System and method for separating and recovering chlorine salts based on fly ash plasma melting

A plasma and fly ash technology, which is applied in chemical instruments and methods, centrifugal separation water/sewage treatment, ion-exchange water/sewage treatment, etc. and other problems to avoid secondary pollution and solve the problem of separation and recovery of miscellaneous salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

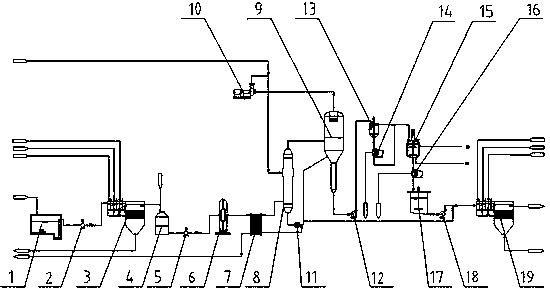

[0023] Such as figure 1 As shown, it is a chlorine salt separation and recovery system based on fly ash plasma melting of the present invention, including a regulating tank 1, a feed pump 2, a coagulation sedimentation tank 1 3, a water tank 4, a water pump 2 5, an ion exchange Softening resin tank 6, plate heat exchanger 7, heater 8, separation chamber 9, compression fan 10, slurry pump 11, thickener one 12, centrifuge one 14, thickener two 15, centrifuge two 16, Mother liquor tank 16, mother liquor pump 17 and coagulation sedimentation tank two 18. The adjustment tank 1 of the present invention is connected with the coagulation sedimentation tank-3 through the feed pump 2, and the high-salt waste water formed after the fly ash is melted by the plasma and eluted with chlorine salt is collected in the adjustment tank 1 with uniform quality and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com