Method and equipment for conditioning and heat-setting textile articles

A processing method and technology for textiles, applied in textiles and papermaking, equipment configuration for processing textile materials, heating/cooling fabrics, etc., can solve the problems of diluting steam, increasing the number of continuous processing cycles, entering, etc., to achieve low-cost, fast cycle , the effect of uniform humidity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

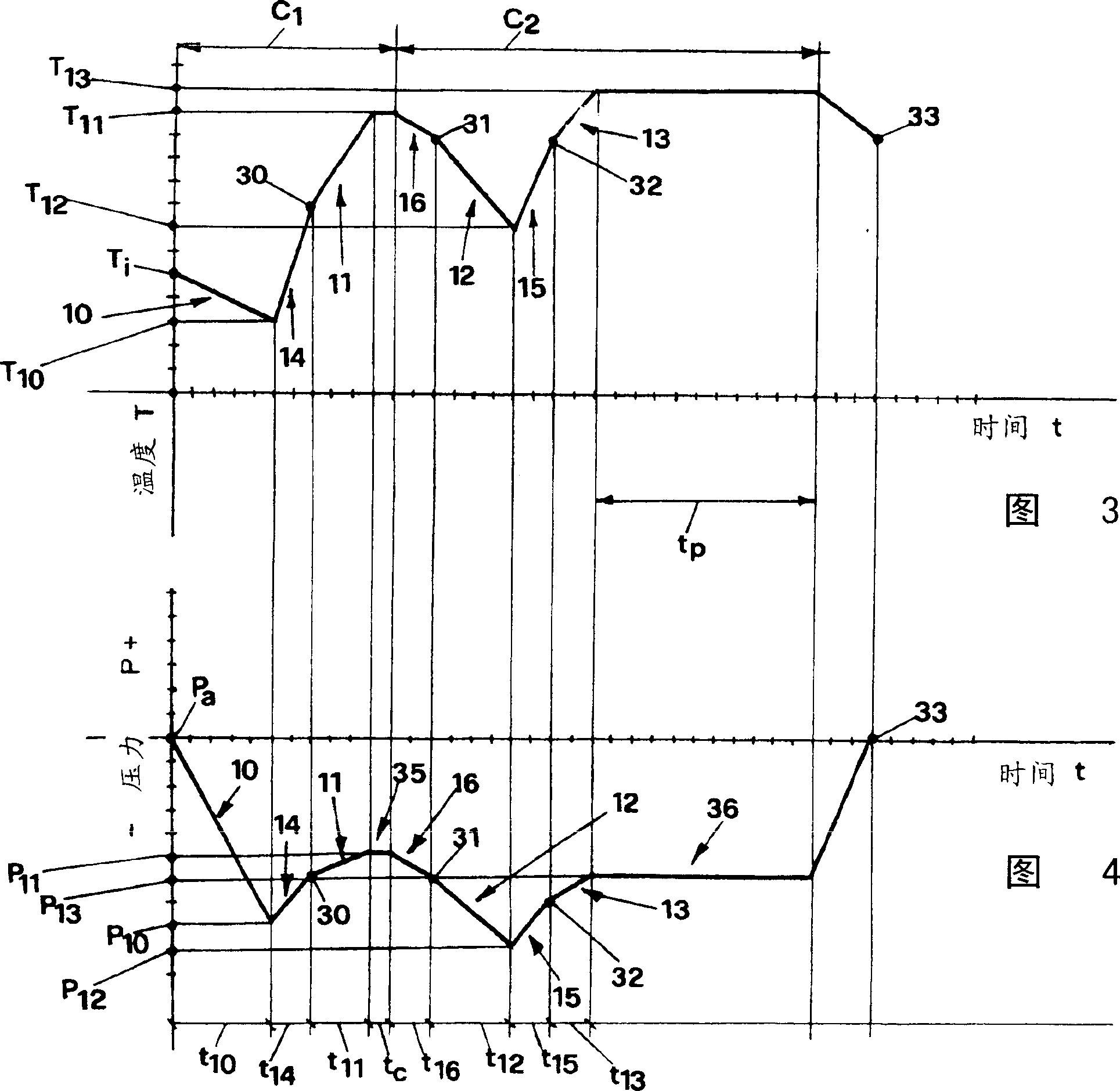

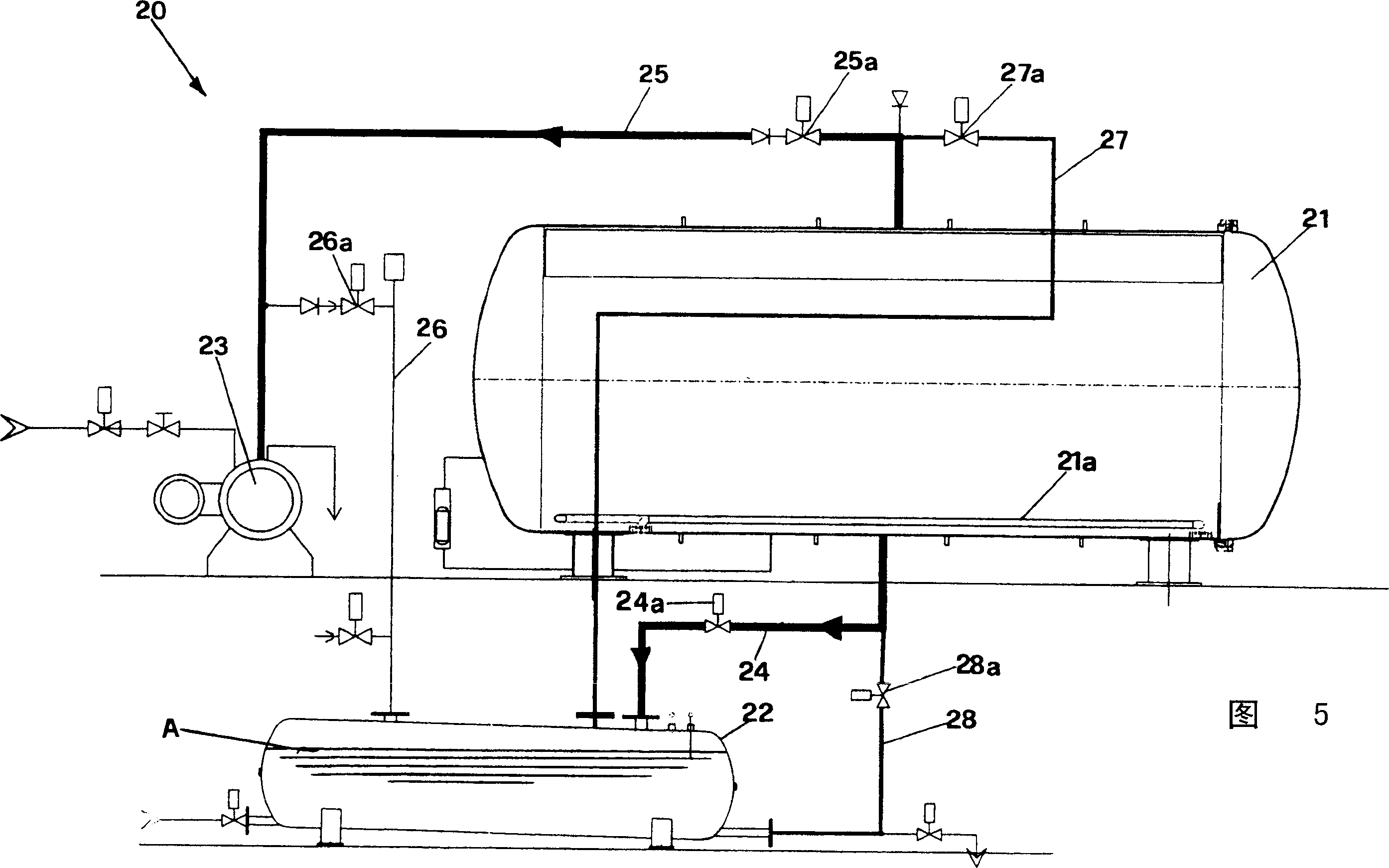

[0048] The treatment method of the present invention will be described in conjunction with the temperature-pressure diagrams respectively shown in FIGS. 3 and 4 and the equipment for realizing the method is generally indicated by 20 in FIGS. 5 and 6, which includes: an autoclave 21; a water recovery tank 22 ; Vacuum pump 23 .

[0049] The method and apparatus of the present invention will be further described below when used to treat yarn; however the same method and apparatus can also be used for the treatment of yarn and other textiles.

[0050] As regards the processing method, it consists in feeding the conical bobbins or bobbins of yarn to be processed into the autoclave 21, which are arranged on suitable support fixtures so that the steam circulates freely in the conical bobbins or bobbins .

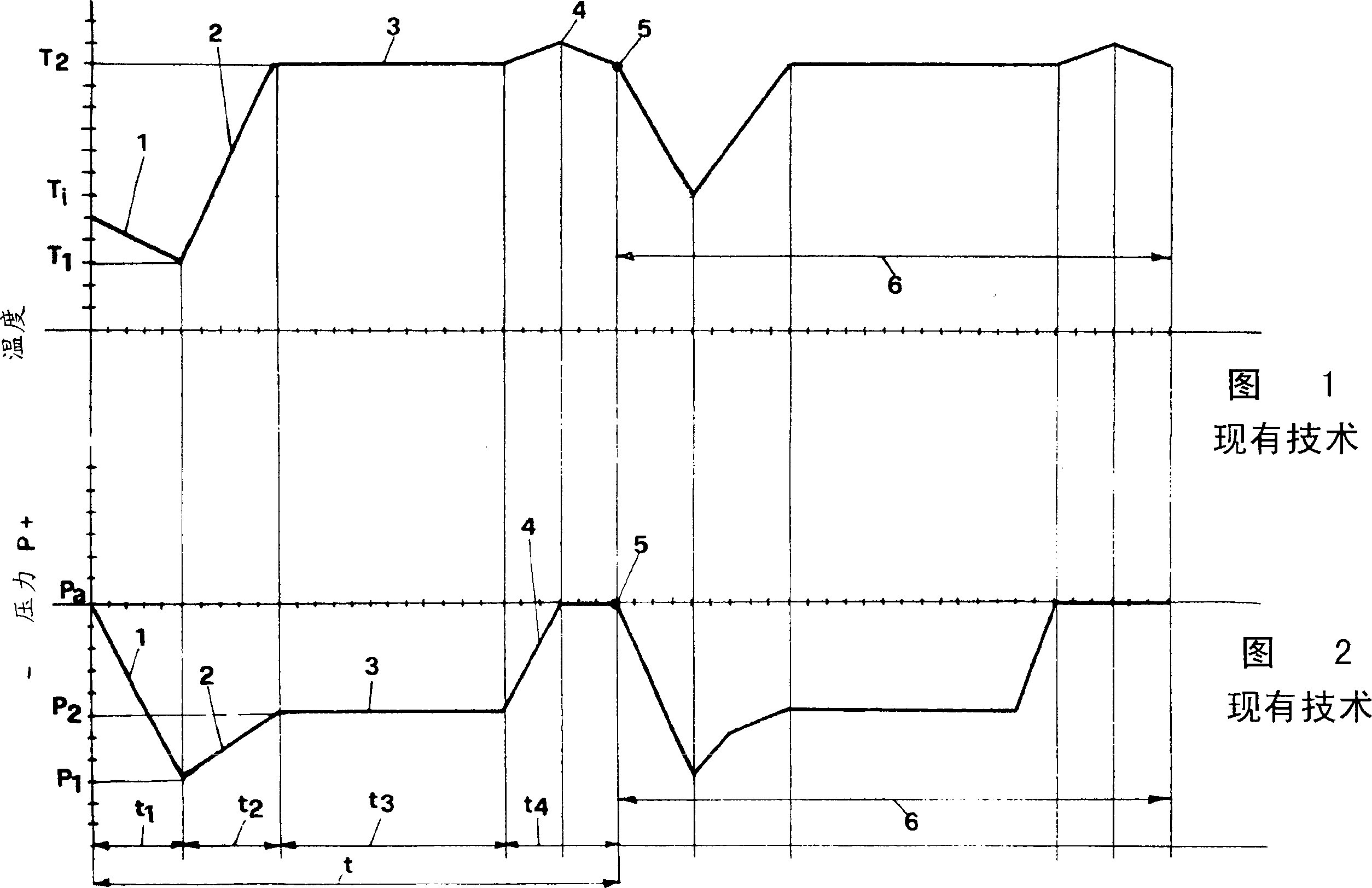

[0051] Preferably, but not necessarily, the thermal cycle is two and is denoted C1 and C2 in Figures 3 and 4, where it can be seen that each cycle includes a negative pressure pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com