Preparation method of nanometer silica polyether (ester) polyol dispersion for modifying polyurethane

A nano-silica and polyurethane technology, applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed low-molecular organic compound treatment, etc., to achieve the effects of improving aging resistance, improving flexibility and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

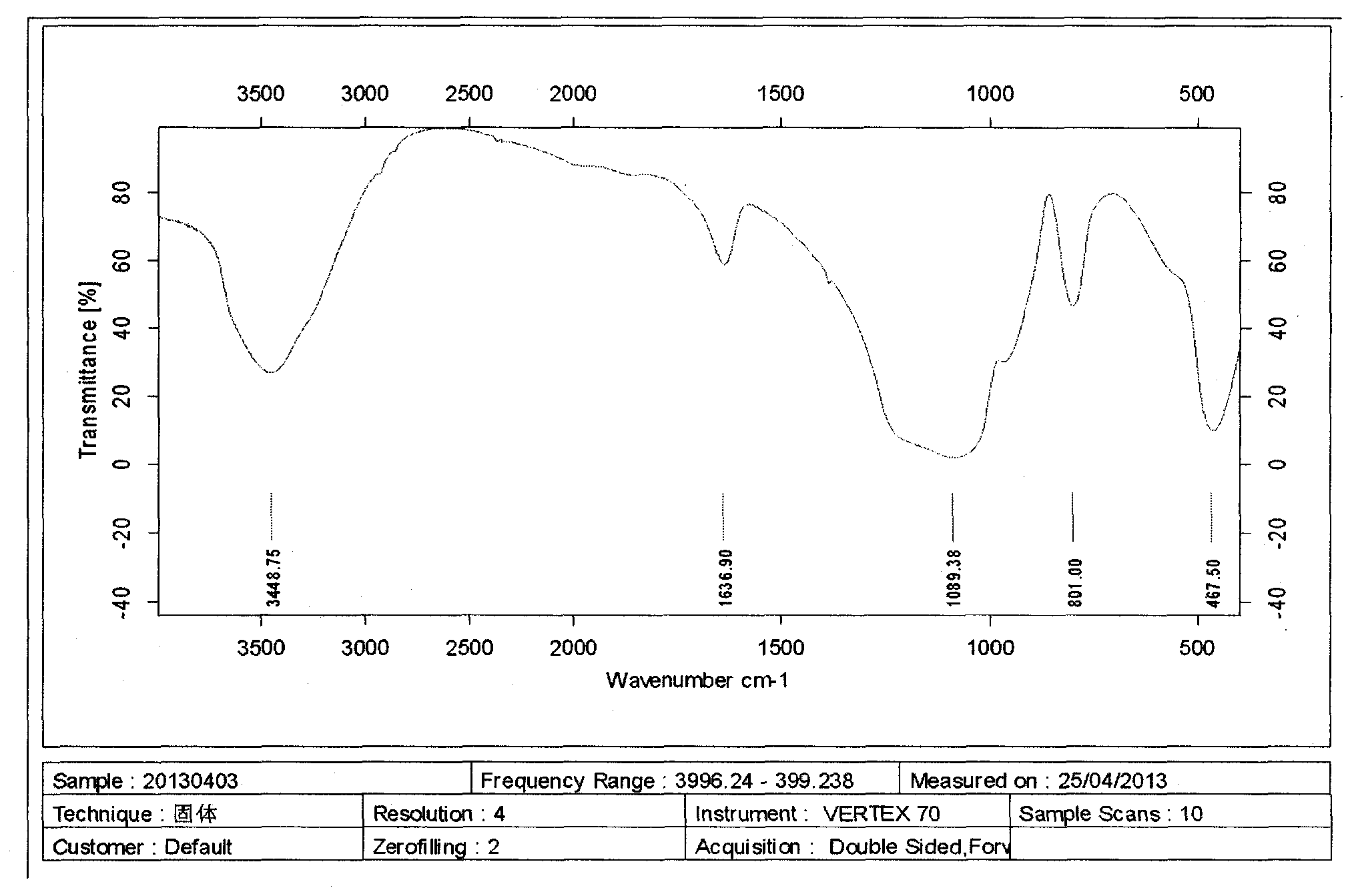

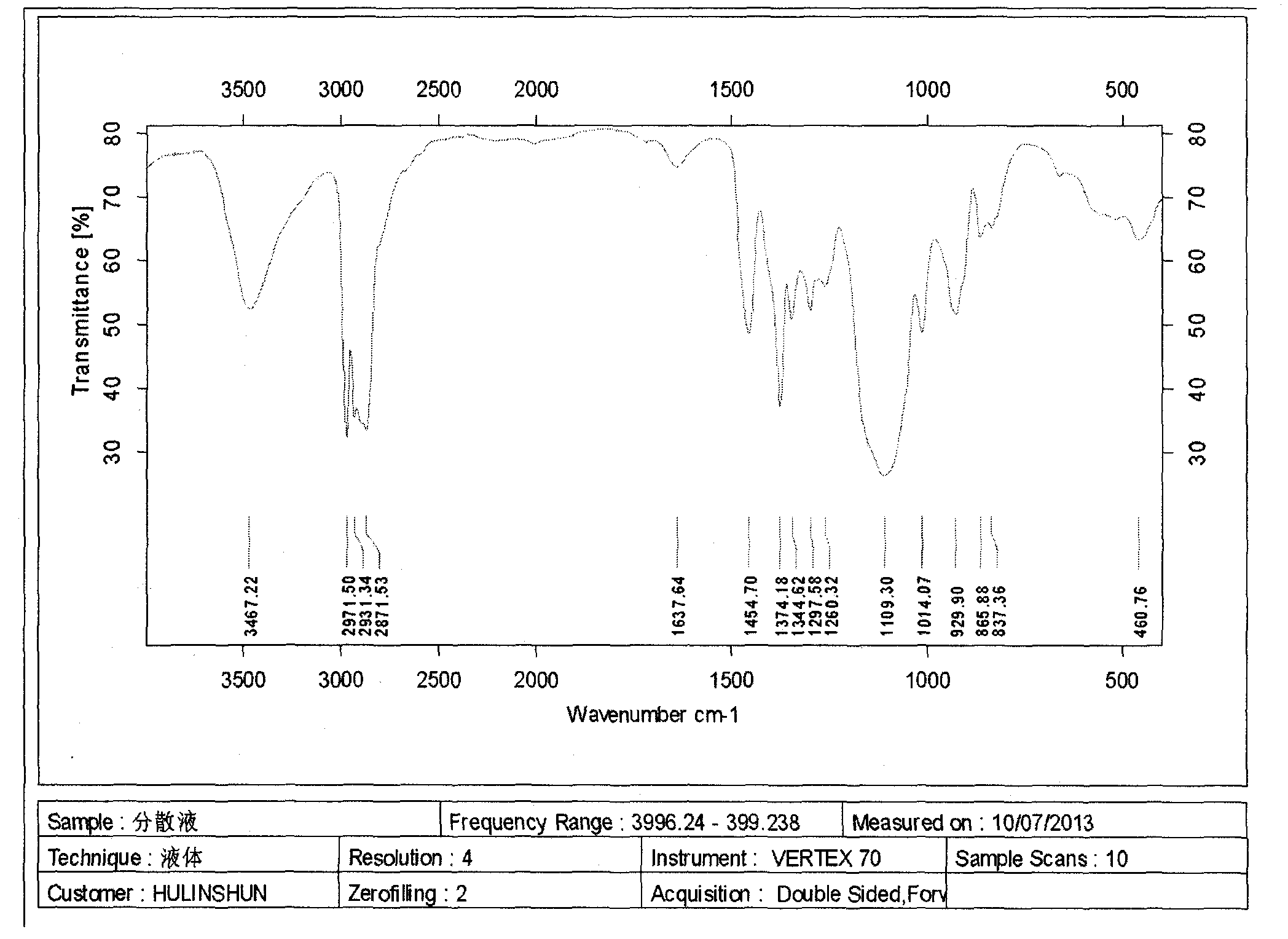

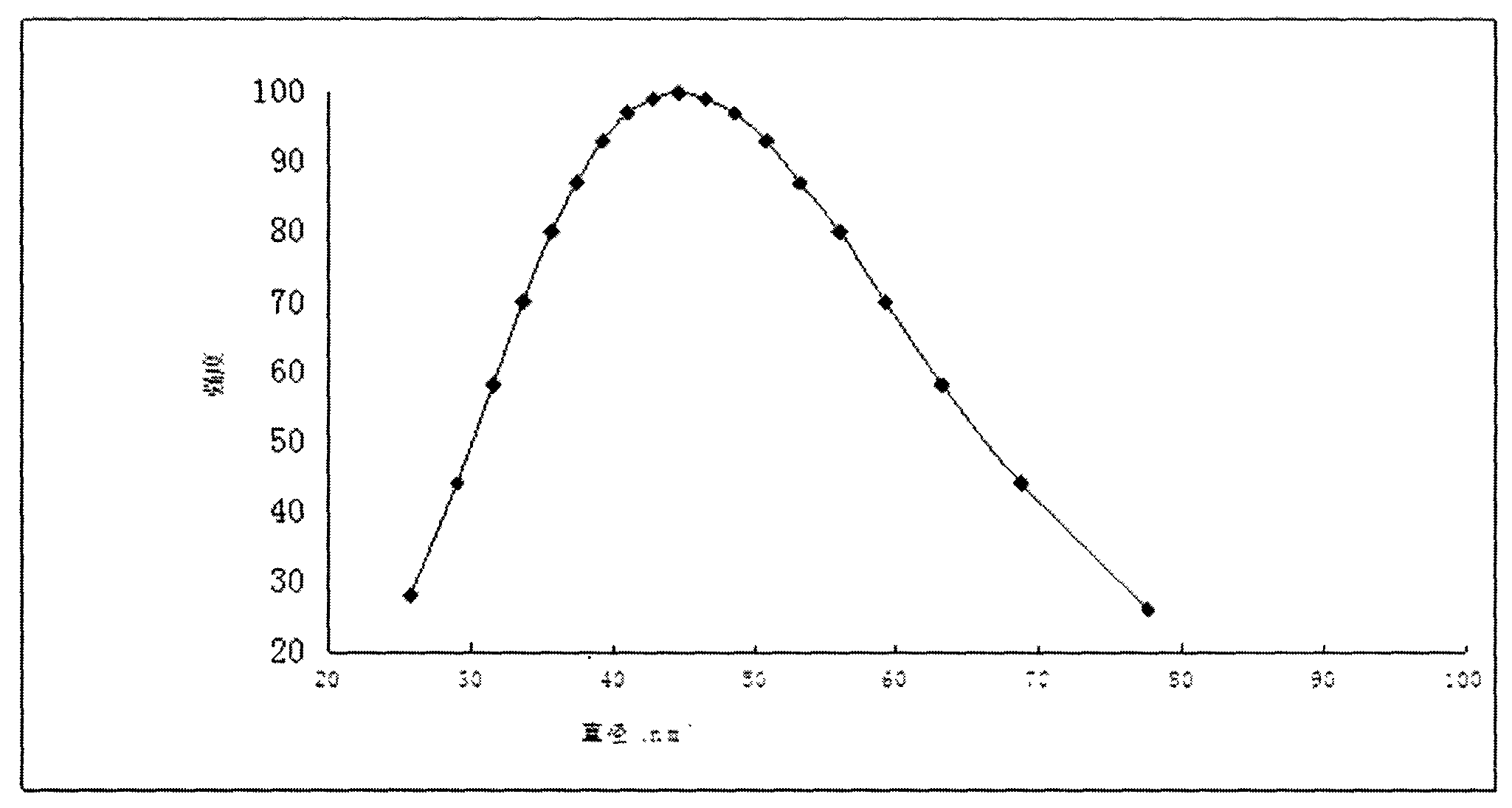

[0027] 1. Take 40mL of 3.6mol / L hydrochloric acid, add it to the flask, cool it down to below 10°C with an ice bath, measure 50mL of 1.0mol / L sodium silicate, and drop it into the flask through the dropping funnel for about 30 minutes , then add 5%-30% silane coupling agent A174 of theoretical silica content, react at room temperature for 2 hours, add 35gNaCl and stir for 30min, then add an equal volume of THF, stir for 2h, pour the liquid in the flask into a separatory funnel, Stand still for 30 minutes, pour the upper liquid into a beaker, add 25g of anhydrous sodium sulfate, stir for 10 minutes, seal and dry overnight, then add 35g of polypropylene glycol (1000) according to 15% solid content, ultrasonic for 2 hours, and remove THF under reduced pressure at 60°C to obtain a clear and transparent Silica polypropylene glycol (1000) dispersion.

[0028] 2. Take 32mL of 3.8mol / L hydrochloric acid, add it to the flask, cool it down to below 10°C with an ice bath, measure 100mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com