Cloth flattening apparatus

A leveling device and cloth technology, applied in textile and papermaking, fabric surface trimming and other directions, can solve problems such as unfavorable cloth winding, folding or wrinkling, and achieve the effect of improving market competitiveness, convenient winding and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

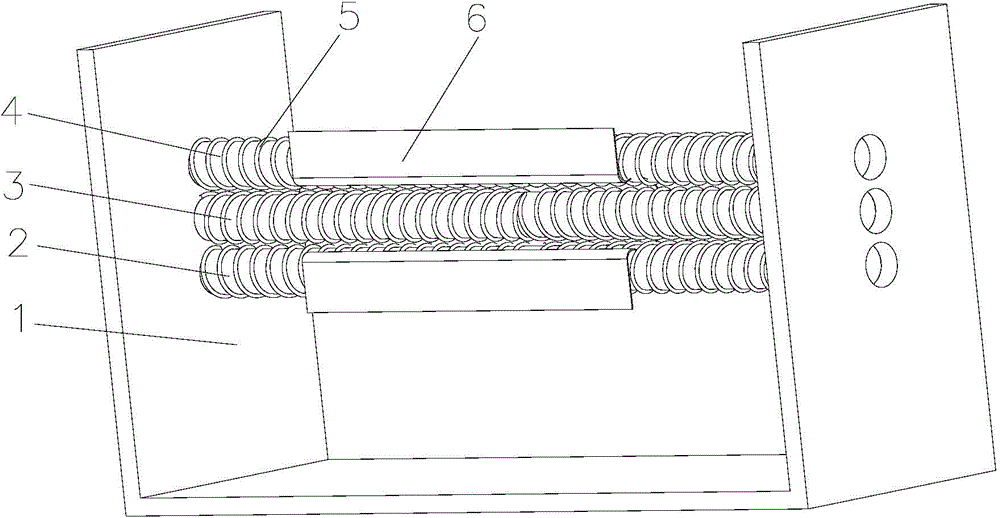

[0016] Such as figure 1 As shown, a fabric leveling device includes a frame 1 and a cloth 6 to be leveled. A number of round rollers are rotatably connected to the frame 1. The two ends of the round rollers are distributed with threads with opposite rotation directions. The round rollers have three respectively Be the first round roller 3, the second round roller 2 and the third round roller 4, the first round roller 3 is in contact with the front of the cloth 6, the second round roller 2 and the third round roller 4 are all in contact with the back side of the cloth 6, The first round roller 3 and the second round roller 2 have the opposite helical directions at the corresponding positions, the second round roller 2 and the third round roller 4 have the same helical directions at the corresponding positions, and the third round roller 4 is at the first Directly above the round roller 3, the first round roller 3 is directly above the second round roller 2, the tooth width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com