Silicon oxide/carbon cathode material of lithium ion battery and preparation method of material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of composite structure, difficult commercialization, low Coulombic efficiency, etc., and achieve high electrochemical activity and charge-discharge capacity. The effect of reducing volume expansion effect and improving circulation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

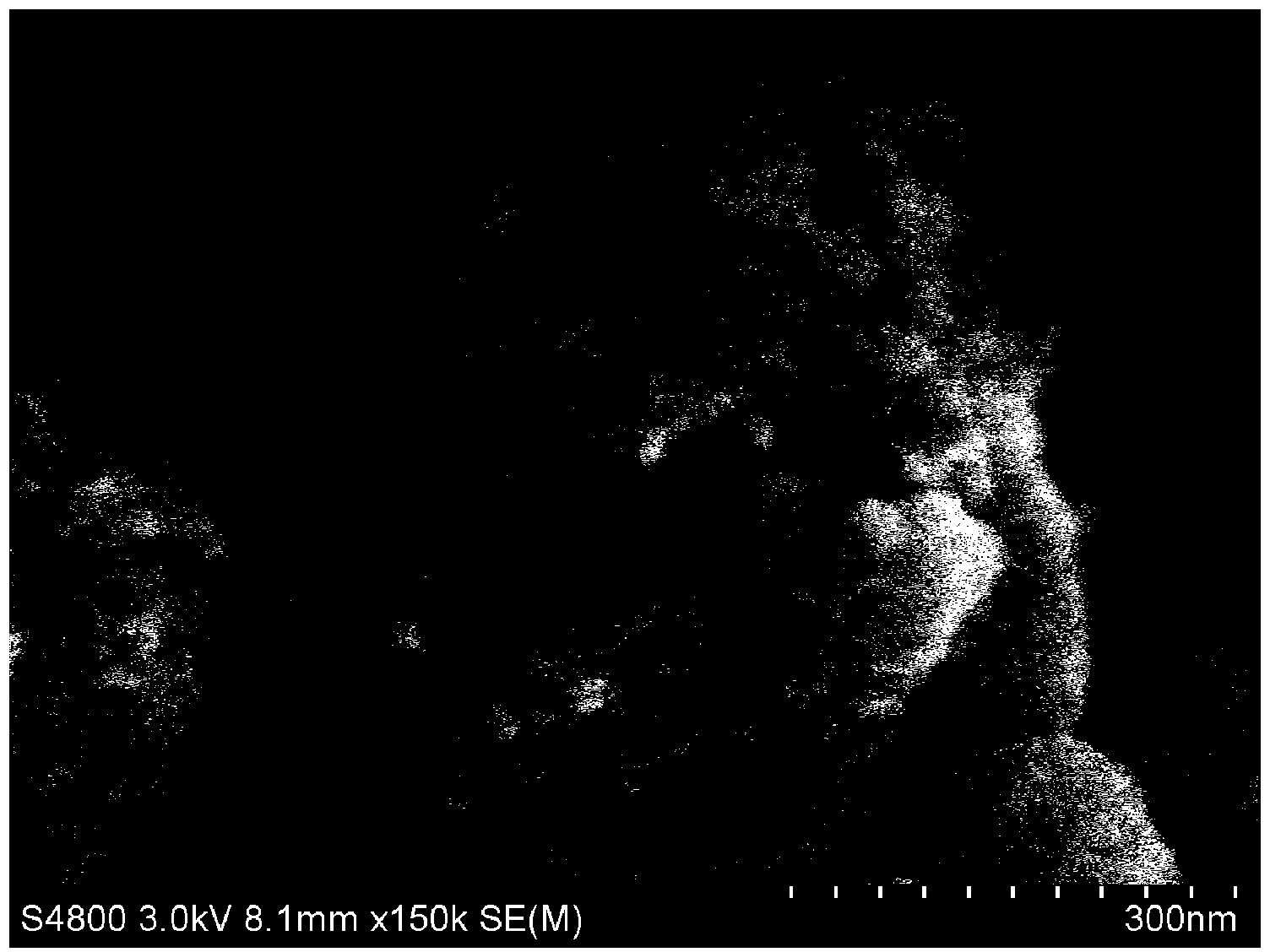

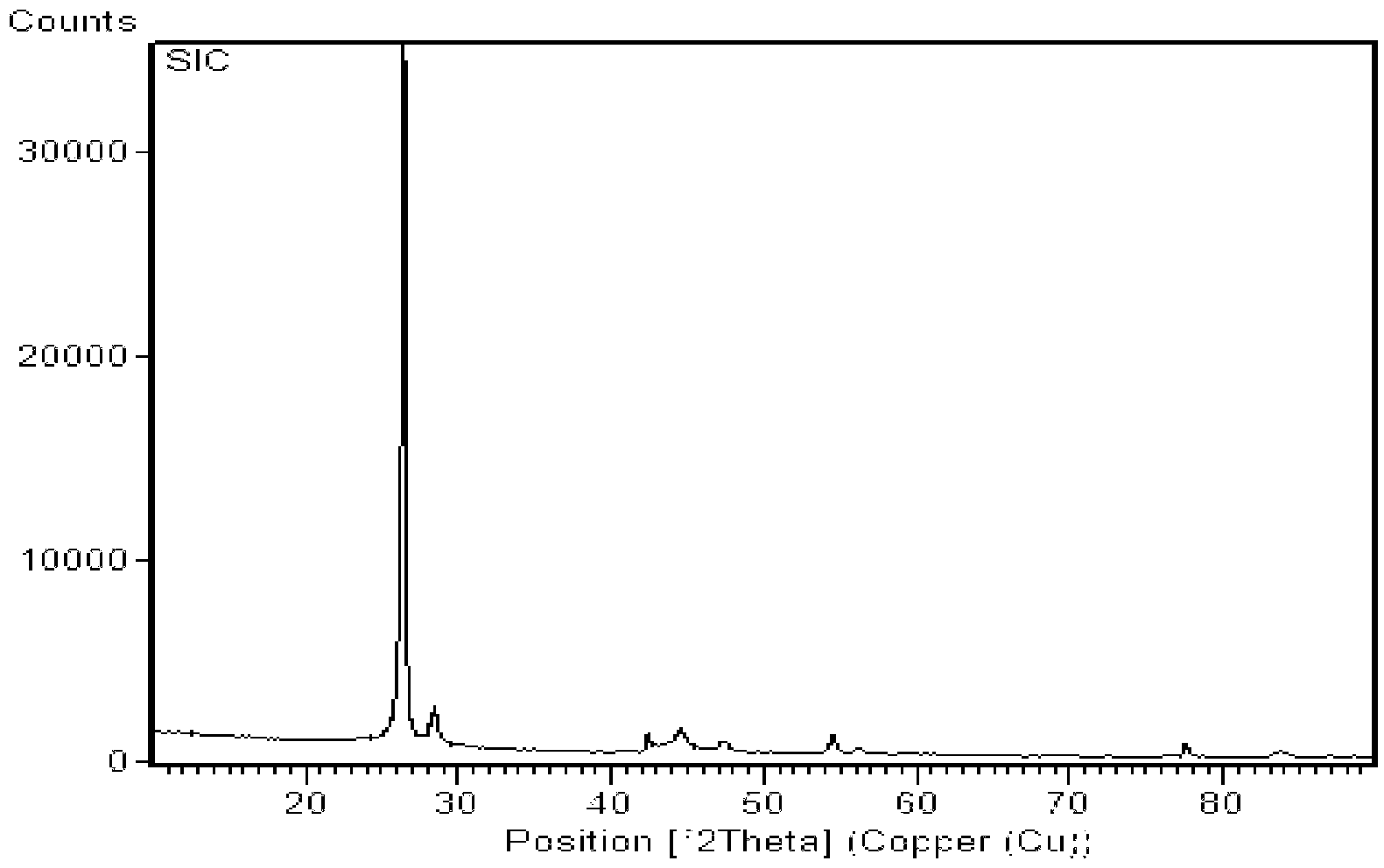

[0065] SiO with a particle size of 20~400nm 0.5 The powder is dispersed in ethanol to form a slurry, and the solid content is controlled at 20%; then an appropriate amount of iron powder is added to the above slurry to mix and stir until a uniform slurry is formed, in which SiO 0.5 The molar ratio of iron powder and iron powder is 1:0.4; add artificial graphite with a particle size of 0.5~30 μm to the uniform slurry, mix and disperse evenly, and dry to obtain a mixture, in which artificial graphite accounts for 70%; place the mixture under nitrogen conditions, At a heating rate of 5°C / min, heat up to 1100°C, hold for 3 hours, and cool naturally in the furnace to room temperature to obtain a composite material; place the above composite material in 2.0mol / L dilute hydrochloric acid solution for 5 hours, vacuum filter, remove Repeatedly washing with ionic water to neutrality and drying to obtain a compound; according to the mass percentage, mix and disperse 80% of the compound, ...

Embodiment 2

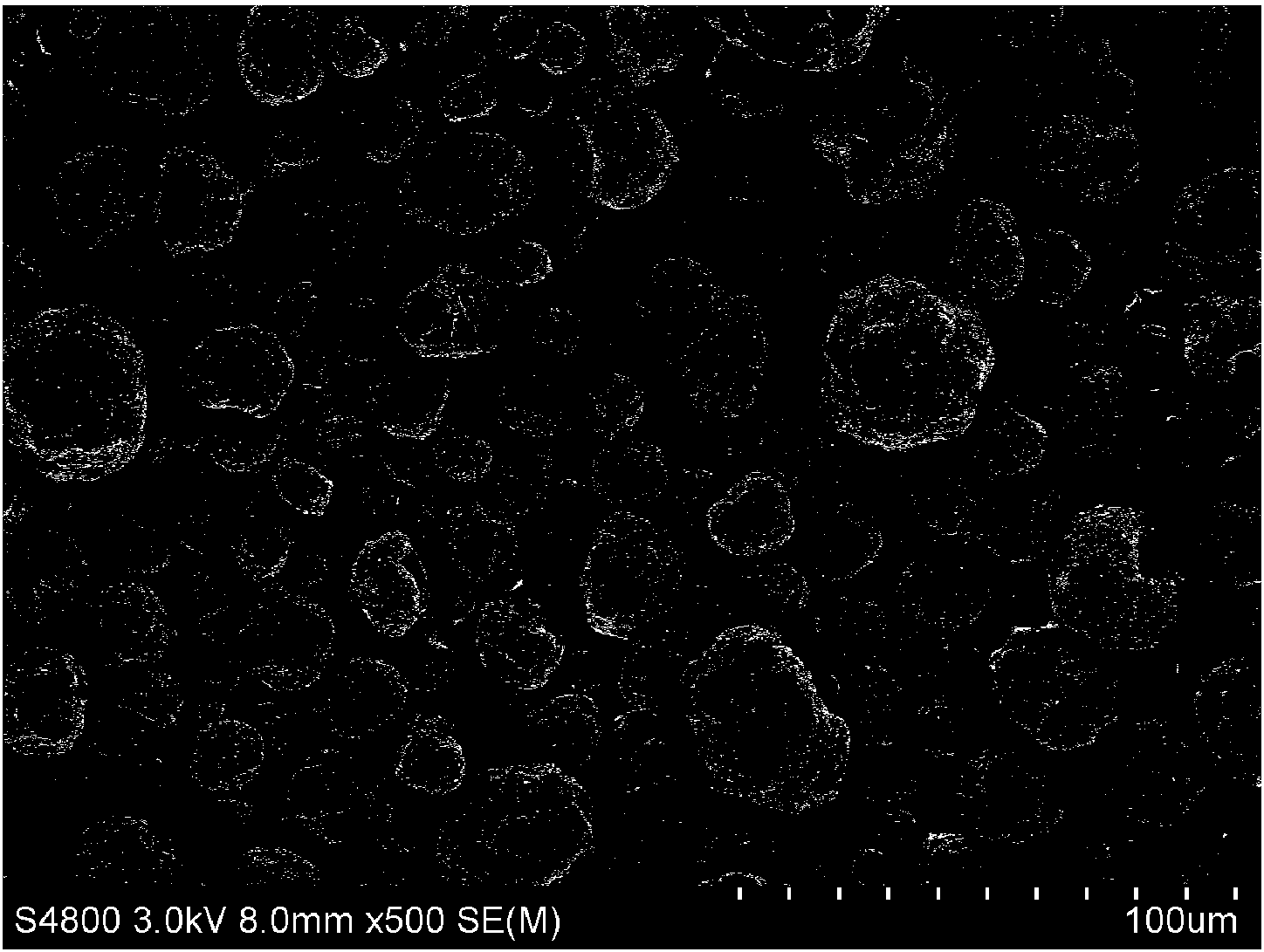

[0067] SiO with a particle size of 300~600nm 0.8 The powder is dispersed in ethanol to form a slurry, and the solid content is controlled at 15%; then an appropriate amount of aluminum powder is added to the above slurry and mixed and stirred until a uniform slurry is formed; wherein SiO 0.8The molar ratio of aluminum powder and aluminum powder is 1:0.3; add mesophase carbon microspheres with a particle size of 0.5-50 μm to the above slurry, mix and disperse evenly, and dry to obtain a mixture, in which mesophase carbon microspheres account for 65%; will get The mixture was placed under argon gas, heated to 750°C at a heating rate of 6°C / min, kept for 2 hours, and cooled naturally to obtain a composite material; the above composite material was fully soaked in 1.0mol / L dilute sulfuric acid solution for 8 hours, After vacuum filtration, deionized water was repeatedly washed to neutrality, and the compound was dried; according to the mass percentage, 60% of the compound, 40% of ...

Embodiment 3

[0069] SiO with a particle size of 500~2000nm 1.0 The powder is dispersed in n-butanol to form a slurry, and the solid content is controlled at 25%; then an appropriate amount of zinc powder is added to the above slurry, mixed and dispersed evenly, wherein SiO 1.0 The molar ratio of zinc powder and zinc powder is 1:1.1; artificial graphite with a particle size of 5-35 μm is added to the above slurry, mixed and dispersed evenly, and dried to obtain a mixture, in which artificial graphite accounts for 65%; the obtained mixture is placed in argon Under the same conditions, the temperature was raised to 900°C at a heating rate of 4°C / min, held for 6 hours, and naturally cooled to room temperature in the furnace to obtain a composite material; the composite material was fully soaked in 1.0mol / L dilute hydrochloric acid solution for 12 hours, and vacuum filtered , repeatedly washed with deionized water until neutral, and dried to obtain a compound; according to the mass percentage, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com