Formula and preparation process of lightweight elastic inner support body

An internal support and lightweight technology, applied in tire parts, transportation and packaging, special tires, etc., can solve the problems of the decline of the comprehensive mechanical properties of filled rubber, the rapid deterioration of service performance, and the lack of surface active hydroxyl groups. Endurance, improved fuel economy, mitigation of materiel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

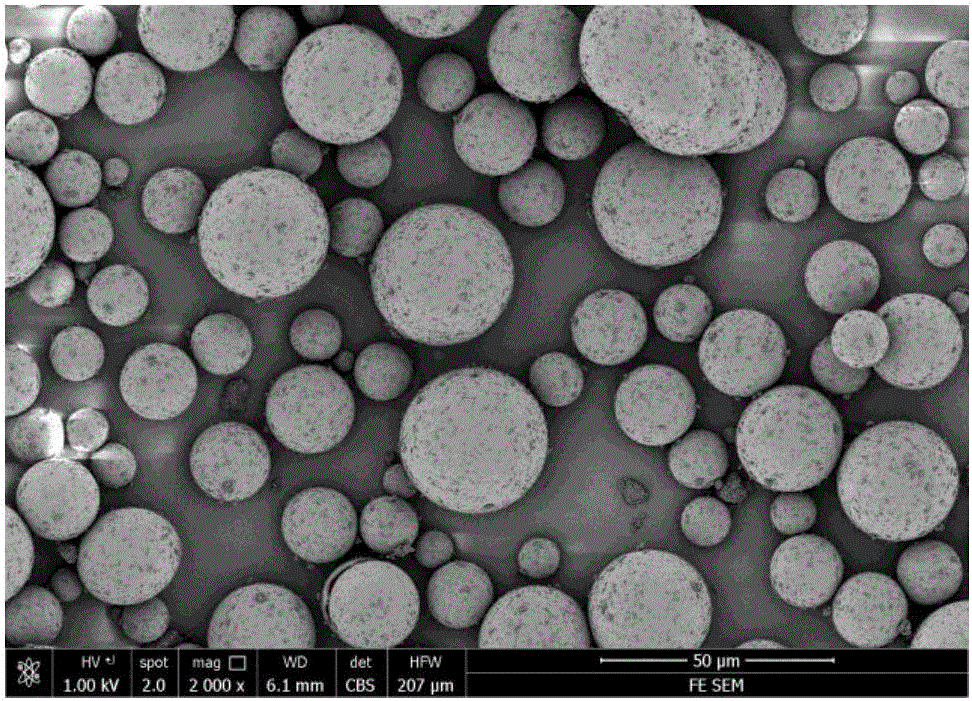

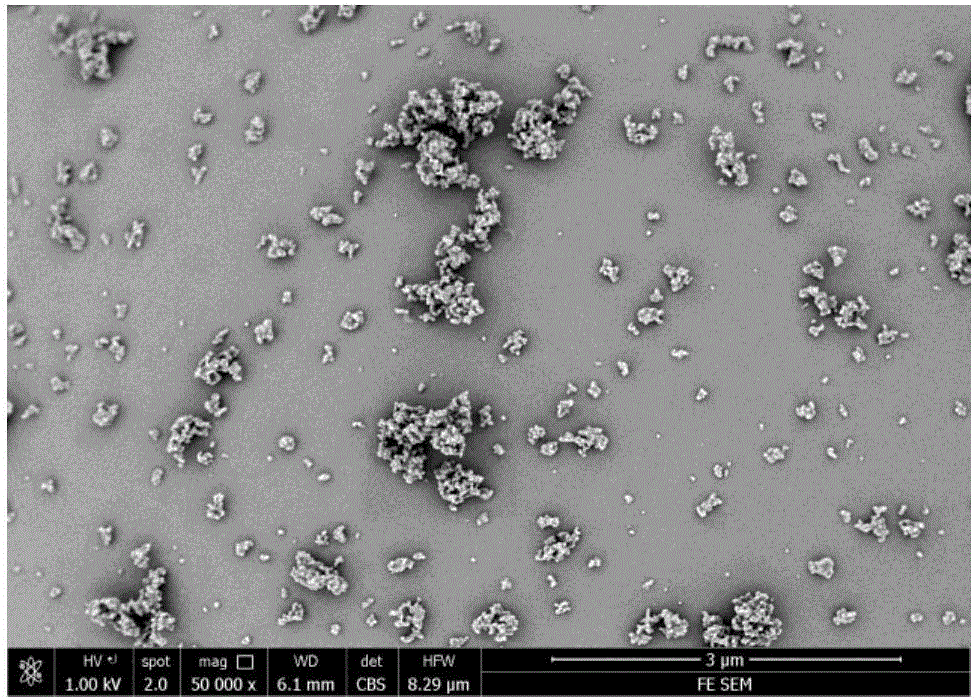

[0051] The present invention also provides a method for preparing modified glass microspheres, comprising: cleaning the glass microspheres in the first step, adding the glass microspheres into deionized water, stirring, filtering, adding to absolute ethanol, stirring, and standing for 12 hours, Filter and dry for use; the second step is to hydrolyze the sulfur-containing organosilicon compound, put the sulfur-containing organosilicon compound, distilled water, and acetic acid into a beaker according to the mass ratio of 1:0.2:0.02, and hydrolyze at room temperature for 1 hour under magnetic stirring Add a certain amount of absolute ethanol (the mass ratio of absolute ethanol to the sulfur-containing organic compound is 100:1); in the third step, the glass beads are grafted with the sulfur-containing organosilicon compound, and a certain amount of glass beads (the glass beads and the sulfur-containing organic compound) are weighed. Sulfur-organic compound (mass ratio: 100:1) is ...

Embodiment

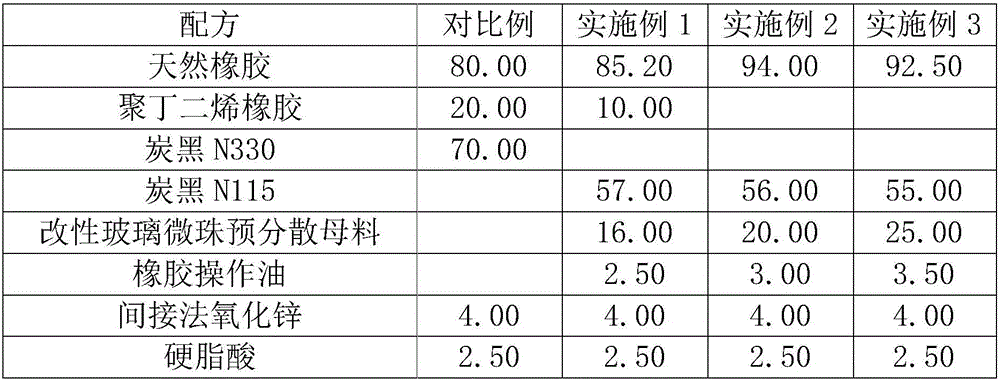

[0058] Each component was weighed according to the proportions of Examples 1-3 in Table 1, and elastic inner support body materials were prepared according to the above-mentioned preparation method.

[0059] Adjust the speed of the internal mixer to 55 rpm, add raw rubber composed of natural rubber and polybutadiene rubber, press the top bolt for 30 seconds, lift the weight, add zinc oxide, stearic acid, and carbon black, and put the internal mixer Adjust the speed to 50 rpm, press the top bolt for 40 seconds, lift the weight, adjust the speed of the internal mixer to 45 rpm, press the bolt for 40 seconds, lift the weight, press the top bolt for 25 seconds, and remove glue at 165°C; open the mixer Unloading, cooling and stacking;

[0060] Adjust the speed of the internal mixer to 50 rpm, add a section of masterbatch, press the top bolt for 15 seconds, lift the mound, add anti-aging agent and protective wax, adjust the speed of the internal mixer to 45 rpm, and press the top bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com