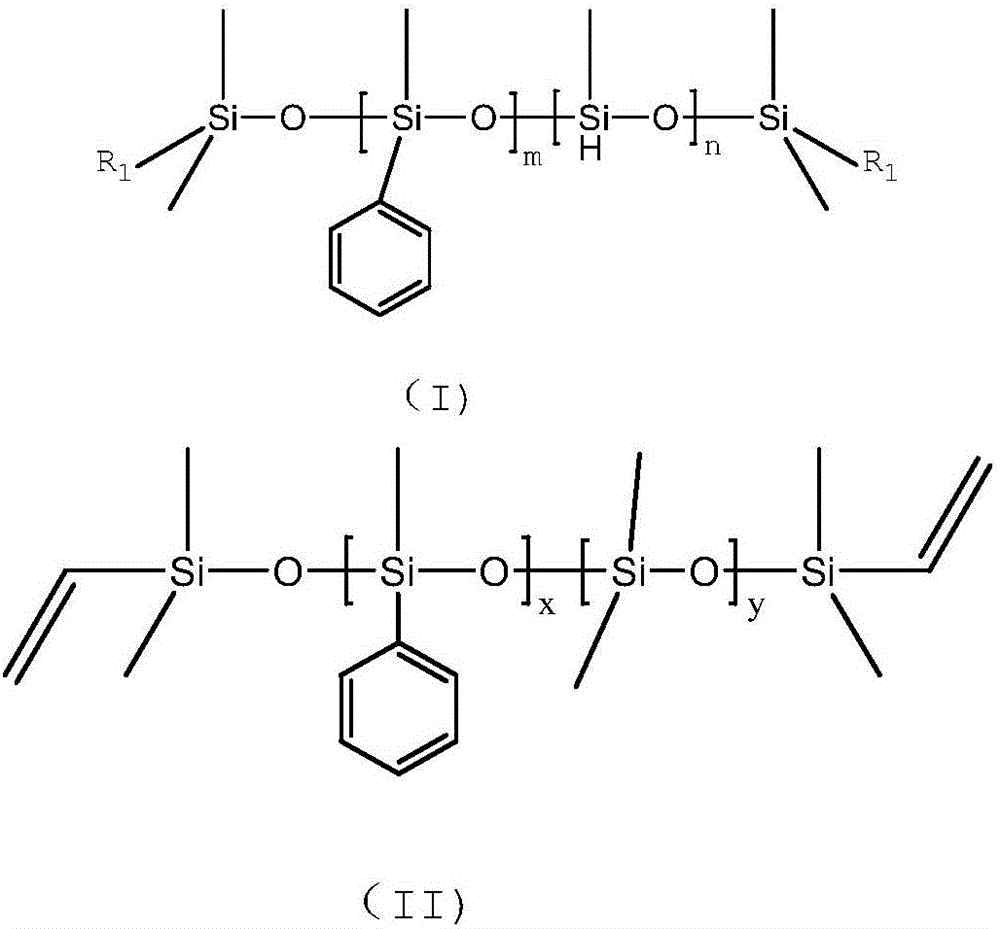

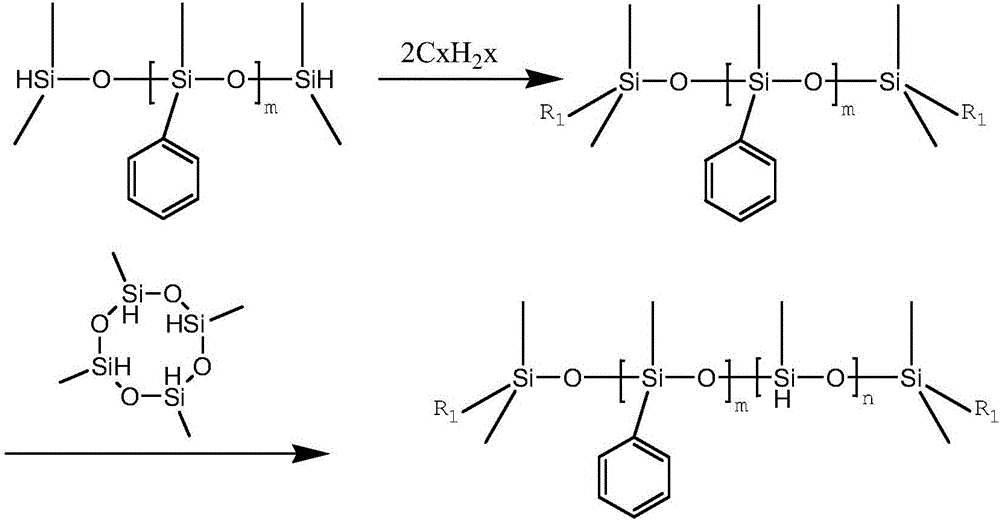

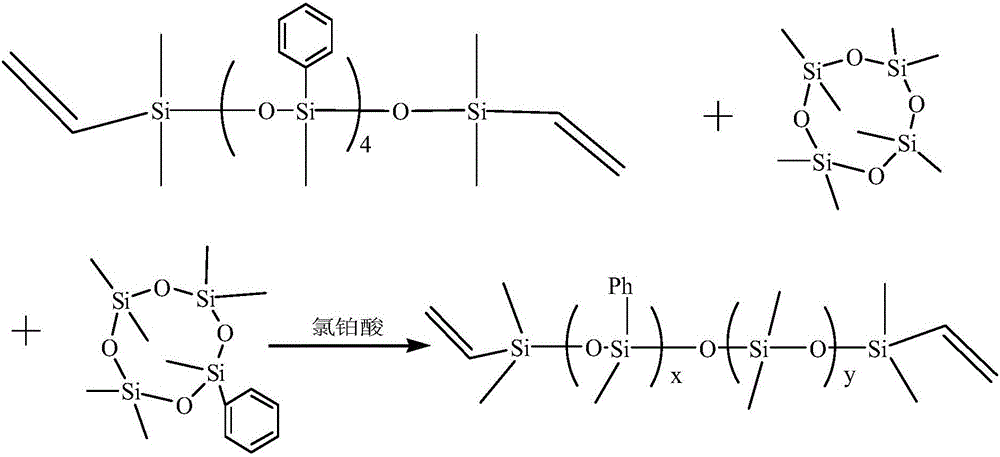

[0033] The preparation of the copolymer of the first polymer and the second polymer of embodiment 1

[0034] Step 1) Introduce the first polymer with 47.5% molar percentage and the second polymer with 52.5% molar percentage into the reactor, mix uniformly, and protect with nitrogen gas; wherein, the R in the first polymer 1 =C 8 h 17 , n / m=4 / 3, the average molecular weight is 2286; y / x=4 / 5 in the second polymer, the average molecular weight is 3858.

[0035] Step 2) Add the catalyst tetramethylammonium siloxanol, raise the temperature to 100°C, and continue to react for 2 hours at a stirring speed of 60r / min. After the reaction, raise the temperature to 180°C and reduce the pressure to 0.25MPa to destroy the catalyst And remove the low boiler, gradually cool the reactor to obtain the copolymer of the first polymer and the second polymer to obtain A, and its average molecular weight is 15667.

Embodiment 2

[0036] Preparation of the copolymer of the first polymer and the second polymer in embodiment 2

[0037] Step 1) Introduce the first polymer with a molar percentage of 42.5% and the second polymer with a molar percentage of 57.5% into the reactor, mix uniformly, and protect with nitrogen; wherein, the R in the first polymer 1 =C 12 h 25 , n / m=7 / 6, the average molecular weight is 2926; y / x=3 / 2 in the second polymer, the average molecular weight is 4154.

[0038] Step 2) Add the catalyst tetramethylammonium siloxanol, raise the temperature to 110°C, and continue the reaction at a stirring speed of 60r / min for 2.5 hours. After the reaction, raise the temperature to 170°C and reduce the pressure to 0.2MPa to destroy the catalyst And remove the low boiler, gradually cool the reactor to obtain the copolymer of the first polymer and the second polymer to obtain B, and its average molecular weight is 18051.

Embodiment 3

[0039] Embodiment 3 silicone elastomer gel preparation

[0040] Step 1) After the copolymer A prepared in Example 1 was pulverized by a high-speed pulverizer with a rotating speed of 25,000 rpm for 3 minutes, the copolymer particles larger than 60 mesh (about 250-420 microns) were screened out with a sample sieve;

[0041] Step 2) Add 1000g of squalane to the torque rheometer at 80°C and 100r / min, then slowly add 500g of the copolymer particles obtained in step 1), and stir slowly for 3h to swell;

[0042] Step 3) Stir rapidly at 500 r / min for 20 min to obtain a silicone elastomer gel in the form of a uniform gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com