Control method for varying condition operation of throttling refrigerating system of deep freezing mixed working-fluid

A refrigeration system and mixed working medium technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve problems such as complex cycles, increased cooling process time, and system recovery delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

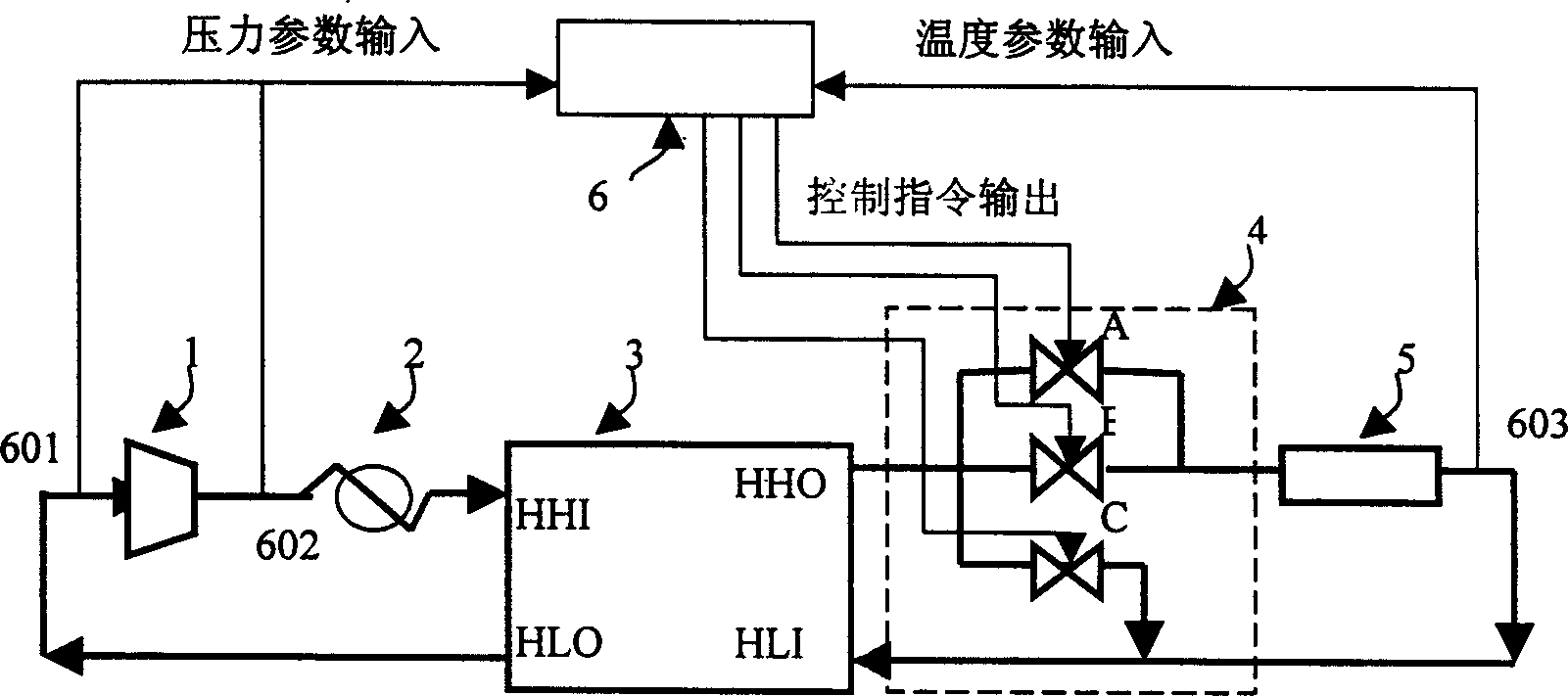

[0127] Embodiment 1: adopt figure 1 The refrigeration process and control system shown in the figure, the system includes a mixed working medium throttling refrigeration process and operation control system, which includes a single-stage oil-lubricated commercial compressor 1 in the refrigeration process, a condenser 2 matched with the compressor, A combination of heat exchangers with a balanced flash vapor-liquid separator is used as the heat recovery unit 3 (see the schematic diagram for the specific structure Figure 5 ), a throttling control unit group 4, an evaporator 5, and some connecting pipes. The operation control system includes a control unit 6 , a compressor intake pressure sensor 601 , an exhaust pressure sensor 602 and an evaporator outlet temperature sensor 603 . The throttling control unit group includes a main throttling element A, an auxiliary throttling element B and a bypass throttling element C.

[0128] According to the variable working condition opera...

Embodiment 2

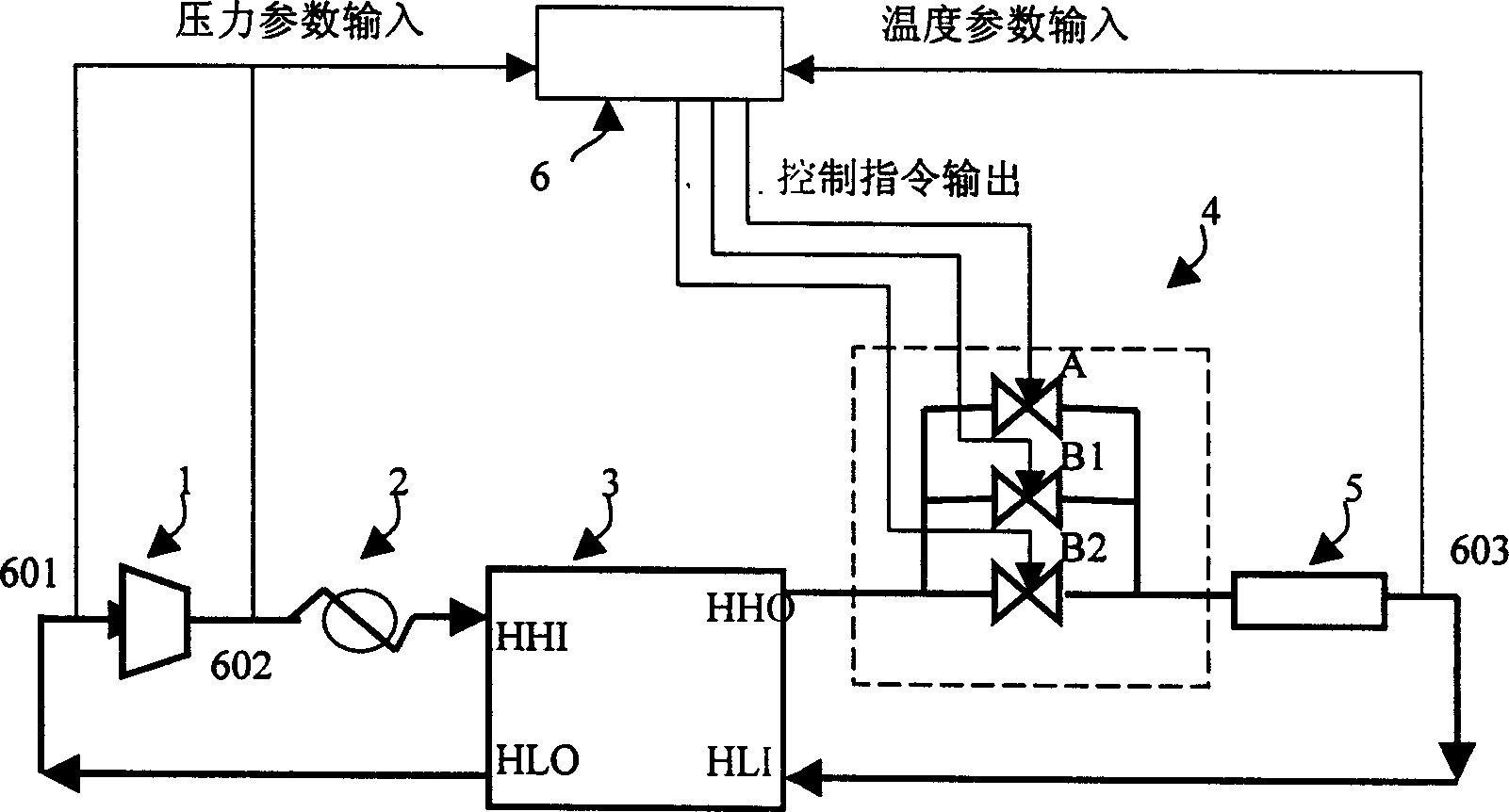

[0139] Embodiment 2: A typical mixed working medium refrigeration and control system, including a mixed working medium throttling refrigeration process and operation control system, which includes a single-stage oil-lubricated commercial compressor 1 in the refrigeration process, and a matching compressor Condenser 2, using a combination of heat exchangers with a balanced flash vapor-liquid separator as the heat recovery unit 3 (see the schematic diagram for the specific structure Figure 4 ), a throttling control unit group 4, an evaporator 5, and some connecting pipes. The operation control system includes a control unit 6 , a compressor intake pressure sensor 601 , an exhaust pressure sensor 602 and an evaporator outlet temperature sensor 603 . The throttling control unit group includes a main throttling element A, a bypass throttling element C, and an auxiliary throttling element B is composed of two parallel controllable throttling elements B1 and B2.

[0140] According ...

Embodiment 3

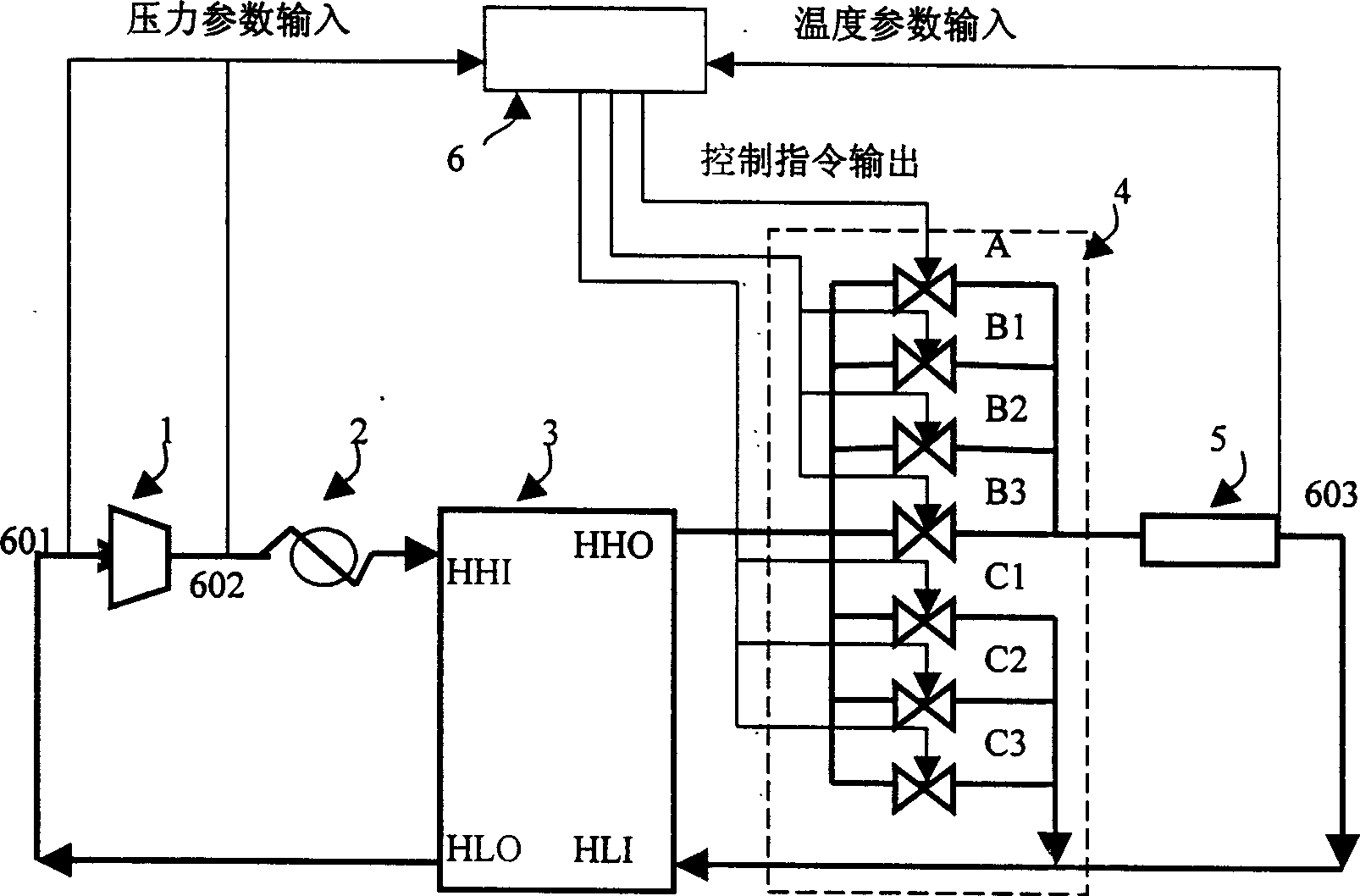

[0157] Embodiment 3: The refrigeration system is the same as that in Embodiment 2, except that the controllable auxiliary throttling element B in the throttling control unit group 4 consists of a parallel controllable auxiliary throttling element B1, a controllable auxiliary throttling element B2 and a controllable auxiliary throttling element B2. Controlled auxiliary throttling element B3, the control steps of the cryogenic mixed working fluid refrigeration system for variable working conditions are as follows:

[0158] 1. For the controlled cooling condition: open the main throttling element A, close the controllable bypass throttling element C,

[0159] 1) When the control unit 6 satisfies one of the following conditions, turn on the controllable auxiliary throttling elements B1, B2 and B3 at the same time:

[0160] ●The discharge pressure value 602 of the compressor unit 1 is within the set value range of 2.0MPa to 2.5MPa;

[0161] The suction pressure value 601 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com