Pure cotton fabric and non-ironing finishing method thereof

A technology of non-iron finishing and pure cotton fabrics, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., which can solve the problem of fabric slippage and high non-ironing appearance. It is a qualitative help for product development , It is difficult to spin yarns and other problems, to achieve the effect of good fabric warp and weft wrinkle recovery angle performance, fabric non-ironing performance improvement, non-ironing tear strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

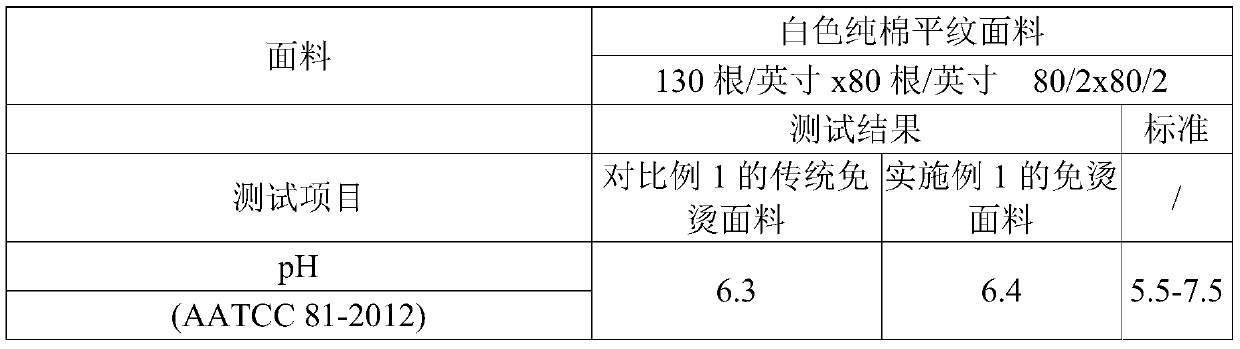

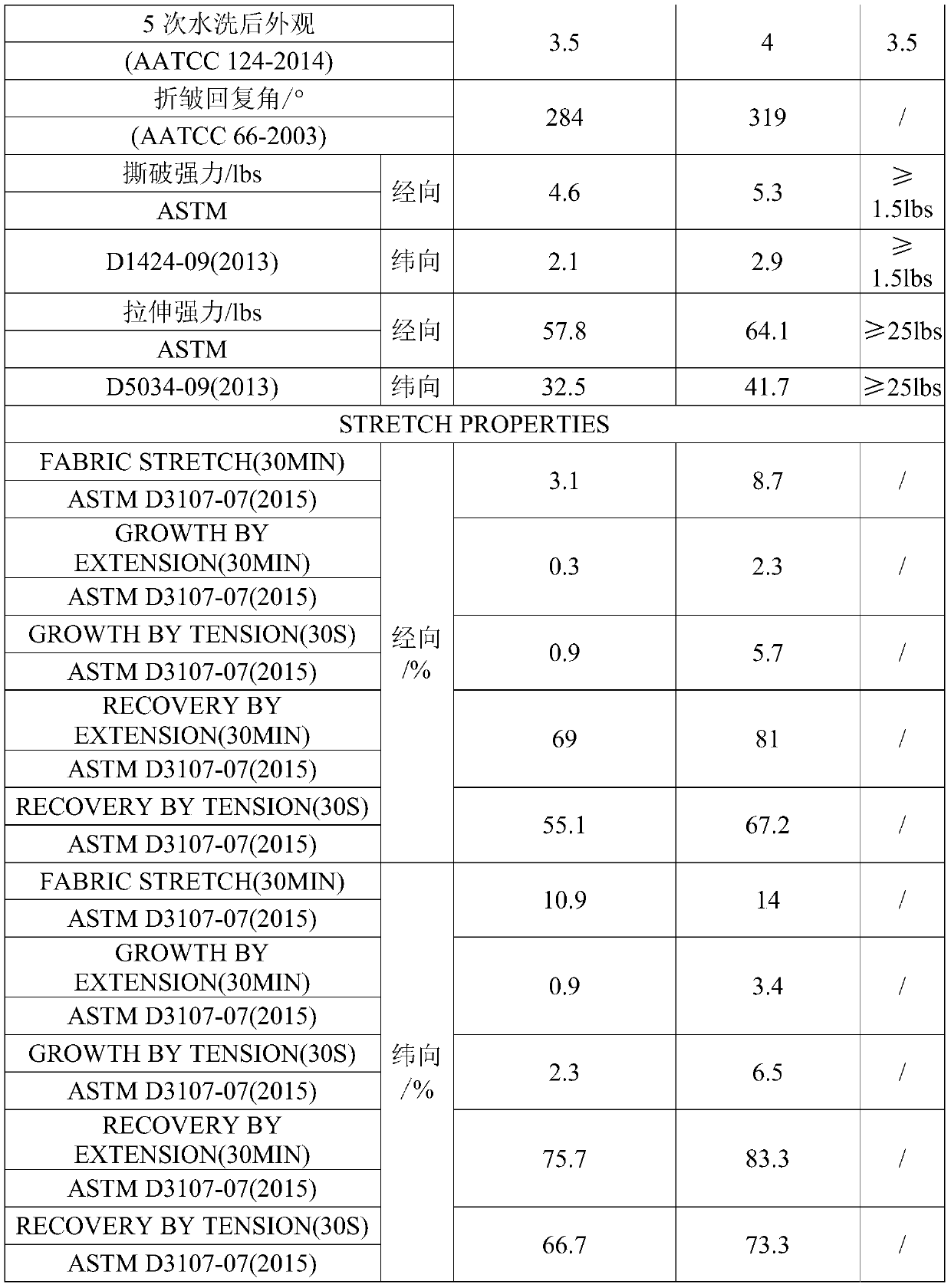

Embodiment 1

[0045] The present embodiment provides a high non-iron method for improving tear strength, which comprises the following steps:

[0046] Plain weave, its specification is pure cotton 80s / 2×pure cotton 80s / 2, and the warp density×weft density is 130×80 threads / inch.

[0047] After the fabric is desized by desizing enzyme, it passes through the integrated scouring and bleaching machine equipped with scouring, bleaching and finishing liquid. The concentration of caustic soda in the scouring, bleaching and finishing liquid is 140g / L, and then it is arranged to be rolled and stacked in a wet state. at 25°C, the stacking time is 8 hours, and then scouring, bleaching and steaming at 110°C for 2 minutes;

[0048] Afterwards arrange padding resin shaping finishing solution, which contains 20% resin finishing agent, 2% resin catalyst, 5% amino silicone softener, 4% strong protective agent, and 0.3% penetrating agent. The fabric is dipped and rolled in the finishing solution, dried by a...

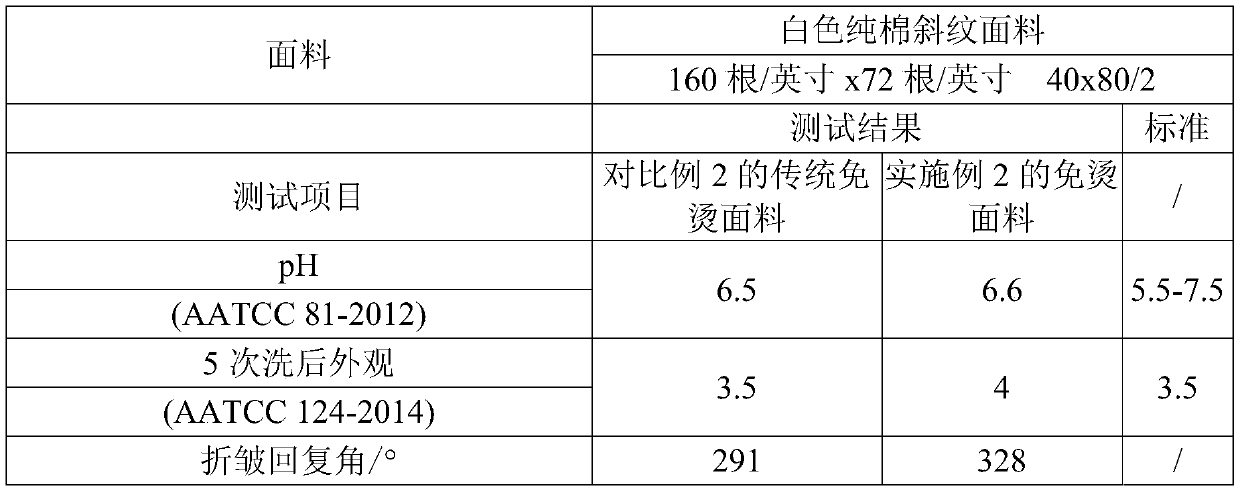

Embodiment 2

[0058] The present embodiment provides a high non-iron method for improving tear strength, which comprises the following steps:

[0059] Twill fabric, its specification is pure cotton 40s × pure cotton 80s / 2, and the warp density × weft density is 160 × 72 threads / inch.

[0060] After the fabric is desized by desizing enzyme, it passes through the integrated scouring and bleaching machine equipped with scouring, bleaching and finishing liquid, in which the concentration of caustic soda in the scouring, bleaching and finishing liquid is 160g / L, and then it is arranged to be rolled and stacked in a wet state at a stacking temperature of 30°C , stacked for 12 hours, and then bleached and steamed at 110°C for 2.5 minutes;

[0061] Afterwards arrange the resin finishing and shaping, the resin finishing solution contains 18% resin finishing agent, 1.8% resin catalyst, 5.5% amino silicone softener, 4.5% strong protective agent, 0.3% penetrating agent, the fabric is finished Dipping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com