Method preparing catalyzer through liquid phase ball-milling partial reduction method and ternary copper catalyzer

A catalyst and ternary copper technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve difficult ternary copper composite materials, long reaction process, product purity impact, etc. problems, to achieve the effect of easy control of shape and particle size, high product purity, and adjustable component composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Put 5.0g of analytically pure copper oxide powder and 25g of grinding beads into a stainless steel ball mill jar, add 5.0g of water and 0.5g of hydrazine hydrate in turn; grind on a planetary ball mill for 6 hours, filter the resulting product, dry and disperse it, and then The ternary copper catalyst can be obtained; after chemical analysis, the composition is: 10.1% Cu, 51.5% Cu 2 O and 38.4% CuO.

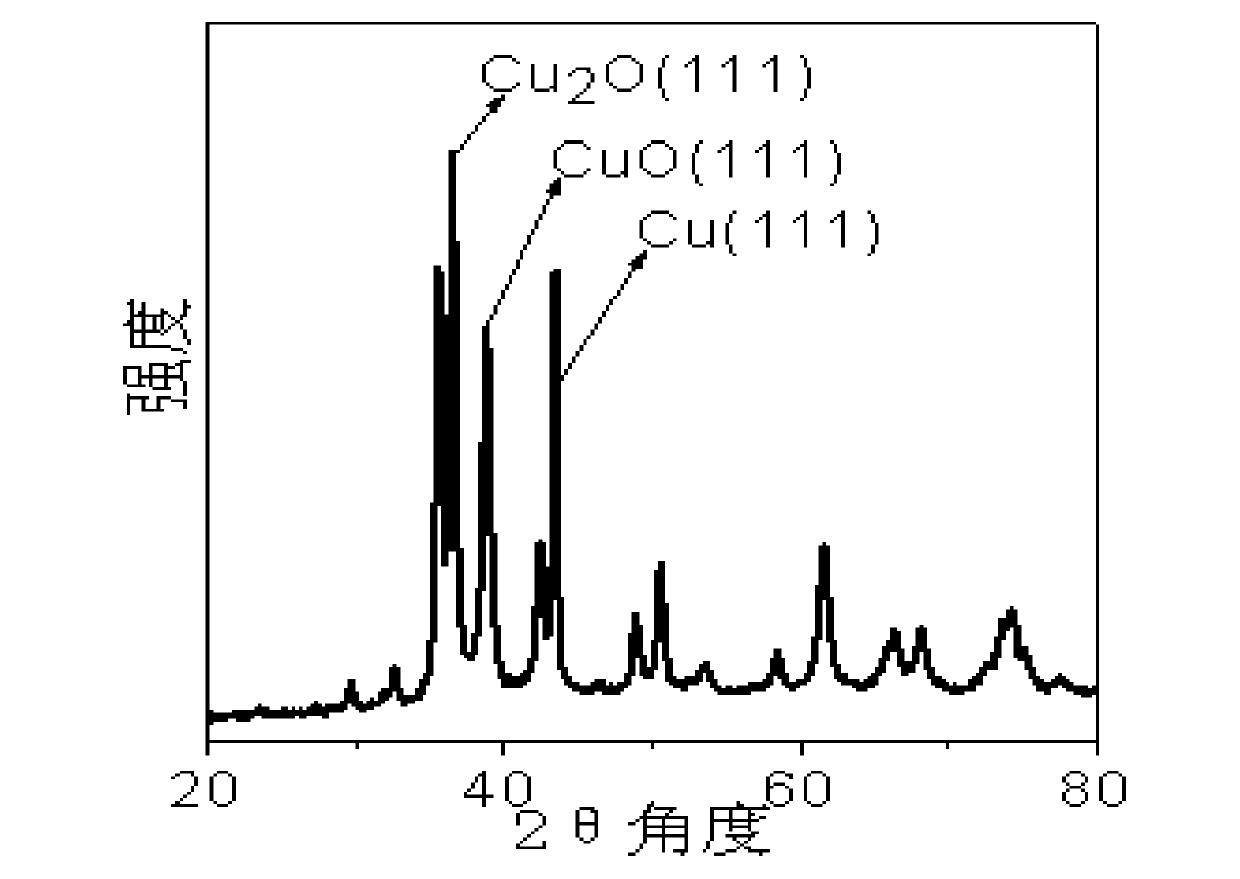

[0043] The ternary copper catalyst material prepared above was subjected to an XRD test on an X'Pert PRO MPD multifunctional X-ray diffractometer produced by Panalytical Company of the Netherlands (Panalytical).

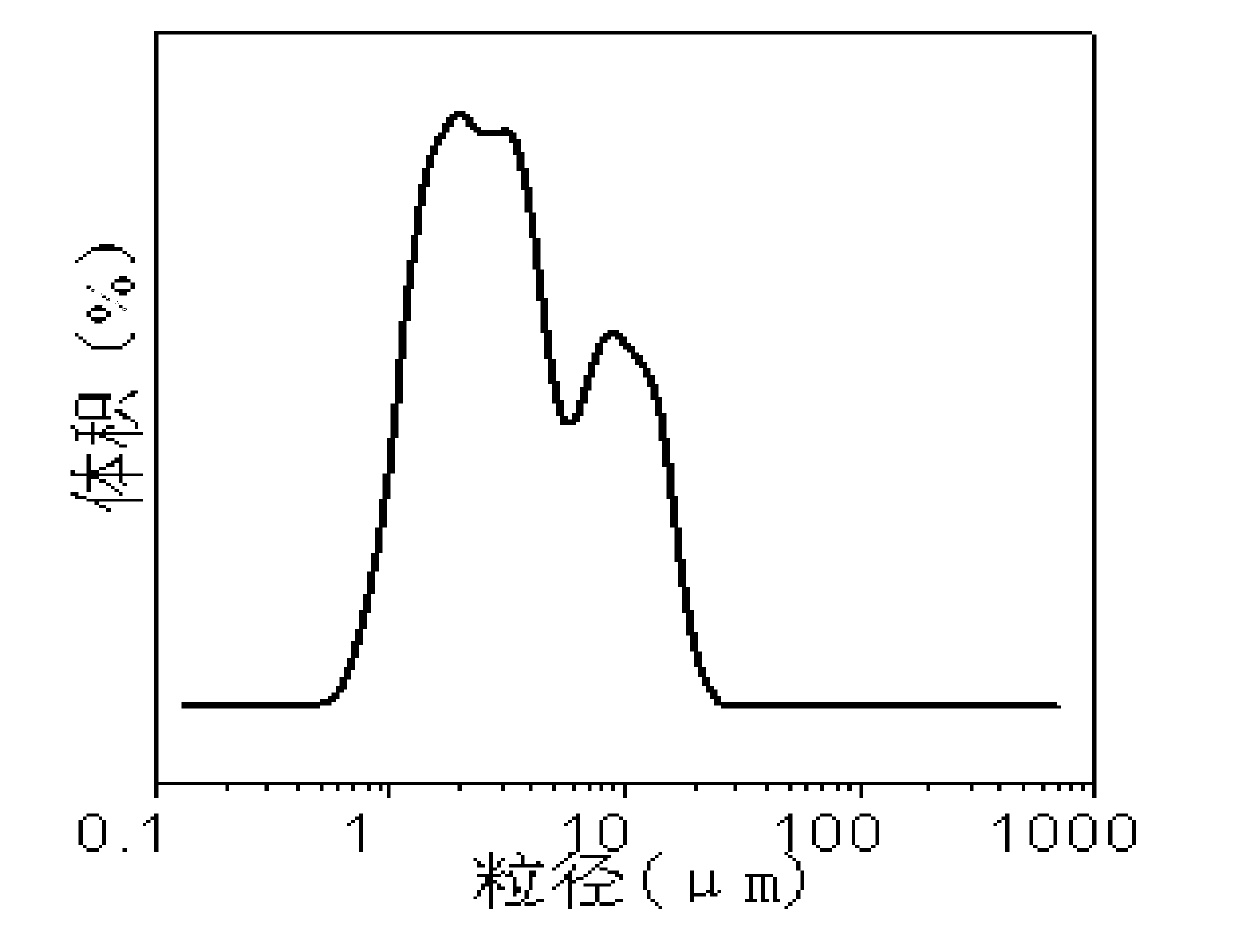

[0044] The particle size analysis of the ternary copper catalyst material prepared above was performed on a Dandong Baite BT-9300Z laser particle size distribution analyzer.

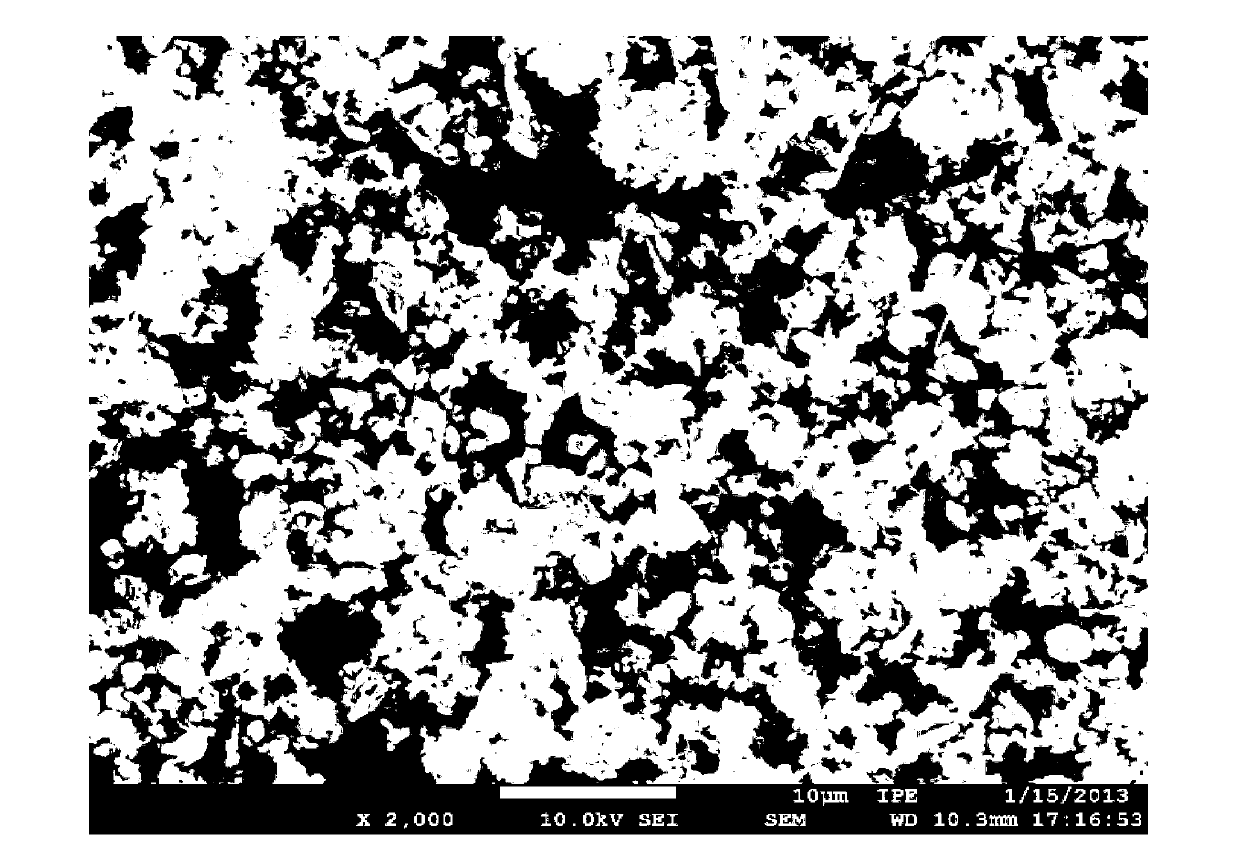

[0045] The surface morphology of the ternary copper catalyst material prepared above was observed with a JSM7100F field emission scanning electron microscope produced by Japan Electronics ...

Embodiment 2

[0050] Put 10.0g of copper oxide powder calcined from copper oxalate, 0.25g of zinc oxide powder and 25g of grinding beads into a grinding pot, add 20.0g of water and 5.0g of formaldehyde in sequence; grind on a stirring mill for 8 hours, and pump the resulting product After filtering, drying and dispersing, the ternary copper catalyst can be obtained; after chemical analysis, the composition is: 20.2% Cu, 33.3% Cu 2 O and 46.5% CuO.

[0051] Figure 4 It is the XRD figure of the copper-based catalyst that embodiment 2 obtains, wherein 2θ=36.4 ° is Cu 2 The characteristic peak of O, the shoulder peak composed of 2θ=35.5° and 2θ=38.7° is the characteristic peak of CuO, and 2θ=43.3° is the characteristic peak of Cu. It can be seen that the catalyst prepared by this method is composed of Cu, Cu 2 A ternary copper catalyst composed of O and CuO.

[0052] Figure 5 For the particle size analysis of the copper-based catalyst obtained in Example 2, it can be seen from the figure ...

Embodiment 3

[0055] Put 5.0g of copper oxide powder oxidized from copper powder and 50g of grinding beads into the drum mill, add 5.0g of water and 10.0g of hydrazine hydrate in turn; grind on the drum mill for 24h, filter the obtained product with suction, dry and disperse After that, the copper-based catalyst can be obtained; after chemical analysis, the composition is: 90.0% Cu, 5.0% Cu 2 O and 5.0% CuO, the particle diameters of which are all less than 50 microns, and most of them are 10-20 microns; the particles of the copper-based catalyst are sheet-like, with a large diameter of about 10-20 microns and a very thick sheet. Thin, substantially less than 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com