Flexible heat conduction sheet and preparation method thereof

A heat conduction sheet, flexible technology, applied in the field of flexible heat conduction sheet and its preparation, can solve the problems of small filling amount, inability to realize continuous production, small filling amount of silicone rubber, etc., and achieve the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The raw materials for the preparation of the flexible thermal conduction sheet provided by the present invention include 80-95 parts by mass of vinyl polysiloxane, preferably 90-95 parts by mass. The viscosity of the vinyl polysiloxane is 1000-300000 mPa·s, preferably 2000-20000 mPa·s, more preferably 5000-10000 mPa·s.

[0049] The raw materials for the preparation of the flexible thermal conduction sheet provided by the present invention further include 10-20 parts by mass of a toughening agent, preferably 15-20 parts by mass. The toughening agent is selected from one or more of UV curable silicone resins and modified silicone resins, UV curable epoxy resins and modified epoxy resins, UV curable polyurethanes and modified polyurethane resins Various, preferably UV epoxy modified acrylic resin.

[0050] The raw materials for the preparation of the flexible thermal conduction sheet provided by the present invention further include 1.2-1.5 parts by mass of hydrogen-conta...

Embodiment 1

[0073] The formula is: vinyl polysiloxane, vinyl molar content 0.05 mmoles / gm, viscosity 10000mpa.s: 90 parts by mass, epoxy-modified acrylic UV resin: 10 parts by mass, hydrogen-containing polysiloxane, hydrogen-containing moles Content 3.0mmole / gm: 1.6 parts by mass, carbon fiber 100 μm: 100 parts by mass, spherical alumina 5 μm: 150 parts by mass, spherical alumina 20 μm: 50 parts by mass, polyvinylsiloxane-platinum complex 0.2 parts by mass, 0.005 parts by mass of ethynylcyclohexanol, 20 nm of fumed silica: 5 parts by mass.

[0074] Preparation method: calender the above raw materials into sheets, pre-cure with UV, wind up, cut into blocks, mold and press at 120°C for 15 minutes, slice vertically at 2 mm, observe the surface and cross-section under a microscope, and the fibers are arranged in an orderly manner.

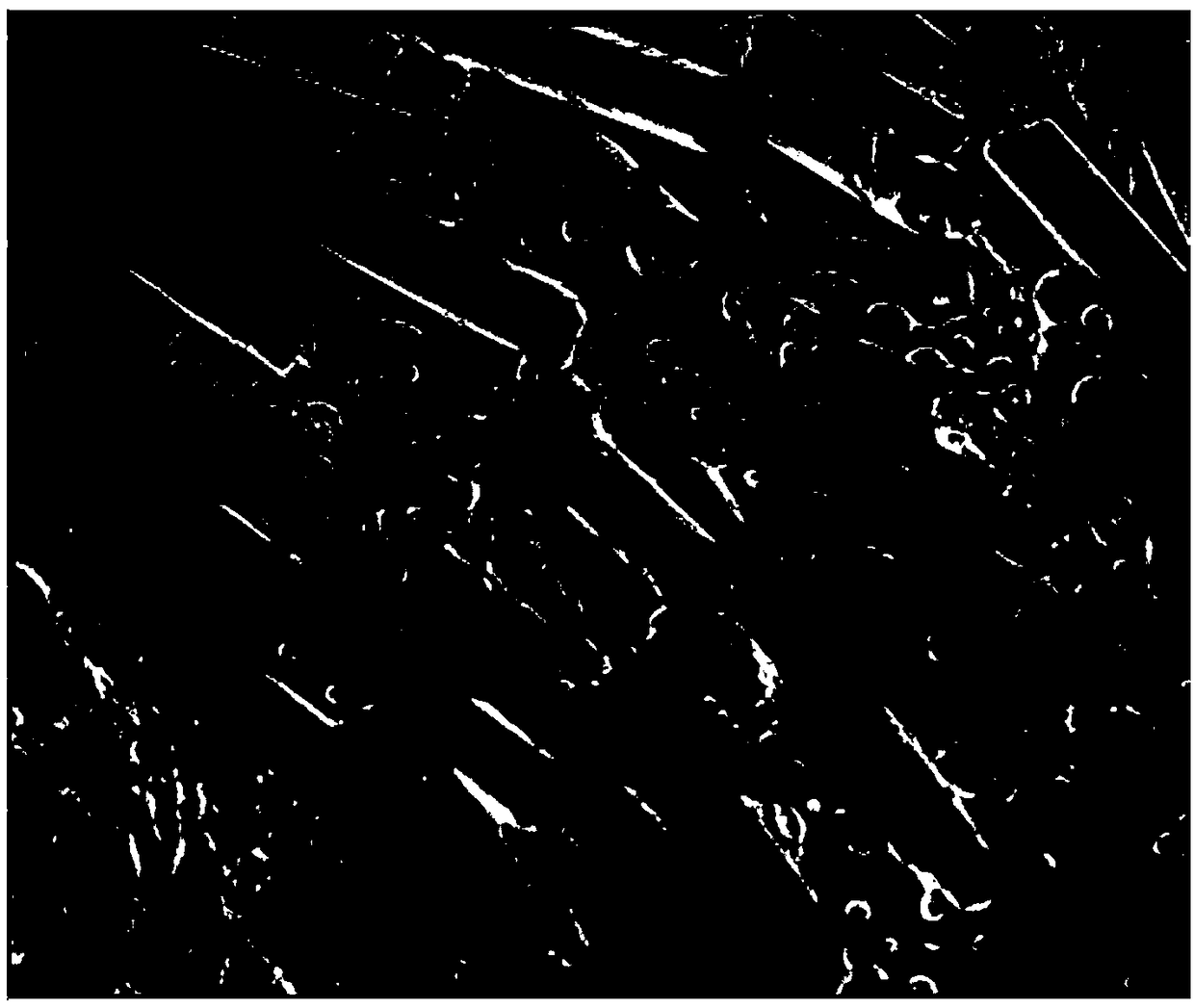

[0075] see figure 1 , figure 1 The scanning electron microscope image of the flexible thermally conductive sheet provided in Example 1.

Embodiment 2

[0081] The formula is: vinyl polysiloxane, vinyl molar content 0.06mmole / gm, viscosity 5000mpa.s: 95 parts by mass, epoxy-modified acrylic UV resin: 5 parts by mass, hydrogen-containing polysiloxane, hydrogen-containing mole Content 0.3%: 1.7 parts by mass, polyvinylsiloxane-platinum complex 0.15 parts by mass, ethynylcyclohexanol, 0.004 parts by mass, carbon fiber 100 μm: 100 parts by mass, spherical alumina 5 μm: 150 parts by mass, nitrogen Boron 15 μm: 20 parts by mass, fumed silica 20 nm: 5 parts by mass.

[0082] Preparation method: Mix the above raw materials and calender into sheets, preliminarily cured by UV, wind up, then cut into blocks, molded and cured at 120°C for 15 minutes, slice vertically at 2 mm, observe the surface and cross-section under a microscope, and the fibers are arranged in an orderly manner.

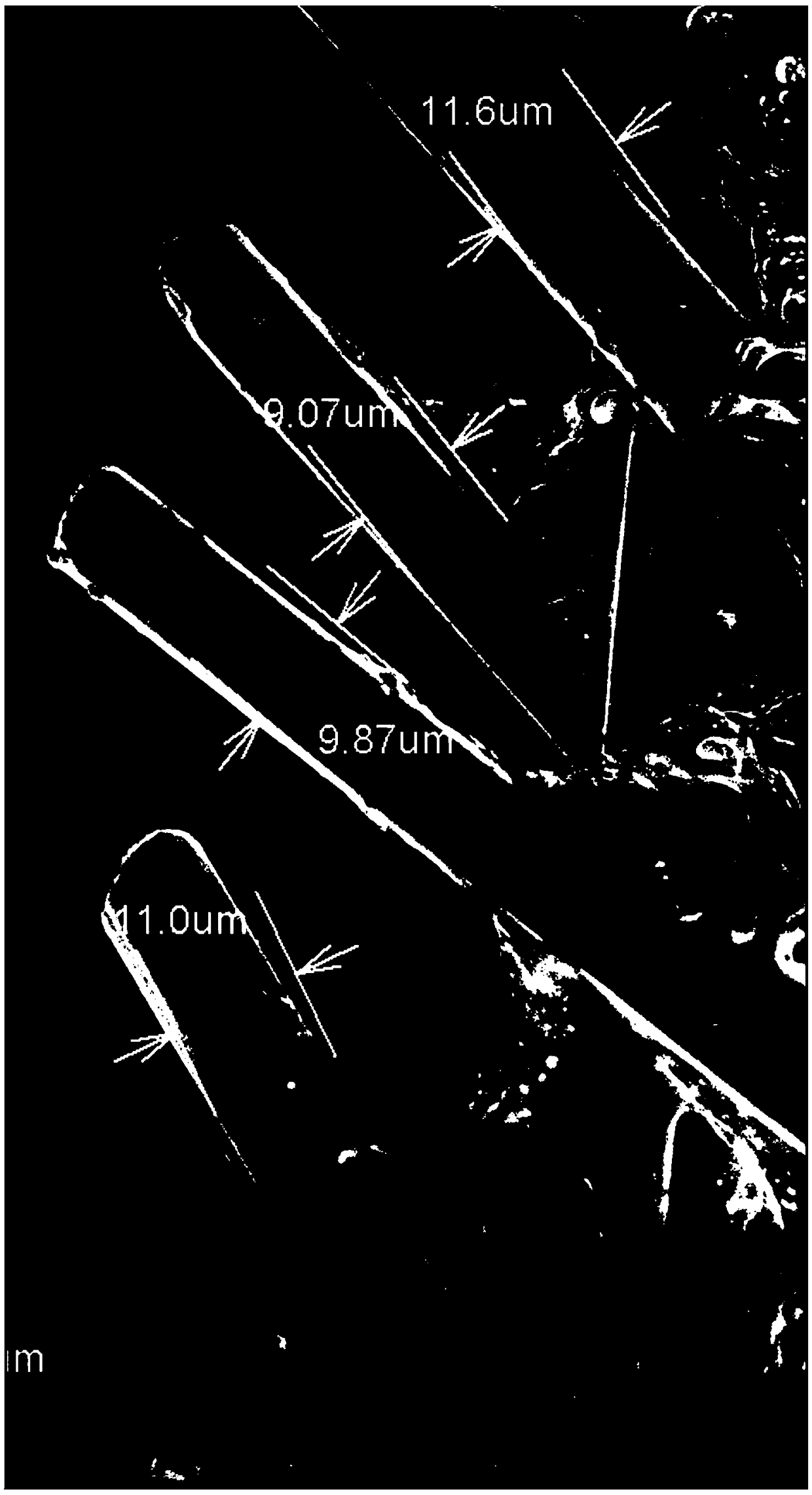

[0083] see image 3 , image 3 The scanning electron microscope image of the flexible heat conduction sheet provided for Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com