Method for quickly forming soft power lithium-ion cell

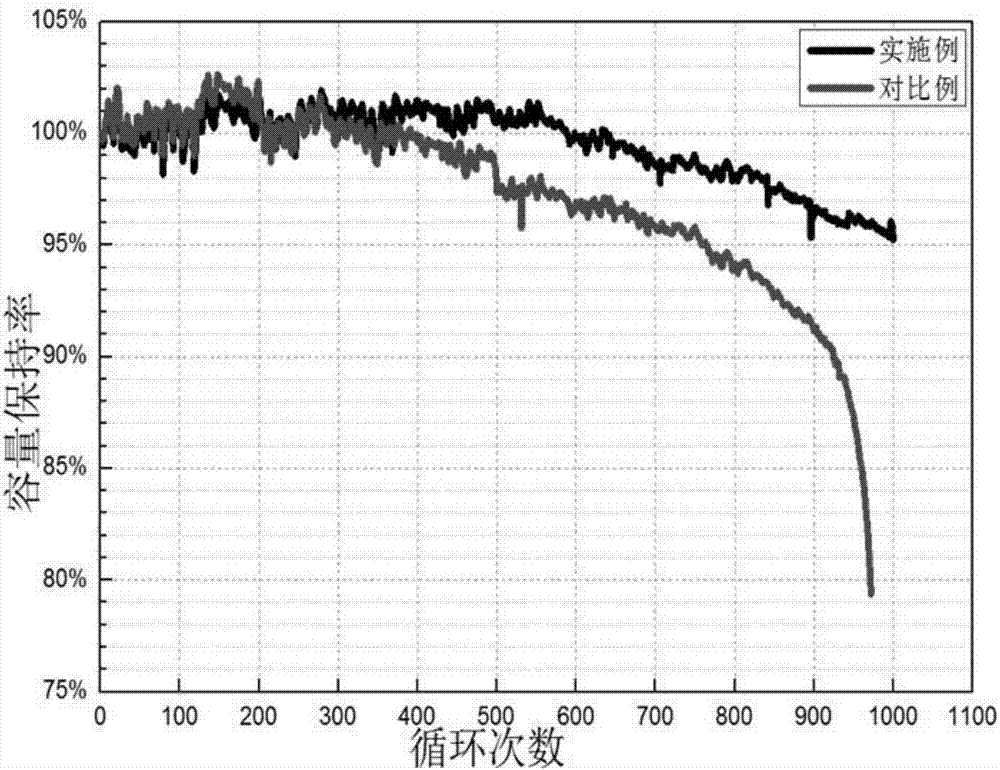

A formation method, lithium-ion technology, which is applied in the field of rapid formation of soft-pack power lithium-ion batteries, can solve the problem that the data size of constant current is not representative, the batteries cannot activate active materials well, and it is unfavorable for large-scale production and Promotion and other issues to achieve the effect of shortening the formation time, avoiding premature failure, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for rapidly forming a soft-pack power lithium-ion battery cell, comprising the following steps:

[0031] S1: Use a heating plate to provide a heat source to heat the cell;

[0032] S2: Use the servo motor to drive the pressure plate to pressurize the cell;

[0033] S3: Carry out step-by-step charging for the battery cell;

[0034] S4: Charge the battery to a high state of charge.

[0035] The temperature for heating the cell is: 30°C.

[0036] The pressurization pressure of the cell is: 0.3MPa.

[0037] The battery cell is charged stepwise, and the specific steps are:

[0038] The first stage: constant current charging, charging to 10% SOC of reversible capacity, charging current 0.05C;

[0039] The second stage: constant current charging, charging to 20% SOC of reversible capacity, charging current 0.2C;

[0040] The third stage: constant current charging, charging to 40% SOC of reversible capacity, charging current 0.4C.

[0041] The final charging cut...

Embodiment 2

[0045] A method for rapidly forming a soft-pack power lithium-ion battery cell, comprising the following steps:

[0046] S1: Use a heating plate to provide a heat source to heat the cell;

[0047] S2: Use the servo motor to drive the pressure plate to pressurize the cell;

[0048] S3: Carry out step-by-step charging for the battery cell;

[0049] S4: Charge the battery to a high state of charge.

[0050] The temperature for heating the cell is: 45°C.

[0051] The pressurization pressure of the cell is: 0.5MPa.

[0052] The battery cell is charged stepwise, and the specific steps are:

[0053] The first stage: constant current charging, charging to 10% SOC of reversible capacity, charging current 0.1C;

[0054] The second stage: constant current charging, charging to 30% SOC of reversible capacity, charging current 0.3C;

[0055] The third stage: constant current charging, charging to 50% SOC of the reversible capacity, charging current 0.5C.

[0056] The final charging ...

Embodiment 3

[0060] A method for rapidly forming a soft-pack power lithium-ion battery cell, comprising the following steps:

[0061] S1: Use a heating plate to provide a heat source to heat the cell;

[0062] S2: Use the servo motor to drive the pressure plate to pressurize the cell;

[0063] S3: Carry out step-by-step charging for the battery cell;

[0064] S4: Charge the battery to a high state of charge.

[0065] The temperature for heating the cell is: 80°C.

[0066] The pressurization pressure of the cell is: 1MPa.

[0067] The battery cell is charged stepwise, and the specific steps are:

[0068] The first stage: constant current charging, charging to 10% SOC of reversible capacity, charging current 0.2C;

[0069] The second stage: constant current charging, charging to 40% SOC of reversible capacity, charging current 0.4C;

[0070] The third stage: constant current charging, charging to 40% SOC of reversible capacity, charging current 0.8C.

[0071] The final charging cut-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com