Metallic oxide/N-doped carbon nano tube as well as preparation method and application thereof

A nitrogen-doped carbon and nanotube technology, applied in the field of composite materials, can solve the problems of high cost of the preparation method, unsuitable for mass production, easy shedding of metal oxides, etc., avoiding pretreatment steps, avoiding solvothermal reactions, good effect of electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 SnO 2 / Nitrogen-doped carbon nanotube composites

[0041] (1) Mix 0.5g of nitrogen-doped carbon nanotubes (the diameter of nitrogen-doped carbon nanotubes is 30-50nm, the length is 5-15μm, and the nitrogen doping amount is 5.0mmol / g) in 10mL of water and 10mL of ethanol During ultrasonic dispersion at 20KHz for 30 minutes, solution A was obtained;

[0042] (2) 1g SnCl 2 2H 2 The O solid was dissolved in 18 mL of absolute ethanol to obtain solution B (SnCl 2 The concentration is 5.58wt%); under the condition of stirring, solution B was dripped into solution A at room temperature, and stirred for 2 hours to obtain a mixed solution;

[0043] (3) Suction filter the mixture, wash it with deionized water and ethanol accordingly, dry it in an oven at 80°C for 5 hours after filtration, and roast it in vacuum at 800°C for 0.5 hour to obtain SnO 2 / Nitrogen-doped carbon nanotube composites

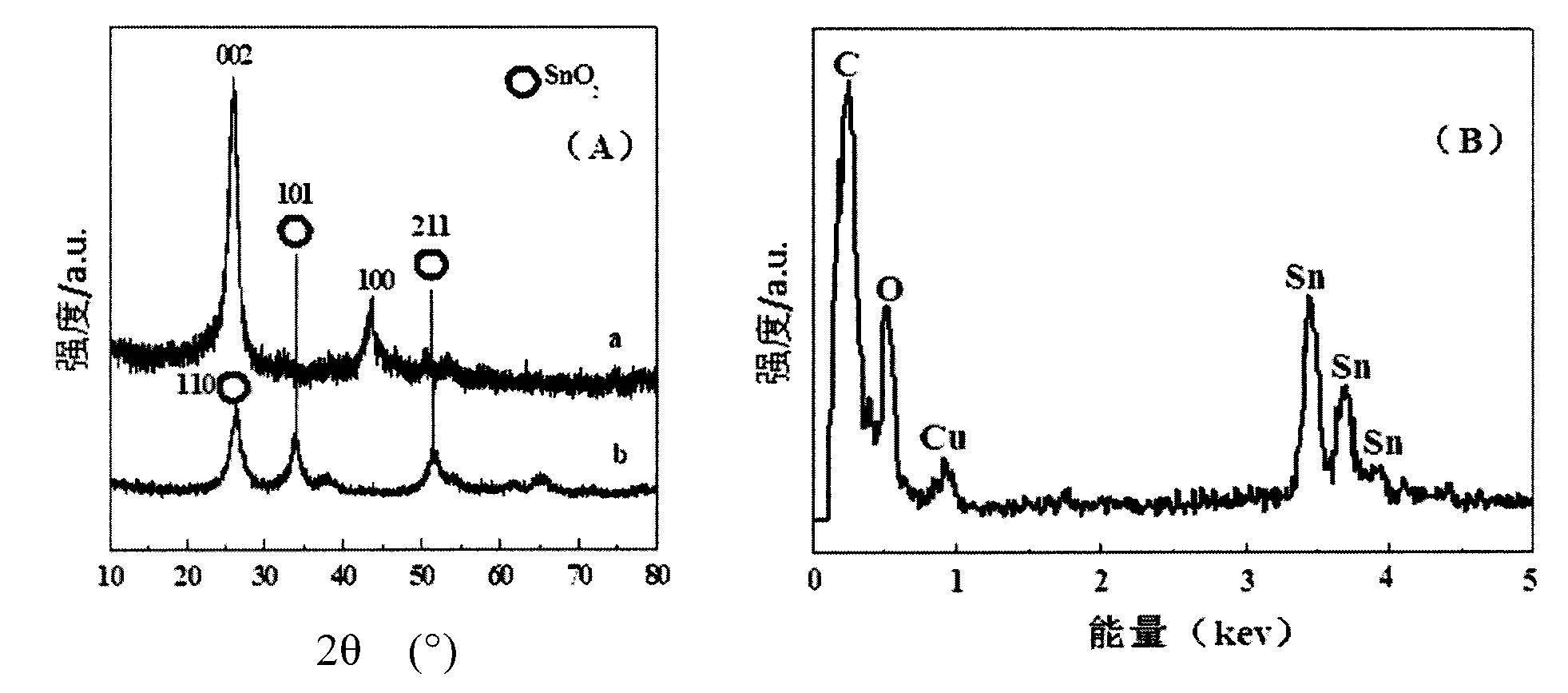

[0044] SnO 2 / Characterization of nitrogen-doped carbon nanotube composi...

Embodiment 2

[0047] Example 2 TiO 2 / Nitrogen-doped carbon nanotube composites

[0048] (1) Mix 1g nitrogen-doped carbon nanotubes (diameter of nitrogen-doped carbon nanotubes is 40-60nm, length is 10-25μm, nitrogen doping amount is 7.2mmol / g) in 8mL water and 240mL isopropanol Ultrasonic dispersion in the solution at 50KHz for 1 hour to obtain solution A;

[0049] (2) Dissolve 6.82mL tetraisopropyl titanate (TPOT) in 80mL isopropanol to obtain solution B (the concentration of TPOT is 9.79wt%); under stirring condition, at room temperature, drop solution B into In solution A, stir for 3 hours to obtain a mixed solution;

[0050] (3) Suction filter the mixture, wash it with deionized water and ethanol accordingly, dry it at 50°C for 0.5 hours, and vacuum roast it at 400°C for 10 hours to obtain TiO 2 / Nitrogen-doped carbon nanotube composites.

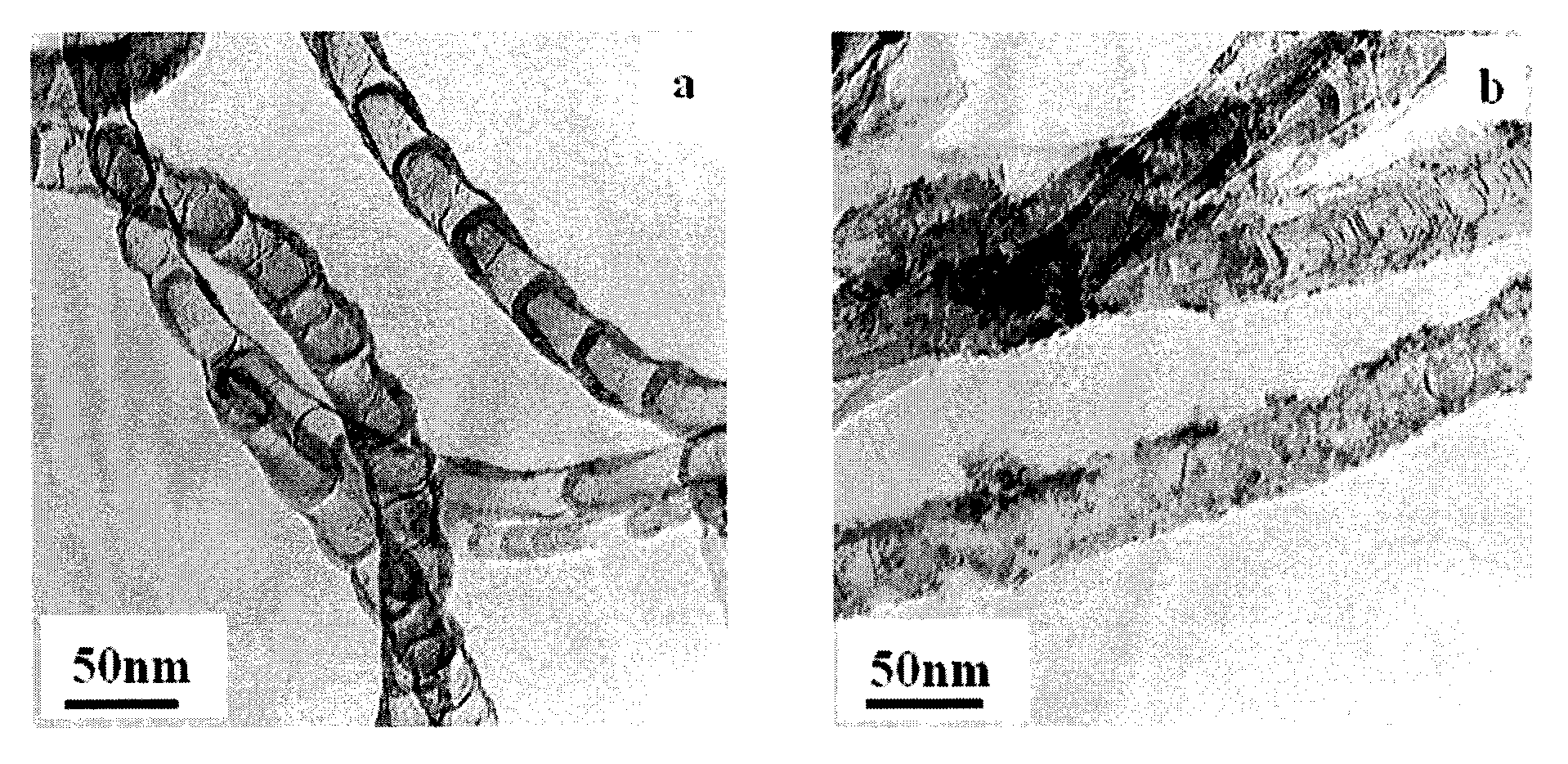

[0051] Analysis of TiO by Transmission Electron Microscopy (TEM) (JEOL-JEM-1005) 2 / Nitrogen-doped carbon nanotube composites. It can be seen...

Embodiment 3

[0052] Example 3 WO 3 / Nitrogen-doped carbon nanotube composites

[0053] (1) Mix 0.5g nitrogen-doped carbon nanotubes (diameter of nitrogen-doped carbon nanotubes is 20-50nm, length is 15-40μm, nitrogen doping amount is 20mmol / g) in 20mL water and 180mL n-butanol The solution was ultrasonically dispersed at 40KHz for 6 hours to obtain solution A;

[0054] (2) 1.62g sodium tungstate (Na 2 WO 4 2H 2 O) The solid was dissolved in 200 mL of water to obtain solution B (Na 2 WO 4 The concentration is 0.76wt%); under the condition of stirring, at room temperature, solution B was dripped into solution A, stirred for 3 hours to obtain a mixed solution;

[0055] (3) Suction filter the mixed solution, wash it with deionized water and ethanol accordingly, dry it in a drying oven at 120°C for 3 hours after filtering, and roast it in vacuum at 600°C for 5 hours to obtain TiO 2 / Nitrogen-doped carbon nanotube composites.

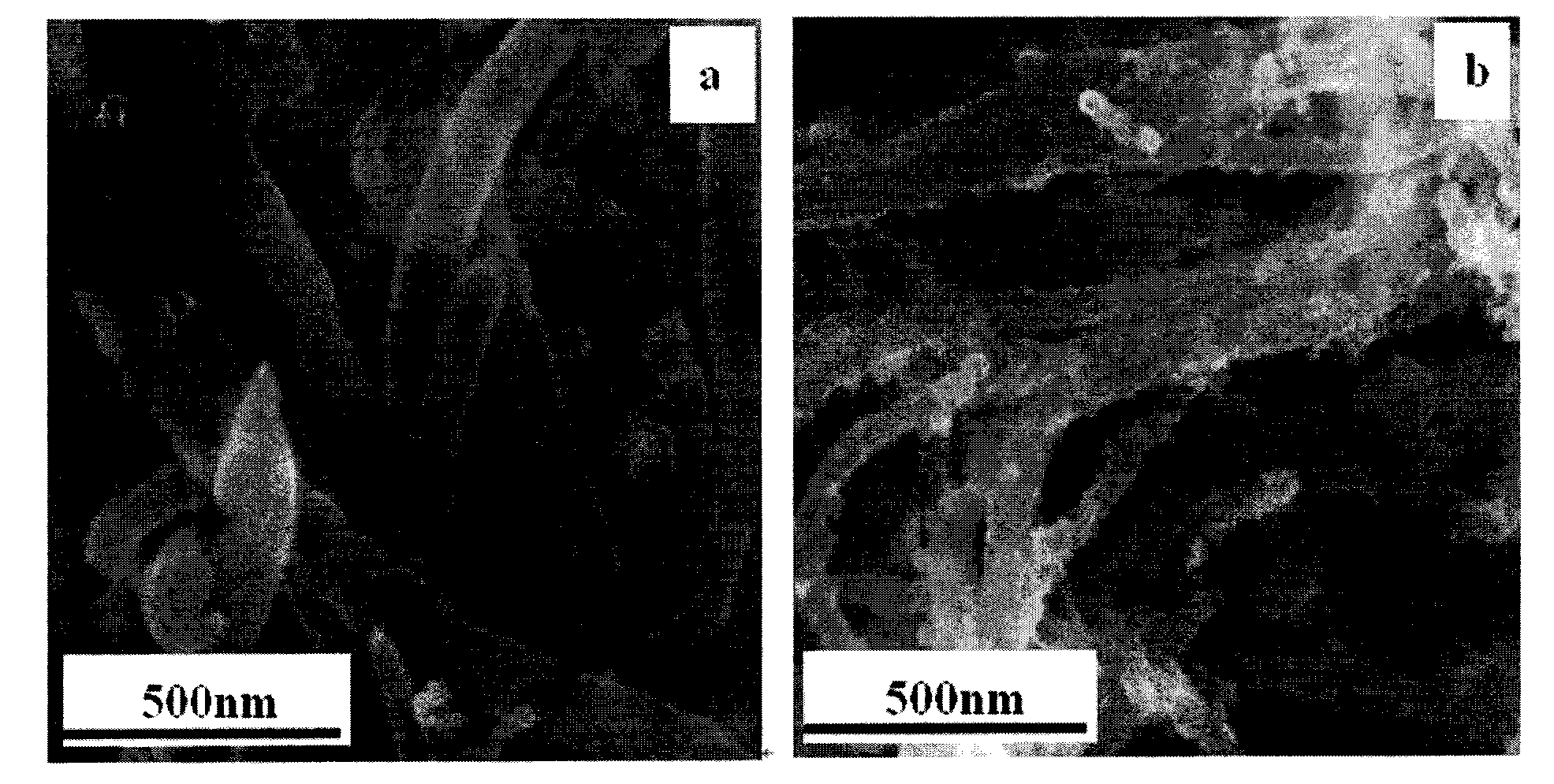

[0056] Analysis of WO by scanning electron microscope (SEM) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com