Processing method of electric heating composite floor, floor and railway vehicle provided with floor

A composite floor and processing method technology, which is applied in the field of rail vehicles, can solve the problems of aluminum honeycomb panels that cannot be combined with heating sheets and wiring, cannot be energized for floor heating, and cannot meet design and use requirements, etc. Quantifying the effect of heating comfort and ensuring safe train operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. For the convenience of description, the words "up", "down", "left" and "right" appear in the following text, which only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

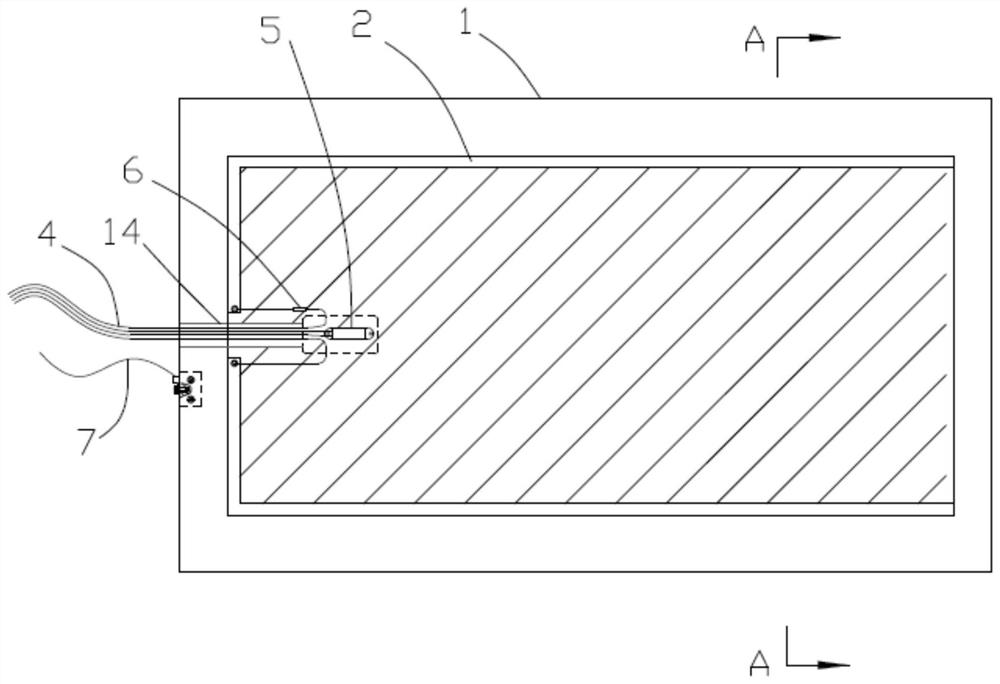

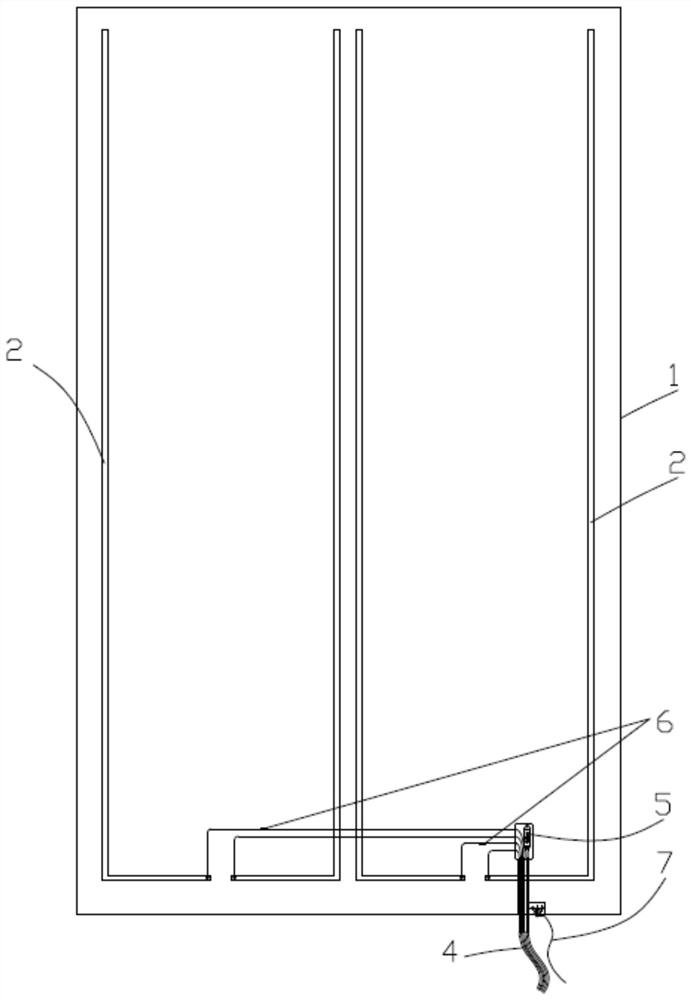

[0035] like figure 1 , figure 2 As shown, the structure of the first embodiment of an electrically heated composite floor provided by this embodiment is as follows: it includes a bottom plate 1 , a heating sheet 2 , a panel 3 , a wiring harness 4 , a temperature control switch 5 and a fuse 6 .

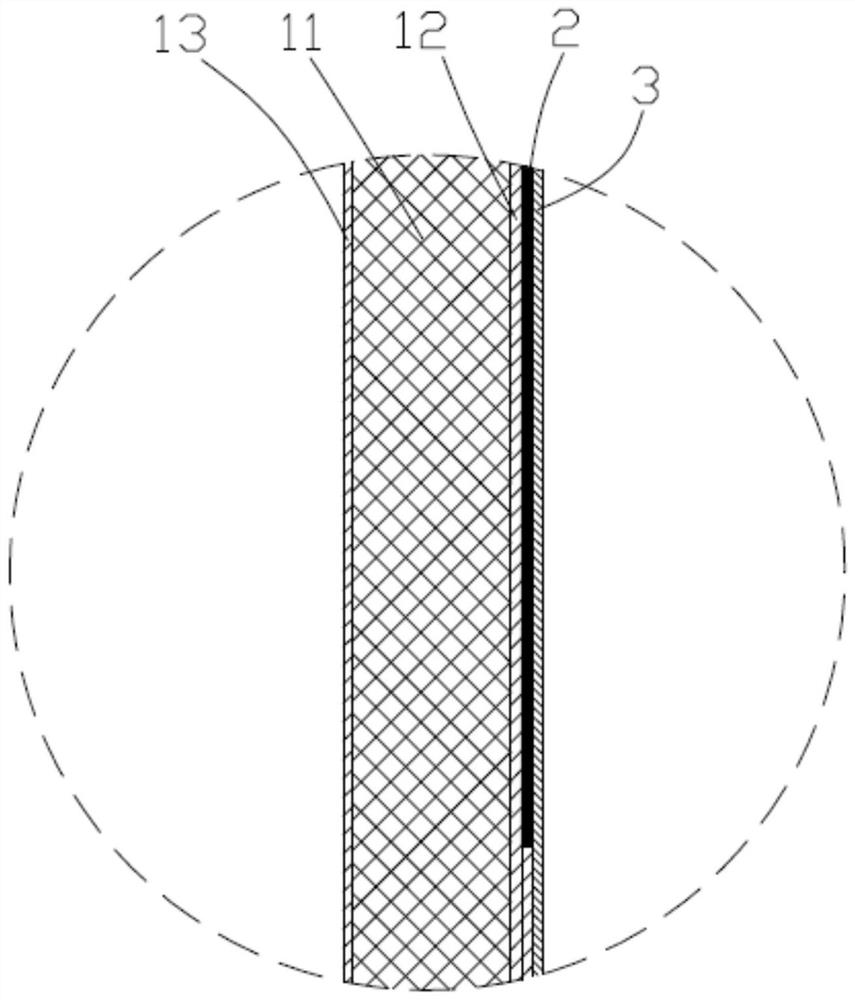

[0036] like figure 2 As shown, the bottom plate 1 includes a core board 11 , a first skin layer 12 laid on one side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com