Condensate oil emulsion de-emulsifier and applications thereof

A technology of demulsifier and condensate oil, which is applied in the field of demulsification in condensate oil emulsion, to achieve the effects of low demulsification temperature, fast demulsification speed and good oil and water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

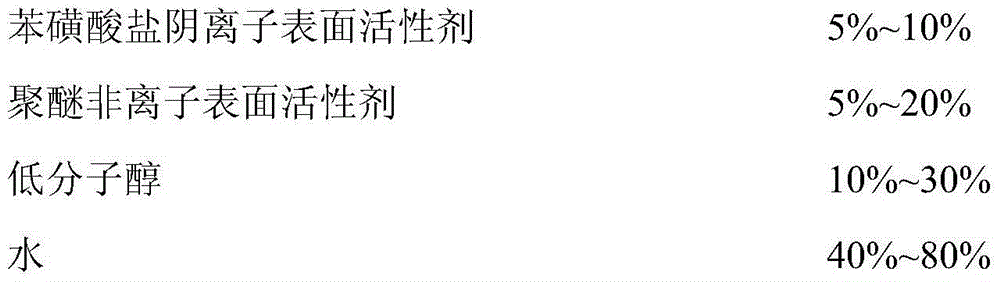

Method used

Image

Examples

Embodiment 1

[0015] The demulsifier is prepared by 10% branched chain dodecylbenzene sulfonate, 8% polyoxypropylene polyoxyethylene glycol ether, 30% ethylene glycol butyl ether, and 52% deionized water. At 5°C, use a stopper measuring cylinder to take 40mL of on-site water samples with a salinity of 1.58g / L and 10mL of on-site condensate oil samples, add 0.1g (2000ppm) of cationic quaternary ammonium salt corrosion inhibitors, shake vigorously up and down for 50 times to make milk, and then add 0.05g demulsifier (1000ppm), shake 10 times and let it stand, the demulsification rate is 98% in 10 minutes.

Embodiment 2

[0017] The demulsifier is prepared by 7% branched dodecylbenzene sulfonate, 15% polyoxypropylene polyoxyethylene glycol ether, 10% isopropanol, and 68% deionized water. At 20°C, use a stopper measuring cylinder to take 40mL of on-site water samples with a salinity of 0.22g / L, and 10mL of on-site condensate oil samples. 0.05g demulsifier (1000ppm), shake 10 times and let stand, the demulsification rate measured 10min is 96%.

Embodiment 3

[0019] The demulsifier is prepared by 5% branched dodecylbenzene sulfonate, 20% polyoxypropylene polyoxyethylene glycol ether, 20% ethanol, and 55% deionized water. At 5°C, use a stopper measuring cylinder to take 80mL of on-site water samples with a salinity of 0.22g / L, and 20mL of on-site condensate oil samples, add 0.2g (2000ppm) of cationic quaternary ammonium salt corrosion inhibitors, and shake vigorously up and down for 50 times to make milk. Add 0.05g demulsifier (500ppm), shake it for 10 times and let it stand still. The demulsification rate is 96% in 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com