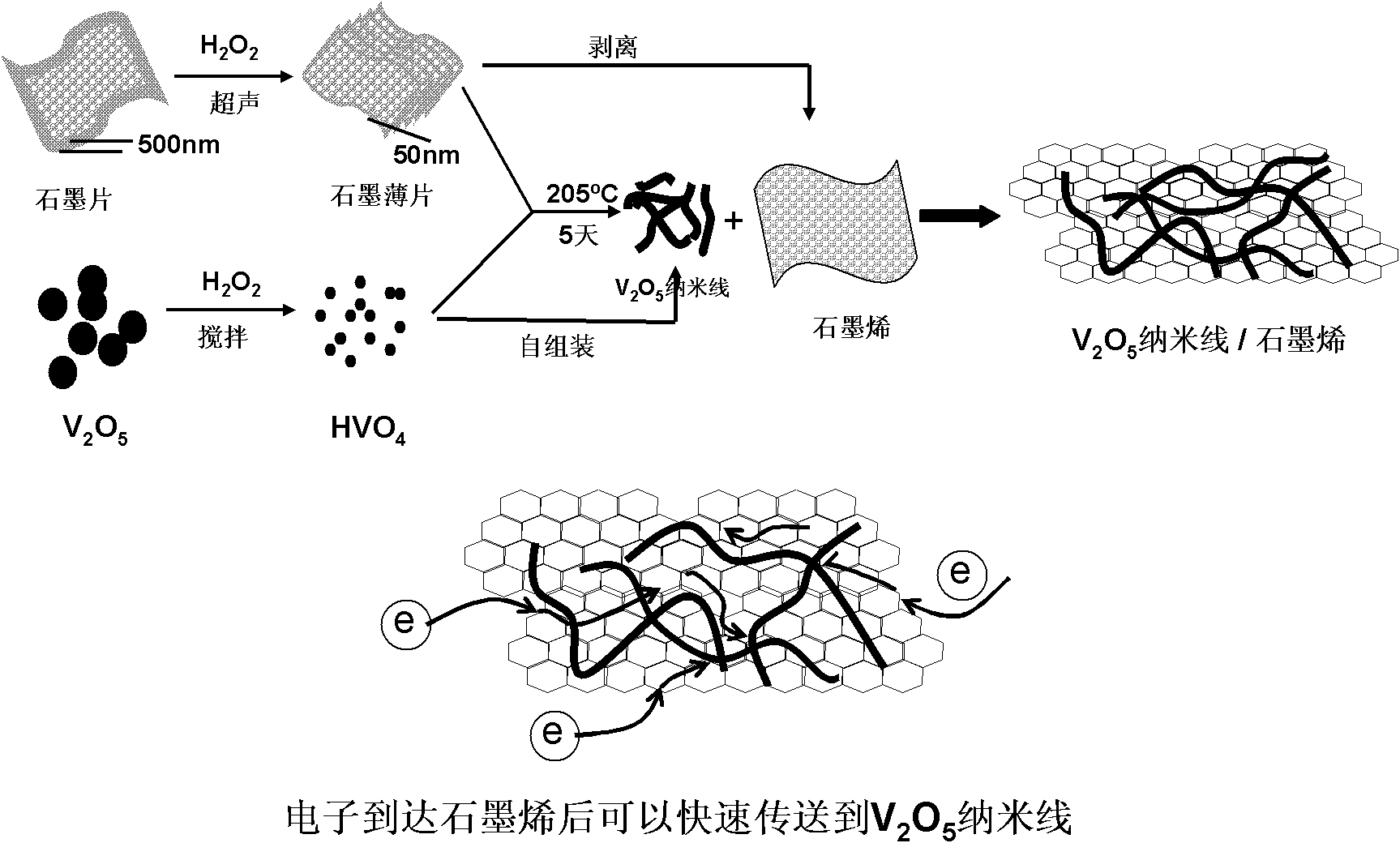

Ultra-long single crystal V2O5 nano wire/graphene anode material and preparation method

A V2O5, cathode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as large toxic gases, improve kinetic characteristics, achieve large-scale production, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

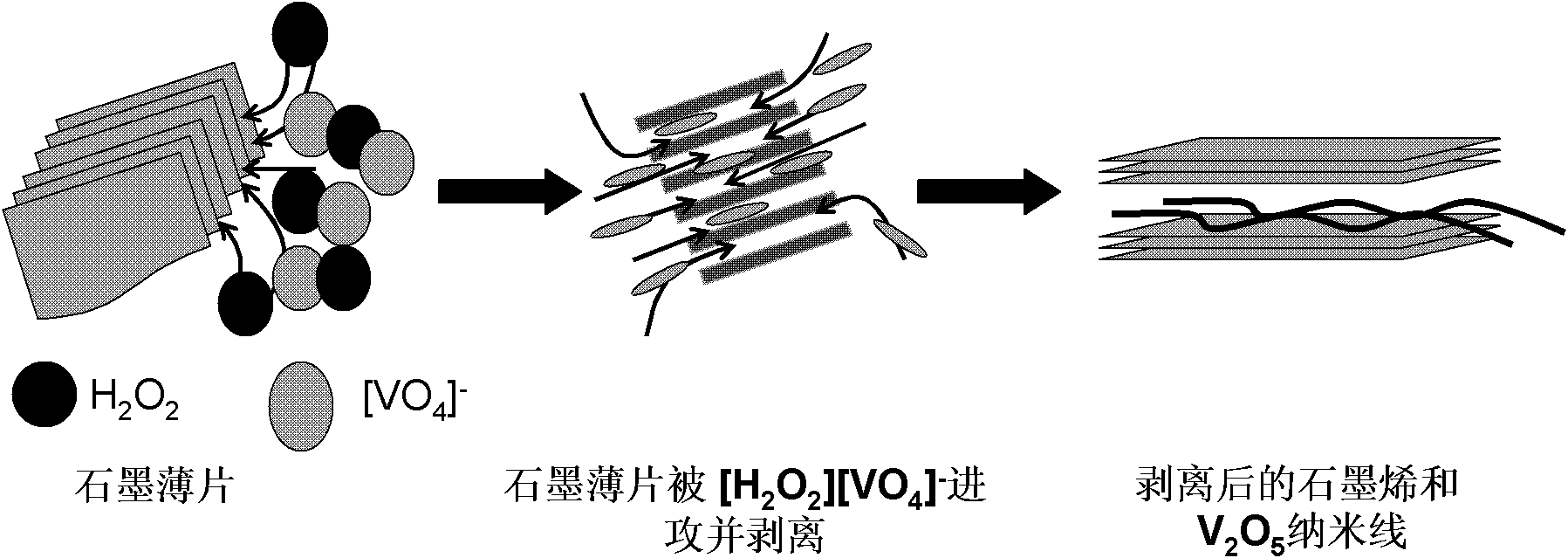

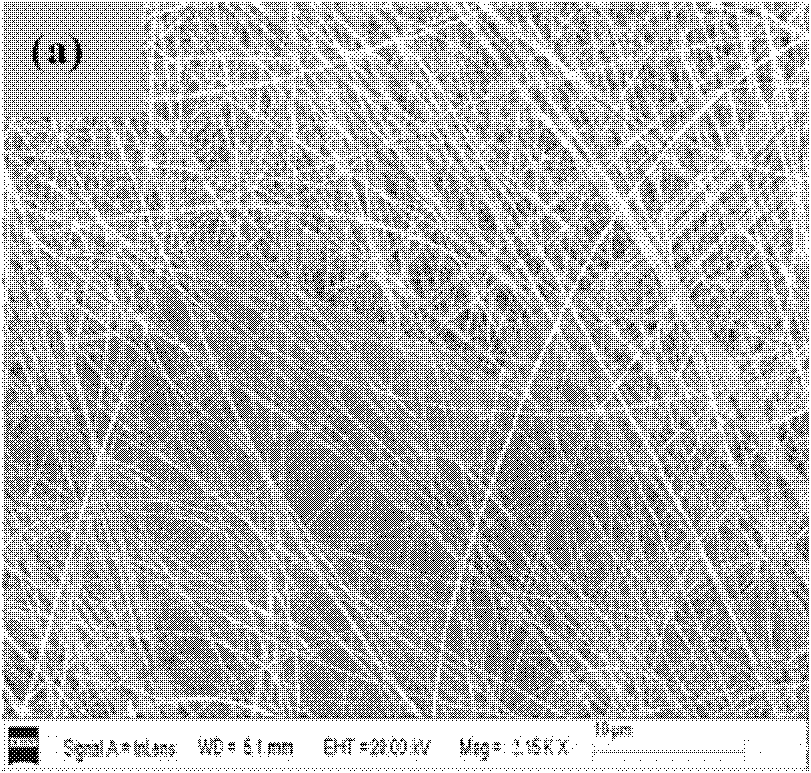

[0033] First, dissolve 0.364 g of V2O5 powder (99.8%) in 20 mL of deionized water, then add 4.0 mL of 30% H 2 o 2 And keep stirring at room temperature for 2 hours; meanwhile, dissolve 0.0182g (5wt%ofV2O5) commercial graphite (KS-6) in 10mL deionized water, then add 3.0mL30%H to the above solution under mechanical stirring 2 o 2 and sonicated at 100W for 6h; then, the above two solutions were mixed into a 50mL autoclave, and kept at 205°C for 5 days; finally, the product was washed with deionized water, centrifuged for 30 minutes, and dried in a vacuum oven at 80°C for 12 hour, and then annealed at 400° C. for 30 minutes in an air atmosphere to obtain an ultralong single crystal V2O5 nanowire / graphene composite positive electrode material. SEM and TEM analysis ( figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 ) shows that V with a length of about tens of microns 2 o 5 The nanowires are orderly distributed on the surface and interlayer of transparent graphene n...

Embodiment 2

[0035] First, 0.182g of V2O5 powder (99.8%) was dissolved in 10mL of deionized water, then 5.0mL of isopropanol was added to the above solution under mechanical stirring and the stirring was continued at room temperature for 4 hours; at the same time, 0.0091g (5wt% ofV2O5) Commercial graphite (super-p) was dissolved in 5 mL of deionized water, then 1.5 mL of isopropanol was added to the above solution under mechanical stirring and ultrasonically degraded at 100 W for 4 h; then, the above two solutions were mixed into a 50 mL autoclave, Keep at 210°C for 4 days; finally, the product is washed with deionized water, centrifuged for 30 minutes, dried in a vacuum oven at 80°C for 12 hours, and annealed at 400°C for 30 minutes in an air atmosphere to obtain VO 2 Nanorod / graphene composite cathode material. X-ray diffraction analysis showed that the final product contained GNS and VO respectively 2 Diffraction peak, and VO 2 GNSs in nanorod / graphene composites maintain their orig...

Embodiment 3

[0037] Will 0.364g V 6 o 13 The powder was dissolved in 20 mL of deionized water, and then 4.0 mL of 30% H was added to the above solution under mechanical stirring 2 o 2 And keep stirring at room temperature for 2 hours; at the same time, dissolve 0.0364g (10wt%ofV6O13) commercial expandable graphite in 10mL deionized water, then add 3.0mL 30%H to the above solution under mechanical stirring 2 o 2and sonicated at 100W for 12; then, the above two solutions were mixed into a 50mL autoclave, and roasted at 215°C for 8 days; finally, the product was washed with deionized water, centrifuged for 30 minutes, and dried in a vacuum oven at 80°C for 12 Hours, annealing at 400° C. for 30 minutes in an air atmosphere to obtain a nanostructured vanadium oxide / graphene composite positive electrode material. X-ray diffraction analysis shows that the final product contains GNS and vanadium oxide diffraction peaks respectively, and the electrochemical test results show that the nanostruct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com