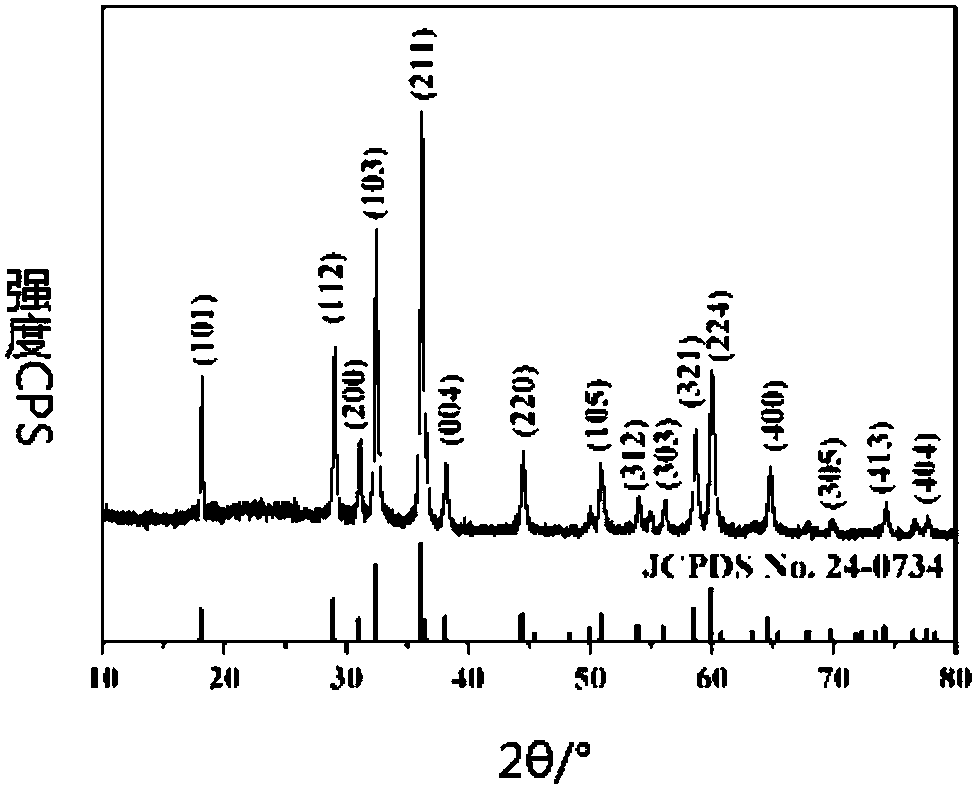

Carbon-coated manganese oxide negative electrode material and preparation method thereof

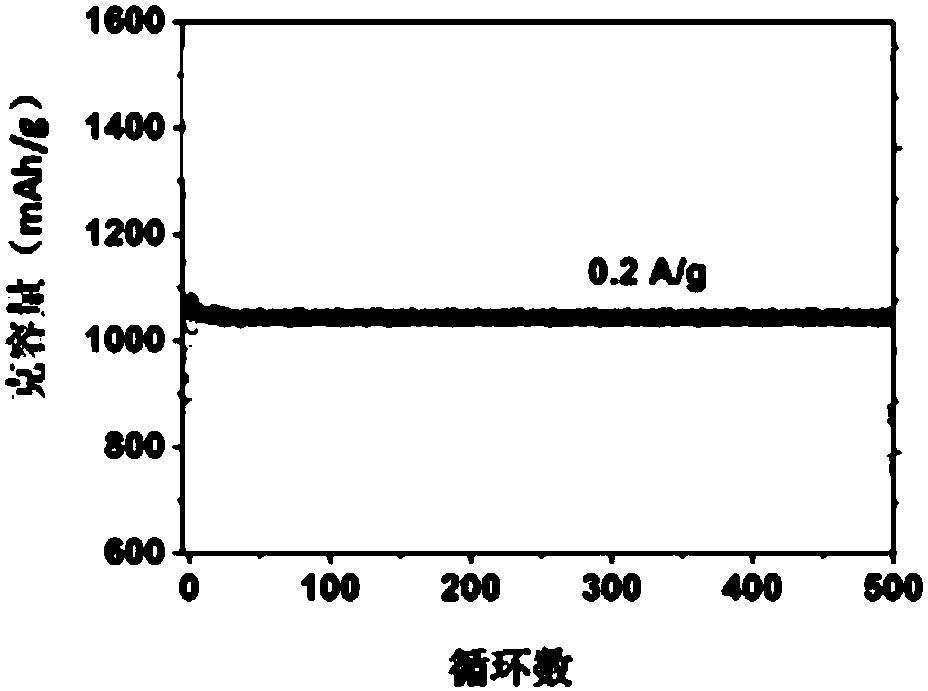

A negative electrode material, manganese oxide technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve problems such as poor electrical performance, and achieve the effect of efficient coating, isolation of contact, and improvement of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A carbon-coated manganese oxide negative electrode material, the raw materials of the carbon-coated manganese oxide negative electrode material include a manganese source, an organic ligand and a solvent; wherein, the organic ligand is an organic compound containing carboxylic acid or nitrogen and carboxylic acid small molecule compounds.

[0030] The preparation method of the carbon-coated manganese oxide negative electrode material, the preparation method comprises the following steps:

[0031] S1. Put the manganese source, organic ligand and solvent in a polytetrafluoroethylene reactor and mix them thoroughly, then place them in a blast drying oven to heat, cool, filter, wash the filter residue, and dry the filter residue to obtain a manganese polymer ;

[0032] S2. Calcining the manganese polymer in a high-temperature furnace and cooling or cooling to room temperature to obtain a carbon-coated manganese oxide negative electrode material.

Embodiment 2

[0034] A carbon-coated manganese oxide negative electrode material, the raw materials of the carbon-coated manganese oxide negative electrode material include a manganese source, an organic ligand and a solvent; wherein, the organic ligand is an organic compound containing carboxylic acid or nitrogen and carboxylic acid Small molecule compounds;

[0035] Wherein, the manganese source is manganese nitrate;

[0036] The organic ligand is 3,5-pyridinedicarboxylic acid;

[0037] Described solvent is deionized water;

[0038] The molar ratio of the manganese source to the organic ligand is 1:0.625;

[0039] The molar volume (mmol / ml) ratio of the manganese source to the solvent is 1:37.5.

[0040] The preparation method of the carbon-coated manganese oxide negative electrode material, the preparation method comprises the following steps:

[0041] S1. Put the manganese source, organic ligand and solvent in a polytetrafluoroethylene reactor and mix them thoroughly, then place the...

Embodiment 3

[0049] A carbon-coated manganese oxide negative electrode material, the raw materials of the carbon-coated manganese oxide negative electrode material include a manganese source, an organic ligand and a solvent; wherein, the organic ligand is an organic compound containing carboxylic acid or nitrogen and carboxylic acid Small molecule compounds;

[0050] Wherein, the manganese source is manganese acetate;

[0051] The organic ligand is 4-pyridinecarboxylic acid;

[0052] Described solvent is dimethylformamide;

[0053] The molar ratio of the manganese source to the organic ligand is 1:0.5;

[0054] The molar volume (mmol / ml) ratio of the manganese source to the solvent is 1:45.

[0055] The preparation method of the carbon-coated manganese oxide negative electrode material, the preparation method comprises the following steps:

[0056] S1. Put the manganese source, organic ligand and solvent in a polytetrafluoroethylene reactor and mix them thoroughly, then place them in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com