Method for improving active dyeing depth of pure cotton fabric

A technology of pure cotton fabric, reactive dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

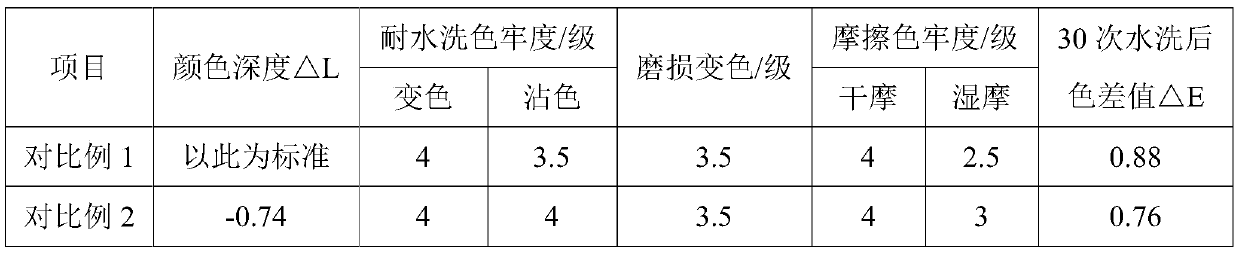

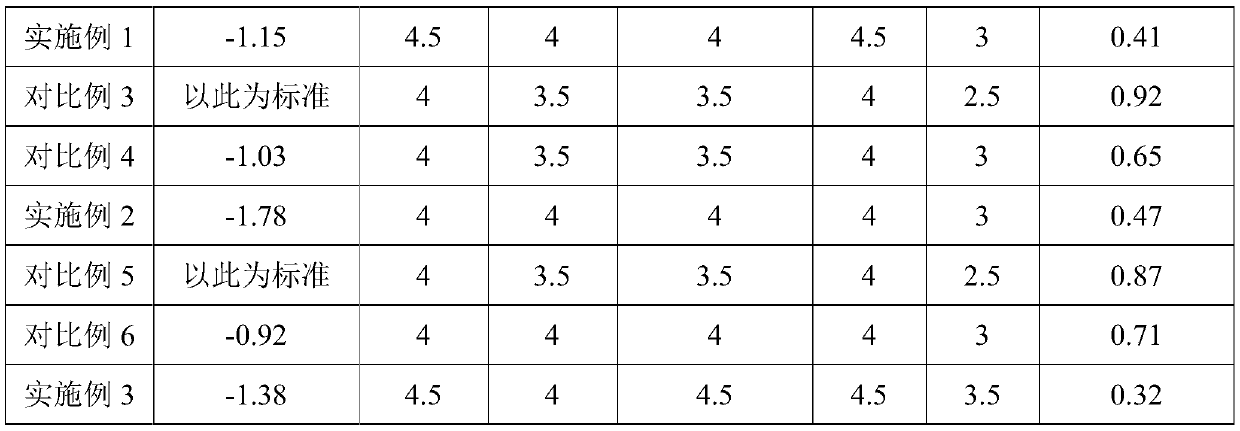

Embodiment 1

[0024] A pure cotton fabric weave specification: CM50*CM50*144*80**57 / 58, pattern: plain weave.

[0025] Adopt the method for promoting the active dyeing depth of pure cotton fabric of the present invention to process above-mentioned pure cotton fabric, the steps are as follows:

[0026] (1) Rolling material: the dyeing solution used is composed of: reactive black 52.10g / L, reactive blue 9.65g / L, reactive red 2.29g / L, penetrating agent 3g / L, anti-swimming agent 10g / L, rolling residue rate of 65%.

[0027] (2) Rolling and stacking: the temperature is 36°C, the stacking time is 2 hours, and the rotation speed is 18r / min.

[0028] (3) Drying: Infrared pre-drying temperature is 650°C, the temperatures of 1-3# drying rooms are 110°C, 110°C, and 120°C respectively, and the circulating air of 1-3# drying rooms is 70%, 80%, and 80% respectively.

[0029] (4) steaming color fixing: carry out padding color fixing solution, steaming, washing, soaping successively; The color fixing solu...

Embodiment 2

[0032] A pure cotton fabric weave specification: CM30*SPANDEX14(70D)*165*72*57 / 58, pattern: 4 / 1 satin.

[0033] Adopt the method for promoting the active dyeing depth of pure cotton fabric of the present invention to process above-mentioned pure cotton fabric, the steps are as follows:

[0034] (1) Rolling material: The composition of the dyeing liquor used is: reactive black 62.18g / L, reactive blue 10.25g / L, reactive red 3.72g / L, penetrant 5g / L, anti-swimming agent 12g / L, rolling residue rate of 65%.

[0035] (2) Rolling and stacking: the temperature is 38°C, the stacking time is 4 hours, and the rotation speed is 20r / min.

[0036] (3) Drying: Infrared pre-drying temperature is 630°C, the temperature of 1-3# drying room is 110°C, 120°C, 120°C respectively, and the circulating air of 1-3# drying room is 80%, 90%, and 90% respectively.

[0037] (4) Steaming and color fixing: sequentially carry out padding color fixing solution, steaming, water washing, and soaping; Dyeing sa...

Embodiment 3

[0040] A pure cotton fabric specification: CM40*CM40*133*72*57 / 58, pattern: plain weave

[0041] Adopt the method for promoting the active dyeing depth of pure cotton fabric of the present invention to process above-mentioned pure cotton fabric, the steps are as follows:

[0042] (1) Rolling material: The composition of the dyeing solution used is: reactive black 25.30g / L, reactive blue 3.28g / L, reactive red 6.42g / L, penetrant 4g / L, anti-swimming agent 10g / L, rolling residue rate of 67%.

[0043] (2) Rolling and stacking: the temperature is 36°C, the stacking time is 3 hours, and the rotation speed is 18r / min.

[0044] (3) Drying: Infrared pre-drying temperature is 660°C, the temperature of 1-3# drying room is 110°C, 120°C, 120°C respectively, and the circulating air of 1-3# drying room is 80%, 90%, and 90% respectively.

[0045](4) Steaming color fixing: Carry out padding color fixing solution, steaming, water washing, soaping successively; Dyeing salt 2g / L, darkening agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com