A manufacturing method for a continuous fiber winding reinforced thermoplastic tube and a winding device

A technology of continuous fiber and winding reinforcement, applied in the field of manufacturing method and winding device of continuous fiber winding reinforced thermoplastic pipe, can solve the problems of poor smoothness of the outer wall of the pipe, secondary damage of the continuous fiber, and reduction of the performance of the continuous fiber, etc., to achieve The effect of small gaps, good firmness, and no reduction in performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

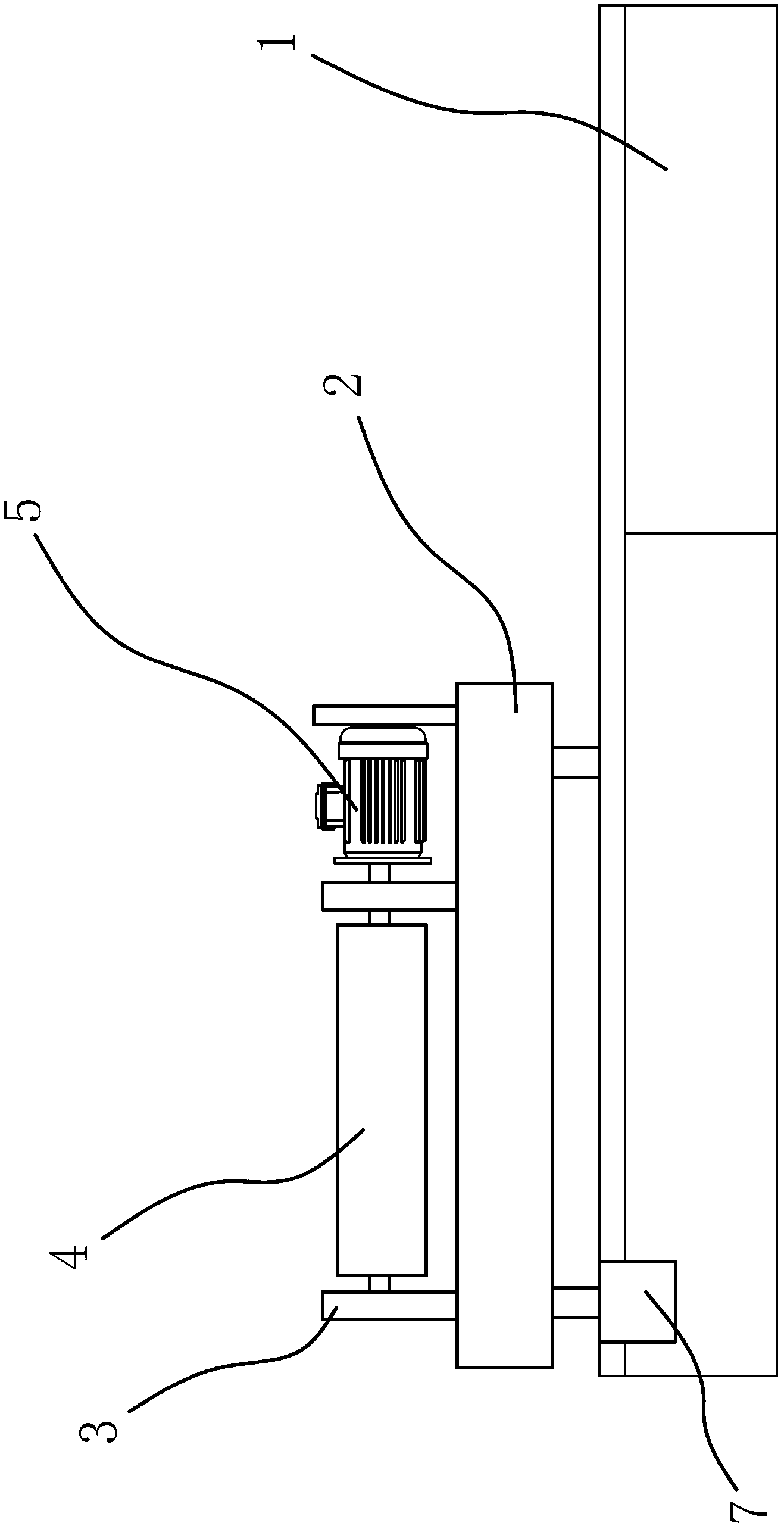

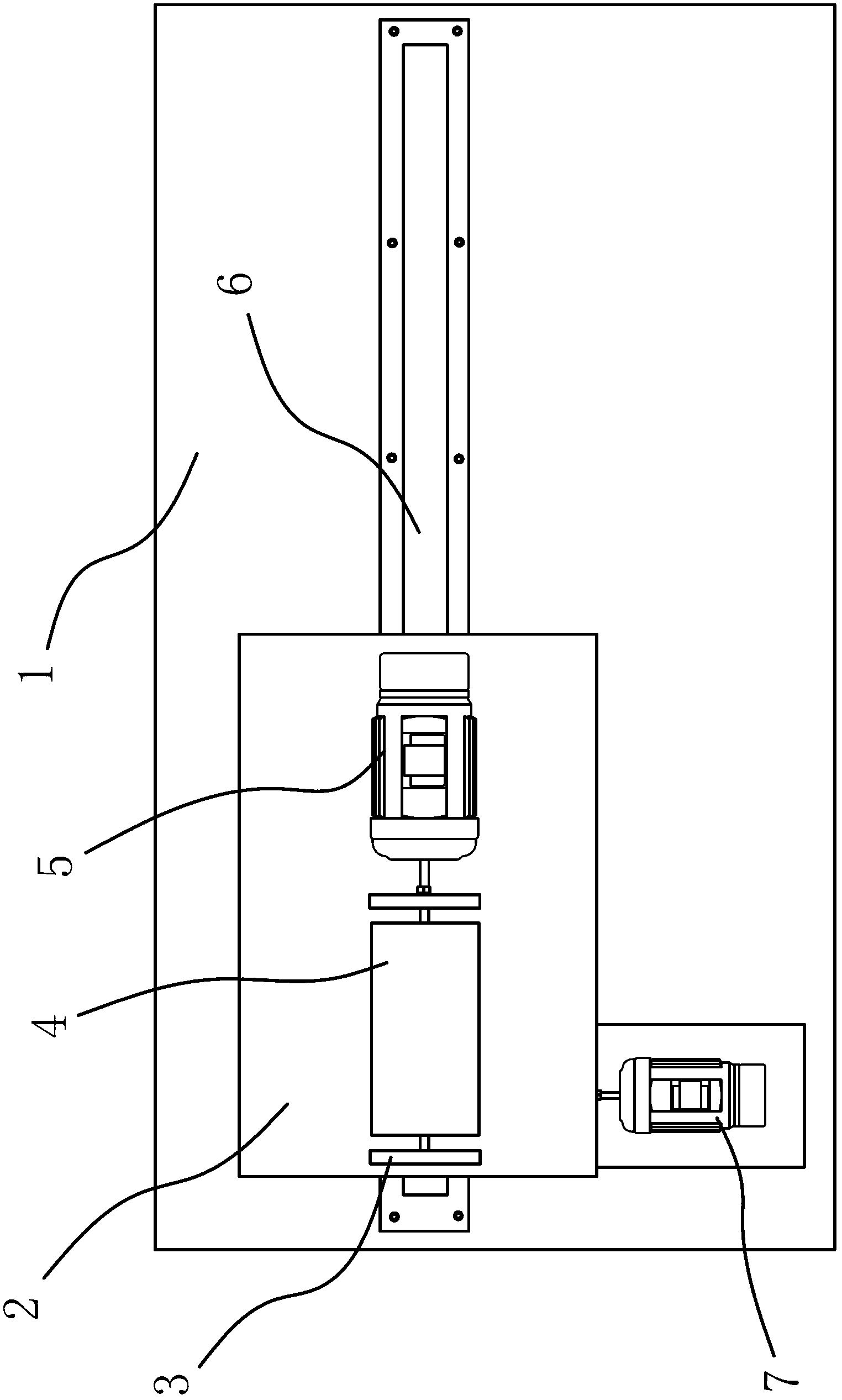

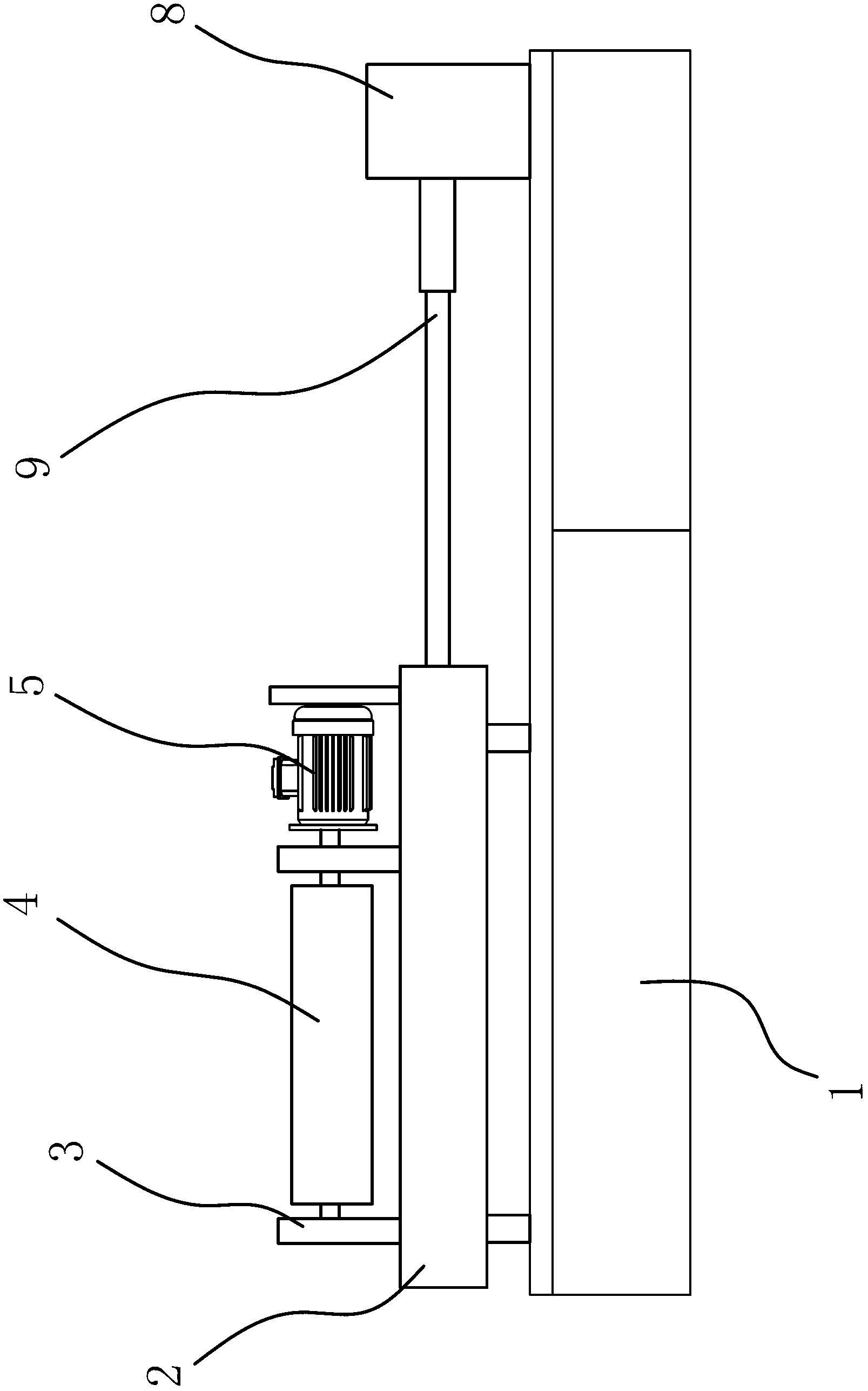

[0037] This example is mainly used to prepare a continuous fiber winding reinforced thermoplastic pipe with a three-layer structure of an inner lining layer, a structural layer and an outer protective layer. The specific process is as follows:

[0038] First, the clamping part: the mold core 4 is set on the clamp 3 of the winding device, the inner liner is a thermoplastic pipe made of PP (high polymer polypropylene) material and has been extruded, and it is sleeved on the mold core 4, the coiled continuous fiber tape is positioned on the tensioning device, and then the continuous fiber tape passes through the tensioning device and the heating area of the ceramic infrared heater and is melted and connected with the inner lining layer, and the continuous fiber tape is controlled to pass through the tensioning device The tension after tensioning is 10N-35N.

[0039] Secondly, rotary winding and heating: the winding device is used to drive the core 4 to rotate and move along its...

Embodiment 2

[0042] This example is mainly used to prepare a continuous fiber winding reinforced thermoplastic pipe with a three-layer structure of inner lining layer, structural layer and outer protective layer. The specific preparation process is basically the same as that of Example 1, and the difference lies in: It is a thermoplastic pipe made of PE (high-density polyethylene) material and has been extruded. During the preparation process, the winding speed of the continuous fiber tape is controlled at 5m / min-20m / min, and a stainless steel heater is used for heating during the winding process. The heating temperature is 450-600°C. The prepared pipe does not produce air bubbles, the smoothness of the outer wall of the pipe and the firmness of the pipe are good, the continuous fiber is not damaged or broken, and the overall pipe strength, stiffness, impact resistance and toughness of the pipe are good.

Embodiment 3

[0044] This example is mainly used to prepare a continuous fiber winding reinforced thermoplastic pipe with a three-layer structure of inner lining layer, structural layer and outer protective layer. The specific preparation process is basically the same as that of Example 1, and the difference lies in: It is a thermoplastic pipe made of nylon material and has been extruded. During the preparation, three continuous fiber strips are used side by side and spirally wound on the inner liner. Heat, the preheating temperature is 450-500°C, and the ceramic infrared heater is used to heat during the winding process, the heating temperature is 700-750°C, and the winding speed of the continuous fiber tape is controlled to be 3m / min-18m / min. The prepared pipe does not produce air bubbles, the smoothness of the outer wall of the pipe and the firmness of the pipe are good, the continuous fiber is not damaged or broken, and the overall pipe strength, stiffness, impact resistance and toughnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com