Improved clothing textile cloth dyeing, drying and winding device

A technology for textile cloth and equipment, which is applied in the field of cloth drying and winding equipment, can solve the problems that the adjustment of cloth roll thickness, the adjustment of winding cloth elastic structure is not perfect, the structure is not perfect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

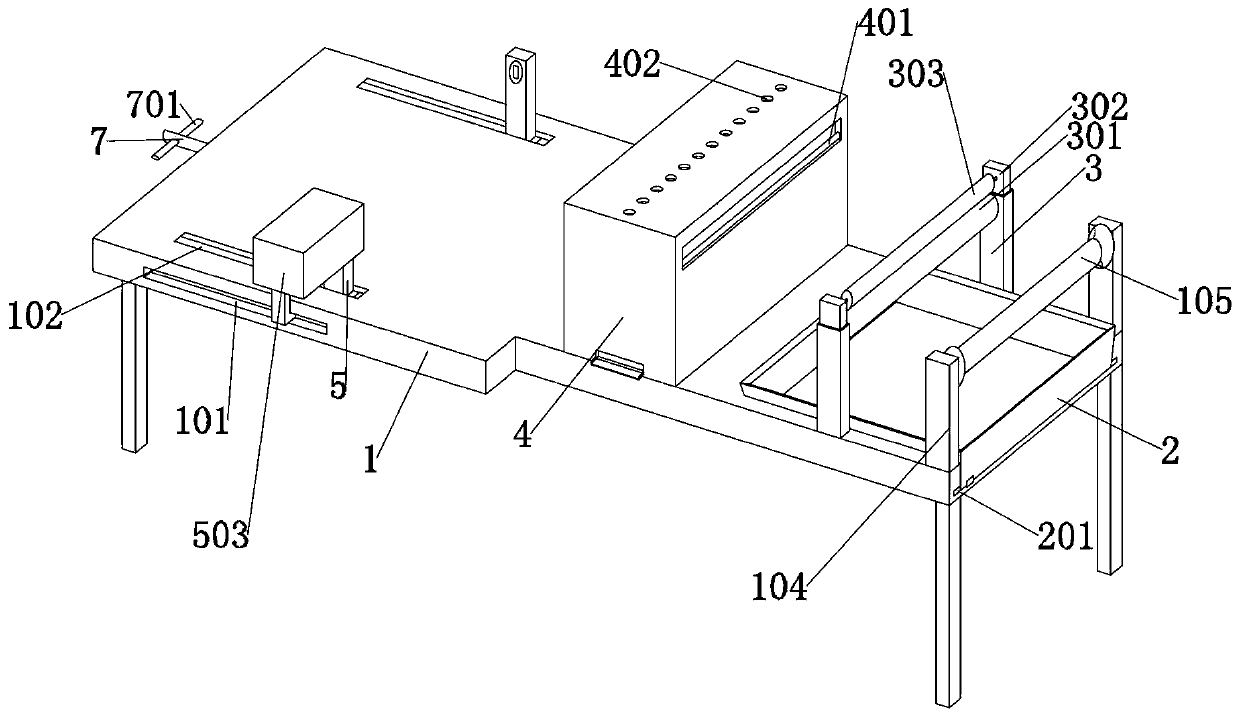

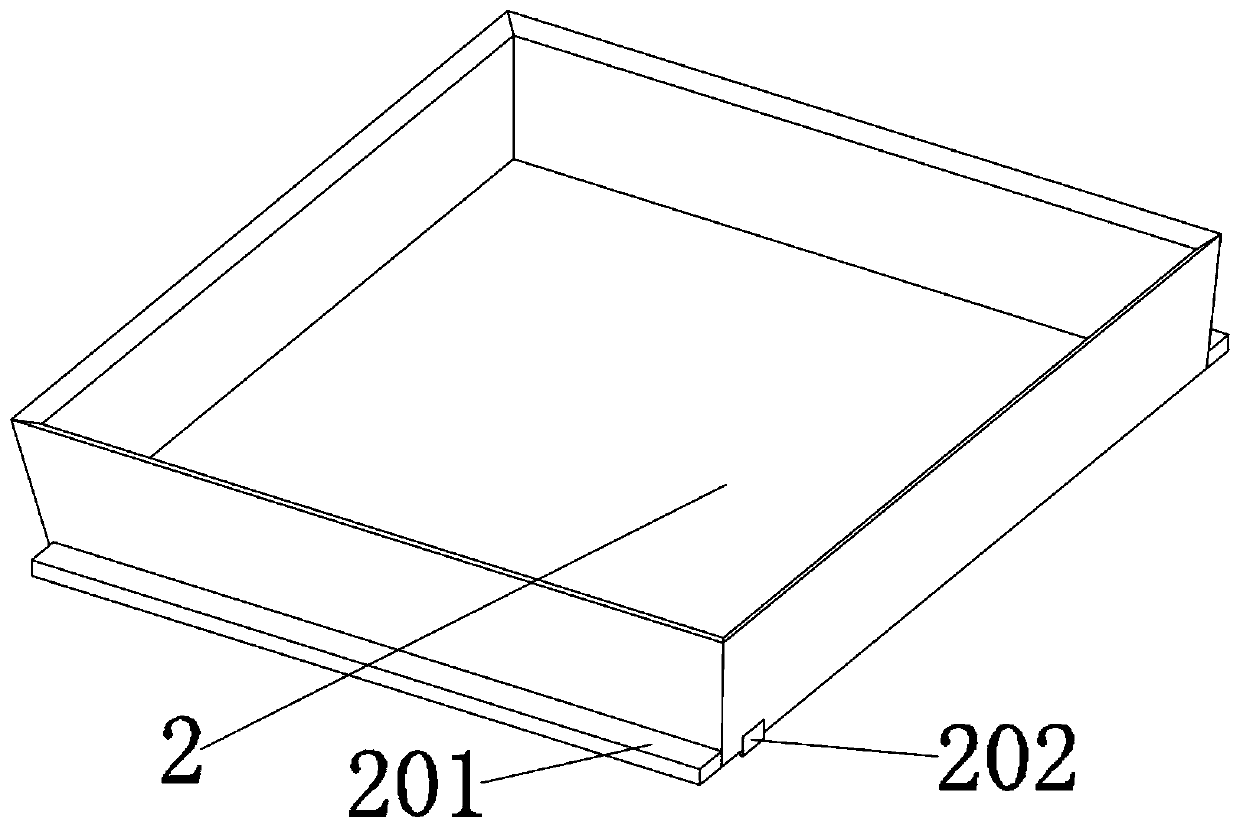

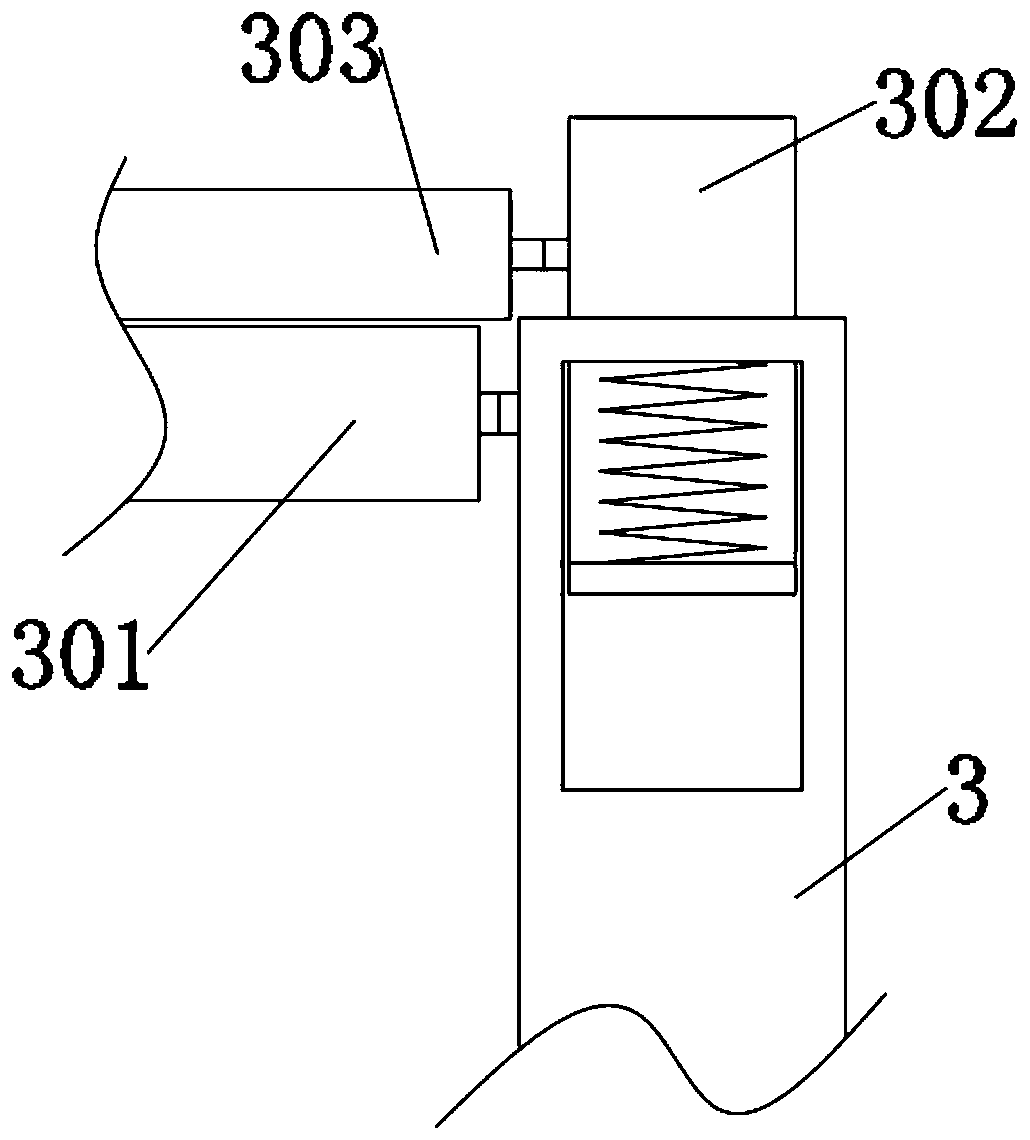

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033]The invention provides an improved dyeing, drying and rolling equipment for clothing textile fabrics, which includes: a main body 1, a side tank 101, an inner compartment 102, a retaining slot 103, a support rod 104, a guide rod 105, a moving bin 2, a guide Part 201, switch part 202, bottom part 3, bottom rod 301, tension part 302, tension rod 303, drying bin 4, guide rod 401, air outlet 402, dryer 403, flow guide part 404, moving part 5. Embedding groove 501, rotating part 502, motor compartment 503, shaft 6, guide 601, inserting rod 602, rotating rod 7, manual rod 701 and baffle 702; main body 1 is a plate-shaped structure, and the bottom of main body 1 The corners are installed with supporting feet by welding, and the side of the main body 1 is provided with a side groove 101 of rectangular structure, and the interior of the main body 1 is provided with an inner compartment 102, and the upper right edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com