Fixation method and equipment for screen printing of natural fiber fabrics by reactive dye

A technology of reactive dyes and natural fibers, which is applied in the processing of textile materials equipment configuration, textile material processing, textiles and papermaking, etc., can solve the problems of screen printing dye delay, adhesion, color matching, deformation and distortion of screen printing, and achieve anti- Suffering from "seam head" flaws and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A color-fixing method for screen printing natural fiber fabrics with reactive dyes, the grammage output by screen printing equipment is >200g / m 2 The reactive dye screen printing printed cotton fabric is the color fixing object, and the wet pile fixing method is adopted, and the following steps are followed in turn:

[0062] a, screen printing fabrics for the front side of the reactive dyes, lining the isolation chemical fiber fabric polyester cloth, and the cloth heads of the two are wound together on the wet stack winding roller;

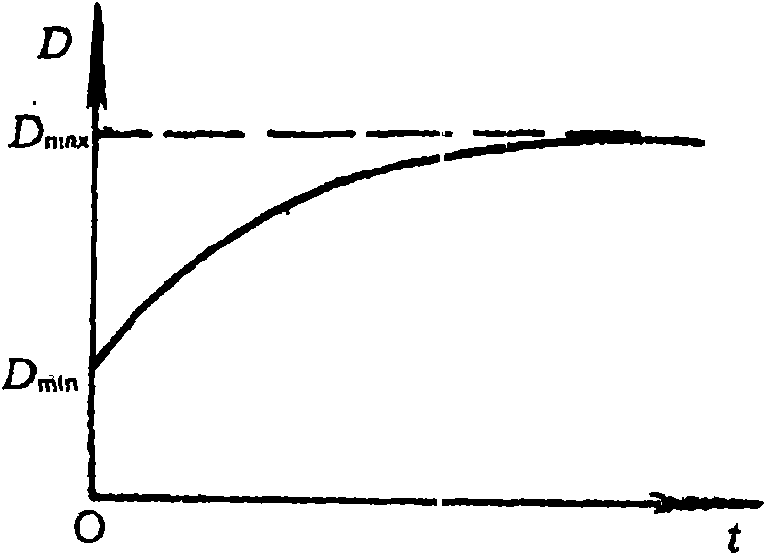

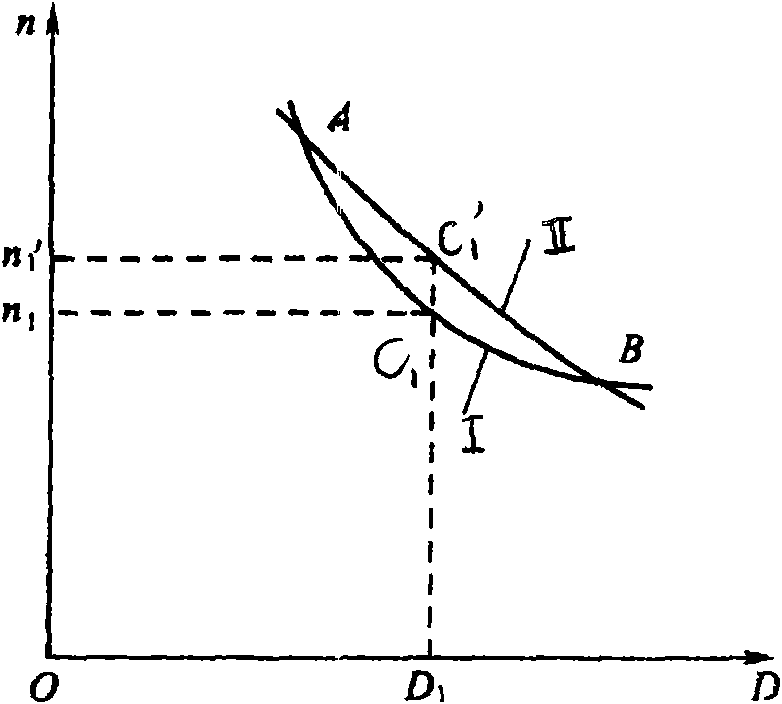

[0063] b. The screen printing cloth on the front side of the fabric reactive dye is directly output by the screen printing equipment and moves in open width, and enters the wet stack production unit together with the isolated chemical fiber fabric polyester cloth. Coil into a shaft. Then the winding roller is separated from its driving motor, and then the winding roller full of the fabric is transported to the wet stacking area through the...

Embodiment 2

[0066] A color-fixing method for screen-printed natural fiber fabrics with reactive dyes, the weight of which is downloaded and output by screen-printing equipment is 2 The reactive dye screen printing silk fabric is the color fixing object, and the wet pile fixing method is adopted; in its processing steps, except for the winding line speed of the winding roller described in the b step, the line moving with the open width of the screen printing fabric The ratio of speed is 1: 1.05, and the wet stacking time described in step b is 15 hours, others are all the same as embodiment one.

Embodiment 3

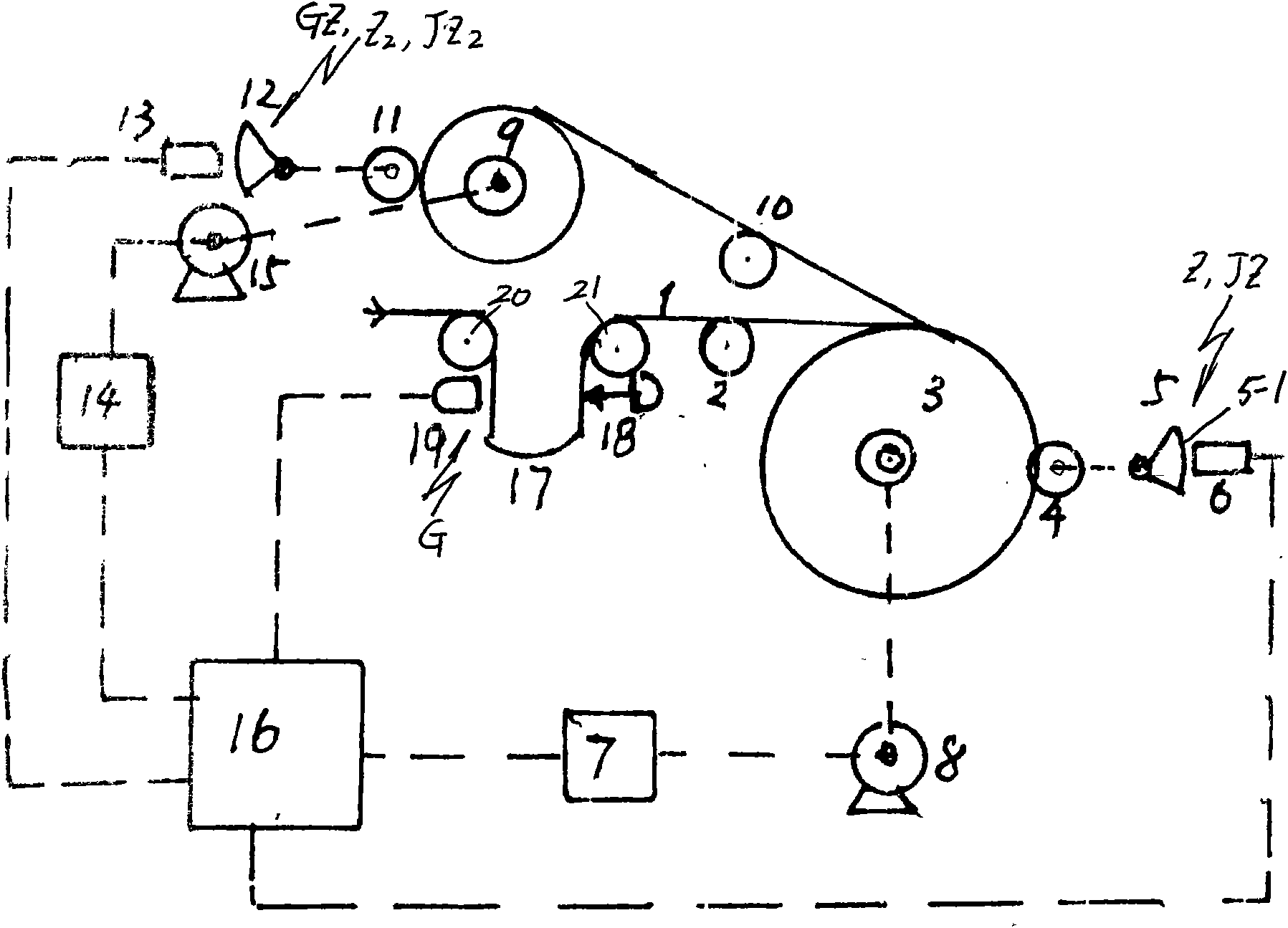

[0067] Embodiment three, please refer to the attached image 3 .

[0068] A kind of equipment that is used for described fabric color fixing method, comprises a wet stack winding roller 3; The wet stack winding roller 3 can be supported on the A frame and can rotate; A motor 8; The motor 8 can be connected with The wet stack winding roller 3 is coaxially quickly assembled and disassembled; a frequency converter 7; the frequency converter 7 is electrically connected to the motor 8; a PLC controller 16; the PLC controller 16 is electrically connected to the frequency converter 7; 21; a pair of cloth guide rollers 20, 21 are arranged on the cloth feeding side of the wet stack winding roller 3, and a distance is kept between the two; thereby making the fabric form a vertical loop 17 in its open-width movement; a photoelectric control Device pair G; the light source 18 and the photoelectric sensor 19 of the photoelectric controller pair G are respectively arranged under a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com