Fabric printing and cutting device for textiles

A cutting and printing technology, applied in the cutting of textile materials, textiles and papermaking, printing, etc., can solve the problems of inability to mass-produce products, low production efficiency, and imperfect subsequent printing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below.

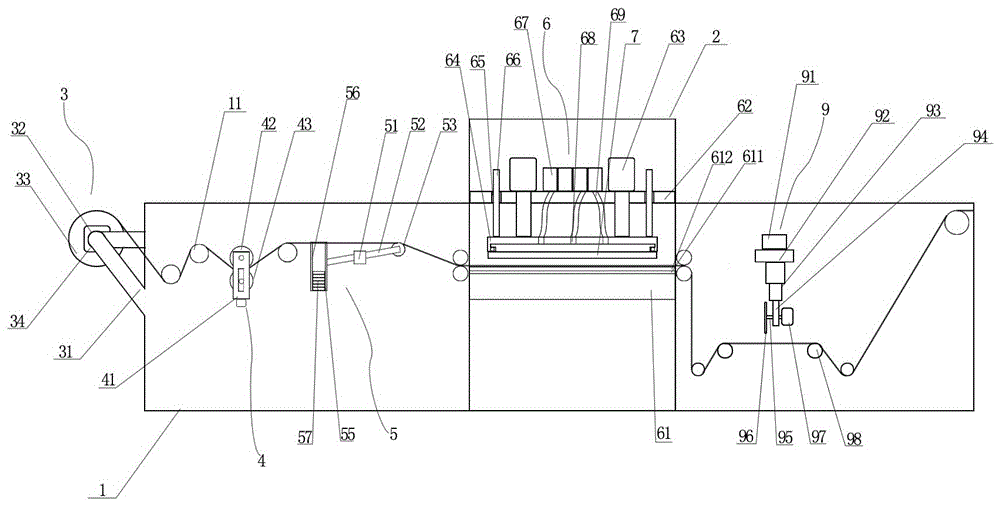

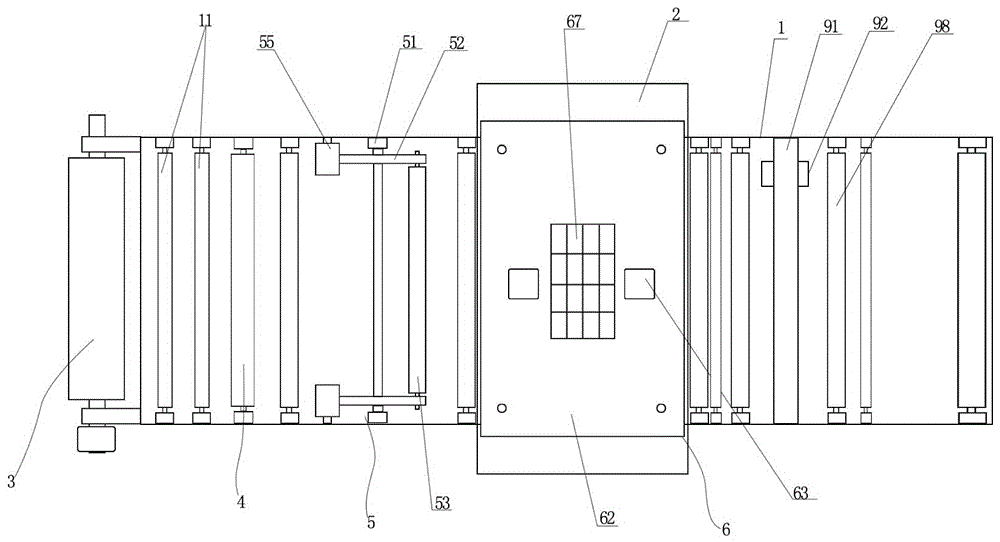

[0020] like Figure 1 to Figure 3 As shown, a weaving printing and cutting device for weaving of the present invention includes a first frame 1 and a second frame 2 arranged in a cross, and the second frame 2 is higher than the second frame 2, and is characterized in that : the first frame 1 includes a feeding device for conveying the weaving, and the second frame 2 includes a printing mechanism 6 for weaving printing;

[0021] The feeding device includes a loom stocker 3, a loom tractor 4 and a tension mechanism 5, the loom stocker 3 is arranged on the outer side of the first frame 1, and the loom tractor 4 is provided with two In the first frame 1 and divided into both sides of the second frame 2, the tensioning mechanism 5 is arranged in the first frame 1 between the weaving tractor 4 and the second frame 2;

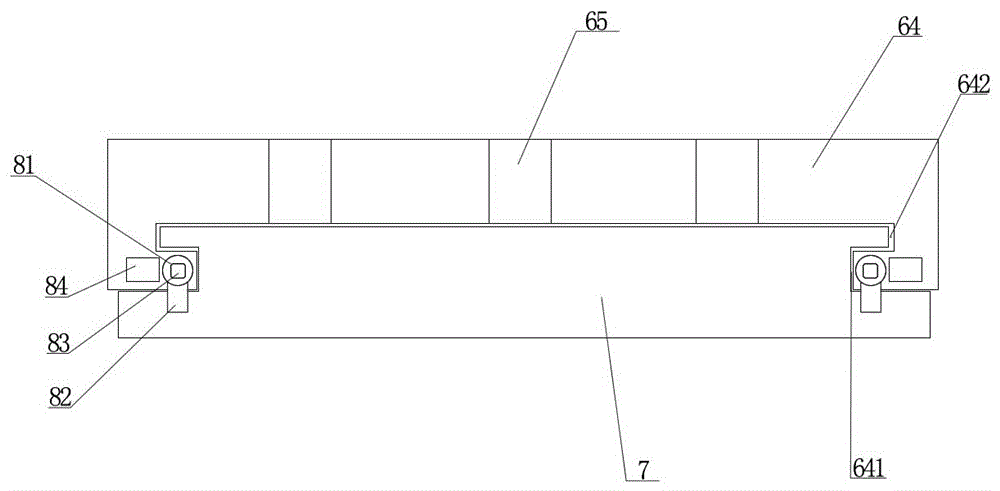

[0022] The printing mechanism 6 includes a receiving seat 61 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com