Pretreatment technology for co-refining of heavy oil and tire rubber powder

A pretreatment and tire powder technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of continuous feeding and lack of fluidity of raw materials, and achieve the effect of weakening the swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment provides a pretreatment process for co-smelting heavy oil and tire rubber powder, which is characterized in that it includes the following steps:

[0021] Preheat the catalytic cracking oil slurry to 260°C, add the waste tire powder crushed to a particle size of 60 mesh into the raw material oil at a uniform speed at a ratio of 1:3 and mix evenly, pour nitrogen into the raw material tank, and the pretreatment temperature is 260°C , the residence time is 20min, and the stirring rate is 450r / min. The variation of the viscosity of the mixed slurry with temperature is shown in the table below:

[0022] temperature / ℃

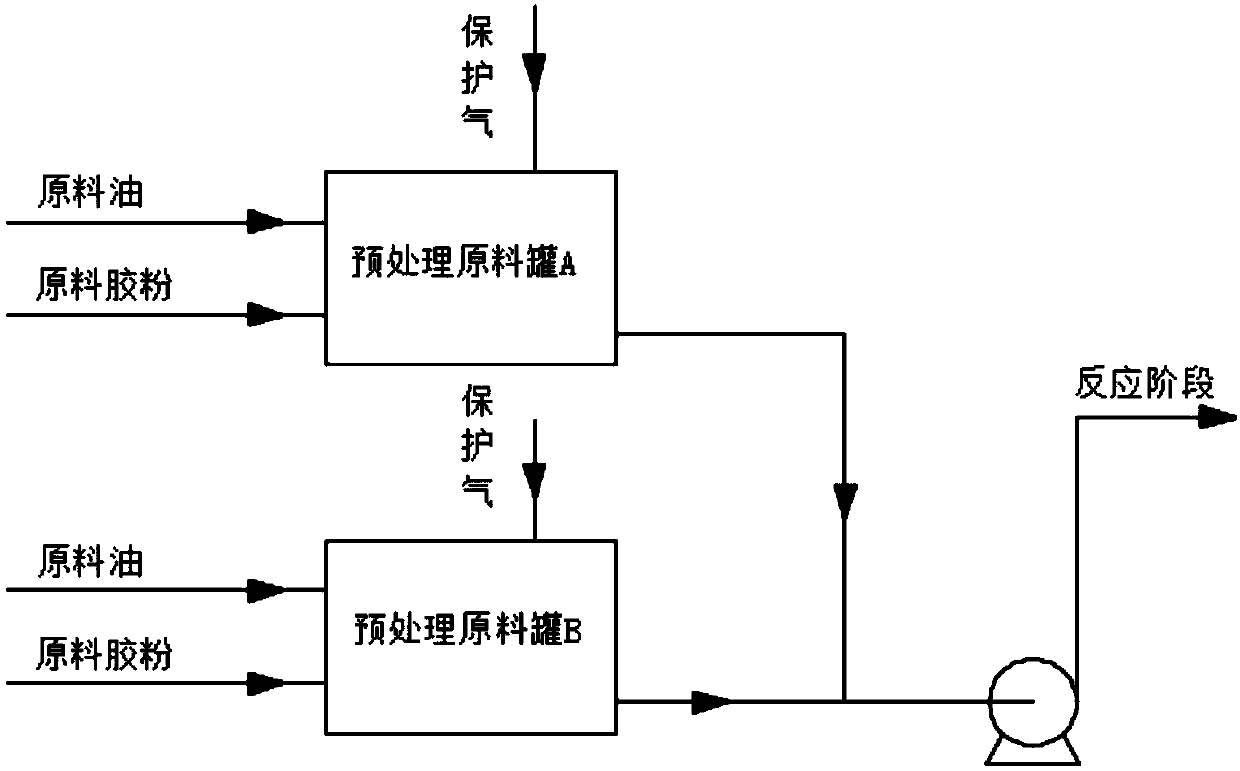

[0023] It can be seen from the above data that a uniform, stable and fluid mixed slurry is obtained by using the method of this example, and the continuous operation of co-refining of oil and tire powder can be realized through the feeding mode of double raw material tanks

Embodiment 2

[0025] This embodiment provides a pretreatment process for co-smelting heavy oil and tire rubber powder, which is characterized in that it includes the following steps:

[0026] Preheat the residual oil to 200°C, add the waste tire powder crushed to 80 mesh particle size into the raw material oil at a uniform speed at a ratio of 1:2 and mix evenly, protect under nitrogen atmosphere, pretreatment temperature is 250°C, residence time is 30min, stir The speed is 450r / min. After pretreatment, measure the viscosity change with temperature:

[0027] temperature / ℃

[0028] It can be seen from the above data that the method of this example is used to obtain a uniform, stable and fluid mixed slurry, and the continuous operation of co-refining of oil and tire powder can be realized through the feeding mode of double raw material tanks.

Embodiment 3

[0030] This embodiment provides a pretreatment process for co-smelting heavy oil and tire rubber powder, which is characterized in that it includes the following steps:

[0031] Preheat the coal tar to 240°C, add the waste tire powder crushed to 100 meshes into the raw material oil at a uniform speed in a ratio of 1:4 and mix evenly, under the protection of nitrogen atmosphere, the pretreatment temperature is 200°C, the residence time is 60min, and the stirring rate is 450r / min. After pretreatment, measure the viscosity change with temperature:

[0032] temperature / ℃

[0033] It can be seen from the above data that the method of this example is used to obtain a uniform, stable and fluid mixed slurry, and the continuous operation of co-refining of oil and tire powder can be realized through the feeding mode of double raw material tanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com