Sewage treatment device

A technology for sewage treatment devices and treatment pools, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., and can solve problems such as inability to clean the filter screen in time, inability to achieve solid-liquid separation, and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

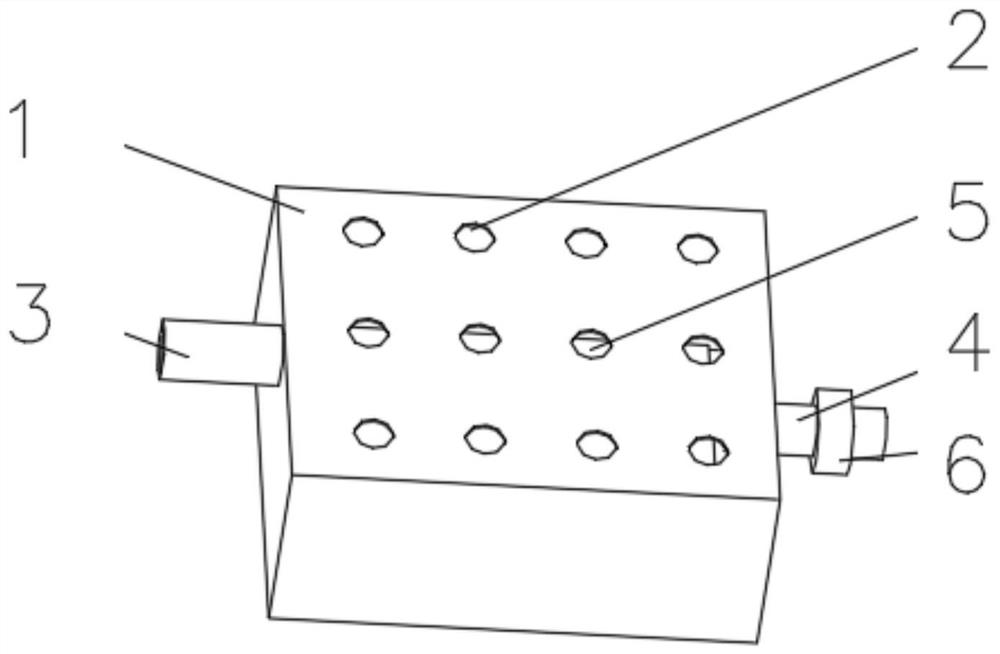

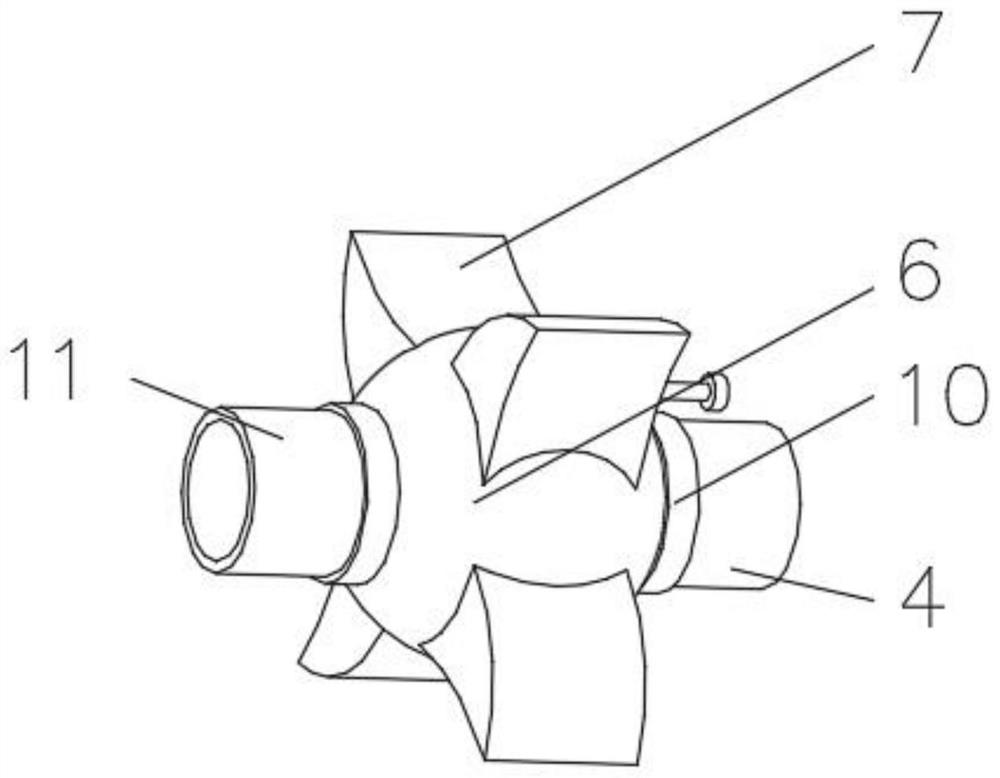

[0032] see Figure 1-4 , the present invention provides a technical solution: a sewage treatment device, comprising a treatment pool 1, one side of the treatment pool 1 is connected with a feed pipe 3, and the side of the treatment pool 1 away from the feed pipe 3 is connected with a discharge pipe 4 , the inner bottom of the treatment tank 1 is fixedly connected with a sedimentation frame 5, the outer side of the discharge pipe 4 is equipped with a filter frame 6, the outside of the discharge pipe 4 is provided with a bearing 10 near the position of the filter frame 6, and the filter frame 6 is far away from the discharge One side of the pipe 4 is communicated with a discharge pipe 11 , and a filter device 8 is installed on the inner wall of the filter frame 6 .

[0033] A motor 12 is installed outside the filter frame 6 , the output shaft of the motor 12 is rotatably connected with a rotating rod 13 , and the rotating rod 13 is fixedly connected with the filter frame 6 .

...

Embodiment 2

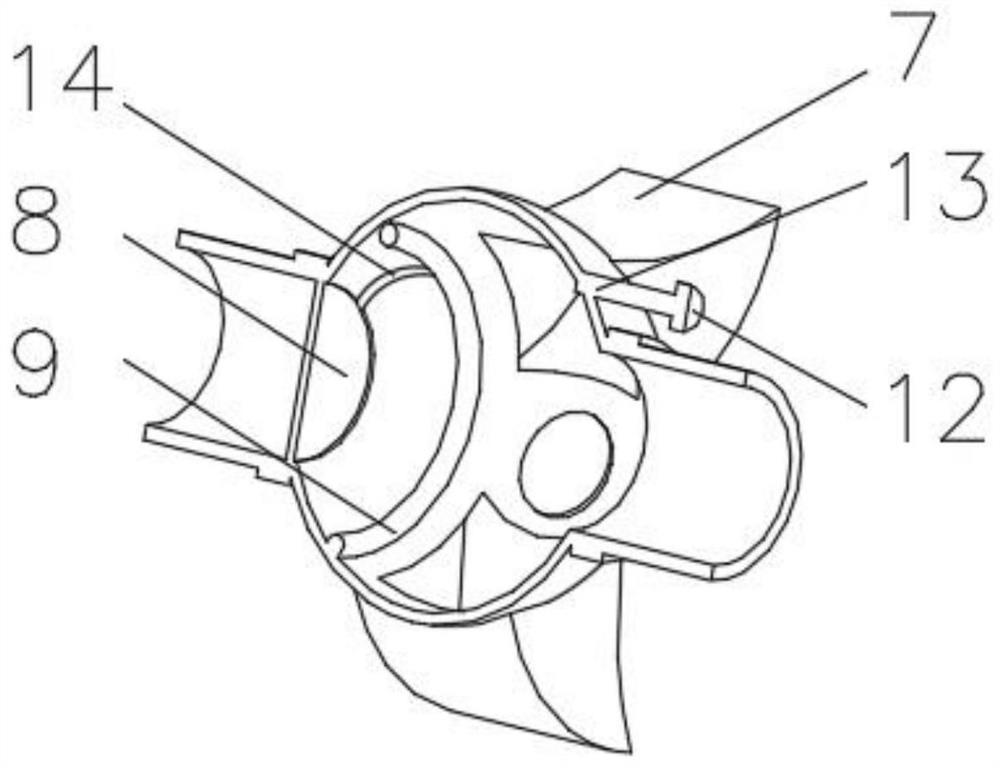

[0038] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a cleaning device 9 is installed on the inner wall of the filter frame 6 close to the filter device 8, the cleaning device 9 includes a rotating shaft 91, and the outer part of the rotating shaft 91 is sleeved with A curved plate 92, a spring 93 is installed on one side of the curved plate 92 close to the filter frame 6, and the end of the spring 93 away from the curved plate 92 is fixedly connected with a push plate 94, and the side of the curved plate 92 away from the spring 93 is installed A ball 95 is provided, and a curved groove 96 is provided on the surface of the ball 95 .

[0039]The inwall of filter frame 6 is equipped with guide rope 14 near the position of clearing device 9, and one end of guide rope 14 is fixedly connected with round frame 81, and the end of guide rope 14 away from round frame 81 is fixedly connected with arc plate 92.

[0040] When in use,...

Embodiment 3

[0043] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 2, a separation device 7 is installed inside the filter frame 6, the separation device 7 includes a shell 71, and the inner wall of the shell 71 is uniformly provided with a circular groove 72, and the circular groove The inner wall of 72 is equipped with elastic plate 73, elastic plate 73 is fixedly connected with connecting plate 74 on one side away from circular groove 72, is fixedly connected with elastic net 75 between connecting plate 74, and one side of elastic net 75 is equipped with connecting rope 76 , one end of the connecting rope 76 runs through the elastic net 75, and one side of the shell 71 is provided with a material intake 77.

[0044] During use, when the rotating rod 13 drives the filter frame 6 to rotate, the centrifugal force causes the sundries in the sewage to fall into the inside of the separation device 7. At this time, the elastic plate 73 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com