Preparation method of mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material

A technology of mullite fiber and composite material is applied in the field of preparation of mullite fiber felt reinforced SiO2-Al2O3 aerogel composite thermal insulation material, which can solve the problems of reduced thermal insulation performance, complicated preparation process, poor temperature resistance and the like , to achieve the effect of increasing operability and controllability, simplifying process steps and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

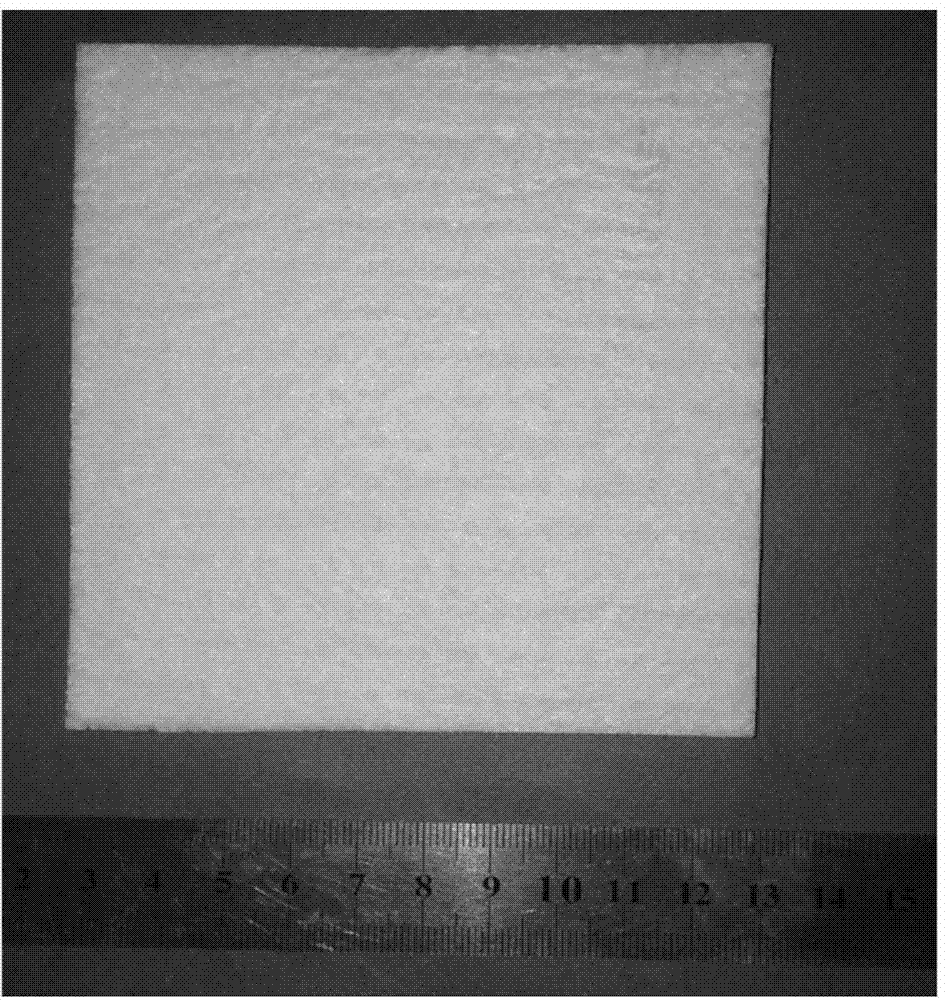

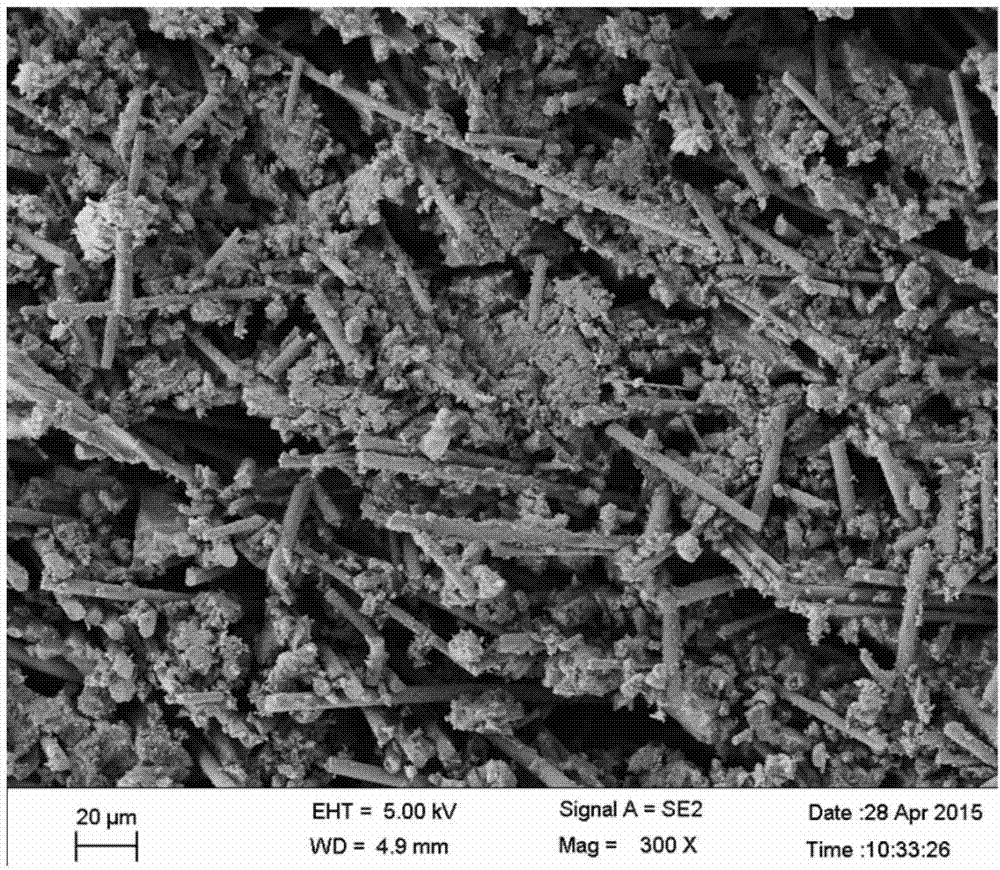

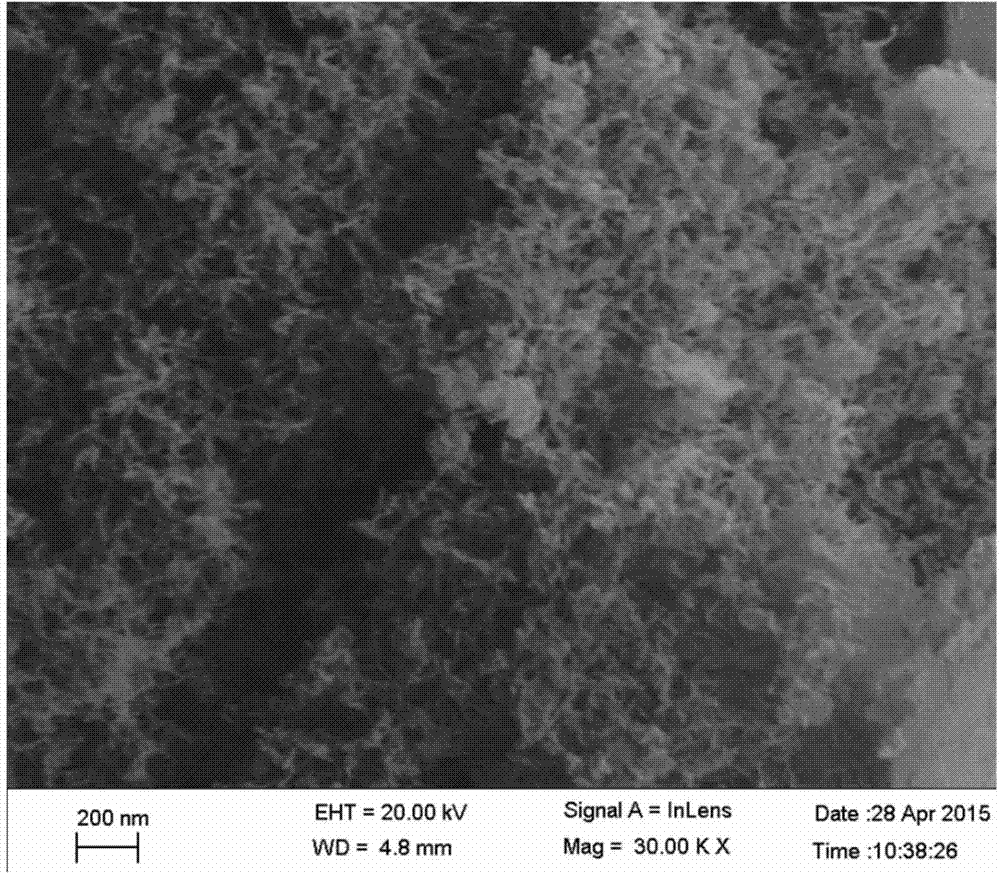

example 1

[0030] The mullite fiber felt was placed in a muffle furnace, raised to 600°C at a rate of 2°C / min and kept for 2 hours, then naturally cooled to room temperature to obtain a surface-pretreated mullite fiber felt. Mix aluminum chloride hexahydrate, tetraethyl orthosilicate, ethanol, and water uniformly at a molar ratio of 1:0.125:15:50, and stir evenly at a temperature of 50°C for 2 hours to hydrolyze the components to obtain silicon aluminum Composite sol. After the silicon-aluminum composite sol is cooled to 25°C, add a certain amount of propylene oxide, wherein the molar ratio of propylene oxide to aluminum chloride is 8, then continue to stir for 10 minutes and then slowly inject it into the mullite fiber mat . The mullite fiber mat reinforced SiO 2 -Al 2 o 3 After the composite wet gel was left at room temperature for 24 hours, ethanol was added to age it, and ethanol was added to replace it in an oven at 30°C for 8 times, 24 hours each time. Finally, the wet gel com...

example 2

[0032] The mullite fiber felt was placed in a muffle furnace, raised to 700°C at a rate of 4°C / min and kept for 2 hours, then naturally cooled to room temperature to obtain a surface-pretreated mullite fiber felt. Mix aluminum chloride hexahydrate, tetraethyl orthosilicate, ethanol, and water uniformly at a molar ratio of 1:0.25:12:40, and stir evenly at a temperature of 60°C for 1 hour to hydrolyze the components to obtain silicon aluminum Composite sol. After the silicon-aluminum composite sol is cooled to 25°C, add a certain amount of cis-2,3 butylene oxide, wherein the molar ratio of cis-2,3 butylene oxide to aluminum chloride is 7, and then continue After stirring for 30 minutes, slowly inject it into the mullite fiber felt. The mullite fiber mat reinforced SiO 2 -Al 2 o 3 After the composite wet gel was left at room temperature for 16 hours, n-hexane was added to age it, and ethanol was added to replace it in an oven at 40°C for 5 times, 24 hours each time. Finally,...

example 3

[0034] The mullite fiber felt was placed in a muffle furnace, raised to 600°C at a rate of 6°C / min and kept for 3 hours, then naturally cooled to room temperature to obtain a surface-pretreated mullite fiber felt. Mix aluminum nitrate nonahydrate, tetraethyl orthosilicate, ethanol, and water uniformly at a molar ratio of 1:0.33:9:45, and then stir evenly at a temperature of 45°C for 3 hours to hydrolyze the components to obtain a silicon-aluminum composite Sol. After the silicon-aluminum composite sol is cooled to 25°C, add a certain amount of glycidol, wherein the molar ratio of glycidol to aluminum nitrate is 10, then continue to stir for 40 minutes and slowly inject it into the mullite fiber mat Inside. The mullite fiber mat reinforced SiO 2 -Al 2 o 3 After the composite wet gel was placed at room temperature for 24 hours, ethanol was added to age it, and ethanol was added to replace it in an oven at 40°C for 5 times, 24 hours each time. Finally, the wet gel composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com