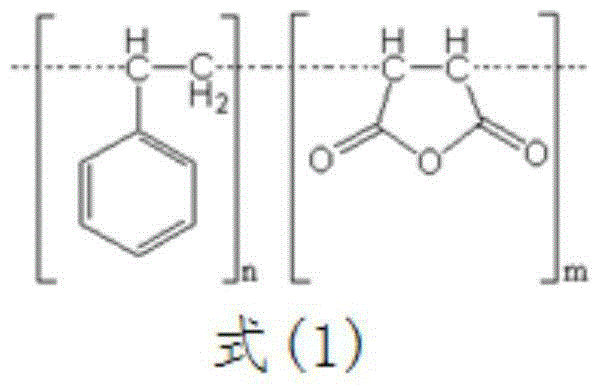

Transparent polyester type polyurethane hot-melt adhesive composition

A technology of polyester polyurethane and hot melt adhesive, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., and can solve problems such as not mentioning the transparency of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

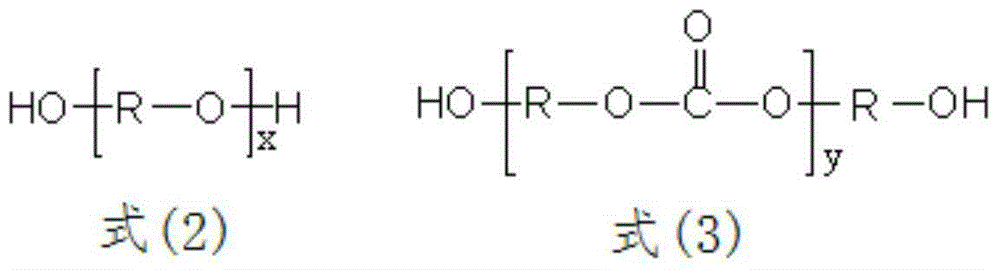

preparation example Construction

[0041] For the preparation method of the above-mentioned aliphatic-aromatic copolyester diol, please refer to CN104629663.

[0042] The aforementioned diisocyanates are aromatic diisocyanates or aliphatic / alicyclic diisocyanates or mixtures thereof. Specific examples include diphenylmethane diisocyanate (MDI), hydrogenated MDI, toluene diisocyanate (TDI), hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI), naphthalene diisocyanate (NDI), benzene Dimethylene diisocyanate (XDI), hydrogenated XDI, p-phenylene diisocyanate (PPDI), etc., preferably MDI, HDI and IPDI.

[0043] Based on the total weight of the polyester polyurethane to be formed, the above-mentioned diisocyanate is added in an amount of 0.1-5% by weight, preferably 0.2-2% by weight.

[0044] The weight-average molecular weight of the polyol graft-modified styrene-maleic anhydride copolymer used in the present invention is generally 3000-30000, preferably 10000-25000. The content of the maleic anhydrid...

Embodiment

[0064] 1. Source of raw materials

[0065] The aliphatic-aromatic copolyester diol used in this example is self-made. The dimer acid was purchased from the British Croda Company, and the brand name was Pripol 1013. Styrene maleic anhydride copolymer is provided by Polyscope China Branch, the brand name is SZ 10010. The diisocyanates MDI, TDI, TDI and IPDI were purchased from BAYER Company in Germany. Polytetrahydrofuran ether glycol (PTMEG) was purchased from Sanxi Sanwei Company with a molecular weight of 2000. Polypropylene glycol (PPG) polycarbonate diol was purchased from Jiangsu Haian Petrochemical Plant with a molecular weight of 3000. Polycarbonate diol (PCD) was purchased from Ube, Japan, brand UH-CARB200, molecular weight 2000. All other raw materials were purchased from reagent companies.

[0066] 2. Performance test method

[0067] Each performance parameter is tested as follows in the embodiment:

[0068] (1) Melting point (Tm)

[0069] DSC method test, aft...

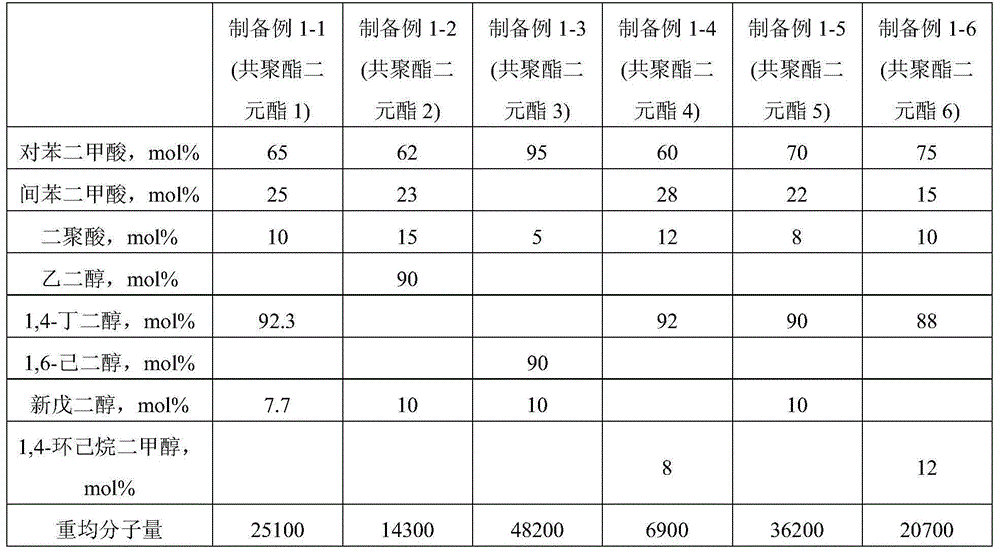

preparation example 1-1

[0088] Preparation Example 1-1 Copolyester Diol 1

[0089] Add 48 mol of 1,4-butanediol and 4 mol of neopentyl glycol into a 20L reaction kettle equipped with a thermometer, a mechanical stirrer, a fractionating column and a condenser, and raise the temperature to 100°C to completely melt the neopentyl glycol. Stirring was started, and 26 mol of terephthalic acid, 10 mol of isophthalic acid, 4 mol of dimer acid and 10 g of n-ethyl phthalate were added. Continue to raise the temperature. When the temperature rises to about 160°C, water droplets begin to distill. The distillation temperature is 98-105°C. Continue to raise the temperature until the temperature in the kettle reaches about 230°C. molecular weight oligomers. Reduce the stirring speed, slowly add 5 grams of n-ethyl phthalate and 4 grams of trimethyl phosphate, then continue to gradually increase the temperature to about 240-260 ° C, and gradually increase the vacuum degree of the system until the vacuum degree of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com