Novel wire coil for cable production

A new type of cable technology, which is applied in the field of reels for new cable production, can solve the problems of uneven winding, slow winding speed, messy winding of cables, etc., and achieve the effect of speeding up, avoiding disorder, and maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

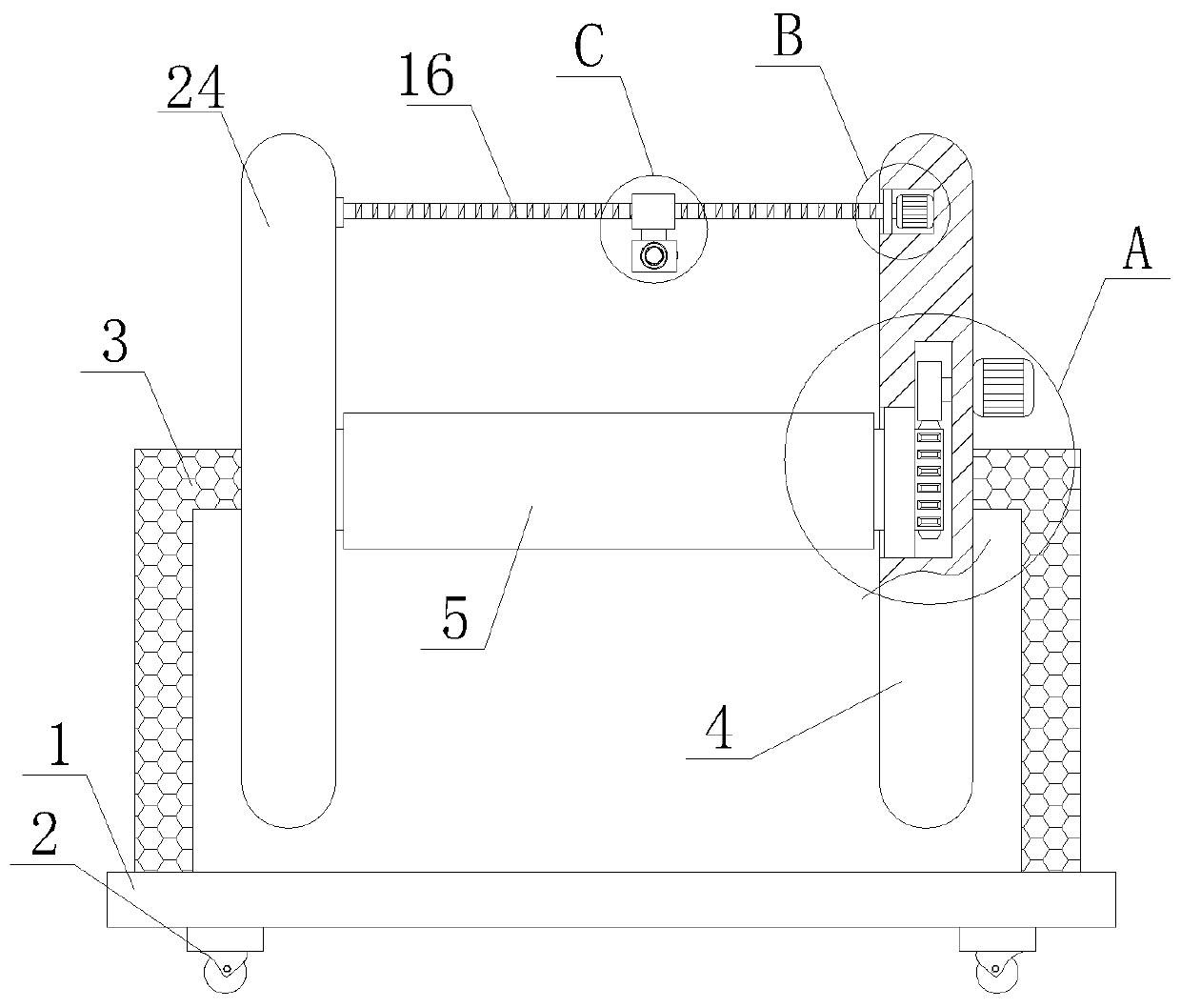

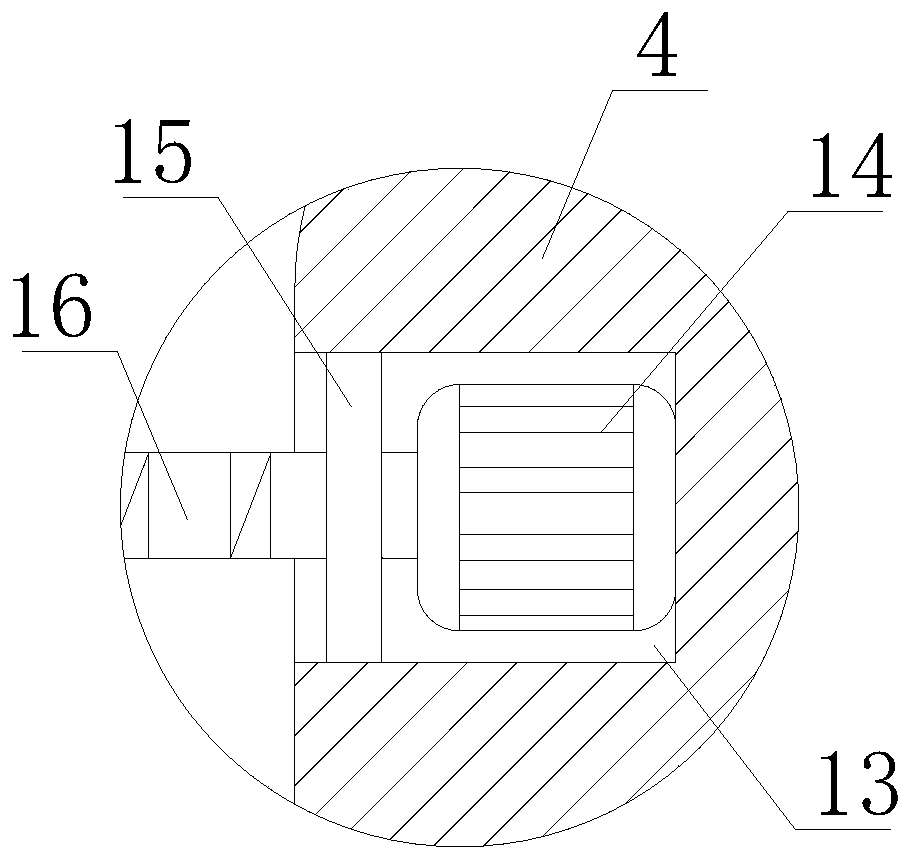

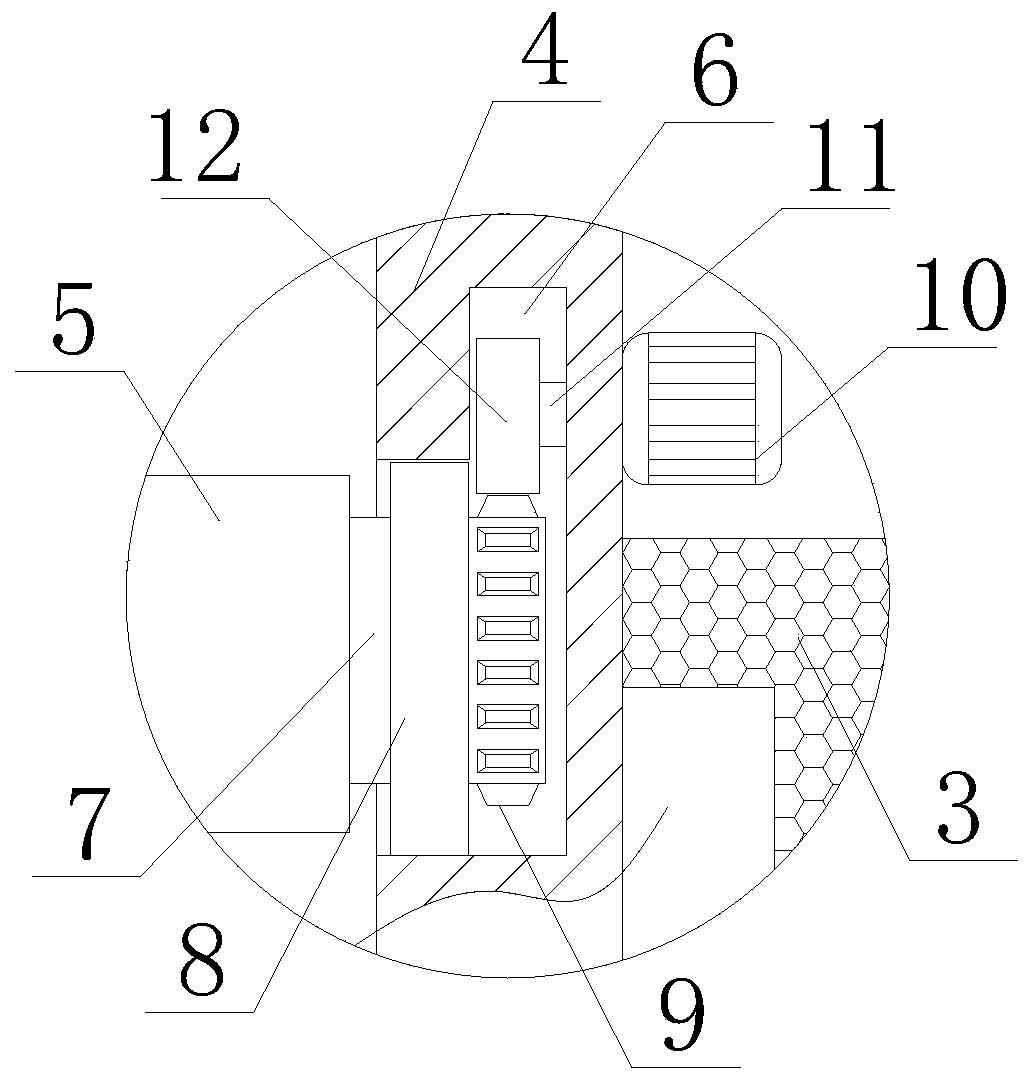

[0029] Attached below Figure 1-5 The present invention is further described with embodiment:

[0030] A new type of wire reel for cable production, comprising a base 1, brackets 3 are welded on both sides of the top of the base 1, a first side plate 24 is installed on the top of one of the brackets 3, and a first side plate 24 is installed on the top of the other bracket 13. The top is equipped with a second side plate 4, a winding roller 5 is arranged between the first side plate 24 and the second side plate 4, and the winding roller 5 is convenient for winding the cable. There is an installation groove 6 on one side, and the two ends of the winding roller 5 are welded with a rotating rod 7, and the rotating rod 7 rotates with the winding roller 5 to rewind the cable without manual operation, which greatly speeds up the cable rewinding bearings 8 are installed on the outer circumferential walls of the two rotating rods 7, so that the rotating rods 7 can rotate freely, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com