Application of Sodium Cyclohexyl Sulfamate in Functional Finishing of Textiles

A technology of sodium cyclohexyl sulfamate and sodium sulfamate is applied in textiles and papermaking, fiber processing, abrasion-resistant fibers, etc. Good effect, excellent effect, the effect of reducing damage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Application of sodium cyclamate in textiles

[0050] It is known that the breaking strength of the undesized pure cotton plain weave fabric before treatment is 508.4N, and the Hunter whiteness is 53.8.

[0051] (1) Preparation of bleaching working solution: with sodium N-cyclohexyl sulfamate 20g / L, stabilizer 4g / L, chelating agent 3g / L, penetrant 2g / L, H 2 O 2 The bleaching solution was prepared in an amount of 65 g / L, and then the pH was adjusted to 12 with NaOH.

[0052] (2) Padding: the fabric is placed in the above-mentioned bleaching working solution for padding treatment, two dips and two rolls, and the over-rolling rate of the fabric is controlled to be 100%.

[0053] (3) Rolling and stacking: The padding fabrics are stacked at 20°C for 24 hours.

[0054] (4) Washing: washing and drying the bleached fabric.

[0055] The fabric treated by this method has a strength retention rate of 95.98% and a Hunter whiteness of 81.83 according to the national s...

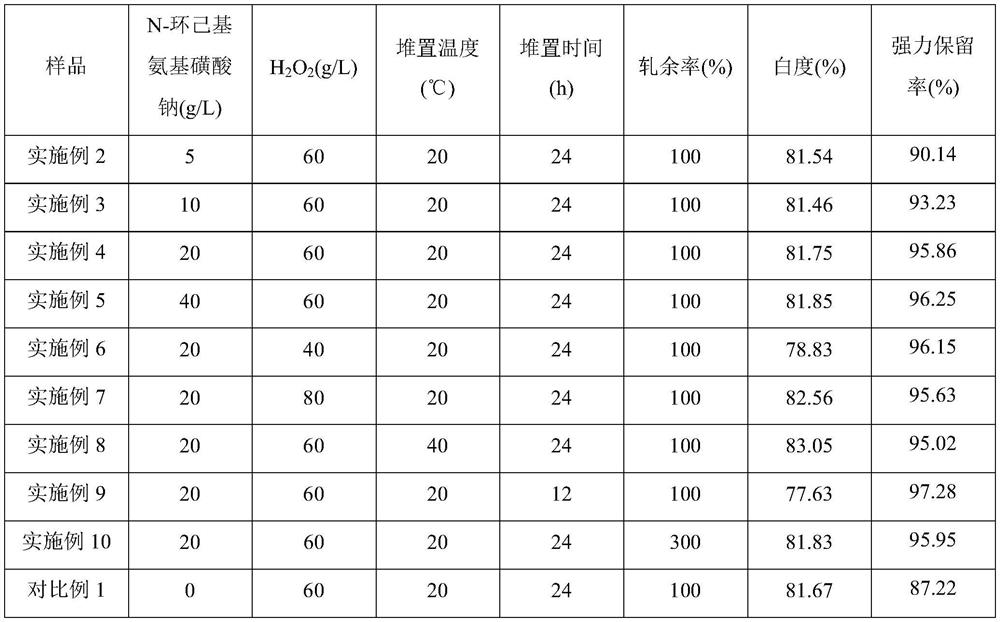

Embodiment 2

[0056] Embodiment 2: a kind of bleaching liquid

[0057] A bleaching solution comprising 5g / L of sodium N-cyclohexyl sulfamate, 4g / L of stabilizer, 2g / L of chelating agent, 2g / L of penetrant and H 2 O 2 60 g / L, pH was adjusted to 12 with NaOH.

[0058] The cotton fabric is bleached with the bleaching solution of the present embodiment, comprising the following steps:

[0059] (1) padding: the fabric is placed in the above-mentioned bleaching solution for padding, two dips and two rollings, and the over-rolling ratio of the control fabric is 100%;

[0060] (2) Rolling and stacking: the cotton fabrics after padding are rolled and stacked, and stacked at 20°C for 24 hours;

[0061] (3) Washing: washing and drying the fabric after cold heap bleaching.

[0062] The breaking strength of the fabric before treatment is known to be 508.4N and the Hunter whiteness is 53.8. The fabric treated by this method has a strength retention rate of 90.14% and a Hunter whiteness of 81.54 mea...

Embodiment 3

[0063] Embodiment 3: a kind of bleaching liquid

[0064] A bleaching solution comprising 10g / L of sodium N-cyclohexyl sulfamate, 4g / L of stabilizer, 2g / L of chelating agent, 2g / L of penetrant and H 2 O 2 60 g / L, pH was adjusted to 12 with NaOH.

[0065] The cotton fabric is bleached with the bleaching solution of the present embodiment, comprising the following steps:

[0066] (1) padding: the fabric is placed in the above-mentioned bleaching solution for padding, two dips and two rollings, and the over-rolling ratio of the control fabric is 100%;

[0067] (2) Rolling and stacking: the cotton fabrics after padding are rolled and stacked, and stacked at 20°C for 24 hours;

[0068] (3) Washing: washing and drying the fabric after cold heap bleaching.

[0069] The breaking strength of the fabric before treatment is known to be 508.4N and the Hunter whiteness is 53.8. The fabric treated by this method, according to the national standards GB / T 3923.1-2013 and GB / T 17644-1998,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com