Combined Stem Puller and Corn Harvester for Corn Harvesters

A corn harvester and combined technology, applied in agricultural machinery and implements, harvesters, applications, etc., can solve the problems of reduced efficiency, increased fuel consumption, broken stems and broken tips of corn, and can save energy and reduce power. Consume, prevent premature stem breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

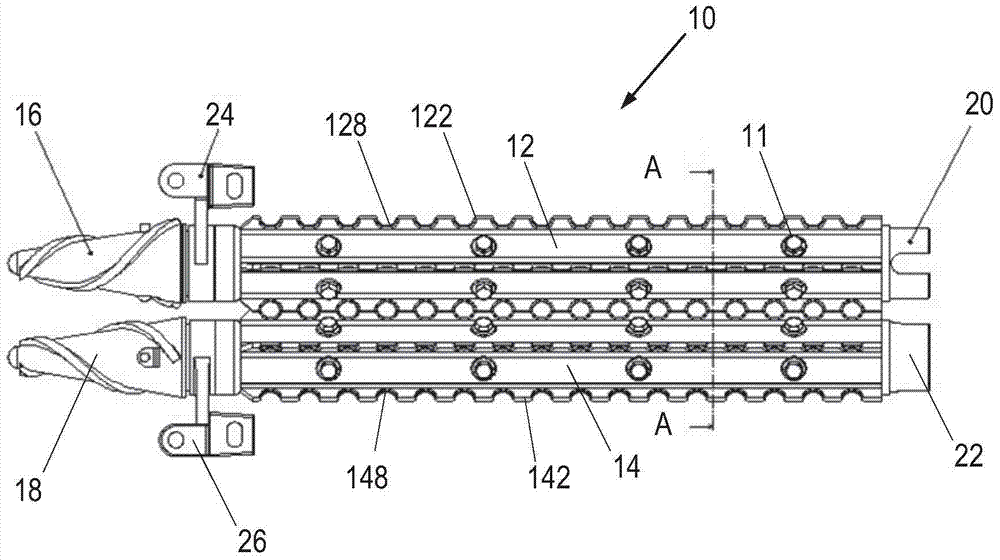

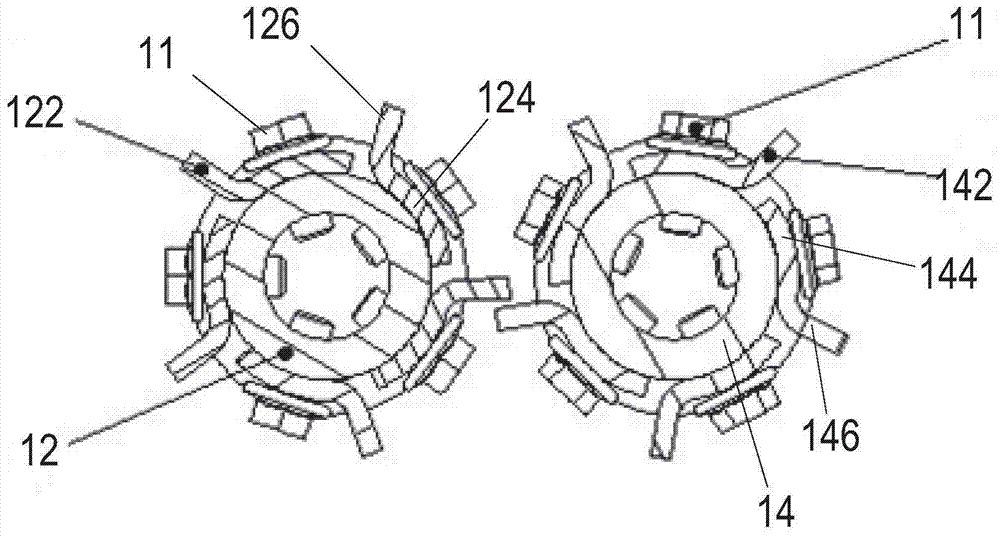

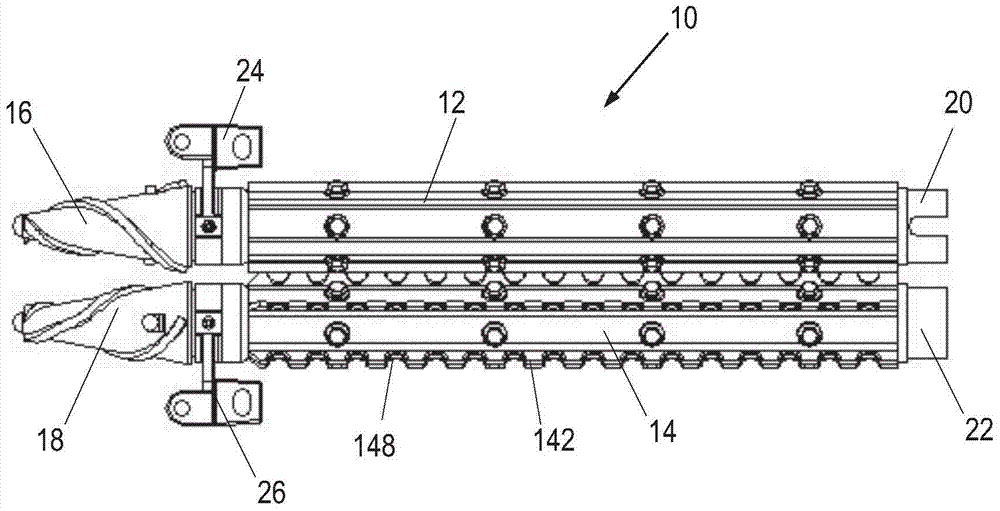

[0024] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0025] For the corn harvester in the prior art, the stalk rollers of the corn harvester are likely to cause broken stems and tips of the corn during the harvesting process, and thus cause a large amount of impurities to enter the main machine, resulting in increased failures of the harvester, increased fuel consumption, and reduced efficiency. Problem, the present invention proposes a stem pulling roller for a corn harvester that solves the above problems. This stem pulling roller can effectively prevent the harvested corn from being prematurely broken during the corn harvesting process, and can combine the harvested corn ear with the The stalks are better separated, thereby preventing the corn s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com