Water stopping method, wire harness processed by the method and water stopping apparatus

A waterproof device and wire harness technology, applied in the direction of line/collector parts, cables, insulated conductors, etc., can solve the problems of reduced core wire gap, abnormal conduction of terminal 52, insufficient waterproof effect, etc., and achieve equipment cost reduction , Improve productivity and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

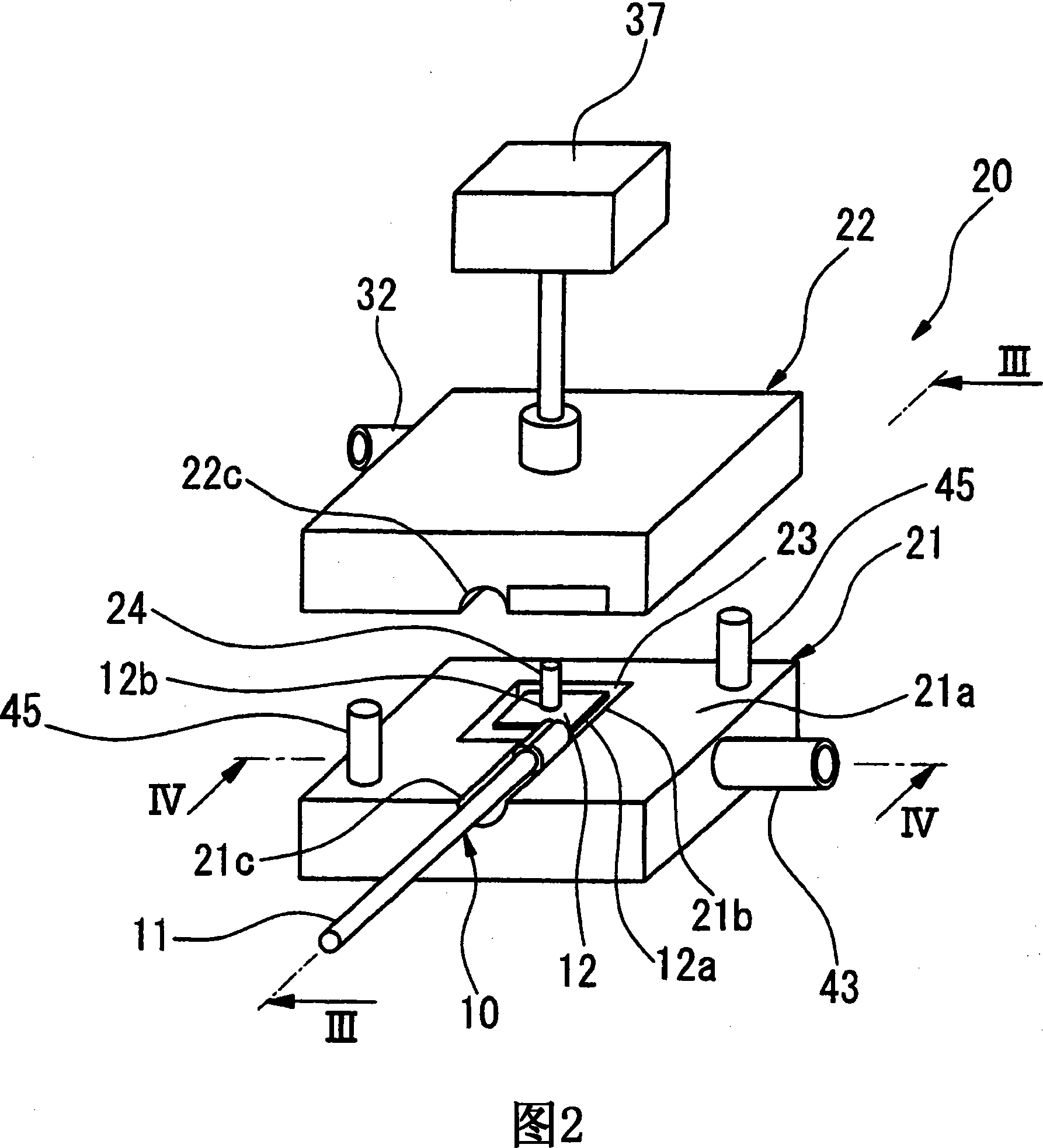

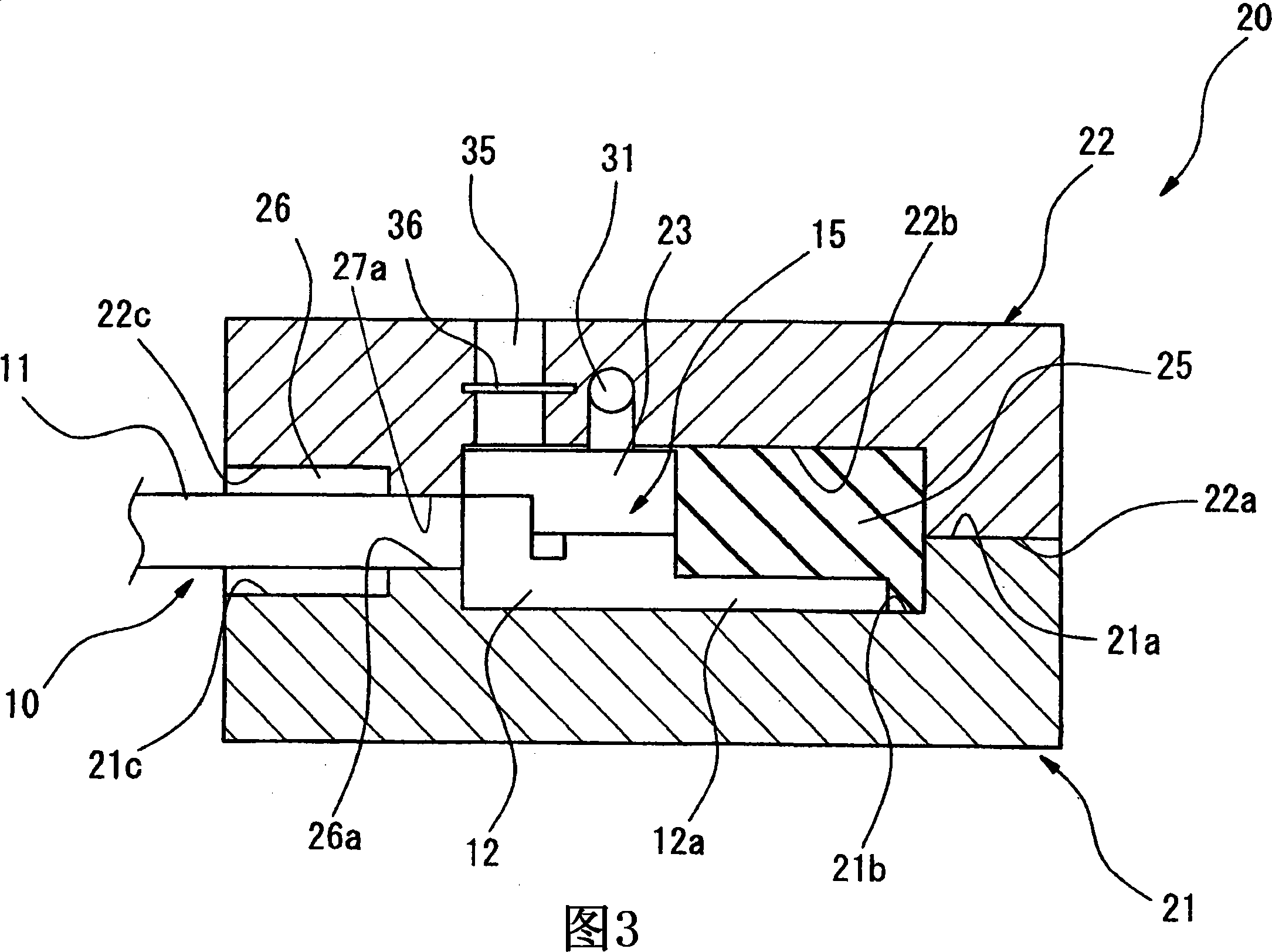

[0079] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0080] Here, an example of a wire harness is given, which includes: a covered electric wire having an insulating covering formed along a plurality of core wires and the periphery of the core wire bundle, and a core wire bundle exposed portion exposed at one end of the covered electric wire The crimped terminals are used to illustrate the waterproofing method, wire harness and waterproofing device of the present invention in which the waterproofing material is forcibly infiltrated between the core wires from the exposed part of the core wire bundle to the inside of the insulation covering.

[0081] Hereinafter, embodiments of the waterproof method, wire harness, and waterproof device of the present invention will be described with reference to the drawings.

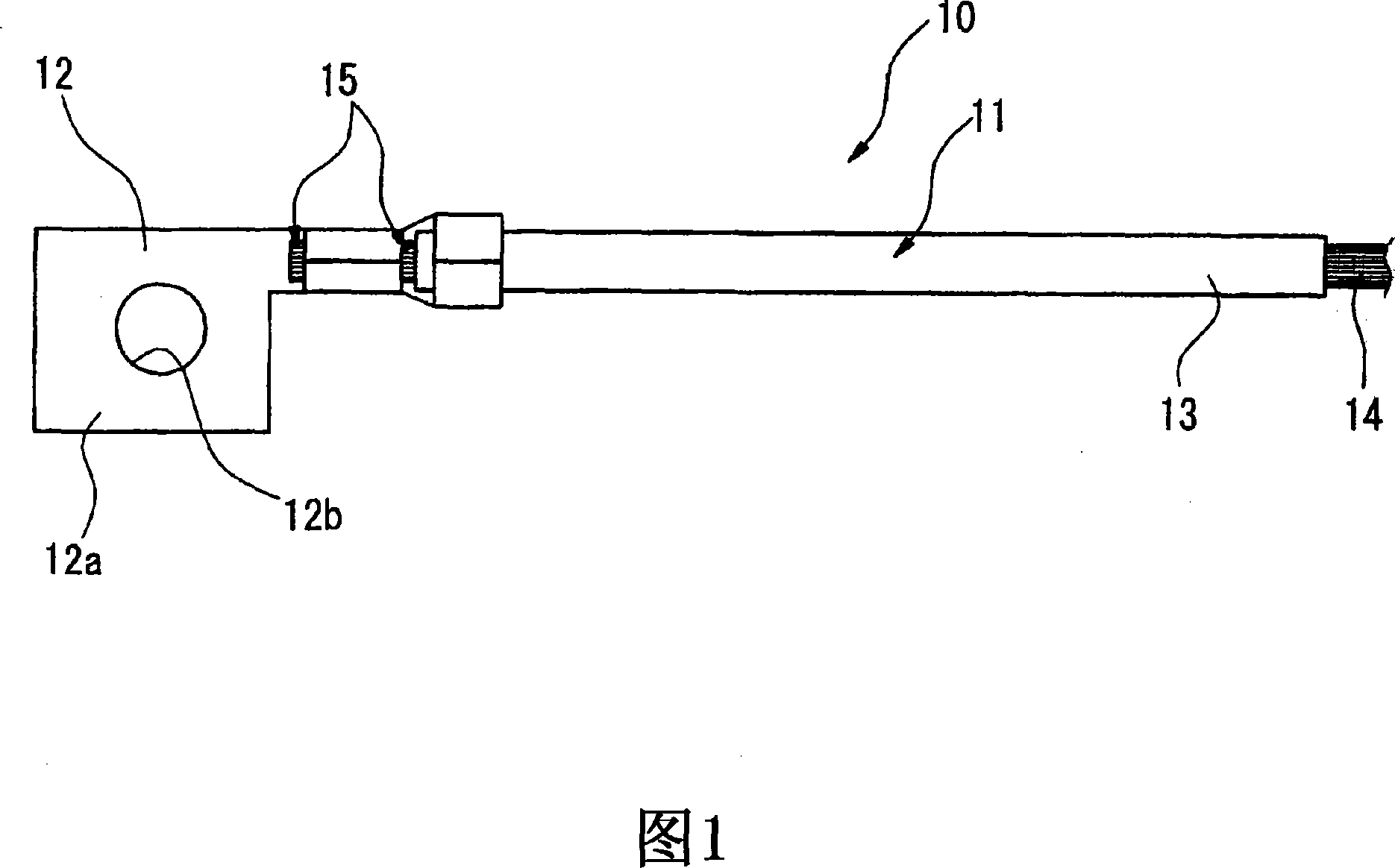

[0082] Fig. 1 is a top view of a coated electric wire that is waterproofed by the waterproof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com