Dry-wet separation device for pig house excrement recycling

A dry-wet separation and resource utilization technology, applied in the field of dry-wet separation devices, can solve the problems of poor separation effect and complex structure, and achieve the effect of simple structure and improved interference separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] It should be noted that the horizontal direction described in this embodiment is a direction parallel to the horizontal slide rail, and the vertical direction is a direction parallel to the first longitudinal slide rail.

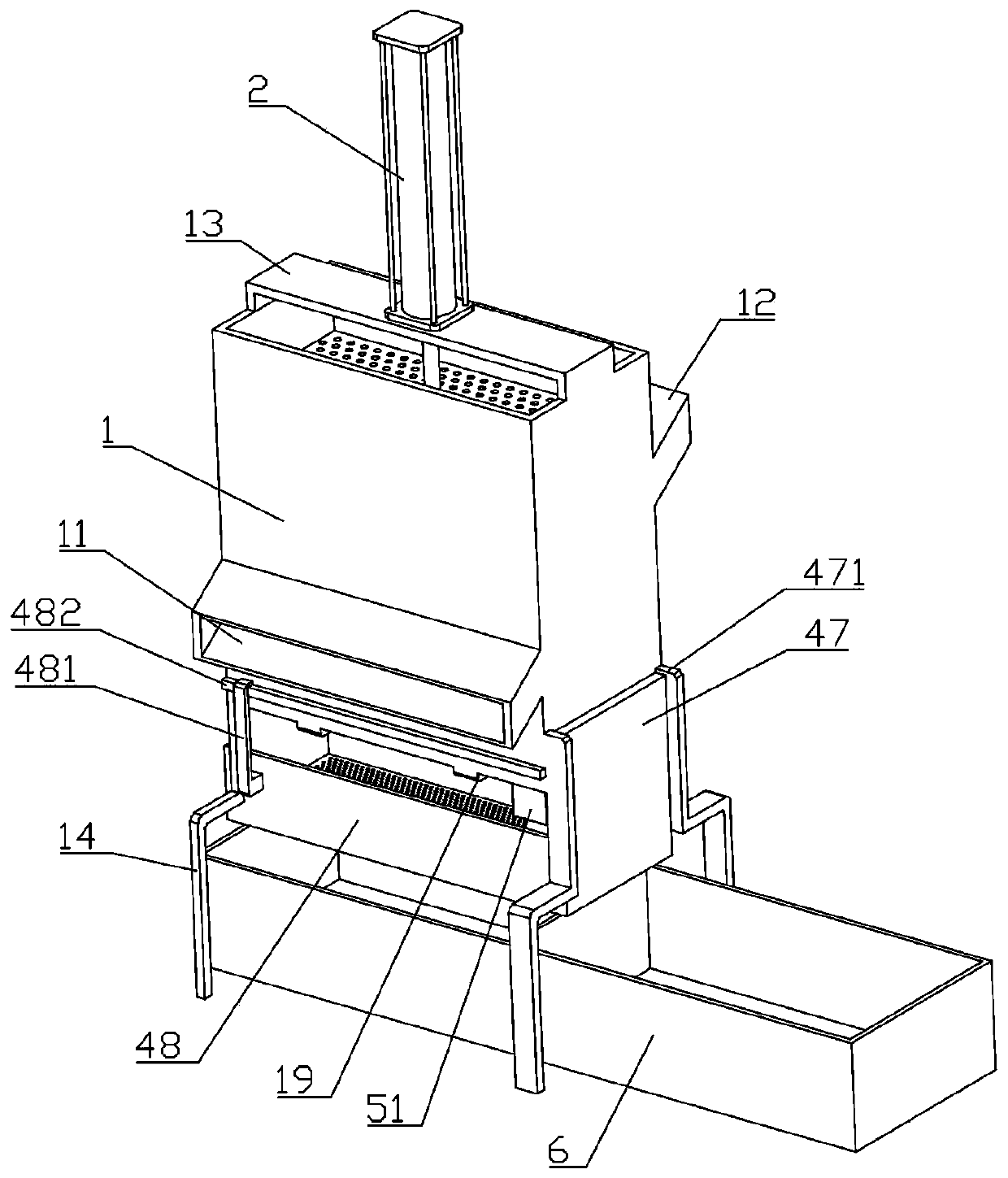

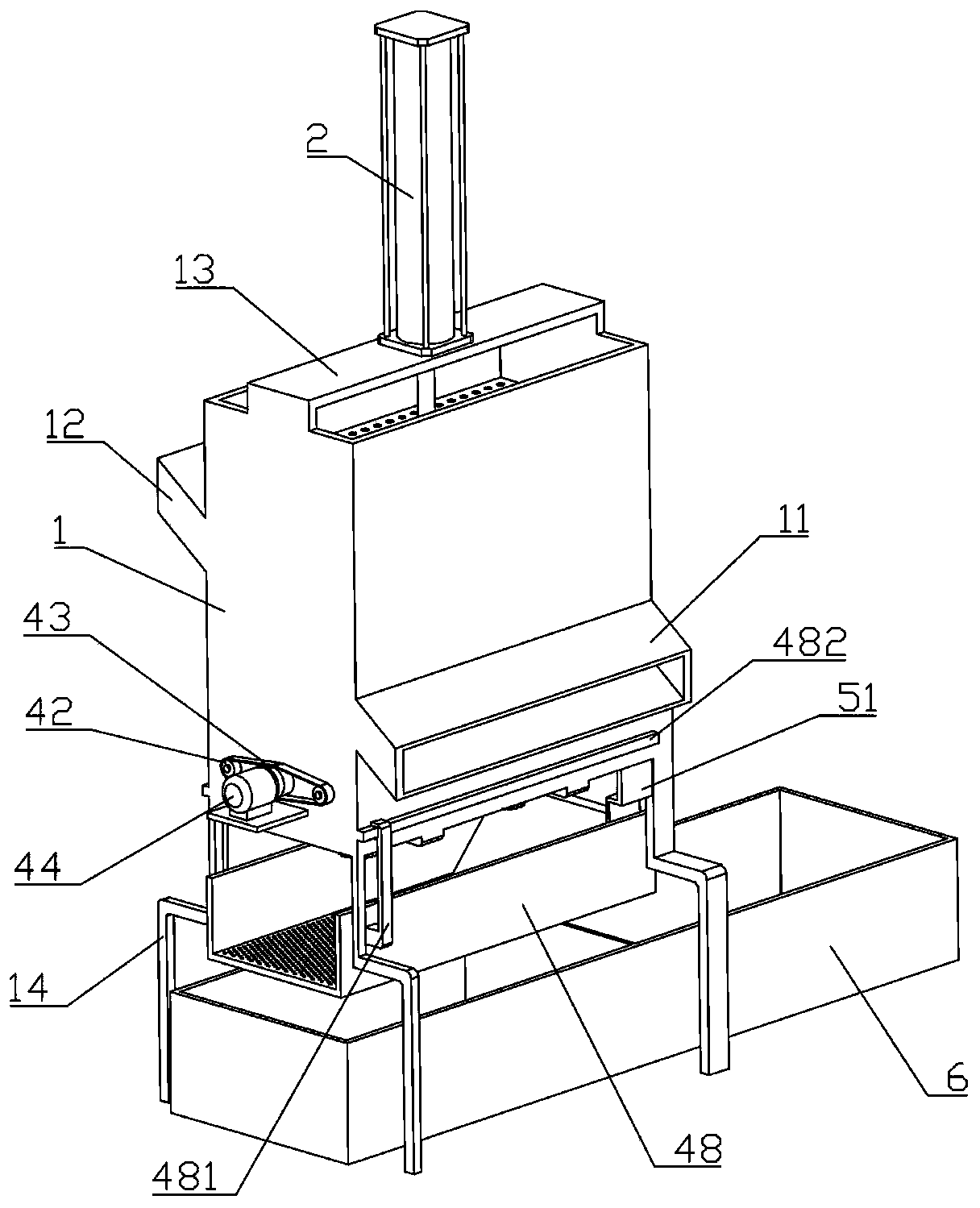

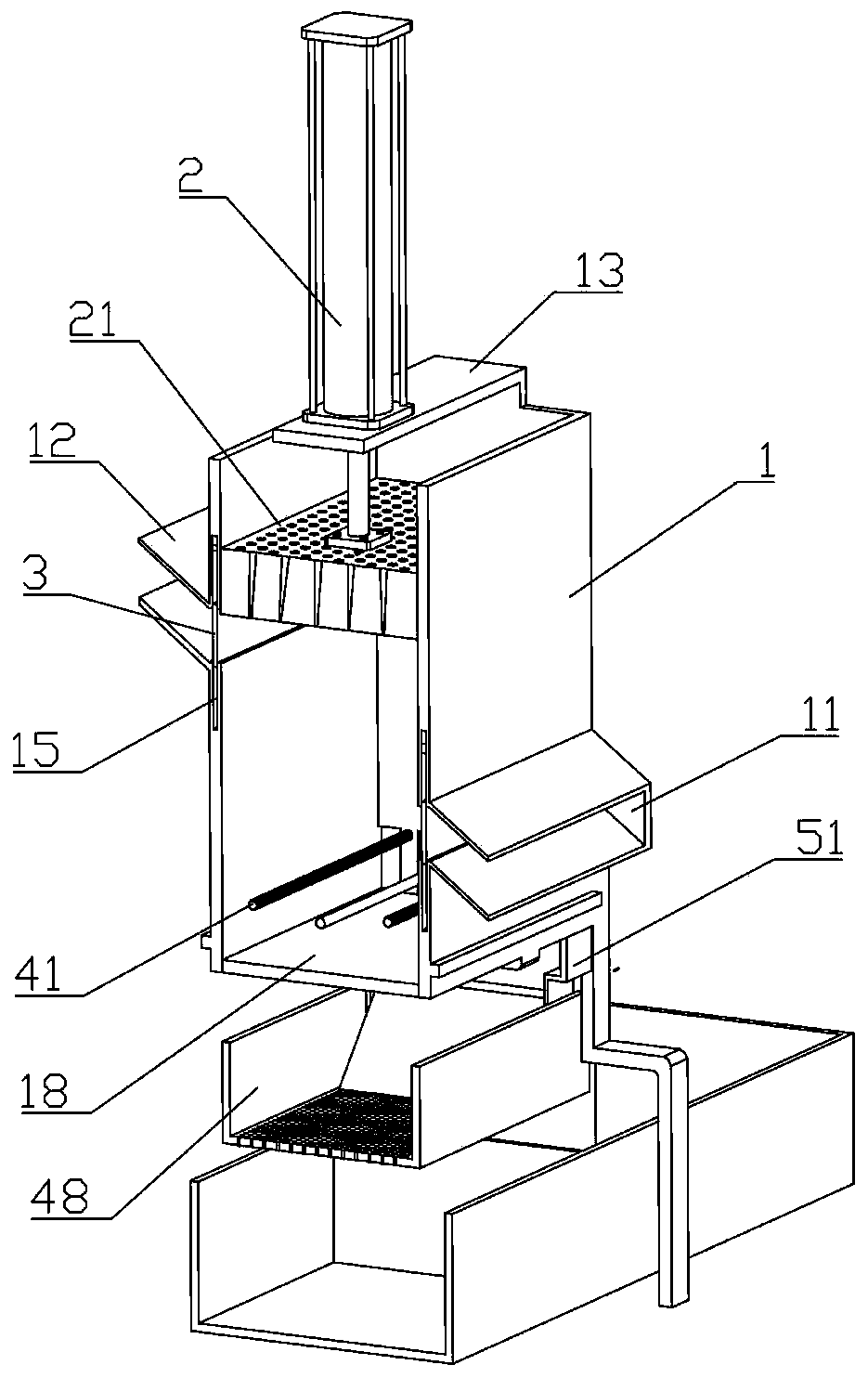

[0038] Such as Figure 1-11As shown, a dry-wet separation device for waste recycling in pig houses includes a separation cylinder 1, a driving cylinder 2 and a first collection tank 48, the top of the separation cylinder 1 is provided with a mounting frame 13, and the driving cylinder 2 is installed on On the mounting frame 13, an extruding block 21 is installed on the output shaft of the driving cylinder 2, and several first filter holes are evenly opened on the extruding block 21. There are two communication ports. The separation cylinder 1 is integrally formed with a feed compartment 12 and a liquid discharge compartment 11 at the two communication ports. Two storage compartments are provided in the wall of the separation cylinder 1, and the two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com