Enzymatic textile bleach-whitening methods

A textile and textile technology, applied in the field of enzyme-catalyzed textile bleaching-brightening, can solve the problems of properly and completely removing sulfur derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

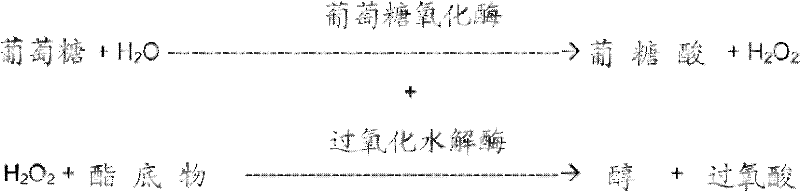

Problems solved by technology

Method used

Image

Examples

Embodiment 1A、2 and 3

[0211] Enzyme-catalyzed bleaching-brightening according to the one-bath two-step exhaust method: prescoured and heat-set nylon 66 fabrics at 175°C using a liquor ratio of 20:1 in the amount of bleaching process, sodium carbonate, said ester substrate, hydrogen peroxide and said perhydrolase in a bath. The temperature was ramped from room temperature to a target temperature of 65°C at a rate of 2°C per minute. The bath was then held at 65°C for 30 minutes and then adjusted to pH 4.5 by adding acetic acid (80%). Subsequently, the optical brightener was added to the bath in the amount given in Table 1, and the treatment was continued at 65° C. for another 20 minutes. After draining, the fabric was rinsed twice at 50°C for 10 minutes each and then dried at 70°C. Each flush contained 0.5 g / l of a 25% solution of catalase T100 (purchased from Genencor).

Embodiment 1A

[0212] Table 1 Examples 1A, 2 and 3 - Enzyme Catalyzed Bleaching - Brightening

[0213] Example #

1A

2

3

Bleached products 1) [g / l]

0.9

0.9

0.9

Sodium carbonate buffer [g / l]

2.0

2.0

2.0

Ester substrate 2) [g / l]

3.0

3.0

3.0

Hydrogen peroxide 35% [ml / l]

6.0

6.0

6.0

Peroxidase 3) [mg / l]

1.7

1.7

1.7

FWA(1a) 4) [%]

0.4

0.36

FWA(2) 5) [%]

0.26

Shading dye 6)

6)

[0214] 1) LTC (commercially available from Huntsman)

[0215] 2) Propylene glycol diethyl ester

[0216] 3) corresponds to 1.0 g / l EcoWhite (1×) (product of Genencor)

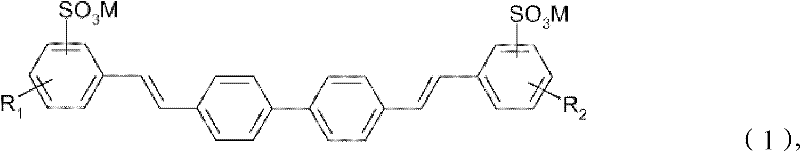

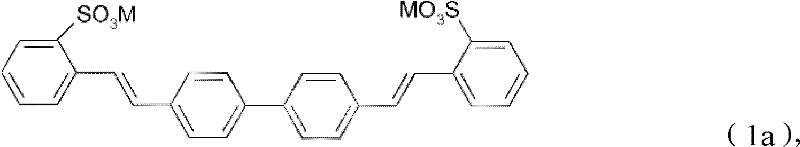

[0217] 4) Fluorescent whitening agent of formula (1a); [%] based on the weight of fabric

[0218] 5) Fluorescent whitening agent of formula (2); [%] based on the weight of fabric

[0219] 6) 0.00025% of 7-phenyl-5,9-bis(ph...

Embodiment 1B

[0231] Enzyme-catalyzed bleaching-brightening according to the two-bath two-step exhaust method:

[0232] (i) Pre-scoured and heat-set nylon 66 fabric at 175°C, treated with a bath ratio of 20:1 in a bath containing:

[0233] According to the 0.9g / l bleaching process given in Table 1,

[0234] 2.0g / l sodium carbonate buffer,

[0235] 3.0 g / l ester substrate (propylene glycol diethyl ester)

[0236] 6.0ml / l of 35% hydrogen peroxide, and

[0237] 1.7 mg / l of perhydrolase, which corresponds to 1.0 g / l of EcoWhite (1x) (product of Genencor).

[0238] The temperature was ramped from room temperature to a target temperature of 65°C at a rate of 2°C per minute. The bath was then held at 65°C for 50 minutes. After draining, the fabric was rinsed twice at 50°C for 10 minutes each and then dried at 70°C. Each flush contained 0.5 g / l of a 25% solution of catalase T100 (product of Genencor).

[0239] (ii) The dried fabric obtained according to step (i) was treated with a liquor r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com