Patents

Literature

89 results about "Sucrose polyester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

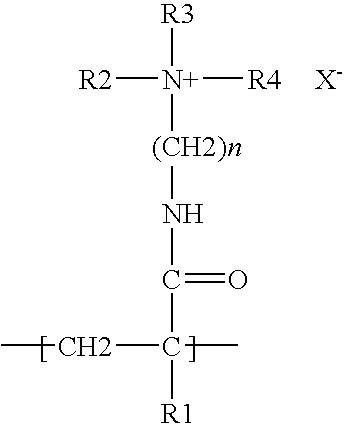

Sucrose polyester (SPE) a synthetic nonabsorbable fat that, when added to the diet, reduces plasma cholesterol levels by increasing the excretion of cholesterol in the feces. It is formulated to have the characteristic texture, taste, and consistency of regular margarine or vegetable oil and adds no calories to the diet. Olestra A proprietary, FDA ...

Hair Care Compositions Comprising Sucrose Polyesters

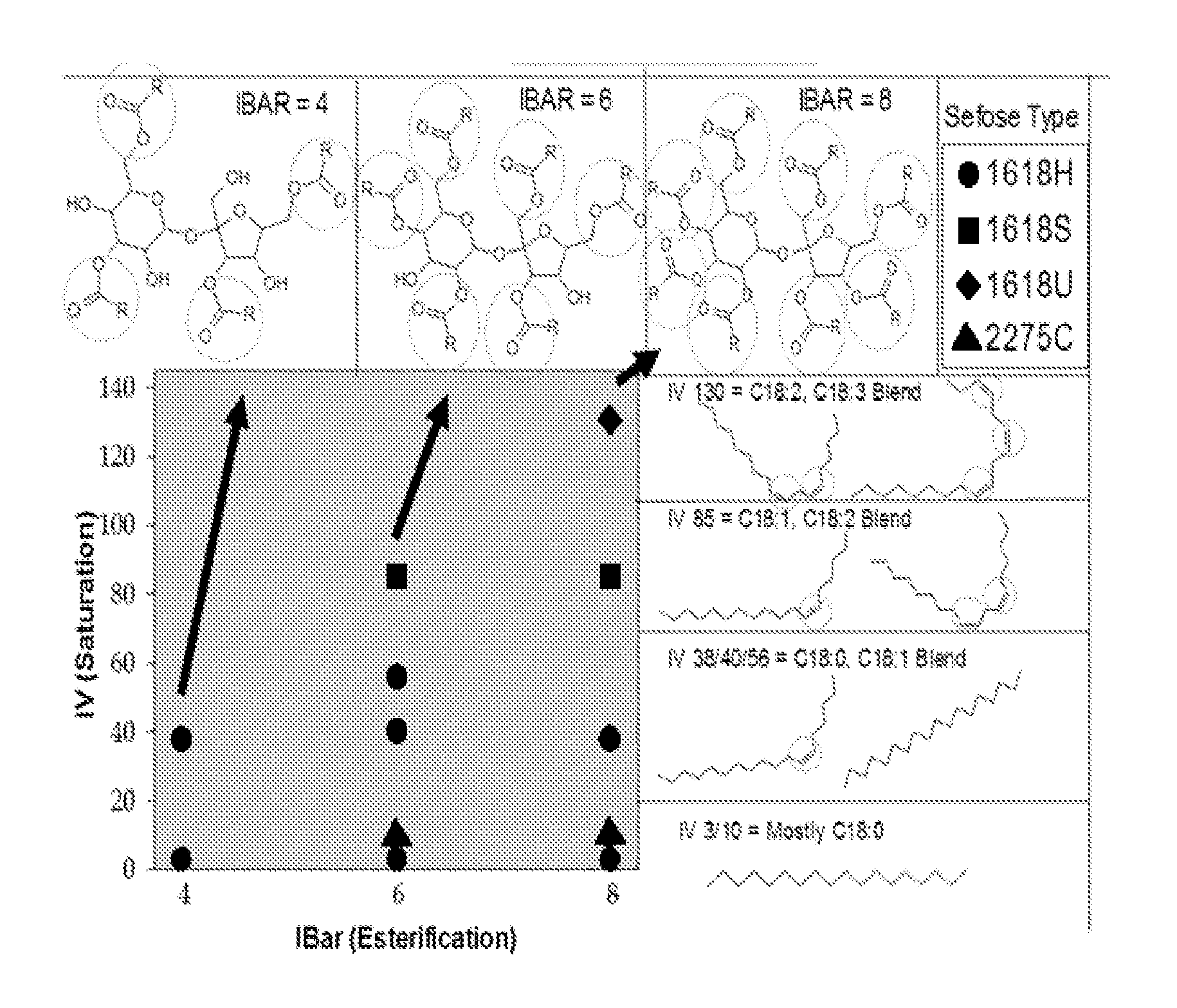

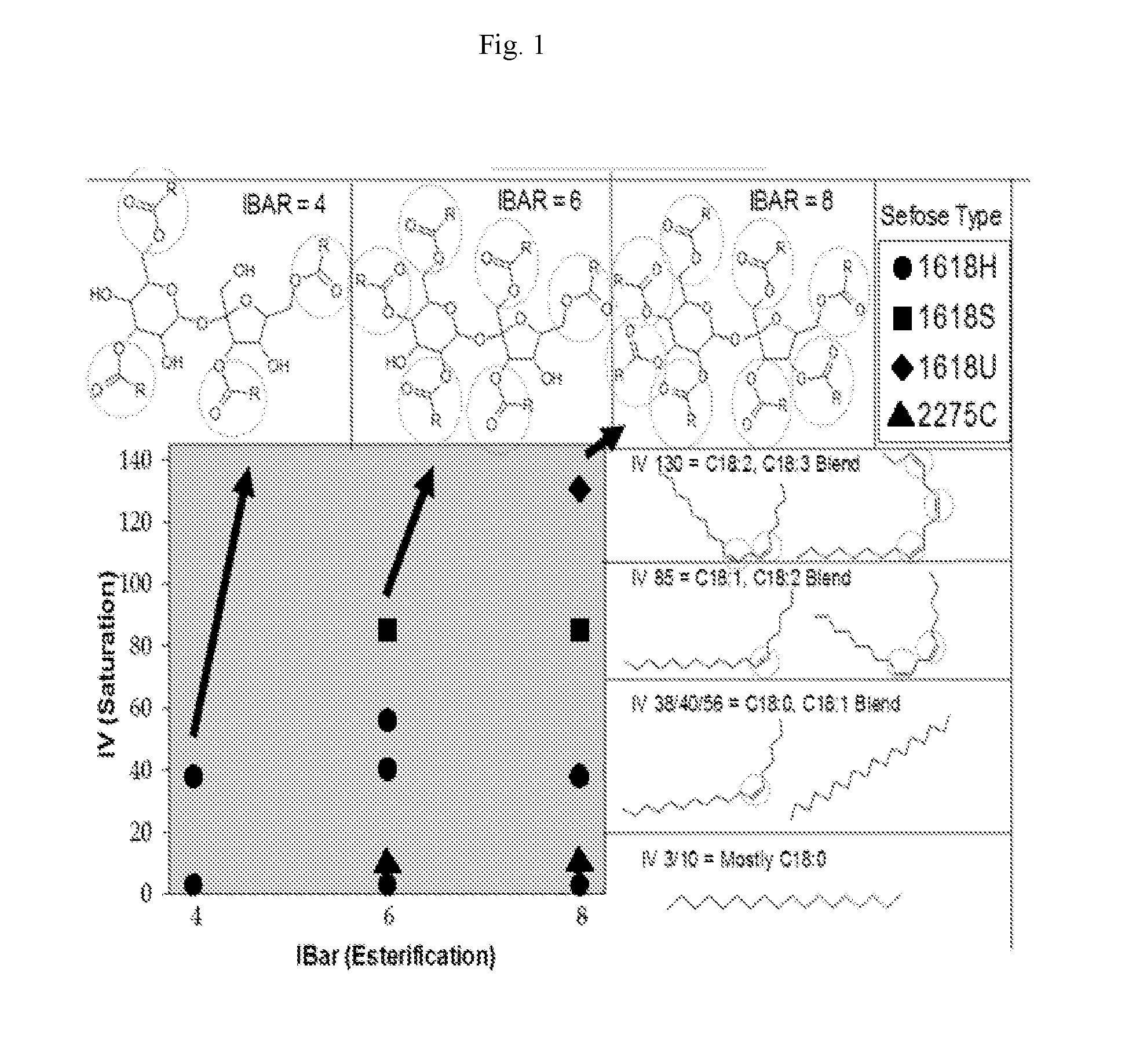

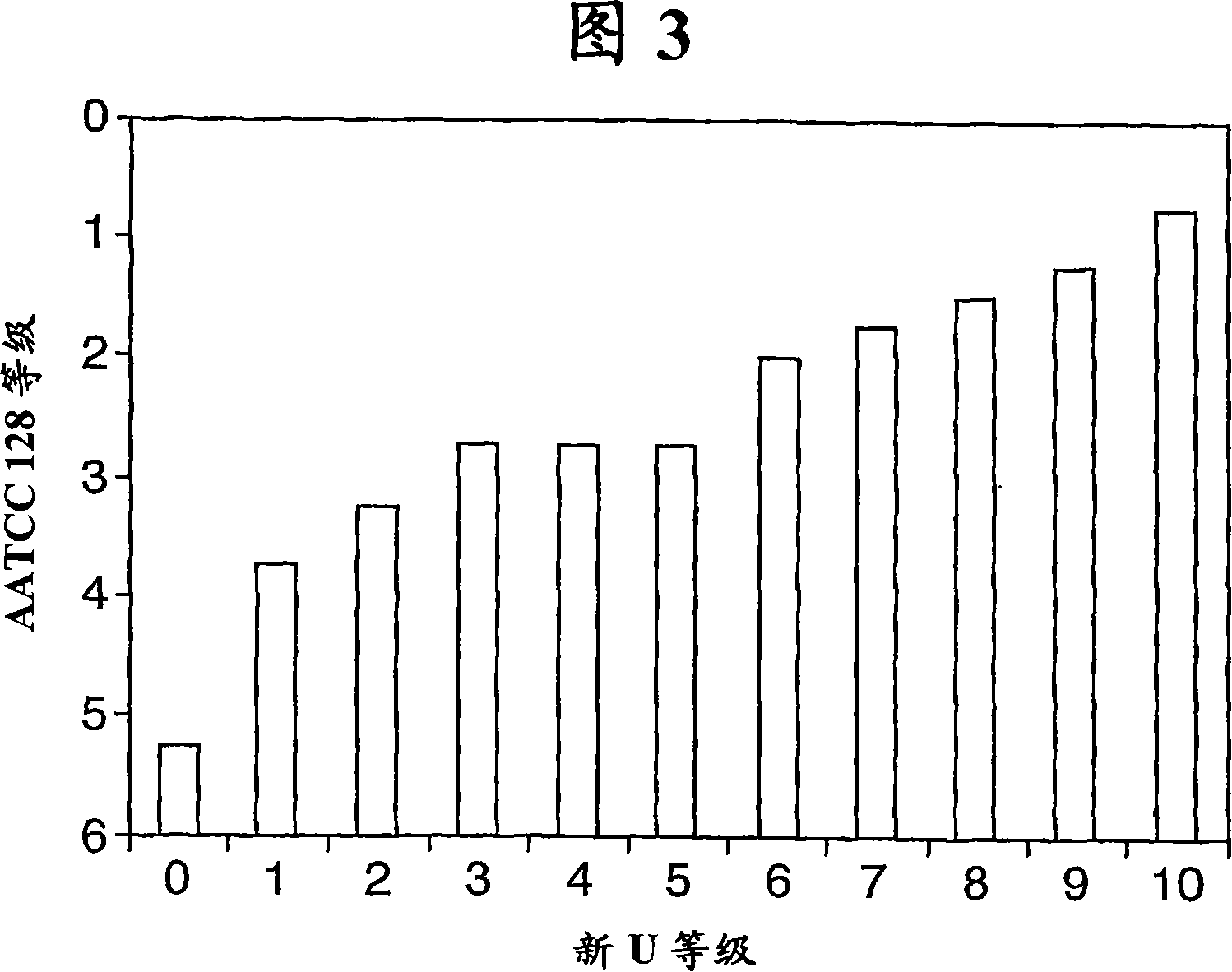

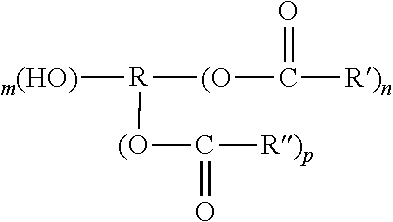

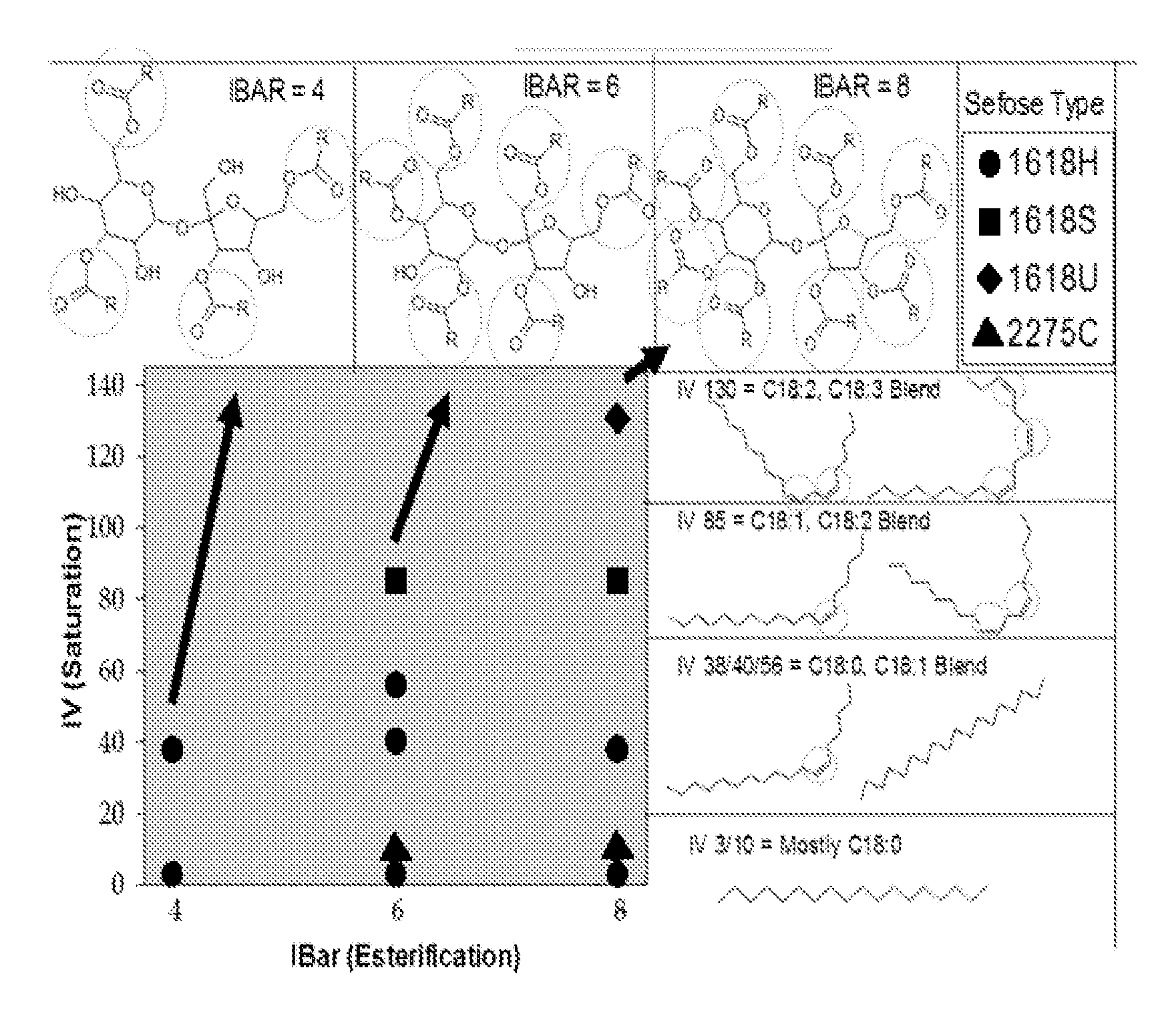

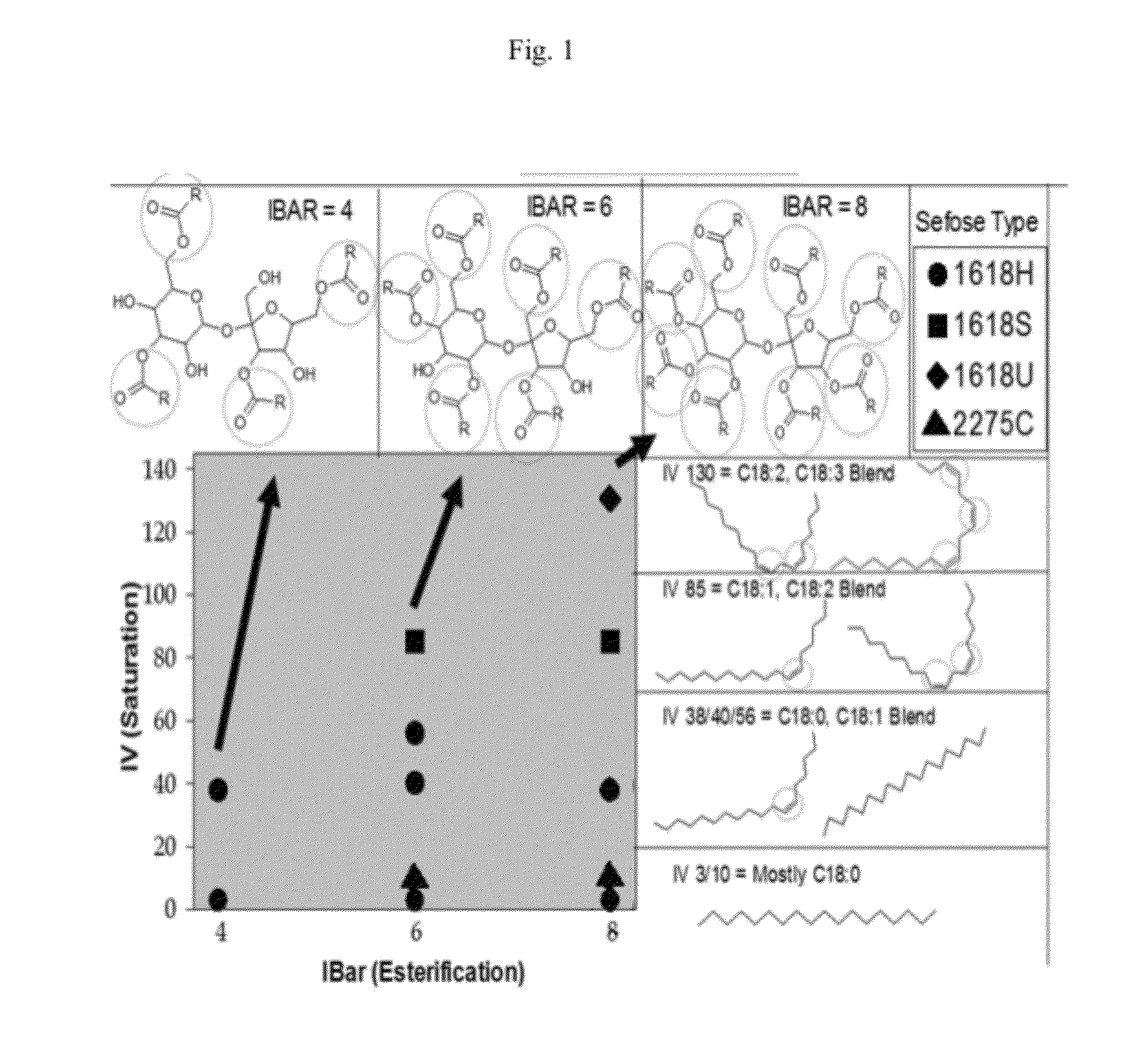

A hair care composition having a conditioning active comprising a sucrose polyester having a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and an aqueous carrier, and may further comprise optional ingredients including but not limited to, silicone, cationic polymers, and fatty alcohols. The composition can also comprise a blend of sucrose polyesters, wherein the blend comprises two or more sucrose polyesters, wherein at least one sucrose polyester has a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and at least one sucrose polyester has an IBAR between about 1 and about 8, and an IV between about 1 and about 135, and wherein the sucrose polyester blend has an IBAR of at least 5 and an IV of about 1 and about 135.

Owner:THE PROCTER & GAMBLE COMPANY

Personal care composition comprising a pre-emulsified formulation

ActiveUS20140309154A1Improve stability and deposition and hair conditioning benefitCosmetic preparationsHair cosmeticsPolyesterPersonal care

The present invention is directed to a personal care composition comprising a pre-emulsified emulsion comprising from about 0.25% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified emulsion is from about 20 nanometer to 20 microns; from about 5% to about 50% of one or more anionic surfactants, by weight of said hair care composition; at least about 20% of an aqueous carrier, by weight of said hair care composition wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Hair care composition comprising a pre-emulsified formulation

A hair care composition comprising from about 0.25% to about 80% of a pre-emulsified emulsion comprising from about 0.005% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified oil in water emulsion is from about 20 nanometers to 20 microns; and a cationic surfactant system wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Hair care composition comprising discrete particle of oily component

InactiveUS20160095808A1Improved conditioning benefitClean feelCosmetic preparationsHair cosmeticsZero shear viscosityDiscrete particle

Disclosed is a hair care composition comprising: a discrete particle comprising an oily component, wherein the oily component comprises one or more materials selected from the group consisting of: (A) metathesized unsaturated polyol esters; (B) sucrose polyesters; (C) fatty esters with a molecular weight greater than or equal to 1500; and mixtures thereof, wherein the oily component has a Zero Shear Viscosity at 25° C. of from about 102 Pa·s to about 109 Pa·s, and has a melting point of from about 35° C. to about 60° C.; and wherein the discrete particle has an average particle size in the hair care composition of from about 0.5 microns to about 20 microns. The hair care composition provides improved conditioning benefits, clean feel, and / or hair styling benefit.

Owner:THE PROCTER & GAMBLE COMPANY

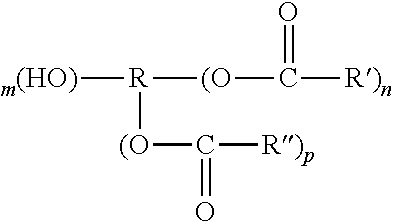

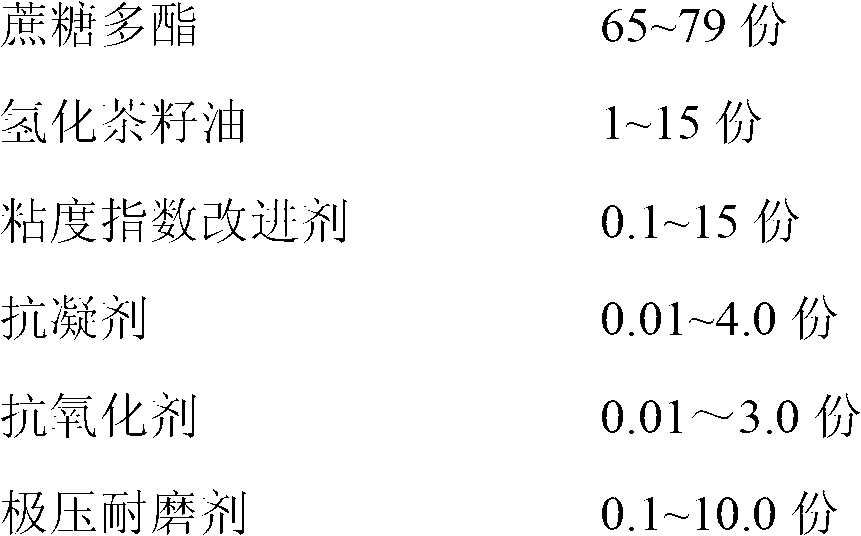

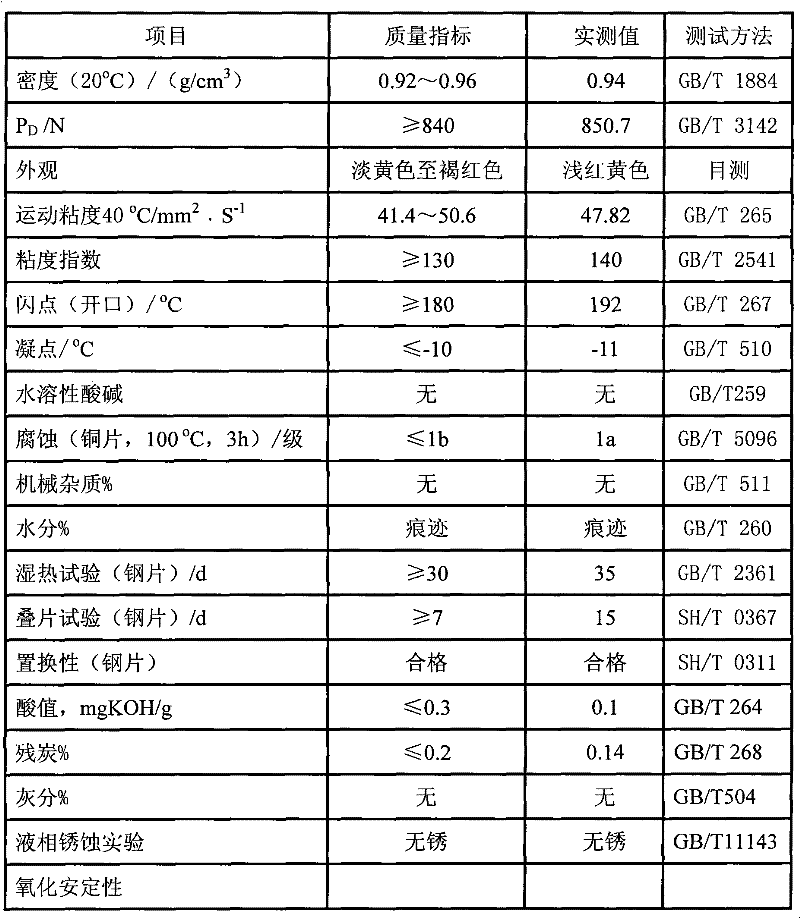

Food-grade lubricant using sucrose polyester as base oil and preparation method thereof

The invention discloses a food-grade lubricant using sucrose polyester as base oil and a preparation method thereof. The food-grade lubricant is prepared from the following raw materials in parts by weight: 65-79 parts of sucrose polyester, 1-15 parts of hydrogenated tea seed oil, 0.1-15 parts of viscosity index improver, 0.01-4.0 parts of anticoagulant, 0.01-3.0 parts of antioxidant and 0.1-10.0 parts of extreme-pressure anti-wear agent. The preparation method comprises the following steps: premixing, dissolving, filtering and inspecting. The food-grade lubricant is prepared from the base oil sucrose polyester with the average esterification degree of 6-8 with other high-quality assistants; and the product has the advantages of oxidation resistance, high biodegradation rate, excellent lubricating property, high viscosity-temperature characteristics, high safety, high stability and the like.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION CENT FOR ANALYSIS & TEST RES +1

Hair Care Compositions Comprising First and Second Sucrose Polyesters

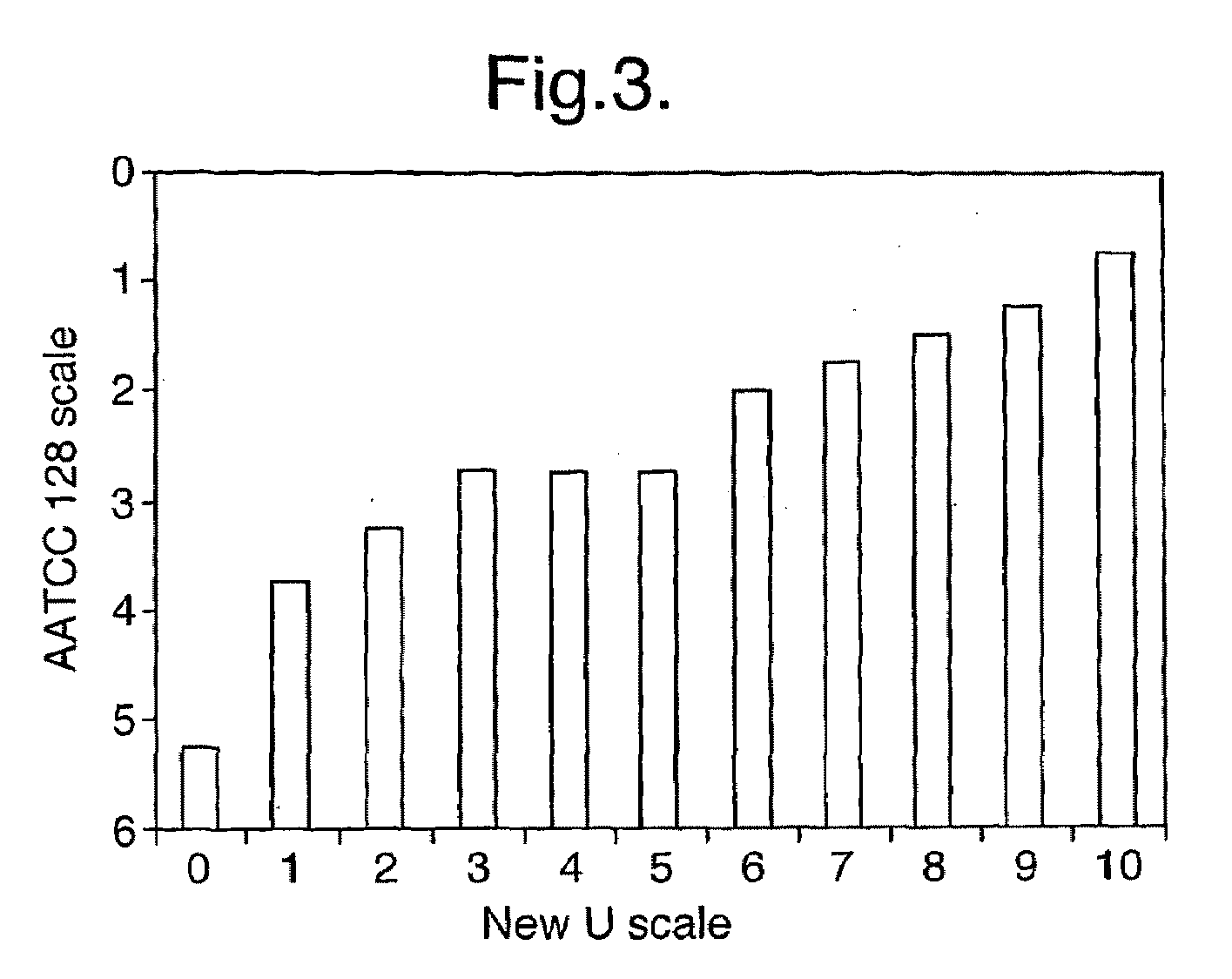

InactiveUS20110045039A1Friction reduction/smoothnessReduce frictionCosmetic preparationsHair removalFriction reductionPolyester

A hair care composition comprising: a) at least one first sucrose polyester has a melting point of above 30° C. and an iodine value (IV) of from 0 to 70; b) at least one second sucrose polyester has a melting point of 30° C. or less and an iodine value (IV) of from above 70 to about 180; and c) an aqueous carrier, for delivering conditioning benefits especially friction reduction on dry hair.

Owner:THE PROCTER & GAMBLE COMPANY

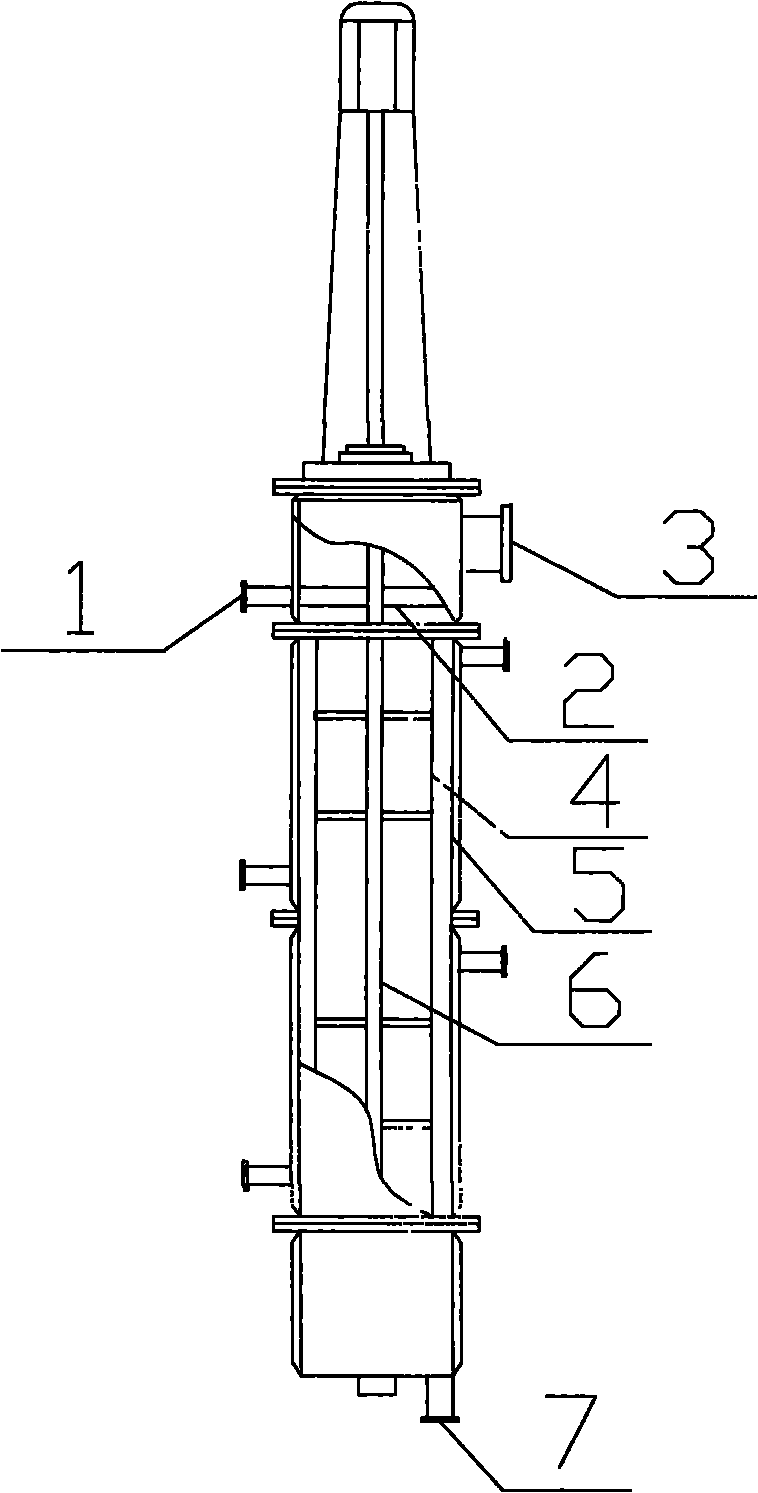

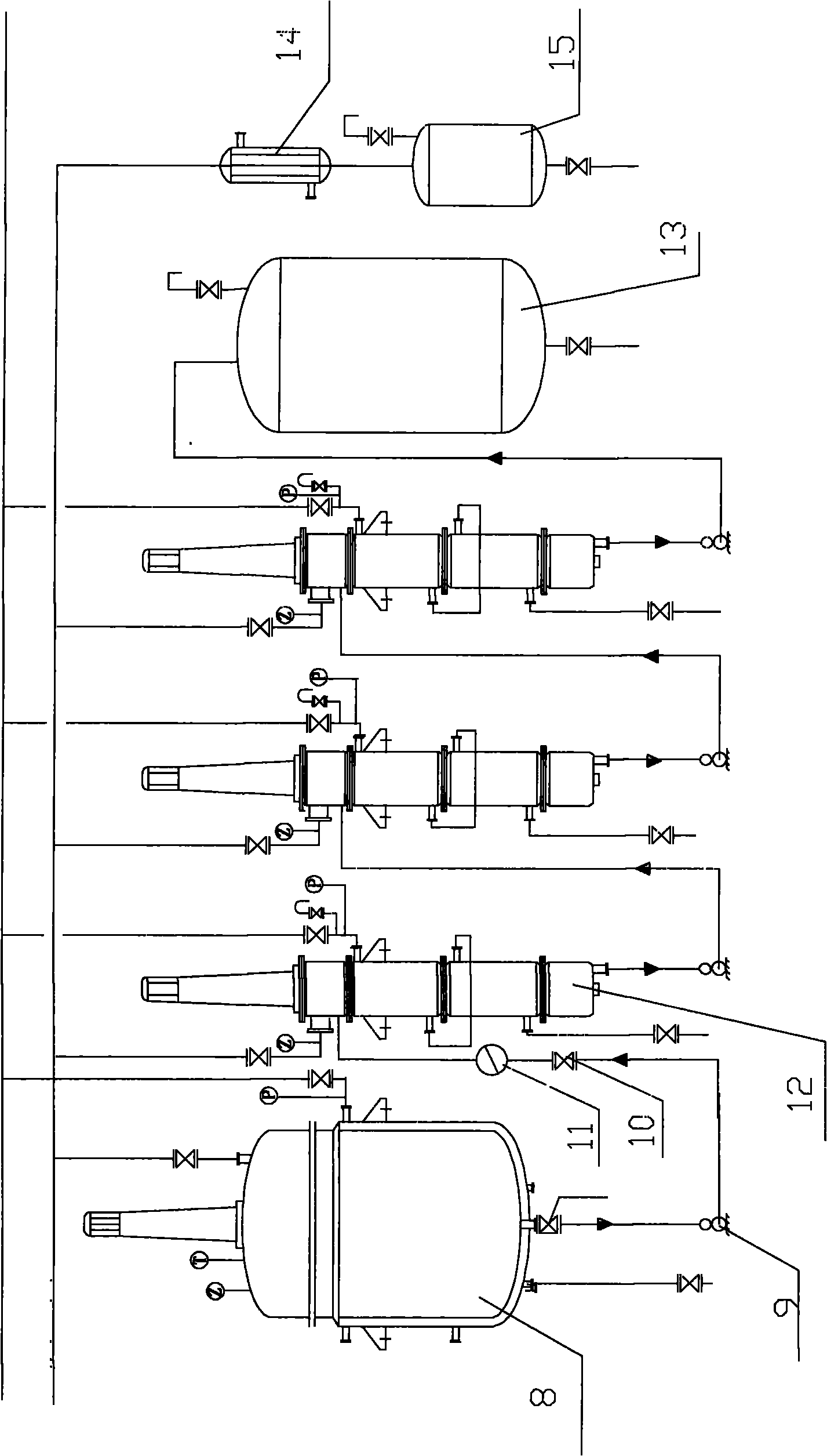

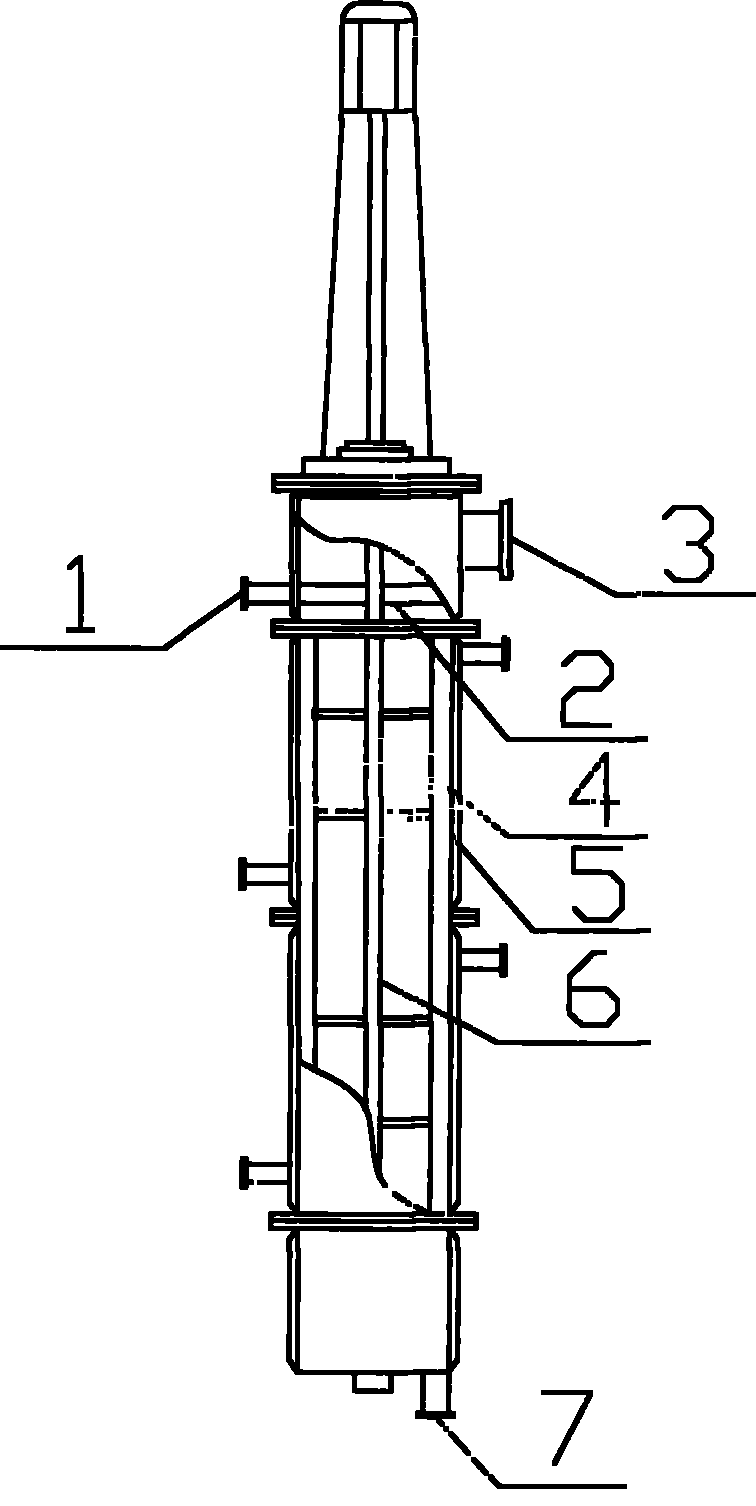

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

InactiveCN102093438AIncrease contact areaSimple interfaceEsterified saccharide compoundsSugar derivativesResource utilizationPOTASSIUM STEARATE

The invention discloses a process for synthesizing sucrose polyester, particularly a process for synthesizing sucrose polyester by using a rotating film transesterification flow reactor. The process comprises the following steps: methyl oleate, sucrose powder, potassium stearate and potassium carbonate are added into a mixing kettle, and heated while stirring; the materials enter the rotating film transesterification flow reactor to react; the crude fatty acid sucrose polyester product obtained after the reaction enters a product storage tank, and the reaction product methanol enters a methanol receiver after being cooled by a condenser; and the crude product in the product storage tank is neutralized with acetic acid, washed and dried to obtain the sucrose polyester product. The low-boiling-point substances generated in the process provided by the invention are quickly removed out of the reaction system, thereby being beneficial to the generation of the product, greatly increasing the reaction speed and enhancing the product quality. The process can be used for continuous-feeding production, is beneficial to large-scale production, enhances the production efficiency, has the advantages of high yield and simple process, lowers the production cost and raises the resource utilization ratio.

Owner:ADANA FOOD TECH LIUZHOU

Sucrose polyesters

ActiveUS20110129592A1Great tasteLow in fatEsterified saccharide compoundsSugar derivativesPolyesterCarbon chain

Disclosed herein are compositions that include a blend of sucrose polyesters, wherein each sucrose polyester includes a sucrose moiety and a plurality of fatty acid ester moieties, wherein a percentage range of the combined fatty acid ester moieties of the sucrose polyesters in the blend have a carbon chain that has trans content.

Owner:THE PROCTER & GAMBLE COMPANY

Universal machinery lubricating oil in pharmaceutical industry

InactiveCN102212411AImprove stabilityImprove antioxidant capacityLubricant compositionAntioxidantAdditive ingredient

The invention provides universal machinery lubricating oil in the pharmaceutical industry. The universal machinery lubricating oil is characterized by comprising the following ingredients in percentage by weight: 80-95 percent of base oil, 1.5-8 percent of antioxidant, 0.5-5 percent of antiwear agent, 1.0-5 percent of antirust agent, 0.1-3 percent of antifriction agent, and 0.3-4 percent of lubricating additive. Sucrose polyester with wide sources and environment friendliness is adopted as base oil, and a new compound additive is increased, therefore, the lubricating oil has comprehensive properties superior to those of the traditional mineral oil, as well as good stability, inoxidizability, rust prevention and biodegradability, can be used for prolonging the oil draining period, reducingthe waste liquor treating cost, lowering the energy consumption and total production cost, thus being a product with high cost performance and environment friendliness and being beneficial to promotion and application in food, sanitary and pharmaceutical industries.

Owner:SHENZHEN YONGWANFENG IND CO LTD

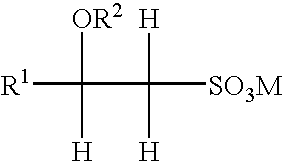

Fabric care compositions

An ironing aid fabric treatment composition comprising: a) a nanoparticle dispersion comprising particles having an average particle size in the range 5 to 500nm, b) a lubricant phase comprising a lubricant selected from silicone oil, sucrose polyester oil and mixtures thereof, and c) water wherein the weight ratio of a) : b) is in the range 4 : 1 to 1: 4. with the proviso that when the colloidal nanoparticle dispersion comprises a silicone resin the composition is not delivered through an iron.

Owner:UNILEVER NV

Personal care composition comprising a pre-emulsified formulation

ActiveUS9655821B2Improve stability and deposition and hair conditioning benefitCosmetic preparationsHair cosmeticsPersonal careEmulsion

The present invention is directed to a personal care composition comprising a pre-emulsified emulsion comprising from about 0.25% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified emulsion is from about 20 nanometer to 20 microns; from about 5% to about 50% of one or more anionic surfactants, by weight of said hair care composition; at least about 20% of an aqueous carrier, by weight of said hair care composition wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Hair care compositions comprising sucrose polyesters

A hair care composition having a conditioning active comprising a sucrose polyester having a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and an aqueous carrier, and may further comprise optional ingredients including but not limited to, silicone, cationic polymers, and fatty alcohols. The composition can also comprise a blend of sucrose polyesters, wherein the blend comprises two or more sucrose polyesters, wherein at least one sucrose polyester has a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and at least one sucrose polyester has an IBAR between about 1 and about 8, and an IV between about 1 and about 135, and wherein the sucrose polyester blend has an IBAR of at least 5 and an IV of about 1 and about 135.

Owner:PROCTER & GAMBLE CO

Composition for non-dairy creamer, non-dairy creamer as well as preparation method and application of non-dairy creamer

Owner:北京中科邦尼国际科技有限责任公司

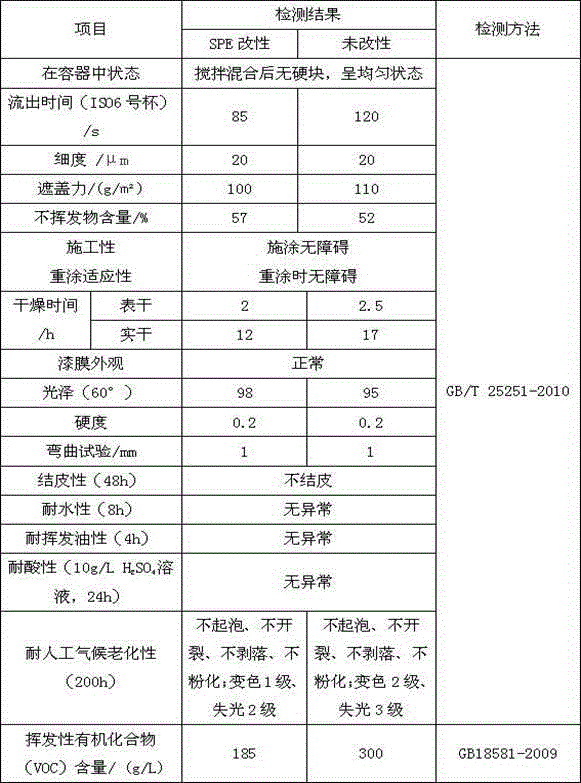

Coating with low-VOC sucrose polyester-modified alkyd emulsion as main material

The invention discloses a sucrose polyester-modified alkyd emulsion which is prepared from the following raw materials by percentage: 20%-40% of sucrose polyester, 20%-40% of alkyd resin, 5%-10% of an emulsifier and 30%-50% of deionized water. The preparation method comprises the following steps: heating a magnetic stirring water bath pan to 70-80 DEG C; mixing the sucrose polyester with the alkyd resin, and then putting into a magnetic rotor; heating and stirring for 50 minutes at the speed of 2.5r / min; putting into deionized water and heating together; taking out the mixture, emulsifying at the rotating speed of 10,000r / min by virtue of a high-speed shearing machine, simultaneously adding the deionized water until phase inversion; and adding the residual water after phase inversion, reducing the rotating speed to 5,000r / min, and further emulsifying for 5 minutes. The invention also discloses a coating with the low-VOC sucrose polyester-modified alkyd emulsion as a main material, and a preparation method of the coating.

Owner:ZHEJIANG SCI-TECH UNIV

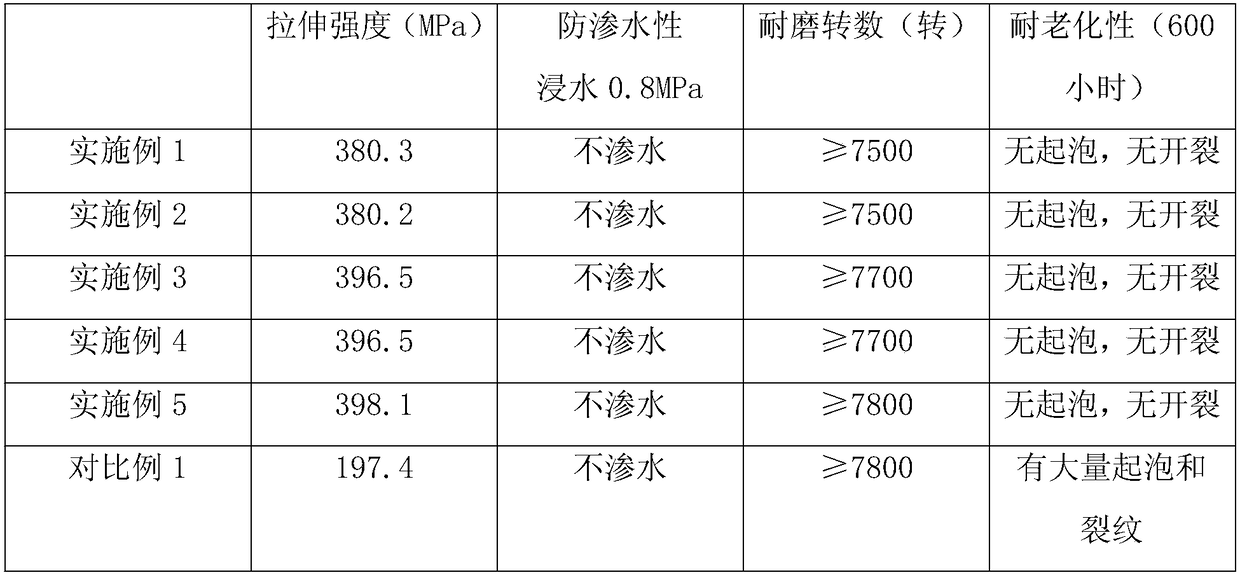

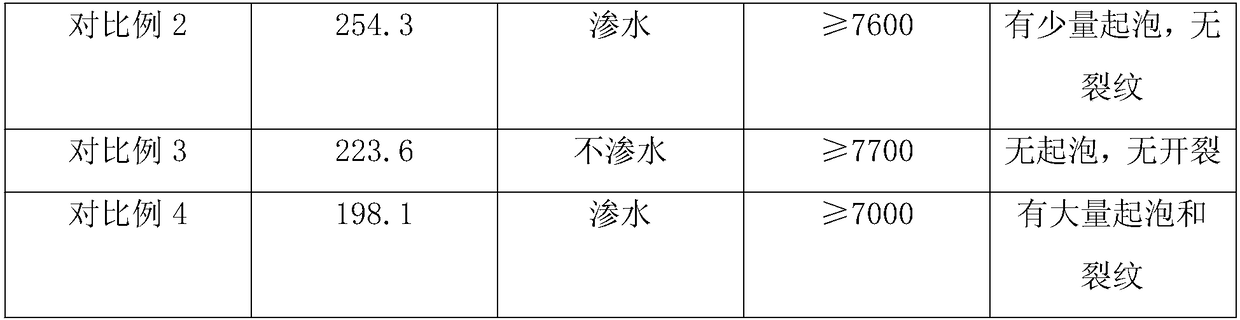

Composite for fire hoses and preparation method of composite

InactiveCN108102265AImprove mechanical propertiesImprove waterproof performancePolyvinyl alcoholPolyvinyl chloride

The invention provides a composite for fire hoses and a preparation method of the composite. The composite is prepared from components in parts by weight as follows: 100 parts of sucrose polyester modified polyvinyl chloride resin, 60-70 parts of a fluorine-containing organosilicone modified polyurethane polymer, 40-50 parts of bisphenol A polycarbonate, 30-40 parts of polyphenyl ether, 10-15 parts of polyacrylamide, 10-15 parts of acrylate, 10-12 parts of medium chain triglyceride, 8-12 parts of polyvinyl acetal, 8-12 parts of dibutyl phthalate, 2-3 parts of calcium stearate, 2-3 parts of cadmium stearate, 1-2 parts of 1,4-butanediol diacrylate and 1-2 parts of dibutyltin dilaurate. Main raw materials comprise sucrose polyester modified polyvinyl chloride resin, the fluorine-containing organosilicone modified polyurethane polymer, bisphenol A polycarbonate and polyphenyl ether, and the composite has good mechanical performance, water resistance, wear resistance and aging resistance through cooperation of the four raw materials and the auxiliary function of auxiliary materials.

Owner:FOSHAN SHIRUI LEADING MATERIAL RES INST GENERAL PARTNERSHIP

Fiber cake with effect of losing weight

The invention relates to a fiber cake with the effect of losing weight. The beneficial effects of L-carnitine and dietary fibers on a human body are utilized, traditional cane sugar and grease are replaced by sodium cyclamate and sucrose polyester respectively, the nutritional collocation balance of various foodstuffs is fully considered, a plurality of auxiliary materials are mixed, and then baking and other processes are performed to form the fiber cake. The fiber cake is crispy in taste, rich in nutrient and low in calorie, thereby being quite suitable for being eaten by overweight people or women who hope to keep in shape.

Owner:张涛

Hair Care Compositions Comprising Sucrose Polyesters

A hair care composition having a conditioning active comprising a sucrose polyester having a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and an aqueous carrier, and may further comprise optional ingredients including but not limited to, silicone, cationic polymers, and fatty alcohols. The composition can also comprise a blend of sucrose polyesters, wherein the blend comprises two or more sucrose polyesters, wherein at least one sucrose polyester has a melting point greater than about 30° C., an IBAR greater than about 5, an IV of about 3 to about 70, and at least one sucrose polyester has an IBAR between about 1 and about 8, and an IV between about 1 and about 135, and wherein the sucrose polyester blend has an IBAR of at least 5 and an IV of about 1 and about 135.

Owner:THE PROCTER & GAMBLE COMPANY

Reflection and heat-insulation coating and preparation method thereof

InactiveCN108102482AReduce usageGood integrityReflecting/signal paintsAcrylic resinAluminum silicate

The invention provides reflection and heat-insulation coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 30 to 40 parts of waterborne acrylic emulsion, 15 to 20 parts of pure acrylic emulsion, 10 to 12 parts of silicone acrylic resin, 5 to 6 parts of sucrose polyester modified polymethylmethacrylate, 3 to 4 parts of lithium silicate,2 to 3 parts of nano tungsten trioxide, 2 to 3 parts of nano aluminum silicate, 2 to 3 parts of nano titanium dioxide, 5 to 8 parts of a dispersant, 0.3 to 0.5 part of a flatting agent, 1 to 2 partsof a film forming auxiliary agent, 1 to 2 parts of a silane coupling agent and 20 to 25 parts of de-ionized water. The coating provided by the invention has excellent environment-friendly performance,construction performance and reflection and heat-insulation performance.

Owner:长沙善道新材料科技有限公司

Hair care composition comprising a pre-emulsified formulation

A hair care composition comprising from about 0.25% to about 80% of a pre-emulsified emulsion comprising from about 0.005% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified oil in water emulsion is from about 20 nanometers to 20 microns; and a cationic surfactant system wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:PROCTER & GAMBLE CO

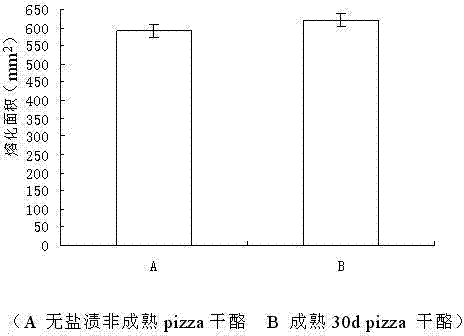

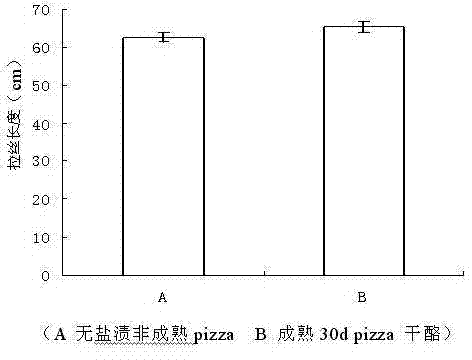

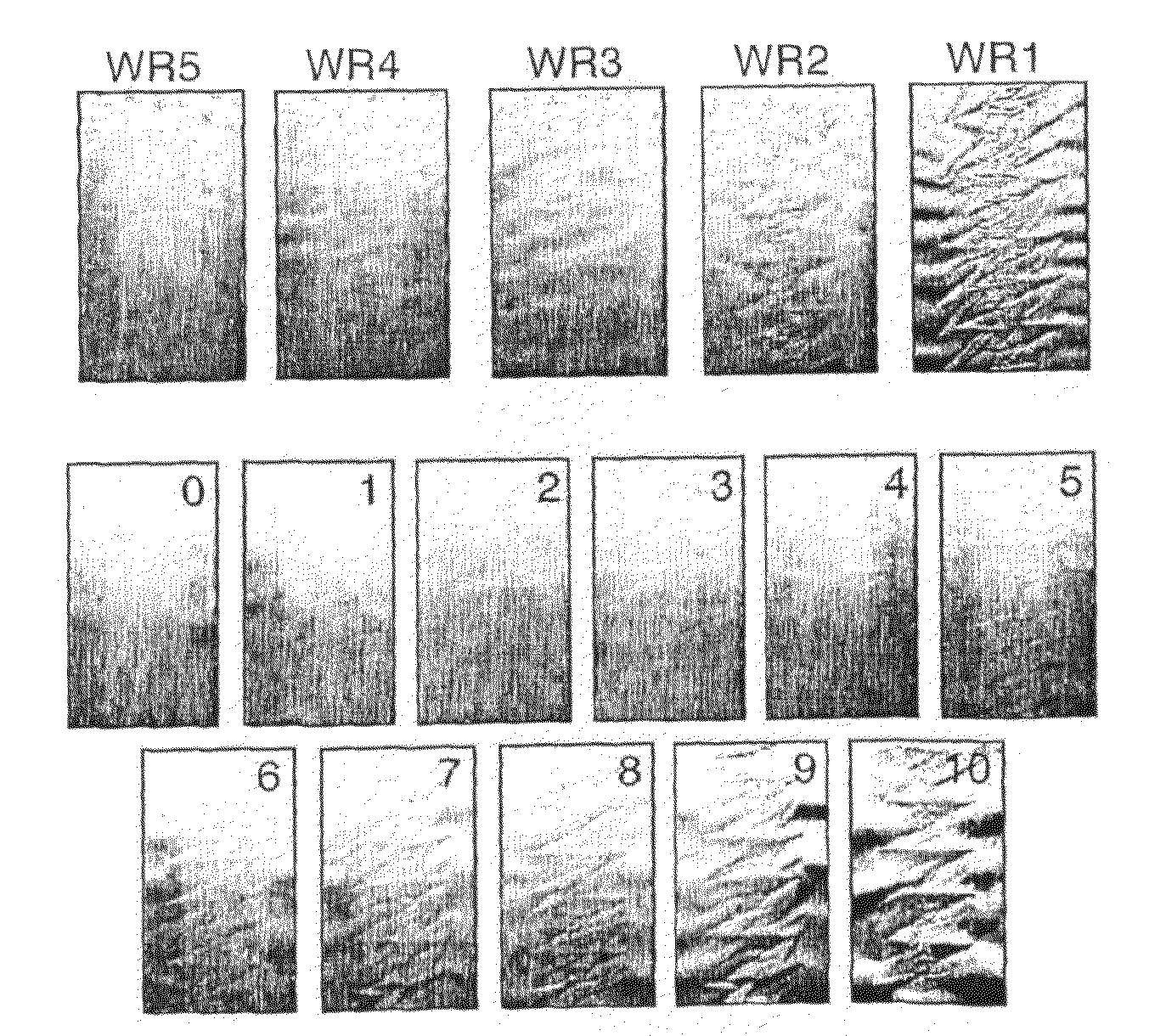

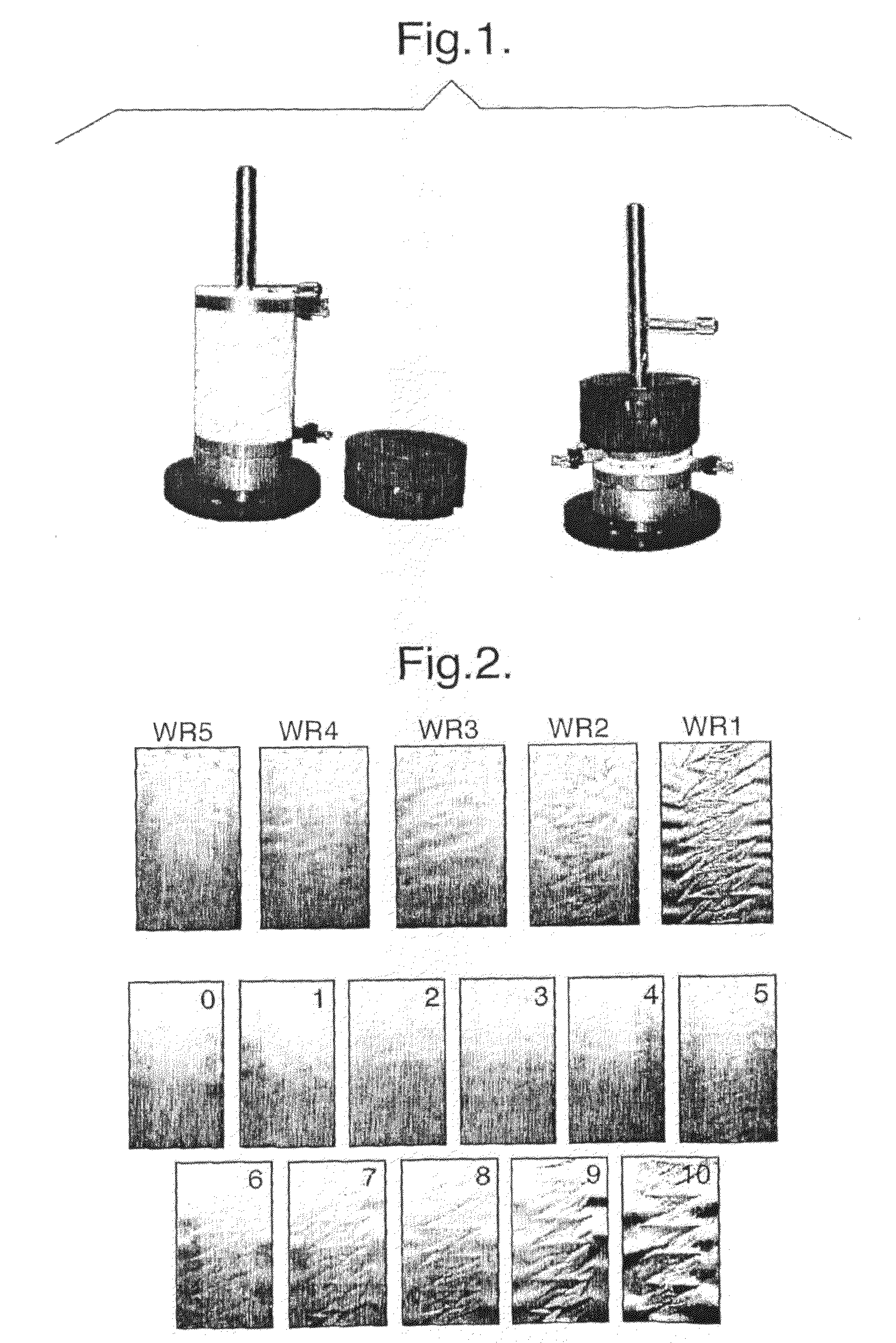

Method for processing pizza cheese

ActiveCN103283857ASimple processEasy to operateCheese manufactureMilk SerumSodium aluminum phosphate

The invention relates to a method for processing a pizza cheese. The method comprises the following steps of: 1, preparing curd; 2, cutting the curd; 3, heating and hot-ironing; 4, discharging whey and collecting curd blocks; 5, brewing by stacking, and texturing; 6, crushing and blending with dry salt; 7, hot-boiling and drawing, namely, boiling the curd blocks treated in the step 6 previously in salt-containing hot water in a weight percentage of 3-4% for 10-20 minutes, and then taking out the curd blocks after leaching and putting the curd blocks in a hot-boiling drawing machine, adding table salt accounting for 0.2-0.8% of the curd blocks by weight, and simultaneously adding sucrose polyester accounting for 0.2-1.2% of the curd blocks by weight, green bean starch accounting for 0.2-1.0% of the curd blocks by weight and sodium aluminium phosphate accounting for 1.5-3.0% of the curd blocks by weight, and then performing rubbing-up drawing for 20-50 minutes while keeping the temperature in the range from 70 DEG C to 80 DEG C; and 8, carrying out cooling and forming, thereby obtaining the pizza cheese. The method provided by the invention is characterized by blending dry salt before drawing, performing hot boiling in salt-containing water and adding the table salt in the drawing process, and thereby being convenient and easy to operate; the method is convenient and easy to operate, free of lots of saline water for soaking, and efficient and energy-saving; and as a result, the processing cost is reduced.

Owner:黑龙江赫益乳业科技有限公司

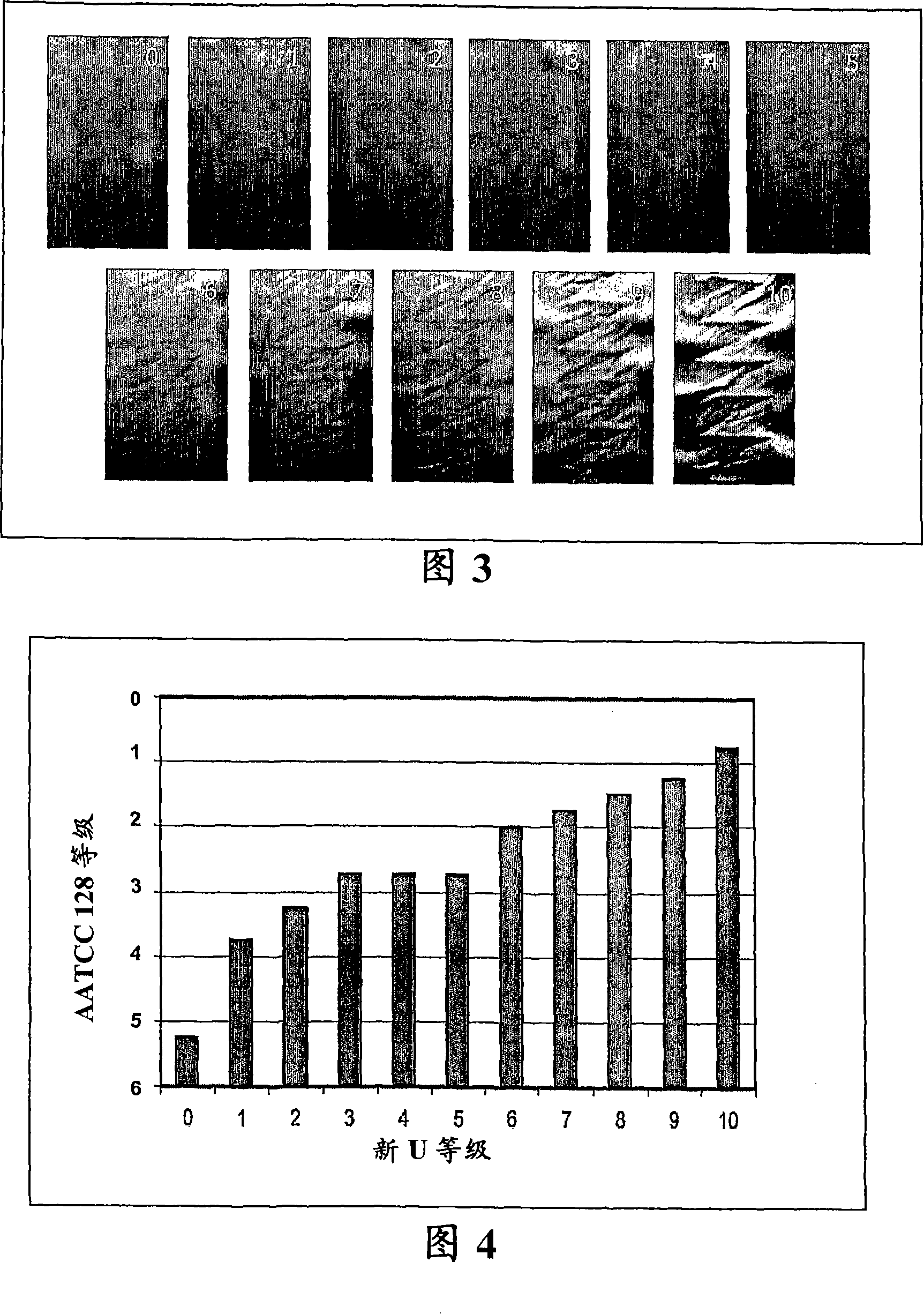

Fabric Care Compositions

An ironing aid fabric treatment composition comprising: a) a nanoparticle dispersion comprising particles having an average particle size in the range 5 to 500 nm, b) a lubricant phase comprising a lubricant selected from silicone oil, sucrose polyester oil and mixtures thereof, and c) water wherein the weight ratio of a):b) is in the range 4:1 to 1:4, with the proviso that when the colloidal nanoparticle dispersion comprises a silicone resin the composition is not delivered through an iron.

Owner:HENKEL IP & HOLDING GMBH

Sucrose polyesters

Disclosed herein are compositions that include a blend of sucrose polyesters, wherein each sucrose polyester includes a sucrose moiety and a plurality of fatty acid ester moieties, wherein from about 50% to about 90%, by weight, of the combined fatty acid ester moieties of the sucrose polyesters in the blend are palmitic fatty acid ester moieties.

Owner:THE PROCTER & GAMBLE COMPANY

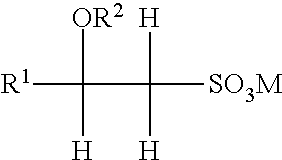

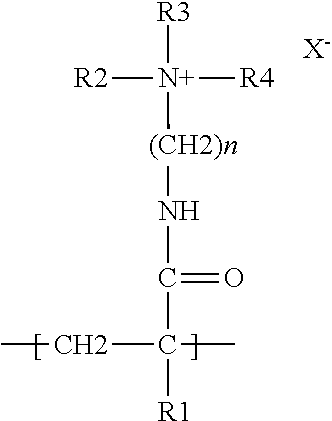

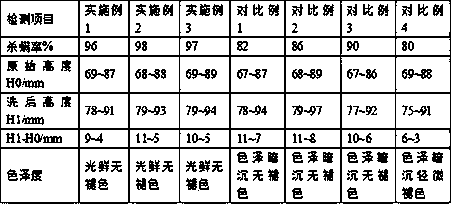

Clothing acarus killing care detergent

InactiveCN108690743ALong-lasting anti-mite effectWon't reuniteBiocideOrganic detergent compounding agentsPolyesterFiber

The invention relates to a clothing acarus killing care detergent, and belongs to the technical field of cleaning agents. Sodium dodecyl benzene sulfonate and calcium chloride serve as raw materials,sodium carbonate is added, acarus killing active matters with micro-capsule structures are formed, and anti-acarus slow release is performed, so that a fabric achieves long-acting anti-acarus effects.Sucrose polyester serves as a raw material, iso-tridecanol polyoxyethylene ether, Tween-80 and the like are added to serve as emulsifiers, fiber surface energy is reduced, fiber friction coefficientis decreased, the fibrillation degree of fibers is weakened, and the elasticity and surface smoothness of the fabric are improved. Decamethyl pentasiloxane, 1, 3-bis (3-amino propyl)-1, 1, 3, 3-tetramethyl disiloxane serve as raw materials, an intermediate is synthesized, hexanedioic acid, Hexanediamine and the like serve as raw materials, a block matrix is synthesized, and care durability is improved. The fabric is cleaned, foamed and wetted by adding tea saponin, and the color and luster of the fabric is improved. The clothing acarus killing care detergent solves the problems that a currentclothing detergent is poor in anti-acarus effect, and washed fabrics are poor in softness and color and luster.

Owner:黄勇

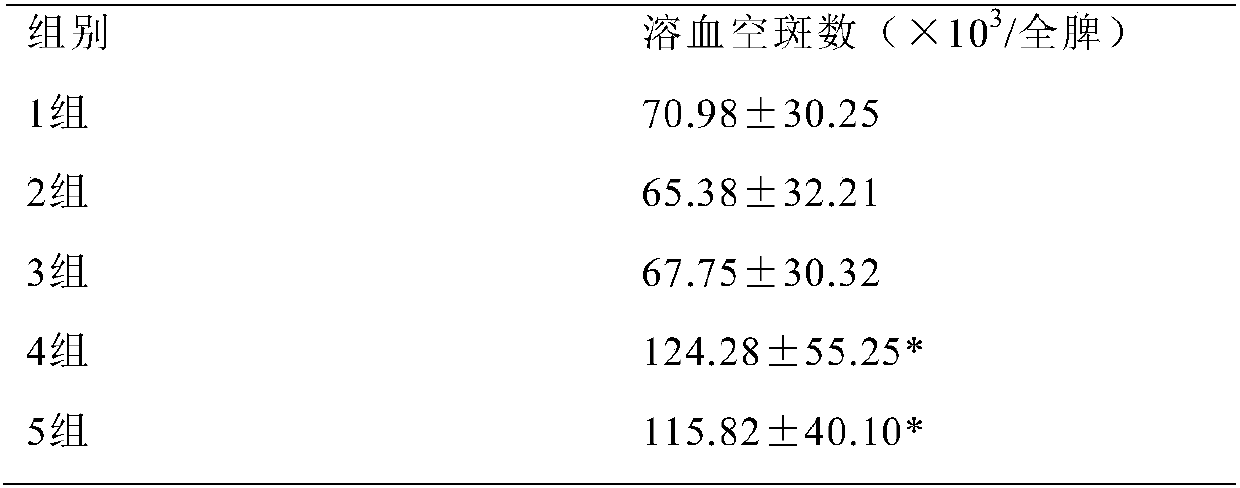

Compound soft capsule containing garlic essential oil and for enhancing immunity, and preparation method of soft capsule

The invention relates to a compound soft capsule containing garlic essential oil and for enhancing immunity. The soft capsule comprises a capsule core and a capsule skin, wherein the capsule core comprises the following raw materials in parts by weight: 10 to 20 parts of garlic essential oil, 10 to 20 parts of sea-buckthorn seed oil, 5 to 15 parts of perilla seed oil, 2 to 10 parts of fullerene, and 30 to 50 parts of bran essential oil; the capsule skin is prepared from the following raw materials in parts by weight: 20 to 40 parts of modified starch plant gum, 5 to 10 parts of sodium alginate, 5 to 10 parts of potassium citrate, 5 to 10 parts of sucrose polyesters, 10 to 20 parts of glycerin, and 50 to 60 parts of purified water; and the mass ratio of the capsule core and the capsule skinis 1:3-3:1. A preparation method of the soft capsule is simple and scientific, mild in conditions, low in production costs, and suitable for industrial production. The soft capsule has a good effectof regulating immunity, and can effectively improve the number of cells generated by rat antibodies.

Owner:太仓市林港农场专业合作社

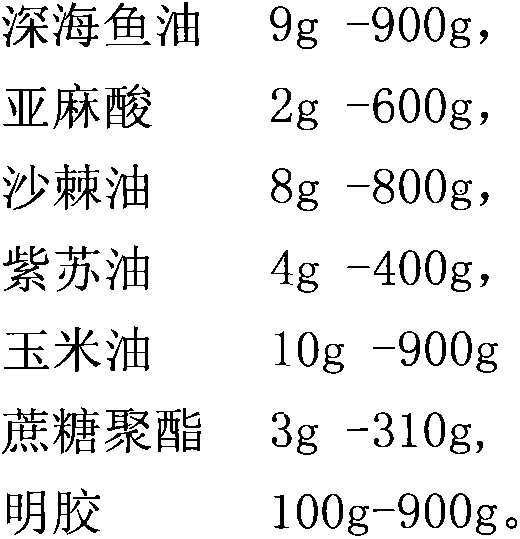

Composition for assisting in reducing blood fat

ActiveCN103690821AReduce cholesterolRealize industrializationOrganic active ingredientsMetabolism disorderCholesterolPerilla oil

The invention discloses a composition for assisting in reducing blood fat. The composition comprises the following main components: 9 g to 900 g of deep sea fish oil, 2 g to 600 g of linolenic acid, 8 g to 800 g of sea buckthorn oil, 4 g to 400 g of perilla oil, 10 g to 900 g of corn oil, 3 g to 310 g of sucrose polyester and 100 g to 900 g of gelatin. The composition has the functions of assisting in reducing the blood fat, protecting the health and losing the weight, and has a remarkable effect of reducing cholesterol.

Owner:BEIJING KANG LISHENG PHARMA TECH DEV

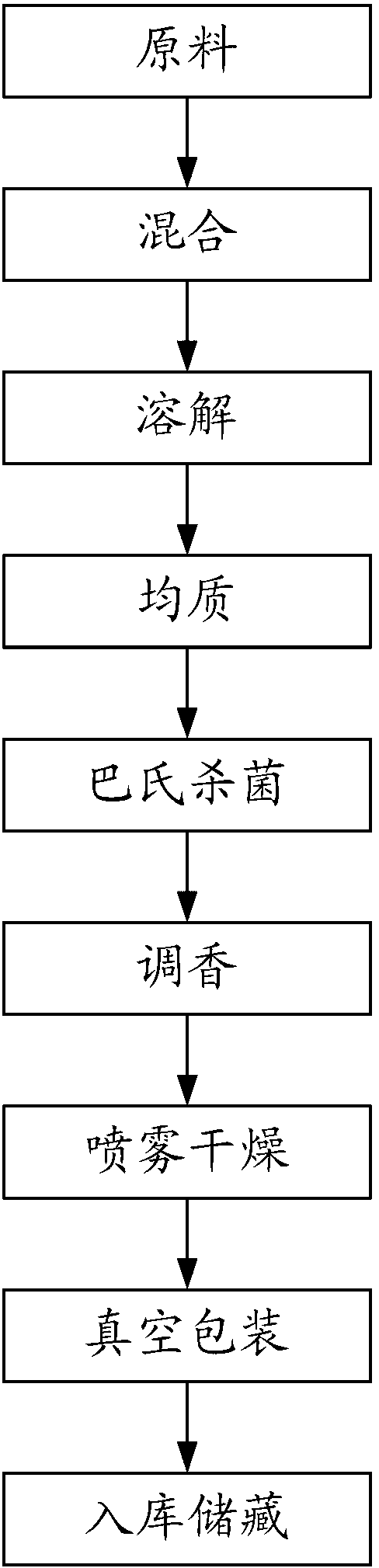

Composition for coffee, coffee and preparation method thereof

InactiveCN104146132AGuaranteed flavorQuality assuranceFood preparationCoffee extractionPolyesterGlucose-Fructose Syrup

The invention discloses a composition used in coffee, an instant coffee, and a preparation method thereof. The composition comprises coffee powder and non-dairy creamer with a weight ratio of 1:1.5-3. The non-dairy creamer comprises the raw materials of, by weight: 25-40 parts of sucrose polyester, 0-3 parts of plant oil, 30-60 parts of glucose syrup, 1.7-14 parts of an emulsifying agent, and 0.25-1.6 parts of a thickening agent. The coffee preparation method comprises the steps that: sucrose polyester, plant oil, glucose syrup, the emulsifying agent, and the thickening agent are mixed and dissolved in distilled water; homogenization and sterilization are carried out; an essence is added, and the mixture is dried, such that the non-dairy creamer is prepared; and the non-dairy creamer is blended with the coffee powder, such that instant coffee is obtained. The non-dairy creamer in the instant coffee is indigestible for human bodies, such that food flavor and quality can be ensured, and people can be prevented from taking excessive calories and fat. The coffee does not contain trans-fatty acid, such that the health risk caused by trans-fatty acid can be effectively prevented.

Owner:北京中科邦尼国际科技有限责任公司

Shortening compositions

Disclosed herein are shortening compositions comprising from about 40% to about 90% sucrose polyester, by weight, wherein said shortening compositions may comprise, based on total weight of the shortening composition, a Solid Fat Index of from about 5% to about 10% solids at 40° C. and a Firmness of from about 90,000 Pa to about 1,500,000 Pa.

Owner:THE PROCTER & GAMBLE COMPANY

Fabric care compositions

InactiveCN101142306AInorganic/elemental detergent compounding agentsCationic surface-active compoundsWrinkle skinSilicone oil

A fabric treatment composition for use in the rinse cycle of a washing machine for reducing in-wear wrinkle in fabrics, the composition comprising: a) a nanoparticle dispersion comprising particles having an average particle size in the range 5 to 500 nm, b) a lubricant phase selected from a cationic fabric softener, a silicone oil, sucrose polyester oil and mixtures thereof, and c) water in which the weight ratio of a) : b) is in the range 3 : 1 to 1 : 3.

Owner:UNILEVER NV

Processor heat-conduction and anti-ageing material for computer and preparation method of material

The invention discloses a processor heat-conduction and anti-ageing material for a computer and a preparation method of the material. The processor heat-conduction and anti-ageing material for the computer comprises a base body and a reinforcement body. The base body comprises polypropylene modified silicone grease and copper powder. The reinforcement body comprises pentaerythritol, ethyl acetate grafted copolymer starch, titanium dioxide, calcium chloride powder, melamine and sucrose polyester. The material is prepared from, by weight, 30-45 parts of polypropylene modified silicone grease, 15-25 parts of copper powder, 12-16 parts of pentaerythritol, 5-10 parts of ethyl acetate grafted copolymer starch, 5-10 parts of titanium dioxide, 2-8 parts of calcium chloride powder, 10-15 parts of melamine and 2-6 parts of sucrose polyester. The heat-conduction and anti-ageing performance of a processor material for the computer is remarkably improved by optimizing the processor heat-conduction and anti-ageing material for the computer. The heat conduction rate of the prepared processor heat-conduction and anti-ageing material for the computer is 7.8-9.2 W / m.K, and tensile strength and breaking elongation are not remarkably changed under artificial accelerated ageing (90 DEG C, 90 d).

Owner:刘雷

Sucrose polyesters

ActiveUS8679569B2Great tasteLow in fatEsterified saccharide compoundsSugar derivativesPolyesterCarbon chain

Disclosed herein are compositions that include a blend of sucrose polyesters, wherein each sucrose polyester includes a sucrose moiety and a plurality of fatty acid ester moieties, wherein a percentage range of the combined fatty acid ester moieties of the sucrose polyesters in the blend have a carbon chain that has trans content.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com