Zero pressure and permeation for preparation of carbon nanometer tube reinforced aluminum base composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparing carbon nanotubes reinforced aluminum matrix composite materials by pressureless infiltration, can solve the problems of difficulty in preparing large components, difficulty in controlling particle uniformity, and limitation of reinforcement phase ratio, etc. Low requirements for equipment, high density and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

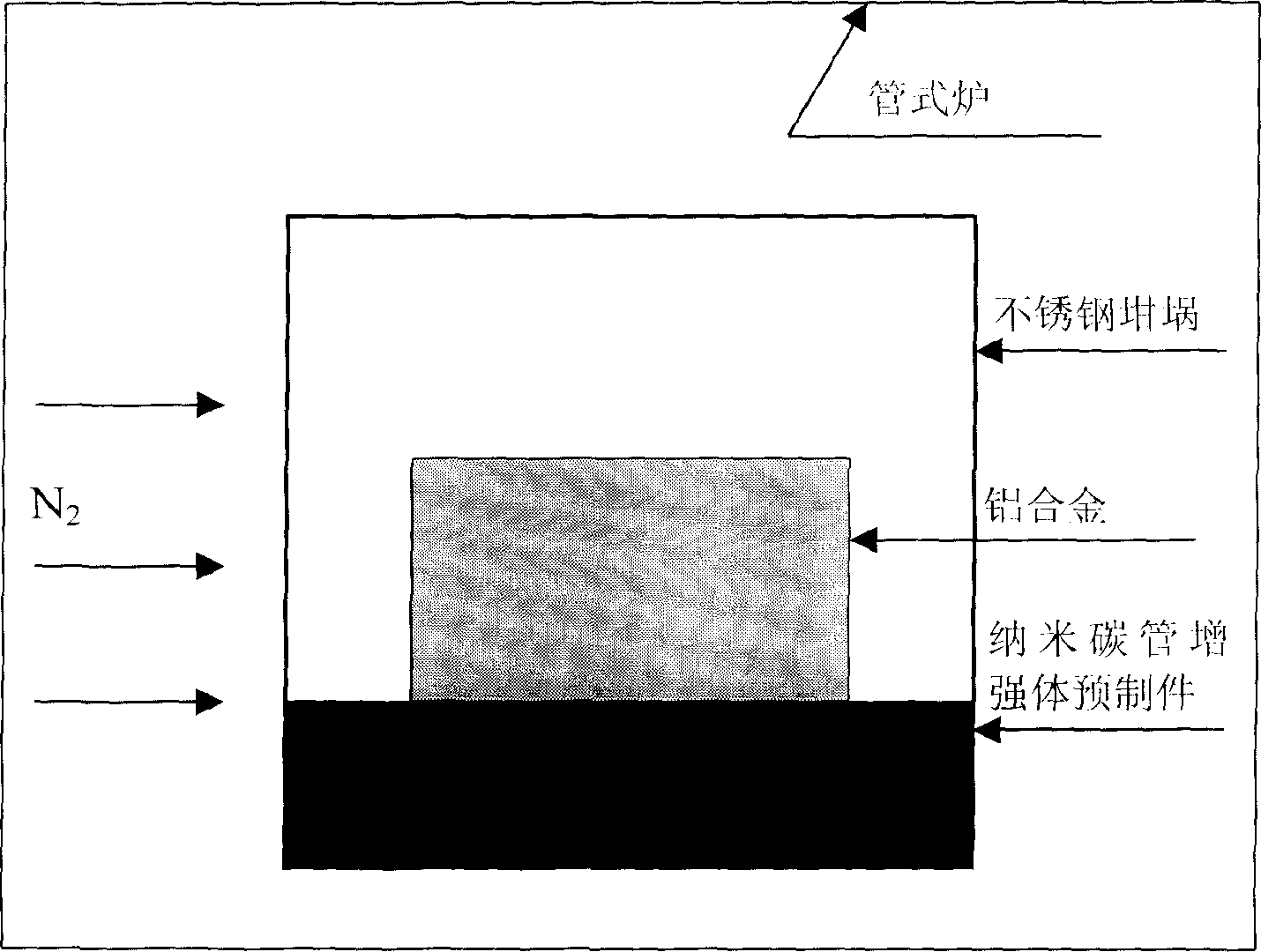

Embodiment 1

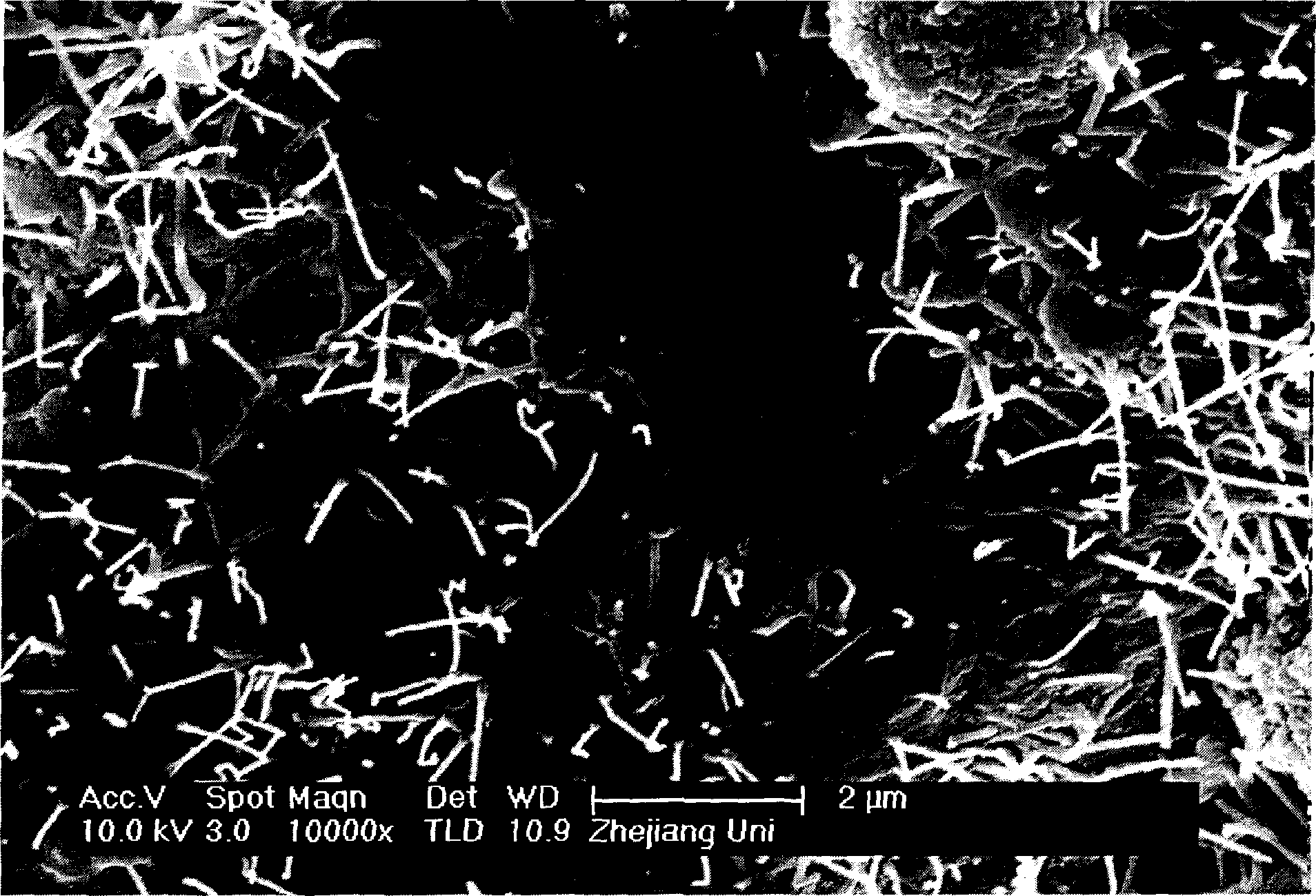

[0013] The powder with volume content of CNTs=10%, Mg=20%, Al=70% is ball-milled and blended in a stainless steel tank under the protection of argon, and the ball-milled powder is molded into a preform and put into a stainless steel crucible, and the aluminum Place the alloy on top of the reinforced powder, put them together in a tube furnace, heat them to 800°C under a nitrogen atmosphere, and keep them warm for five hours, then take them out after the furnace cools down, and then get a carbon nanotube reinforced aluminum with a volume content of 10%. base composite material. figure 2 Shown is the field emission scanning (FEG-SEM) photograph of the fracture of the carbon nanotube-reinforced aluminum matrix composite after infiltration.

Embodiment 2

[0015] The powder with volume content of CNTs=5%, Mg=21.1%, Al=73.9% is ball milled and blended under the protection of argon in a stainless steel tank, and the ball milled powder is molded into a preform and put into a stainless steel crucible, and the aluminum The alloy is placed above the reinforced powder, and then they are put together in a tube furnace and heated to 800°C under a nitrogen atmosphere, and kept for five hours, and then taken out after the furnace cools down to obtain a carbon nanotube reinforced aluminum with a volume content of 5%. base composite material.

Embodiment 3

[0017] The powder with the volume content of CNTs=20%, Mg=17.8%, Al=62.2% is ball milled and blended in a stainless steel tank under the protection of argon, and the ball milled powder is molded into a preform and put into a stainless steel crucible. Place the aluminum alloy on top of the reinforced powder, put them together in a tube furnace, heat them to 800°C under a nitrogen atmosphere, keep them warm for five hours, and take them out after the furnace cools down, so that the carbon nanotubes with a volume content of 20% are produced Reinforced aluminum matrix composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com