Production method for jet printing and dyeing warp yarns of knitted fabric and special device

A technology of woven fabrics and production methods, which is applied to the processing of textile materials, equipment configuration for processing textile materials, and storage of roll-shaped textile materials. It can solve the problems of difficult product quality control, low production efficiency, and high production costs, and achieve production The structure of the device is reasonable, the working effect is good, and the quality is controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

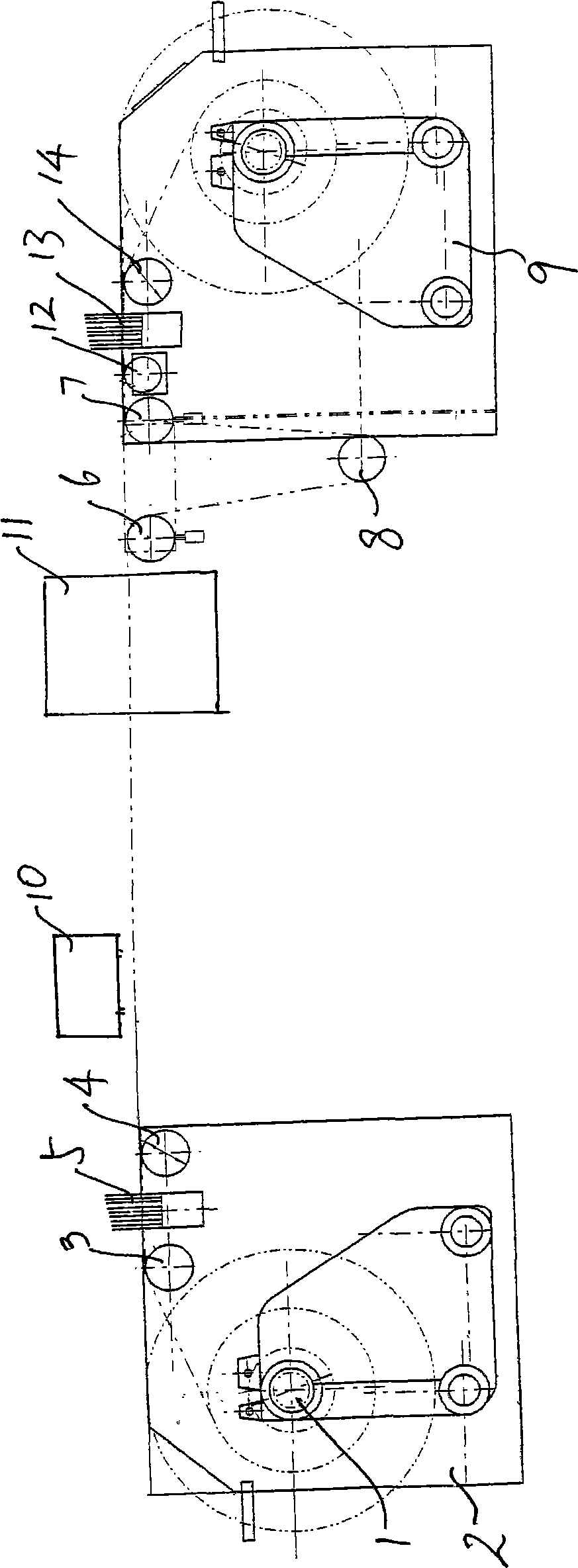

[0020] A kind of production method of warp jet printing and dyeing of woven fabric comprises the following steps:

[0021] (1) Warp the warp yarns of the woven fabric on the warp beam;

[0022] (2) the warp beam is contained on the warp yarn jet printing, dyeing, drying conveying mechanism, and the described conveying mechanism comprises a warp yarn feeding mechanism and a warp yarn take-up mechanism, and the warp yarn sent out by the warp yarn feeding mechanism is through jet printing or jet dyeing, And after drying, the warp yarn of printing or dyeing is wound on the warp beam by the warp yarn take-up mechanism. The jet printing or jet dyeing is performed by a jet head. Spray head is installed on the outer whole piece of warp yarn of warp yarn feeding mechanism guide roller. Drying is carried out by drying mechanism, and drying mechanism is contained in the outer side of guide roll of warp thread take-up mechanism, on the upper and lower sides of whole piece of warp yarn. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com