Method for preparing amides by-product industrial ammonium chloride

A technology of by-product industry and production method, which is applied in the field of ammonium chloride production technology, can solve problems such as the separation and use of unsuitable organic matter and ammonium chloride, complex chemical reactions and other by-products, and achieve the problem of separation, recovery and utilization, protection Equipment and raw materials, precise effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

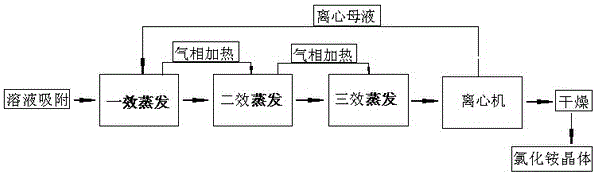

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

[0023] (1) In the adsorption process, the ammonium chloride-containing amide oil solution passes through the resin tower to absorb the oil layer. The adsorption resin is XDA-11 type, and the adsorption temperature is preferably about 55-65°C.

[0024] After the adsorption is completed, use nitrogen to carry out two-stage backflushing of the resin tower in sequence, and backflush the ammonium chloride mother liquor in the tower to the ammonium chloride solution storage tank, and the nitrogen purge pressure is 0.2-0.3MPa.

[0025] When the resin tower is regenerated, it should be cleaned with condensed water first, and then analyzed twice with methanol to dissolve the oil agent adsorbed by the resin into methanol; finally, the resin should be cleaned with condensed water, and the pressure of the washing pump should be about 0.4-0.8MP .

[0026] (2) In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com