Kitchen waste hydrogen-rich energy machine

A technology of kitchen waste and energy generator, applied in combustion methods, lighting and heating equipment, combined combustion mitigation, etc., can solve the problems of low calorific value and high moisture content of kitchen waste, reduce use costs, save boiler fuel, The effect of avoiding heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

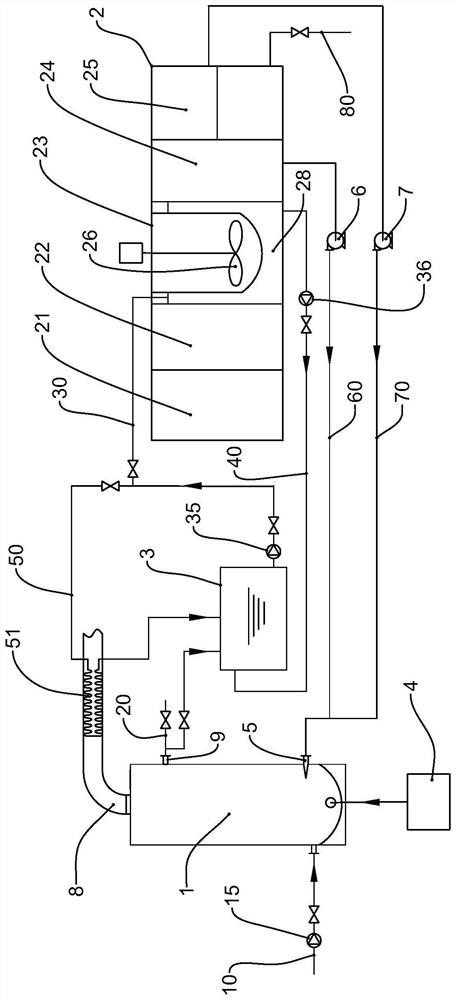

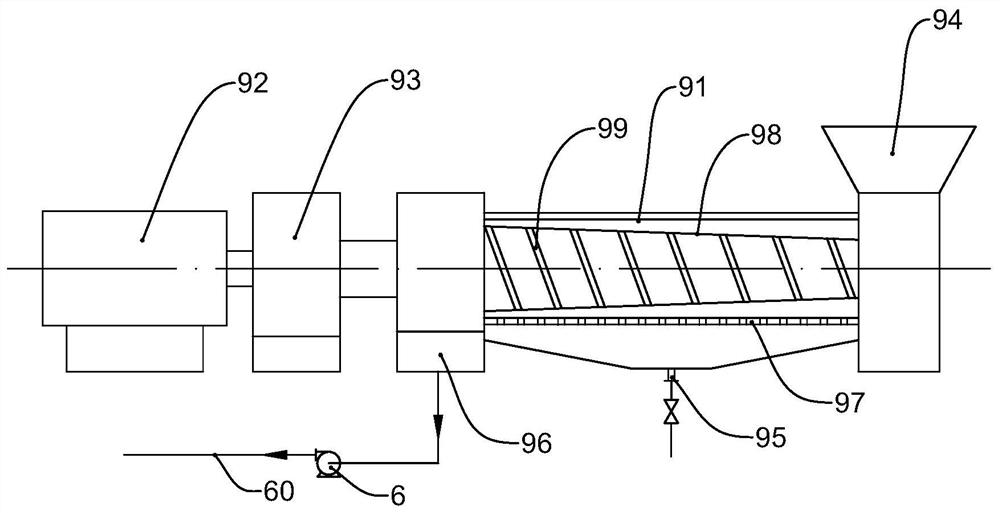

[0028] Such as figure 1 , figure 2 As shown, the food waste hydrogen-rich energy generator in this embodiment includes a hot water boiler 1, a food waste disposer main body 2, a hot water tank 3, and a hydrogen-rich generator 4. The hot water boiler 1 is provided with a hot water outlet 9 , the hot water outlet 9 leads into the hot water tank 3, and the hot water outlet 9 is also connected to the hot water supply pipeline 20 for hot water use in other places such as the kitchen. It includes a compression and finishing section 21, a crushing section 22, a stirring and heating section 23, and a dehydration section 24. The compression and finishing section 21 is used to reduce the volume of kitchen waste and initially squeeze out free water in the kitchen waste. The crushing section 22 It is used to crush the food waste after preliminary sorting and dehydration to make it into a fine and dispersed viscous slurry. The mixing tank 27 of the stirring and heating section 23 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com