Sedimentation type impurity and water separating machine

A slag-water separation and sedimentation technology, applied in textiles and papermaking, fiber raw material processing, etc., can solve the problems of inability to remove impurities, easy to block the pressing system, and equipment production loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

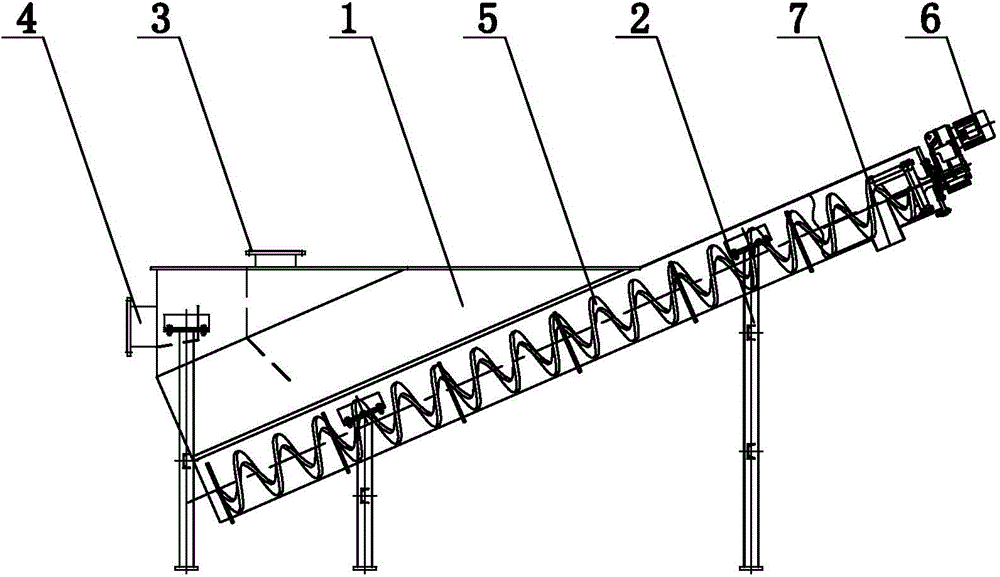

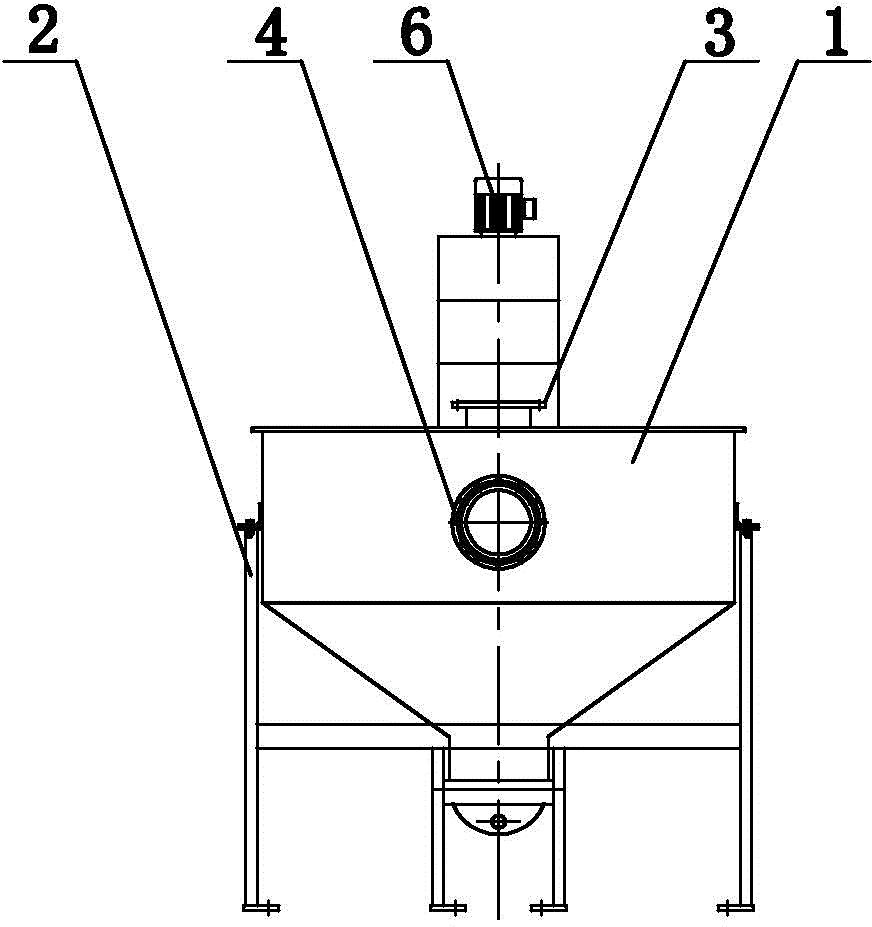

[0016] Embodiment 1: as figure 1 and figure 2 As shown, the sedimentation type slag-water separator according to the present invention is provided with a tank body 1, a fixed support 2 is arranged on the tank body 1, a feed port 3 is arranged at the top of the tank body 1, and an outlet is provided at the tail of the tank body 1. Nozzle 4, screw blade 5 is provided at the inner bottom of the tank body 1, the top of the screw blade 5 is installed on the tank body 1 through a motor 6, and the tank body 1 is provided with a discharge port 7 corresponding to the top position of the screw blade 5.

Embodiment 2

[0017] Embodiment 2: On the basis of the structure described in Embodiment 1, the helical blade 5 is a shaftless helical blade.

Embodiment 3

[0018] Embodiment 3: On the basis of the structure described in Embodiment 2, the spiral blade 5 is connected to the motor 6 through a gearbox.

[0019] Operation steps and working principle:

[0020] In the sedimentation type slag water separator, after the raw material is mixed with water, it enters the tank body 1 through the feed port 3, and the impurities in the raw material settle to the bottom of the tank body 1 under the action of gravity, and the screw blade 5 at the bottom is driven by the motor 6 Constantly rotate and filter, and finally transport the impurities to the outlet 4 and discharge them into the slag collection box. The water and light slag inside the tank 1 overflow through the outlet 4, thus achieving the purpose of solid-liquid separation and effectively removing impurities in the pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com