Metallic oxide/carbon nano-tube composite material as well as preparation method and application thereof

A carbon nanotube and composite material technology, which is applied in active material electrodes, electrical components, electrolytic capacitors, etc., to avoid hydrothermal reactions, excellent electrochemical performance, and avoid functionalization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

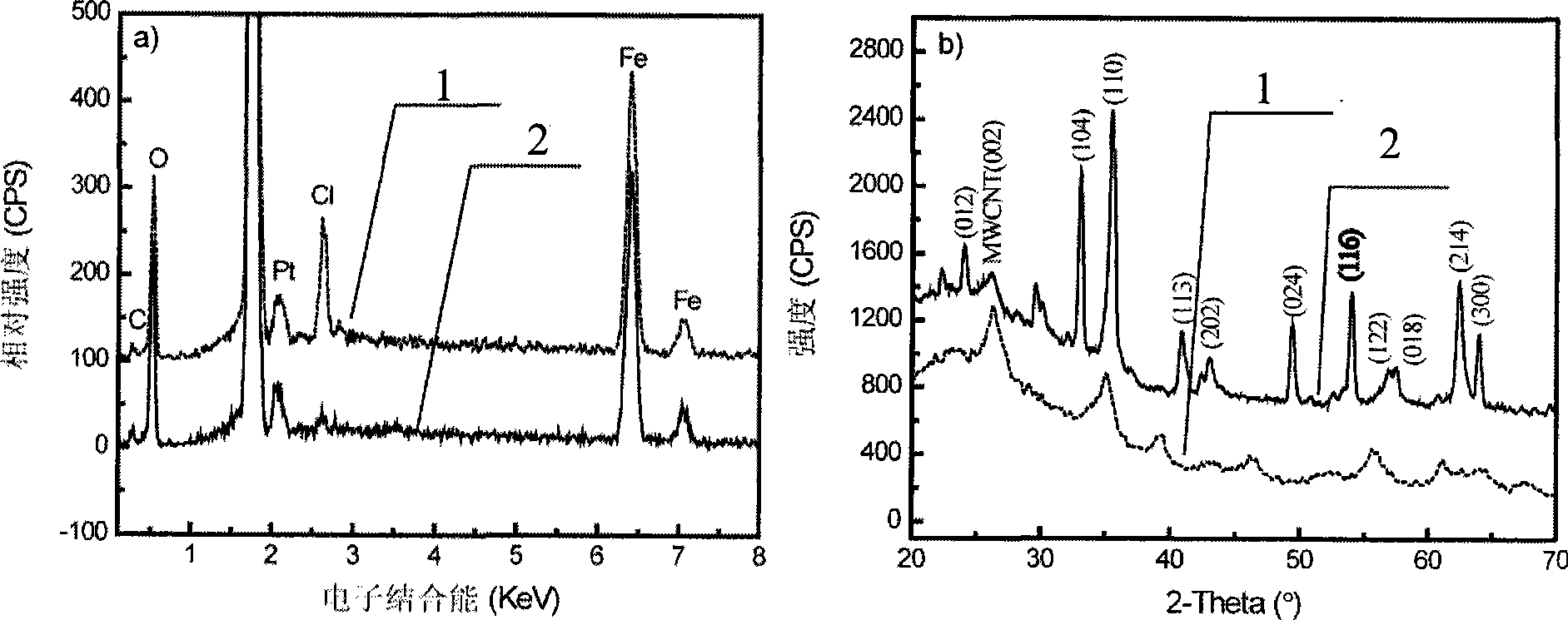

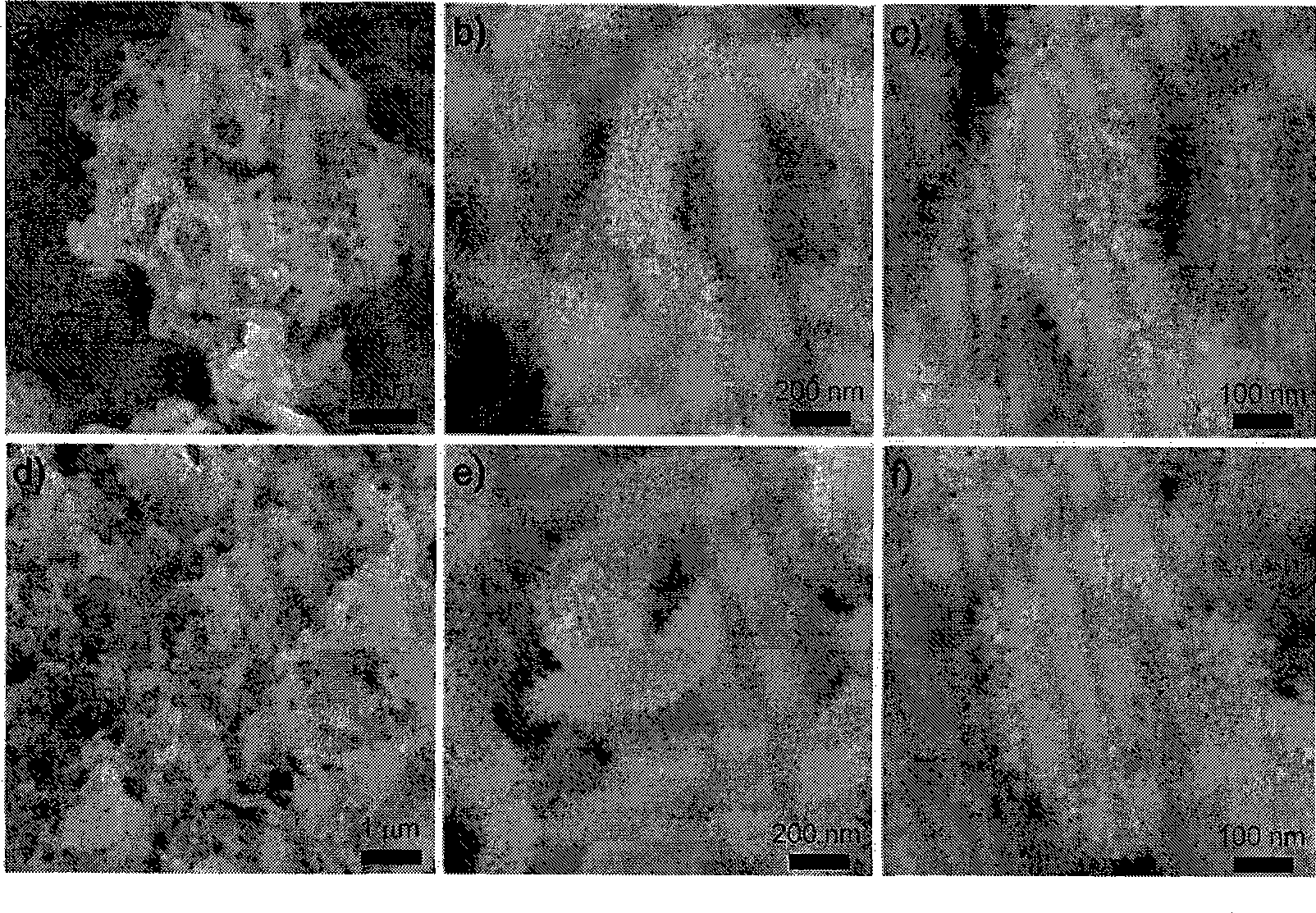

[0037] Embodiment 1, preparation Fe 2 o 3 / Carbon nanotube composites

[0038] Weigh 10 mg of purified carbon nanotubes (Shenzhen Nano Harbor Co., Ltd., carbon nanotubes have a diameter of 60-100 nm and a length of 5-15 μm), add 30 ml of ethanol and 1 ml of Tween-80, and ultrasonically Dispersion was carried out for 5 hours to obtain solution A. Solution B was obtained by dissolving 400 mg of ferric chloride hexahydrate in 2 ml of ethanol. 600 mg of urea was weighed and dissolved in solution A to obtain solution C, and 2 ml of water was added to solution C to obtain solution D. In solution D, the volume ratio of water to ethanol is 1:15. Add solution B to solution D and mix well to obtain solution E. Transfer solution E to a round bottom flask, reflux at 120°C for 10 hours under stirring, centrifuge to separate the solid, wash it with ethanol, and dry at 80°C to obtain Fe 2 o 3 / Precursors of carbon nanotube composites. Then the precursor was annealed as follows: under...

Embodiment 2

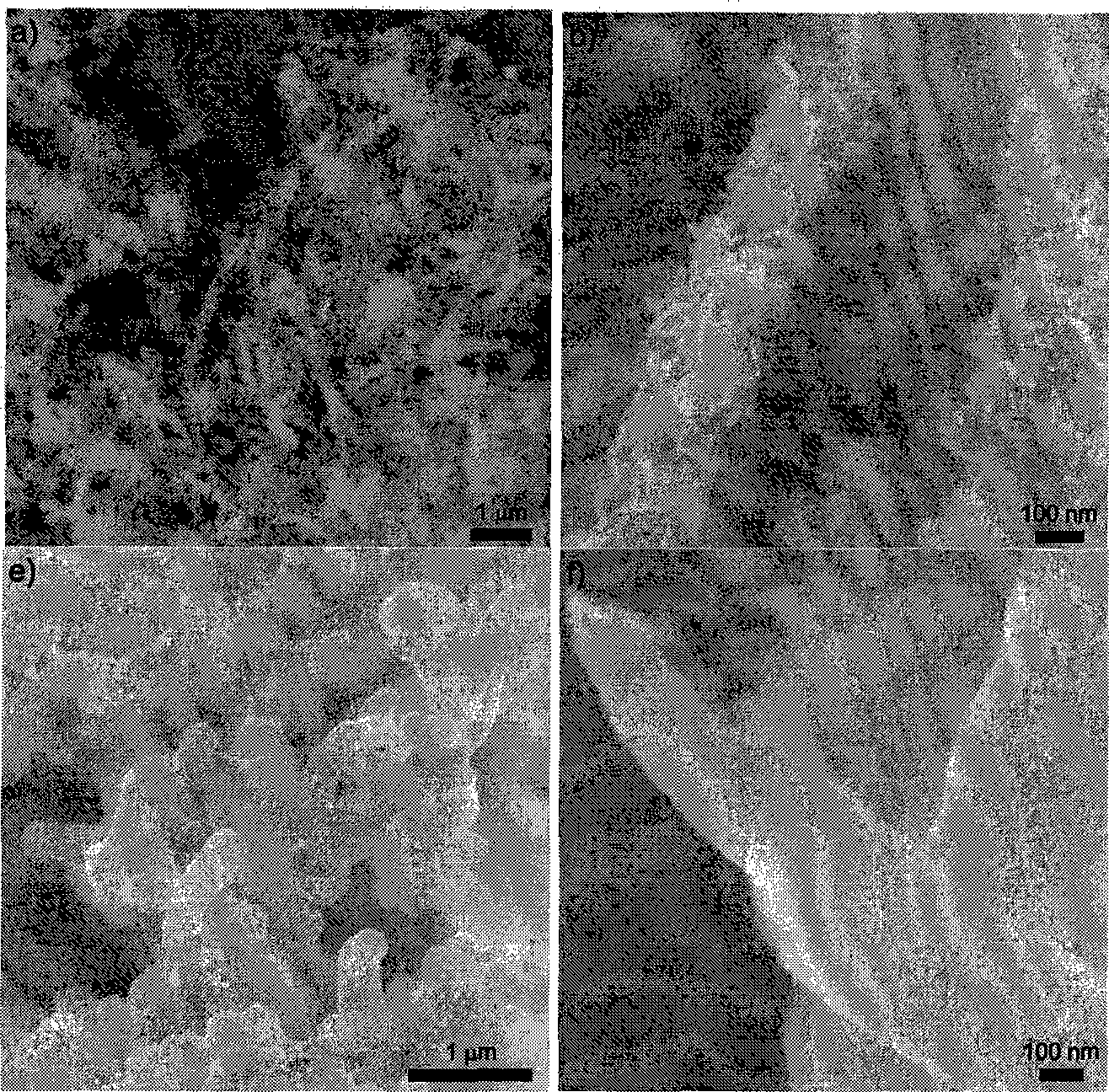

[0044] Embodiment 2, preparation NiO / carbon nanotube composite material

[0045] Weigh 10 mg of purified carbon nanotubes (Shenzhen Nano Harbor Co., Ltd., carbon nanotubes have a diameter of 60-100 nm and a length of 5-15 μm), add 30 ml of ethanol and 1 ml of Tween-80, and ultrasonically Dispersion was carried out for 5 hours to obtain solution A. Solution B was obtained by dissolving 300 mg of nickel chloride hexahydrate in 2 ml of ethanol. Weigh 600 mg of urea and dissolve it in solution A to obtain solution C. Add 2 ml of water to solution C to obtain solution D. In solution D, the volume ratio of water to ethanol is 1:15. Add solution B to solution D, mix well to obtain solution E, transfer solution E to a round bottom flask, reflux at 120°C for 6 hours under stirring, centrifuge to separate the solid, wash it with ethanol, and dry at 100°C to obtain NiO / carbon Precursors for nanotube composites. Then the precursor was heated from 20° C. to 400° C. at a rate of 1° C. / m...

Embodiment 3

[0048] Embodiment 3, prepare RuO 2 / Carbon nanotube composites

[0049] Weigh 10 mg of purified carbon nanotubes (Shenzhen Nanoport Co., Ltd., carbon nanotubes have a diameter of 60-100 nm and a length of 5-15 μm), add 30 ml of ethanol, and ultrasonically disperse for 5 hours to obtain solution A . Solution B was obtained by dissolving 40 mg of ruthenium trichloride in 2 ml of ethanol. Weigh 900 mg of urea and dissolve it in solution A to obtain solution C, add 2 ml of water to solution C to obtain solution D. In solution D, the volume ratio of water to ethanol is 1:15. Add solution B to solution D, mix well to obtain solution E, transfer solution E to a round bottom flask, reflux at 120°C for 10 hours under stirring, centrifuge to separate the precipitate, wash with ethanol, and dry at 80°C to obtain RuO 2 / Precursors of carbon nanotube composites. Then the precursor was heated from 20 °C to 400 °C at a rate of 1 °C / min under nitrogen atmosphere, and kept for 1 hour, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com