Full automatic feeding chemical material operating device for bleaching and dyeing

An operating device, fully automatic technology, applied in the processing of textile materials, textile and papermaking, program control in sequence/logic controllers, etc. , to avoid unstable human operation, avoid secondary pollution, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

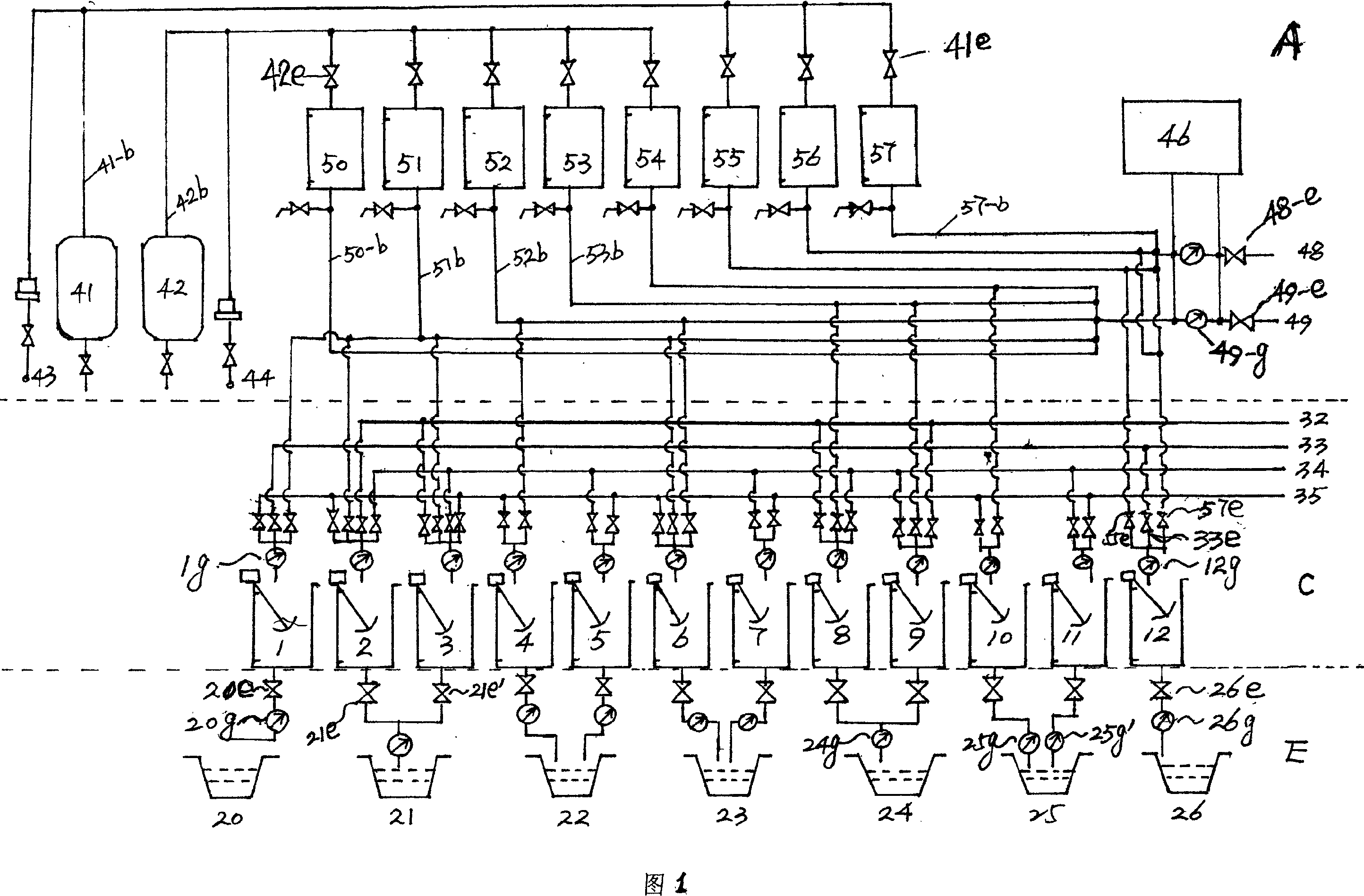

[0017] Example 1: Accompanying drawing 1 is a schematic representation of the structure of the machine used in the bleaching, dyeing and finishing process of the present invention, and accompanying drawing 3 is a schematic representation of the computer operation control arrangement used in the bleaching, dyeing and finishing process of the present invention schematic diagram. As shown in Figure 1, auxiliary agent compound reaction kettle 41,42, standby input pipeline 43,44, finished auxiliary agent is pumped into storage facility 50-57 respectively through pipeline 43,44 or pipeline 41-b, 42-b, and material storage The auxiliary agent output of the tank can be operated by the standby automatic metering controller 46, and the output can be measured and discharged by the output outlets 48 and 49 respectively; it can also be directly connected to the high-level cylinder through the output pipes 50b-57b. This area is classified as equipment installation area A, except for the stan...

example 2

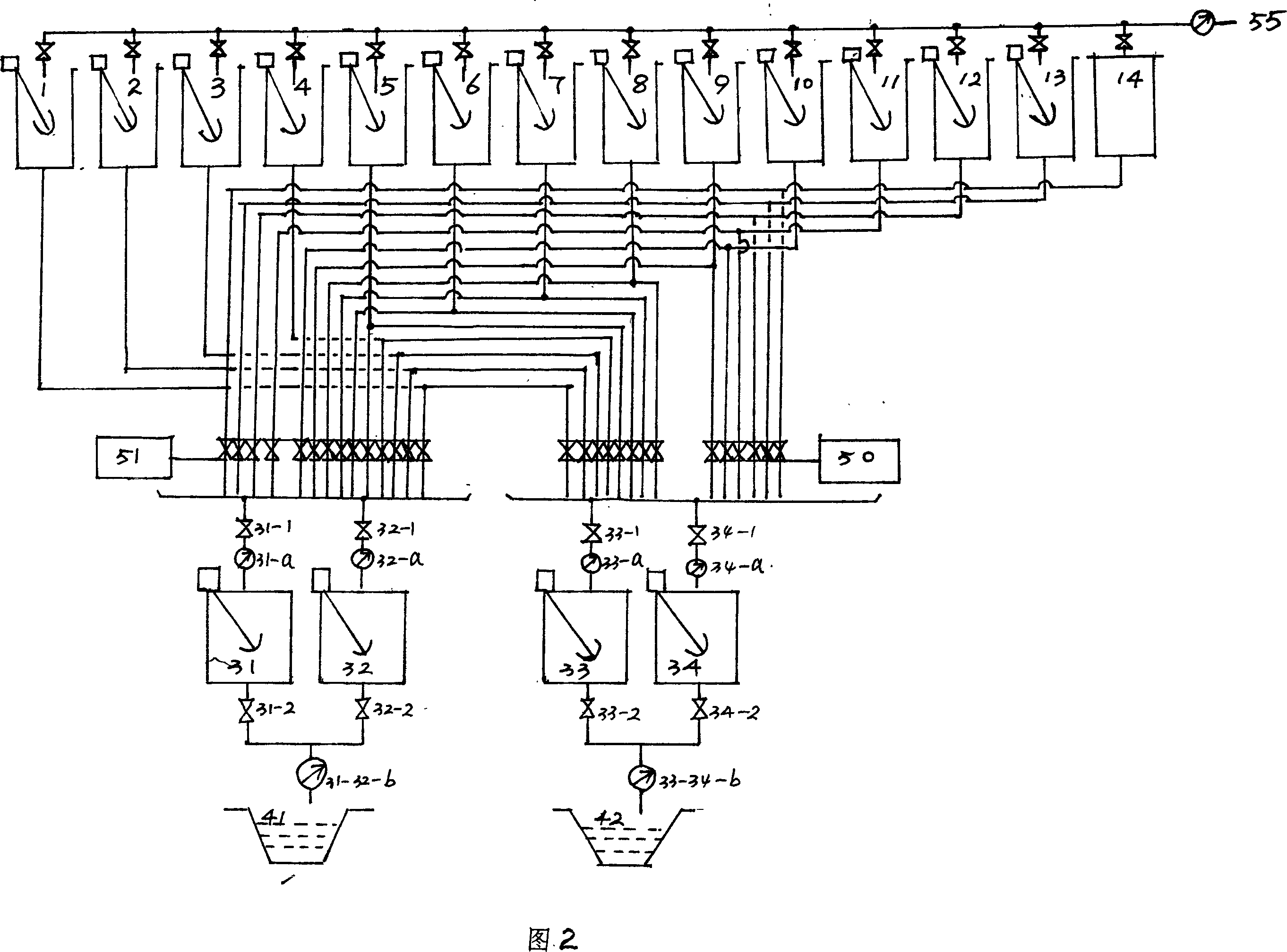

[0018]Example 2: Accompanying drawing 2 is a schematic representation of the layout structure of the machine for automatic delivery of dyestuffs in the dyeing process according to the present invention. As shown in Figure 2, the dye dispersing and dissolving stirring tank is the dye storage tank. The number of stirring tanks is determined by the number of dyes, the number of colors and the process operation mode. There are motor control buttons on each stirring tank, and the discharge pipe The mouth is a T-shaped branch pipe, one of which is the drain pipe of the washing tank. This area is the equipment installation area B. One is directly connected to the high-level cylinder mouth of the dyeing machine and is equipped with valves. It can be optionally arranged side by side on the top of the high-level cylinder. Orbital or rotary compass, and then connect with the fixed interface with valve and flowmeter below to realize automatic feeding by jogging. Alternatively, one pipe, on...

example 3

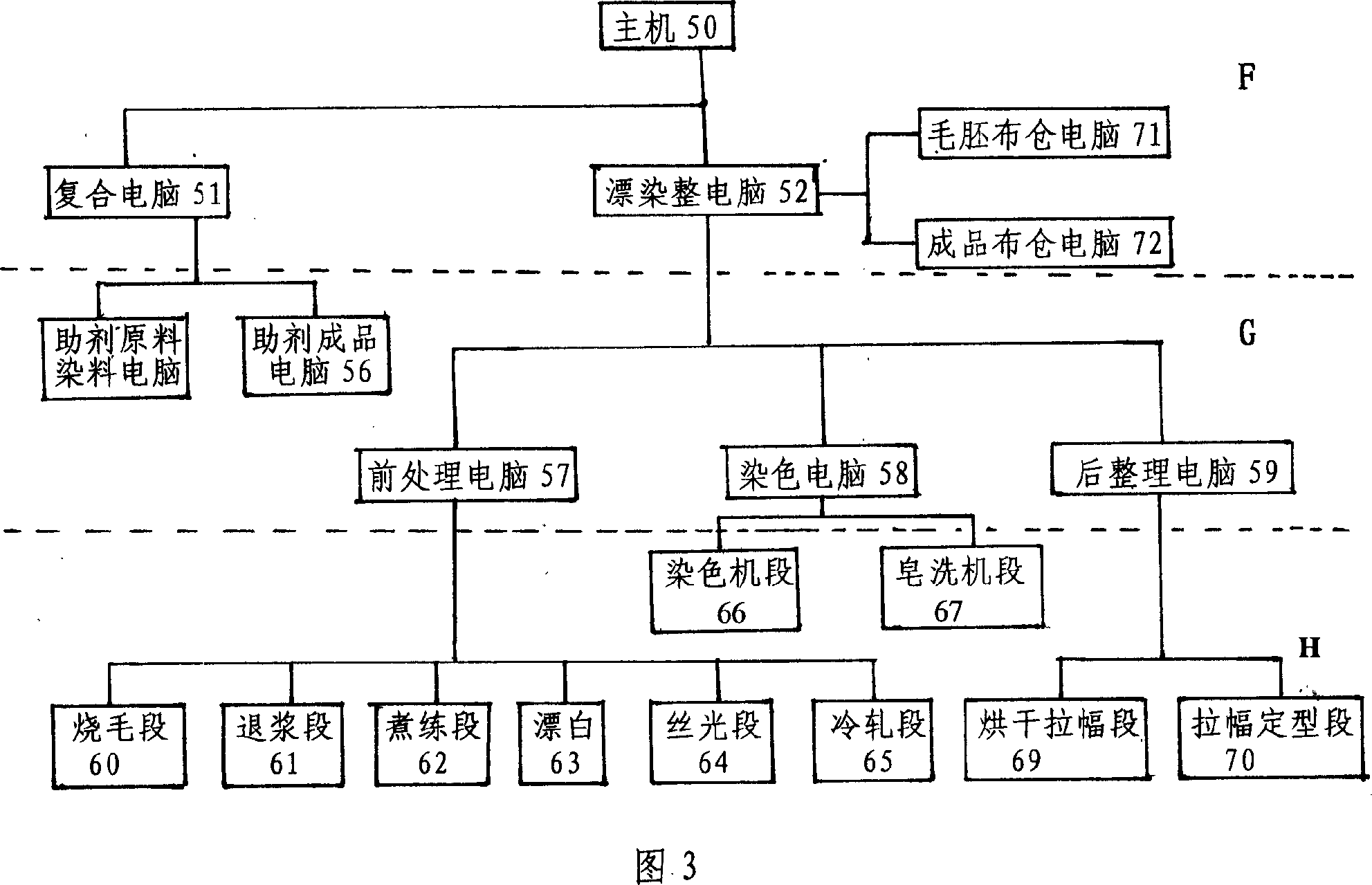

[0019] Example 3: Accompanying drawing 3 schematically shows that the present invention is used in a complete production process of bleaching, dyeing and whole to control the arrangement of computer operations, and accompanying drawing 4 is a schematic representation of the original input data automatic classification storage and data sharing mode of the present invention schematic diagram. As shown in accompanying drawing 3 and accompanying drawing 4, the fully automatic opening chemical material of the present invention, feeding device is made up of two parts of computer control platform and opening chemical material, feeding mechanical device. Among them, the computer electrical automatic control platform has at least 3 computers, preferably more than 10; one main machine 50, with a computer laying machine 51 for the composite auxiliary section, a computer laying machine 52 for monitoring the whole process of bleaching, dyeing, and finishing, and a gray cloth warehouse and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com